TopNotch Products MINI SUPREME User manual

TOP NOTCH PRODUCTS

MINI

SUPREME

Top Notch Products Company

PO Box 1051

Goodlettsville, TN 37072

Phone 615-866-4327

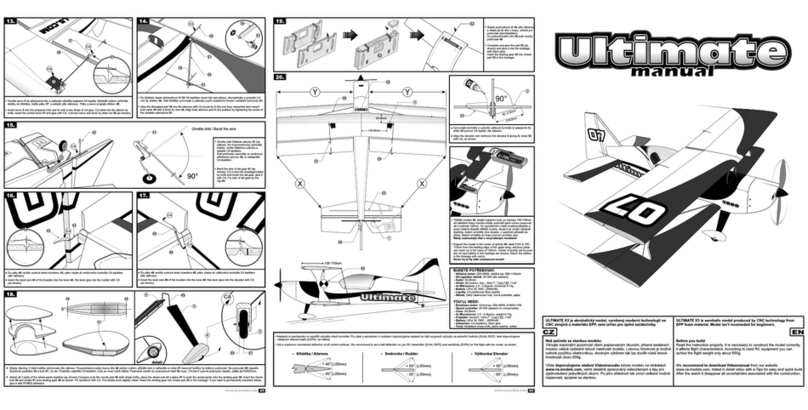

BEFORE YOU BEGIN

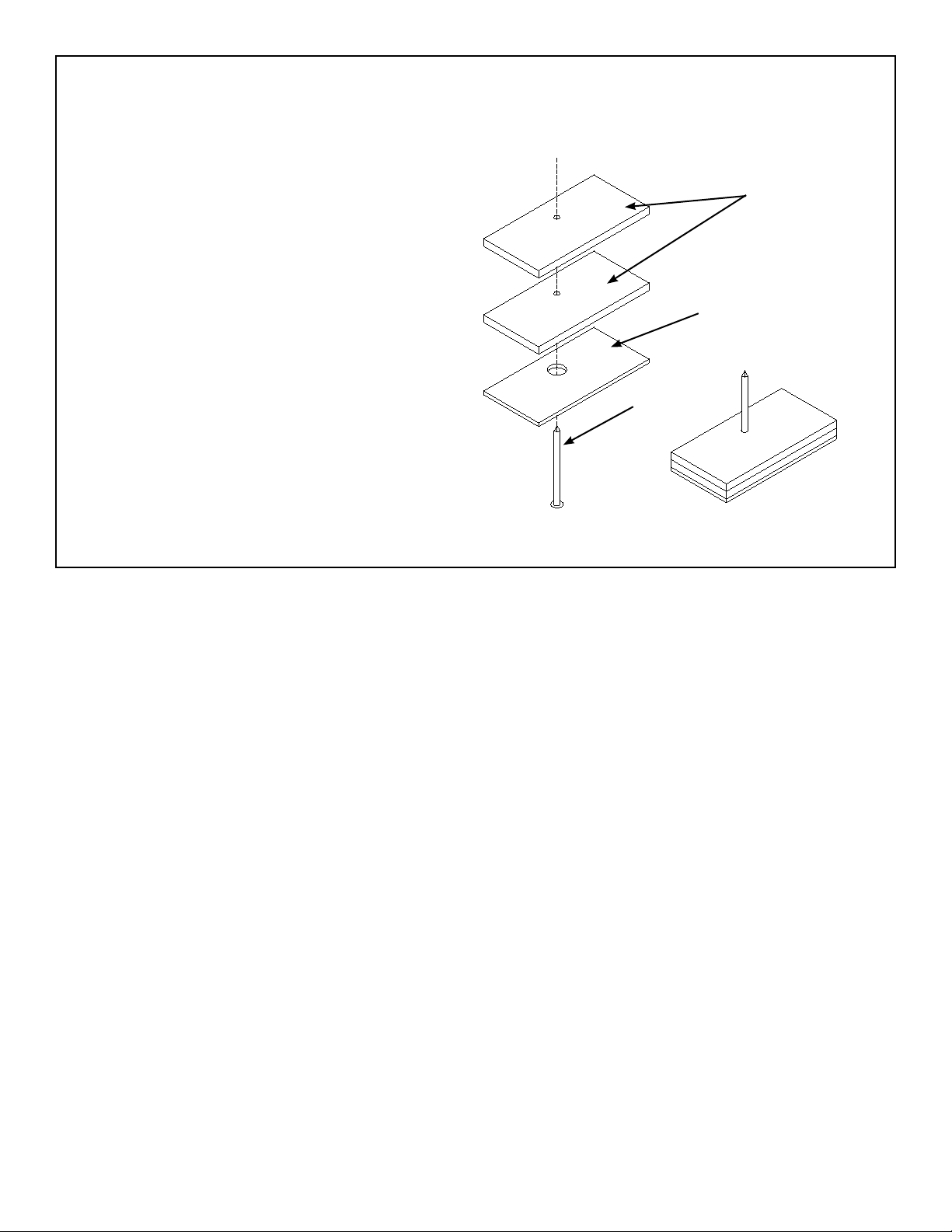

1/4” LPLY (PB)

1/8” LPLY (PB)

8d Nail

Completed pinning block,

two required.

Assemble the registration pinning blocks as

shown at the right. ese will be used through-

out the assembly to insure proper alignment of

parts.

e nail head must be seated below the surface

of the bottom lamination so the block will sit

at on the bench. Use CA or Epoxy to secure the

nail in the block.

If your new to building models, you will need a place to work that can be undisturbed until you complete

the build for best results. I recommend using the back side of a drop in 2” x 4” ceiling tile on your work

bench. This material is soft enough to receive the pins but rm enough to hold your parts securely. They

are available at any home store.

I recommend three types of adhesives, Thin and medium cyan o acrylate known as CA or Super Glue,

aliphatic resin also known as carpenters glue such as Elmer’s or Titebond and Epoxy. Do not use thin

CA on plywood parts.

1

c 1

c 6

c 5

c 4

c 3

c 2

We will begin by building the wing since it will be needed to get the correct lofting of the aft fuselage

section. Place the plan on the building board and cover them with waxed paper or Parchment paper to

protect them from the glue. When a part is called for, refer to the parts locater in the back of this manual

for the sheet number it is on.

. With the wing plan on the building board

and protected with waxed paper, lay a

straight edge over the plans and align it

with the aft edge of the False Leading Edge

(FLE). Secure it there with pins to prevent it

from moving.

Note the standos on FLE, the one with the

line through it is the root end or inboard end.

Align this line with the alignment line noted

on the plans and secure it to the building

board by tack gluing pinning tabs to each

stand o and pinning it to the building board.

Make sure each stando is at on the build-

ing board.

WING ASSEMBLY

The alignment line cut into the rst stando on the root end

must be aligned with the alignment line indicated on the

planes to insure a straight assembly.

Alignment Line

Locate and prepare the spar (SP) by remov-

ing it from the carrier sheet and make sure

all slots are clear. Note the dash cut section

at the root end. Leave that material in place

until directed to remove it. Locate the short

bottom spar doubler (SD BOT) and glue it to

the BOTTOM of the spar at the root end in

the recess provided.

SD-BOT has been installed onto the spar, next the 3/32” x

1/4” spruce will be added.

Locate a stick of 3/32” x 1/4” x 36” spruce

and cut a length to the exact length of the

spar. Glue this to the bottom of the spar.

Once again use a secure straight edge to in-

sure the spar is perfectly straight by pinning

it up against it while the glue cures.

Locate the trailing edge (TE) and remove it

from the carrier sheet and once again make

sure all slots are cleared of all material.

Locate and prepare ribs W1 through W10.

Remove any nubs left by the retainer breaks

with a light sanding. Make sure all slots are

clear of material.

The false leading edge (FLE) is secured to the plans with

pinning tabs tack glued to the standos

2

c 18

c 17

c 16

c 15

c 14

c 13

c 12

c 11

c 10

c 9

c 8

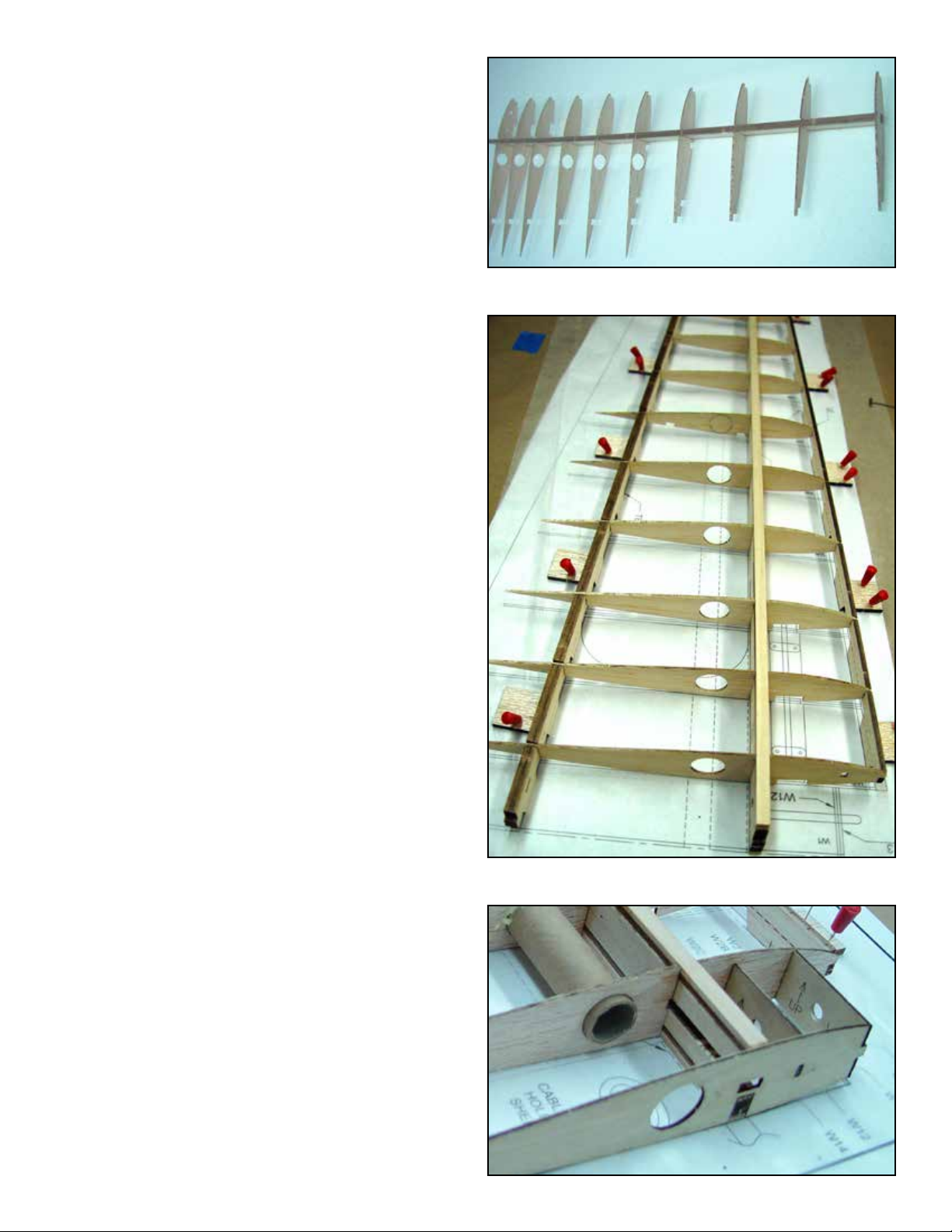

c 7Slide ribs W2 through W10 into their appro-

priate slots in the spar. Make insure that the

bottom of the top notch is ush with the top

of the spar.

Install and glue the Top Spar Doubler (SD

TOP) on the top of the spar at the root end.

Cut a piece of 3/32” x 1/4” x 36” spruce

stick to the exact length of the spar. Glue

this piece to the top of the spar. You should

now have ribs W2 through W9 captive in the

spar.

After step #9 you will have ribs W2 through W9 captive in

the spar assembly

Remove the dash cut section of material at

the root end of the spar assembly.

Place the leading edge tab of each rib into

the appropriate slot in FLE. DO NOR GLUE.

Slide the trailing edge (TE) under the aft

section of the ribs and insert each rib into

the appropriate slot in TE, Do not force any-

thing, when it is correctly lined up it will drop

onto place.

Align the alignment line in the TE stando

with the alignment line on the plans and se-

cure it to the building board with a pinning

tab tack glued to the stando. Like you did

with FLE. Continue down TE and secure ev-

ery other tab in the same manner. Insure that

each stando is at on the building board.

You can now apply glue to all the joints.

Start with the leading edge, then the trailing

edge. As you apply glue insure each rib is

bottomed tin the slot.

Install and glue the root rib (W1) and the tip

rib (W10).

Install and glue W14 between W1 and W2.

Install and glue W12 between W1 and W2.

Note that the slot in W2 is oversize. Install

W12 to the back of the slot. W13 will be in-

stalled in the front of that slot in a later step.

Cut a 11-7/8” length of cable tunnel tubing

and install in between W2 and W7. Glue it

at each rib.

Before applying glue to each joint, insure that each rib is

bottomed in the slot.

RIGHT: The photo illustrates all the work done in steps 15

through 18. Note the dash cut material in the spar has been

removed (Step 10). The hole in W1 is only used to install the

cable tunnel tube which terminates at W2 and W7.

3

c 24

c 23

c 22

c 21

c 20

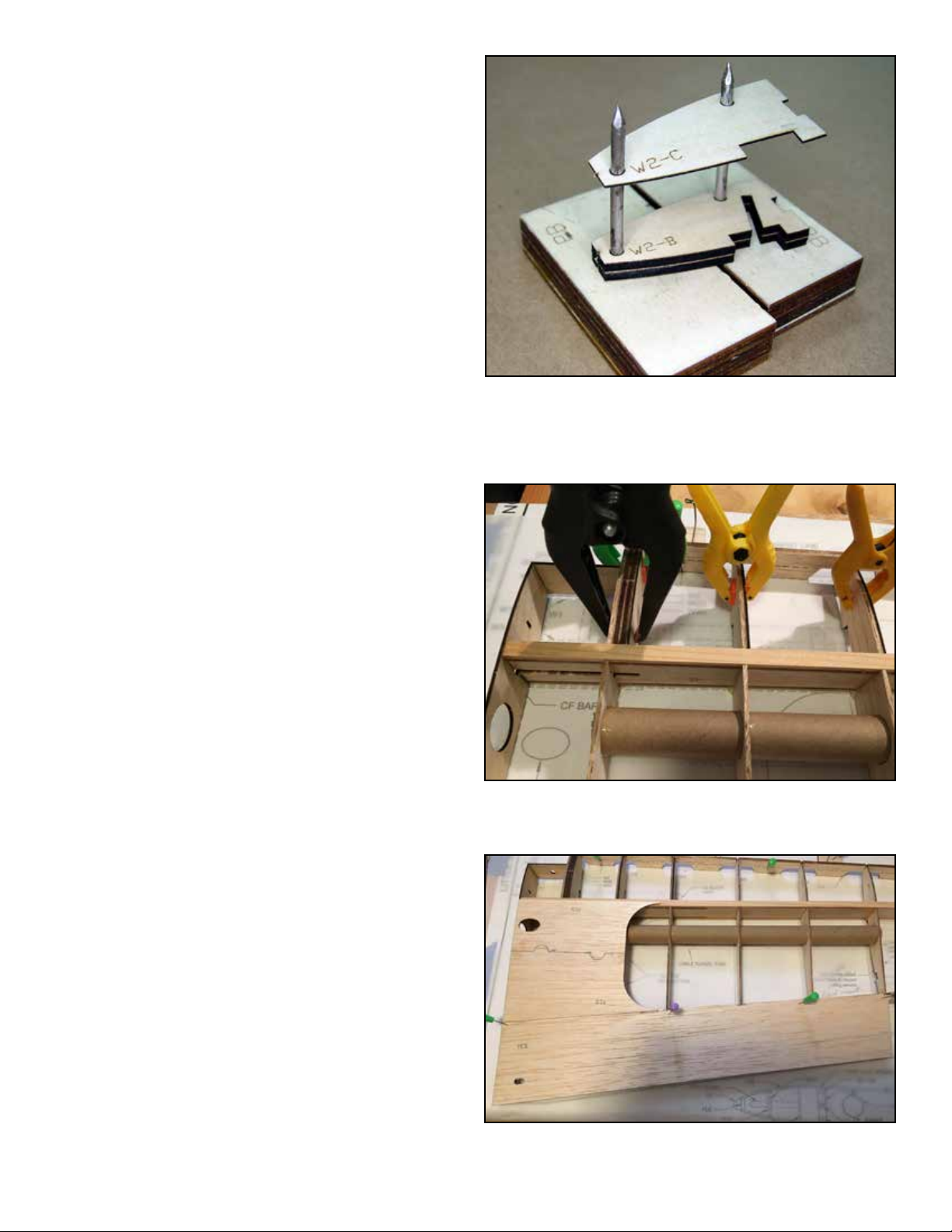

c 19 Use the registration pins to assemble the

landing gear slot, always assemble these

parts with the labeled side UP. Since these

parts are handed, it’s a good idea to assem-

ble both sets at the same time, then select

the correct one for the wing panel you are

working on. This will consist of two W2-B

parts and one W2-C. Place one of the W2-B

parts on the pins and glue another W2-B to

it. Install and glue a W2-C to this and then

install this assembly to the outboard side

of W2. Note that the W2-B/C assembly is

handed and a RIGHT handed version must

be assembled for the right wing.

The landing gear block consisting of two W2-B and one

W2-C being laminated together using the registration pins.

Note that when laminating handed parts, always laminate

them with the labeled side up. This will prevent you from

laminating two of the sane hand.

Install and glue W3-A to the outboard side

of W3.

Install and glue W4-A to the outboard side

of W4.

As cut, the trailing edge should be ush with

the top of the ribs between the root and W7.

However it will be slightly proud of the trail-

ing edge at the back edge. Sand the top of

the trailing edge until it is ush with the ribs

completely. Then install and glue the Trail-

ing Edge Sheeting (TES) to the trailing edge

and ribs between the root and W7. Note that

TES will be ush with the front side of the

trailing edge only between ribs W4 through

W7. It will be set back 1/16” between the

root and W4. Steps 19, 20 and 21, laminating the gear block assembly

as well as W3-A and W4-A, clamps are used to insure good

contact with the paring ribs.

Assemble one TCS TOP and one BCS to

form the center section sheeting. Glue this

assembly to ribs W1, W2 and W3 as well as

the trailing edge and the top of the spar.

Plane or sand the leading FLE to contour

with the leading edge of the ribs in prepara-

tion for sheeting the leading edge.

4

Top trailing edge (step 22) and top center section sheeting

(step 23) install and glued to the wing assembly.

5

c 28

c 27

c 26

c 25 Locate and prepare the top leading edge

sheeting (LES TOP). Best method to install

the top leading edge sheeting is to rst wet

the top side of the sheeting to insure no

splitting. I use a liberal application of Windex

with ammonia and leave it soak for at least

ve minutes. Use medium or thick CA along

the top of the spar only and install LES. Use

a straight edge or other weight to insure the

sheeting remains in contact with the spar

until the glue cures. After this glue cures, re-

move the wing assembly from the building

board and while holding the sheeting into

contact with the ribs and FLE apply fast CA.

Do a section at a time and let cure before

moving on to the next section.

Except for the area along the spar, the top leading edge

sheeting is glued from the open bottom with thin CA.

Snap o all the stand os from FLE and TE

but save them for use on the next wing pan-

el.

The landing gear block is laminated from

LG-A, LG-B and LG-C. Place LG-A on the

registration pins and glue LG-B to it. Note

that one end has an ellipse at the end of the

slot. Make sure these ends match and pull

LG-B snug against the opposite pin. Repeat

this procedure for LG-C.

Use Epoxy to install the gear block assem-

bly into the slots provided in W2, W3 and

W4. Note the end with the ellipse should be

at the root end.

The landing gear block is assembled by laminating LG-A,

LG-B and LG-C together. This will not only support the land-

ing gear but will also provide a small shelf to support the

sheeting.

When the gear block is installed, LG-C should stand 1/16”

proud of the ribs. This will bring it ush with the top of the

leading edge sheeting when installed.

ROOT

6

c 33

c 32

c 31 Assemble the center section sheeting from

one TCS and one BCS section and glue it

to ribs W1, W2 and W3 as well as the spar

and TE.

Installing the bottom leading edge sheet-

ing. The curve on the bottom leading edge

should not require wetting the balsa, install

it dry. Apply a bead of alphabetic resin (El-

mer’s or Titebond) to all ribs and the FLE.

Use a bead of medium CA on the top of the

spar and place the leading edge sheeting in

place and into contact with the spar. Hold it

in that position until the CA has cured. Place

the assembly on the bench with the sheeting

on the bottom and run a sharp blade along

the edge of FLE and trim the sheeting ush

with FLE. Then use strips of masking tape

around the leading edge to pull the sheeting

into contour and into contact with the ribs

and FLE. Set aside to cure.

c 30

c 29 Install and glue the Wing Servo Rails (WSR)

into the notches provided in W7 and W8.

Note that the screw holes should be to the

inside or towards each other. Use 1/4” piec-

es of 1/4” triangle stock to gusset these to

the ribs.

Install the servo rails and use some 1/4” length pieces of 1/4”

triangle stock as gussets between the ribs and the rails.

Sand the trailing edge to contour with the

ribs between W7 and W10 in preparation

for installing the trailing edge sheeting. In-

stall and glue the trailing edge sheeting to

ribs W1 through W7, the trailing edge and

the top trailing edge sheeting. Use clamps,

clothes pins or weights to maintain contact

with the ribs, trailing edge and top sheeting

until the glue cures.

When installing the bottom trailing edge, use plenty of clamps

along the trailing edge. A slight taper on both sheets will yield

a nice crisp trailing edge.

The cap strips are laser cut and should re-

quire little or no trimming to install. Note that

cap strips 7 and 8 on the bottom are notched

for the servo opening, after installing 7 and

8 on the bottom, run a bead of glue along

the interface of the rib and the cap strip on

the outside of the servo bay for support. In-

stall all cap strips, top and bottom, the num-

bers on the cap strips corresponds to the rib

they will attach to.

The cap strips on the bottom of ribs 7 and 8 are shaped to

accommodate the servo opening. The material indicated by

the arrows is scrap ll. You can use the servo mount for po-

sitioning of the ll.

7

c 2

c 1

c 38

c 37

c 36

c 35

c 34 Sand the leading edge smooth. Install and

glue the leading edge (LE). Use pins to sta-

bilize it and tape to pull it snugly against

FLE.

Plane and sand the leading edge shape to

contour. Use the leading edge template to

guide your work

Locate three Wing Tip (WT) parts and use

the registration pins to laminate the three

together to make the wing tip block. Glue

this assembly to W11 and when cured,

plane and sand to shape.

In the circles above are two gussets made from 1/4” triangle

stock, use on both sides. The arrow in th lower part is indica-

tion the glue llet between the cap strip and the rib.

Sand the trailing edge in the aileron bay at

and install and glue the Aileron Bay Trailing

Edge (ABTE). Sand ABTE to contour with

the trailing edge and wing tip. Use a knife

blade to open up the slot for the hinges and

test t the hinges for easy installation, they

should t slightly snug.

Use some scrap balsa to ll in at the front

and back the servo plate (SP) opening. Use

the Servo Plate as a guide.

This concludes the assembly of one wing panel. Place the remaining wing panel plans on the building

board and repeat all the above Wing Assembly Steps. Joining the wing halves will be done later after

we assemble the belly pan.

Assembling the Ailerons

Each aileron is laminated up from two (AIL)

parts using the registration pins to assem-

ble them. After laminating two AIL,s sand

the leading edge and both ends smooth.

NOTE: Although the ailerons will not be permanently attached until after the model is covered, cutting

the hinge slots and temporarily tting the assembly together will make the nal assembly mush easier.

Place the aileron next to the trailing edge

and mark the location of the hinges on the

aileron, then cut slots to accept the hinges.

8

c 3Temporarily secure the aileron assembly

to the wing with pins carefully centering it

in the trailing edge. Use a soft lead pen-

cil to mark the aileron assembly at the root

end and along the leading edge, top and

bottom. Use these lines to guide you when

you shape the ailerons. Plane and sand the

ailerons to shape.

c 5

c 4

Marking the aileron for shaping to the contour of the wing.

Mark the leading edge top and bottom as well as both ends.

The tip can be marked by laying a straight edge on the tip and

projecting a line over the end of the aileron.

Plane a chamfer on both sides of the lead-

ing edge of about 20 degrees but leave

about a 1/16” at at the center for hinging.

Use a sharp X-Acto knife to open up the

slots in the trailing edge for the aileron hing-

es. The slots should be open all the way

through FLE.

c 6Test t the ailerons to the wing with the CA

Hinges. The aileron control horns will be in-

stalled after covering.

c 2

c 1Locate all the belly pan components, BP-

1, BP-3, BP-5, BP-7, BP-9, BP-10 and BP-

11. Also the formed belly pan plastic parts.

Note that BP-11 terminates in an angle at

one end, this is the AFT end. Starting at the

front or opposite end install and glue BP-1

to BP-11. Install BP-3, BP-5, BP-7 and BP-9

from the front to the back. Install and glue

BP-10 at the angles end.

Belly pan formers attached to the belly pan keel. Use only

Pacer 560 canopy glue to attach this structure to the plastic

belly pan.

Locate the plastic formed belly pan. Note at

the sides where it changes from a curved

surface to a straight side. Use the side of

a pencil lead along this edge to dene it.

Trim o the excess plastic from the sides.

Leave a little excess for nal tting. Leave

both ends for now.

c 3Test t the balsa frame work into the plas-

tic pan. You will need to sand a bevel in

the edge of BP-10 so all the formers will t

snugly to the plastic belly pan. To glue any-

thing to a exible plastic part such as his you

need a glue that will remain ex able or it

will break away from the part. Two adhesive

that are excellent for this purpose are Pace

Formula 560 (Also called canopy glue) and

a glue called Grafter’s Pick which is a fabric

Rough trim the sides of the belly pan form using the line cre-

ated by rubbing the side of a soft lead pencil against ridge on

the sides.

ASSEMBLING THE BELLY PAN

9

c 4After curing, trim the front and back to

formers BP-1 in front and BP-10 at the

back. When trimming the plastic at F10, trim

it close and then sand it to exactly match

the angle and face of F10.

The belly pan assembly will be installed onto the wing assembly while attached to the fuselage as-

sembly this is as far as we can go for now. Put these assemblies aside and proceed with building the

fuselage.

After installing the former assembly, sand both ends ush

with the end formers.

glue available at craft stores. Apply a liberal

bead to all surfaces that will contact the belly

pan and install it. Set this aside to thoroughly

cure.

c 3

c 2

c 1

Both wing halves completed and ready for joining. Note the

carbon ber joiner and 1/8” dowel have been Epoxied into

the bottom wing half.

JOINING THE WING HALVES

Cut a 1/2” length of 1/8” dowel and round

over one end. Install it in the hole provided

in W1 just ahead of TE, let it protrude about

1/8”. Do this in one wing half only, this will

engage the hole in the opposite wing half

to align the wing halves when joining them.

Use Epoxy to install the 1/8” x 5/16” x 4”

carbon ber joiner in one wing half and let

this cure.

Apply Epoxy to one W1 on one of the wing

panels. Apply a liberal amount in the slot for

the carbon ber joiner. You can access this

though the hole in W1. Join the wing halves

and install and glue W13. Put the assembly

aside to cure.

c 4Cut two lengths of 3/16” dowel to 1-1/4”

long. Round over one end and smooth the

other end. Use Epoxy to install these in the

hole provided in W13. Make sure they are

glued to W12 as well, leave about 1/4” pro-

truding.

Completed wing assembly, the correct dihedral is set by W13.

Note the Cable opening plate. NOTE: In this photo the belly

pan has been installed. You will install that later in the build.

10

c 3

c 2

c 1Locate the four wheel pant halves. Note

that two of them have dimples in them for

the attachment system. Drill the four small-

er dimples out with a 1/16” bit. Drill out the

larger dimple with a 1/8” drill bit.

Trim the parts down to about 1/4” from the

edge of the part in preparation for trim-

ming out with the trim tool. You will need a

smooth at surface for the next operation.

While holding the part at on a smooth sur-

face make many very shallow cuts around

the periphery of the part. Do not attempt to

cut through but instead just try to score it.

It may take ten or fteen very light passes,

if you put too much pressure it can deect

the blade. Some parts of the plastic are

thinner than others and if you do happen

to break through, no problem just back o

on the pressure and continue. After you are

satised with the scoring, fold the edge of

the rim inward and it should break along

the score. Continue all the way around the

part. If there are any irregularities, a couple

swipes on a at piece of sand paper should

clean up the edge.

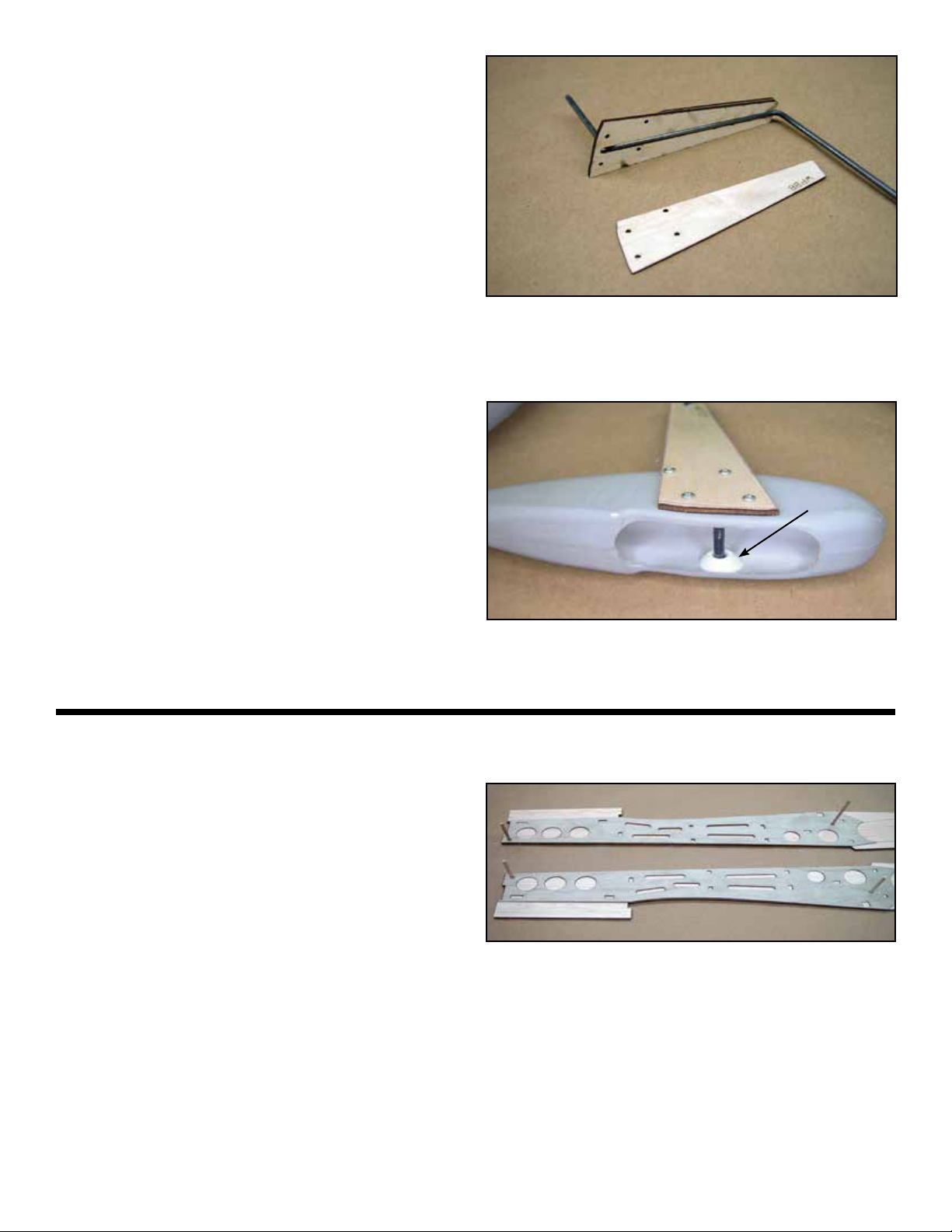

Landing Gear Assembly

The landing gear and wheel pants are assembled as a unit and then installed in the wing. To assemble

the wheel pants they must rst be trimmed to shape. This is easily accomplished using the plastic trim-

ming tool but rst we need to assemble the tool. Locate both parts of the trim tool. Note the tracing of

the X-Acto blade on one part. Use thin CA to glue the X-Acto blade to the part. Then glue the second

Trim Tool part to the rst encapsulating the blade.

RIGHT: The trimming tool components, a new blade must

be used when assembling the tool. The tool is used to only

score the plastic. The scrap can then be removed by exing

at the score. This will give you a clean straight edge to work

with.

Scoring the plastic with the trimming tool will give you a clean

straight edge to work with.

With a good score, the plastic will snap along the score line

leaving a straight edge.

11

c 9

c 8

c 7

c 6

c 5

c 4Remove any burrs from the inside of the

part from the drilling operation. It must be

smooth. Locate the screw plate for the half

you are working on and use a couple pins

through the screw holes to line it up. When

satised with the lineup, glue it with thin CA.

The holes in the screw plate must be aligned with the holes

in the wheel pant side. The screw plate must seat snugly to

the wheel pant.

Locate and prepare the Wheel Pant Joiner

(WPJ). Sand a taper in the last half inch on

both sides down to about 1/16” to allow for

the taper at the aft end of the wheel pant.

Use several pins to locate the center of

WPJ, this will allow the joiner to set only half

way into the wheel pant side.

Apply a liberal bead of Formula 560 Can-

opy Glue along the entire periphery on the

inside of the part and then install the joiner.

Use clothes pins or clamps to insure good

contact with the joiner. Remove any glue

that squeezes out so as not to inter fear

with the installation of the second half. Let

this cure throughly.

After taper sanding he trailing edge, pines are used to limit

the depth that WPJ can seat into the wheel pant half, it must

be half way.

Leave the pins in place on WPJ and apply

a liberal bead of Formula 560 Canopy glue

to the inner edge of the mating wheel pant

half and install it. Use rubber bands or tape

to pull the halves together.

When cured, remove the pins and apply

some Elmer’s wood ller to the center line

joint where necessary. When cured, sand

the joint smooth.

WPJ has been glued to the inboard wheel pant shells with

Pacer 560 Canopy glue.

Glue the outboard half of the wheel well shell to the inboard

assembly.

c 10 Open up the wheel opening and test t that

the wheel has plenty of clearance.

c 14

c 13

c 12

c 11 Locate the formed landing gear wire. I rec-

ommend about 2° of toe in on the main gear

to improve ground handling. When you

place the formed gear in the landing gear

slots in the wing and project a line along the

axles, it should cross the wing tip about 1”

back from the leading edge. Twist the gear

if necessary until you accomplish this.

Locate the landing gear leg components

WPB7, WPB8 and WPB9. Sand a bevel on

WPB7 from the line indicated at the bottom

of the part to the edge for clearance with

the wheel pant.

The landing gear strut cover components. Assemble these

parts with the labeled side up for a left and right hand set.

Note that all these parts are mirrored so

assemble all components with the labeled

side up and you will have a left and a right

assembly. Use the wire landing gear tem-

porarily placed in the slot of WPB9 to insure

the proper gap, then glue on WPB7.

c 15 Install the landing gear wire into the WPB7

WPB9 assembly and then glue on WPB8.

Sand a taper on the bottom of WPB8 from

the bottom up to the line indicator line.

Taper WPB7 from the bottom up to the line for clearance

with he top of the wheel pant.

Place part of the wire gear into the slot when installing WPB7

to WPB9 to insure that the gap remains large enough for the

wire leg.

12

13

c 18

c 17 Trim the axle so when installed to the wheel

pant, it almost touches the opposite (out-

board) side of the wheel pant.

Assemble the gear assembly to the wheel

pant with four #1 x 3/8” sheet metal screws.

When doing this side the axle support but-

ton onto the axle on the inside of the wheel

pant and glue it to the outboard side of the

wheel pant.

c 2

c 1

c 19

c 16

The gear leg assembly is attached to the wheel pant with

four #1 x 3/8” sheet metal screws. Trim the axle just shy of

touching the opposite side and then install the axle support

button.

Install and glue WPB-8 to WPB-9.

Glue WPB8 to WPB9

Remove the four screws and install the

wheel, then reinstall the four screws.

Final installation of the mains gear will be done

after covering the wing

FUSELAGE ASSEMBLY

Locate and prepare the two fuselage sides

(FS) and the two 1/64” ply fuselage dou-

blers (FD). Do not use a water based glue

such as carpenters glue to glue these two

components together. The moisture will

warp them and render them useless.

Use Epoxy or slow setting CA and glue the

doublers (FD) to the fuselage sides (FS).

Be sure to make a left and a right. Use a

piece of 1/8” dowel in the registration holes

to get perfect alignment.

Plywood doublers are glued to the fuselage sides using the

1/8” dowels for registration.

Glue formers C and D into their appropriate

location, refer to the plans for orientation.

c 3

c 6

c 5

c 4

14

Glue the other fuselage side assembly to

this assembly.

Use the square as shown here to insure that formers C and

D are at 90° to the fuselage side.

Locate the rewall (former A), former B

and the Battery Deck (BD). Glue BD to A

and then glue this assembly to B. Use the

square to insure they are at 90 degrees to

each other.

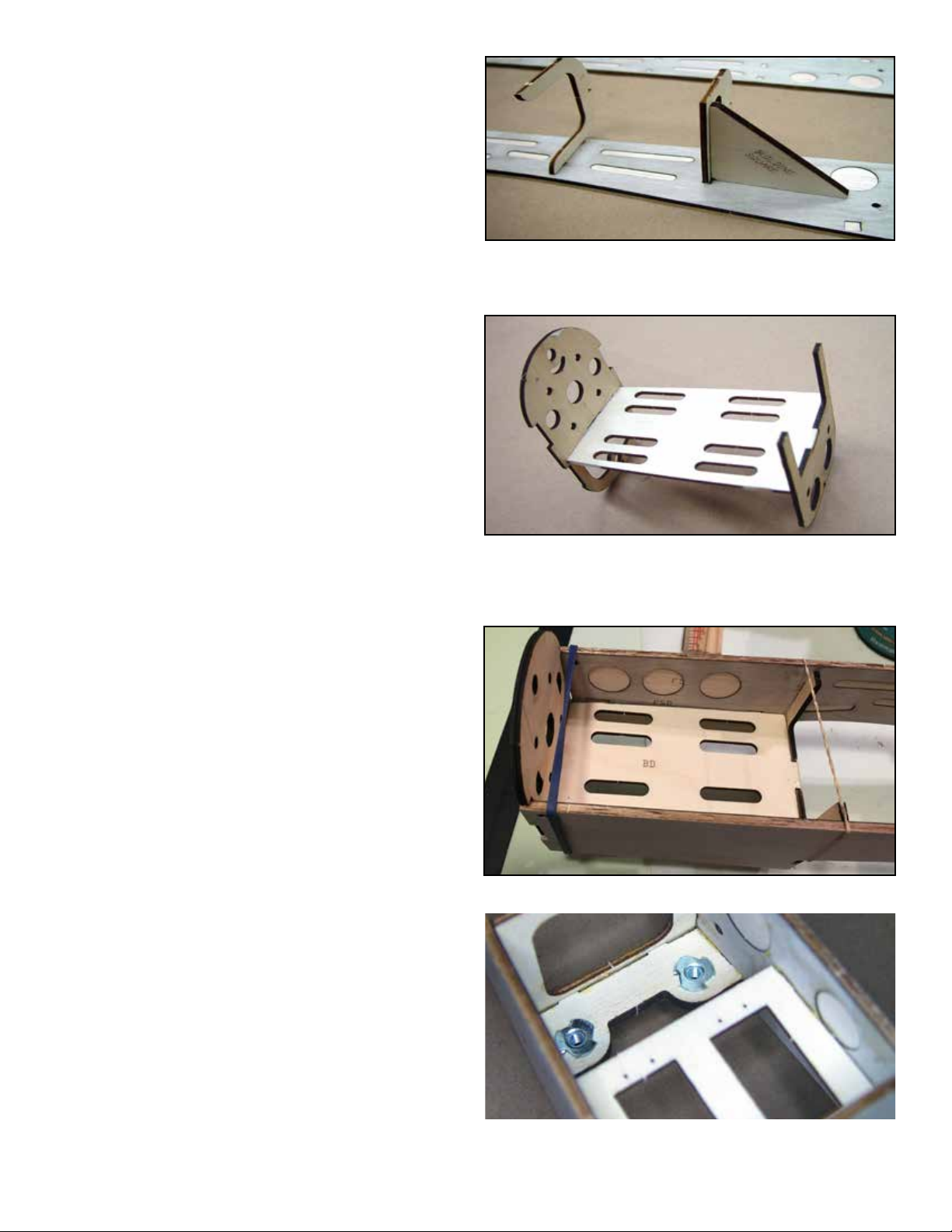

Former A (rewall) and former B assembled with he battery

deck (BD). Use the square to keep all these components

square to each other.

Glue the battery deck assembly to the fuse-

lage assembly.

Use Epoxy to install the battery deck assembly

c 7Install and glue the fuselage servo tray (ST)

to former D and the fuselage sides.

c 8Press two #8-32 blind nuts into the Wing

Bolt Plate (WPB) and glue it to former E

and the fuselage sides. The anges of the

nuts must be facing up.

The servo tray (step 7) and the wing bolt plate (step 8). In-

sure that both are engaged in there notches in the doubler.

15

c 20

c 19

c 18

c 17

c 16

c 15

c 13

c 12

c 11

c 10

c 9Cut two 11-5/8” pieces of 3/16” square bal-

sa stick and glue them to the top inside

edge from former D back to the stabilizer

area.

The photo above illustrates several steps

Locate formers F, G and H as well as the

Aft Fuselage Bottom (AFB). Install but do

not glue formers F, G and H into the fuse-

lage.

Step 9 Step 12

Step 10 &11

Install AFB, when all formers are bottomed

in their respective slots and AFB is ush

with the bottom of the fuselage, apply glue

to all formers and AFB.

Locate the Temporary Guide (Temp Guide)

and tack glue it to the back of former E.

This will support E1 At the correct angle

until the stringers are installed and then it

will be removed.

Install and glue E1 to the top of former E.

c 14 Cut two pieces of 3/16” square balsa to

11” long and install and glue them into the

notches provided in formers E1, F, G and H.

When the glue has set, remove the TEMP

GUIDE.

Step 13 Step 14

Locate the Turtle Deck Sheeting (TDS).

Install and glue it to the aft top fuselage.

The sheeting will sit on top of the fuselage

sides.

Illustrated above are installation of split former E1(step 13)

and the 3/16” stringers (step 14). Note that the TEMP GUIDE

has been removed.

Trim and sand the excess material of TDS

down just until you come in contact with

the top of the formers. It must be at, use a

sanding bar.

Install and glue the Turtle Deck Top (TDT).

Sand the TDT and TDS until they are ush

with E1 at the front.

Sand TDT and TDS until they are ush with

former H at the back.

Next you will plane and sand TDT to shape

to form the turtle deck. Use Template A at

the front and Template B at the aft end to

mark the guide lines for shaping TDT.

Template A is used at E1 and template B is used at former H.

These are guide lines for shaping the turtle deck.

16

c 25

c 24

c 23

c 22

c 26

c 21

Locate the two For Deck Sheets (FDS) and

test t them to formers C and D. Wet the

outside of these sheets and then install

them between formers C and D. Glue them

rst to the fuselage sides and force them

over and into contact with the formers and

BCK and glue them. When cured, sand

them ush with formers C and D.

Install cockpit bulkhead CBH to E1

Install and glue the Cockpit Bulkhead

(CBH) to E1.

Locate and prepare the hatch components

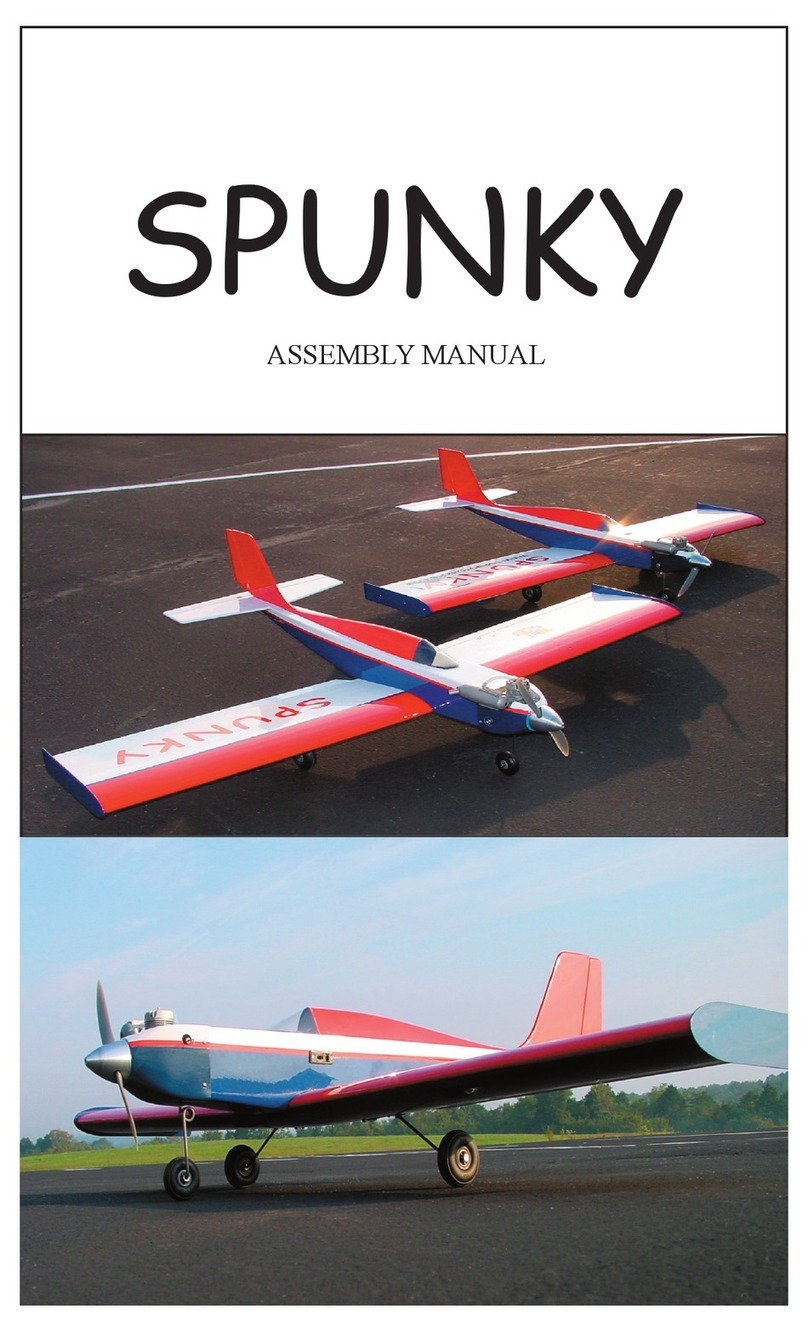

HA-A, HA-B, HA-C, A1, B1 and C1. Lightly

sand the outer edges of HA-B to remove

any nubs and smooth the sides. When the

hatch is completed, HA-B will slide down

between the fuselage sides. Use the 1/8”

dowel pins and assemble HA-A and HA-B.

This is the forward hatch base.

HA-B

HA-A

1/8” DOWEL

The hatch base stack is laminated upside down using 1/8”

dowels for registration.

Install and glue HA-C to HA-A.

Install and glue formers A1, B1 and C1.

Use thick canopy glue or thick CA and in-

stall and glue a 1/8” x 1/4” magnet in the

hole provided in A1.

Glue FDS ush to the top of the fuselage and then shape and

glue it to the formers and BCK.

Glue a 1/8” x 1/4” magnet into A1. No need to worry about

polarity at this point.

17

c 27 Locate and prepare the Hatch sheeting

(HS). Note that the front corner is indicated

by the arrow. Wet the outside of HS. Place

the Hatch assembly at on the building

board, orient HS so the corner marked FC

is located at the front corner of the assem-

bly and the bench. With the edge of HS at

on the building board and snug up against

the hatch assembly, glue HS to HA-A.

c 34

c 32

c 31

c33

c 30

c 29

c 28 Pick the assembly up and pull the sheeting

tightly against B1 and HA-C and apply thin

CA. Do the same at A1 and HA-A.

With a sharp blade, carefully trim the sheet-

ing (HS) ush with the bottom of HA.

The whetted hatch sheeting is rst glued to HA-A and then

rolled over onto the formers and HA-HA-C and glued with

thin CA.

The hatch pull assembly ready to be installed into the hatch.

The pull wire will retract into the hatch when not in use.

Place the hatch onto the fuselage and sand

the sides to contour with the fuselage.

Place the plastic hatch pull on the front of

the hatch, centered and about 5/16” back

from the front. Mark the hatch sheeting for

the opening. Cut the opening and test t

the hatch pull.

Place a 1.8” x 1/4” magnet into the hole

provided in former A (rewall), let it snap

into place with the magnet in the hatch.

Mark the front of the magnet with a Sharpy.

Marker, Remove the hatch from the fuse-

lage and remove the magnet. Glue the

magnet into former A with the marked side

facing forward. Also install and glue a mag-

net in the hole provided at the bottom of

Former A.

Locate the plastic hatch pull. Cut a two inch

length of 1/32” wire and bend it into a U

shape so the legs will t through the two

holes in the hatch pull freely.

Place the U shaped wire into the holes in

the hatch pull, it should drop down into the

depression on top of the pull. About 1/8”

from each end of the wire, put a 90 degree

bend in the wire to prevent it from being

able to exit the plastic pull. Glue this as-

sembly into the hatch ush with the top of

the sheeting.

The hatch pull in the extended position. It will retract into he

recess when not in use. You can access it with a ngernail

or a magnet.

FC

18

c 38

c 37

c 36

c 35 Install and glue a length of 3/16” square

balsa in the notches provided at the bottom

of former A and B.

Locate and prepare the Forward Chin

Sheeting (FCS) and test t to the chin sec-

tion between former A and B. Wet the out-

side of the sheet and then glue it edge to

edge to the fuselage. When this has cured,

pull the sheeting into contact with Formers

A and B and the 3/16” square balsa and

glue it.

A piece of 3/16” square balsa provides the bottom keel be-

tween formers A and B.

Turn the fuselage over and install the wing.

Some sanding of the fuselage may be re-

quired until the wing seats correctly in the

wing saddle. W13 should butt rmly against

former B.

Sand the sheeting ush with former B and the fuselage sides.

Install the #8-32 Nylon bolts through the

bolt wells and then through the wing into

the blind nuts in the fuselage. Turn the

wing bolt wells so the low side is facing out-

ward away from the center of the fuselage.

When satised with the t, glue the wing

bolt wells to the wing.

The wing secured to the fuselage with the wing bolt and the

two bolt wells.

NOTE: Before proceeding with step 38,

check the alignment of the wing. With the

wing in position on he fuselage, measuring

from the wing tip trailing edge to the aft end

of the fuselage. Adjust the wing until both

sides are exactly the same. Mark the wing

and the fuselage so you can keep the wing

in this position while performing step #38.

Table of contents

Other TopNotch Products Toy manuals

TopNotch Products

TopNotch Products Li'l Pup User manual

TopNotch Products

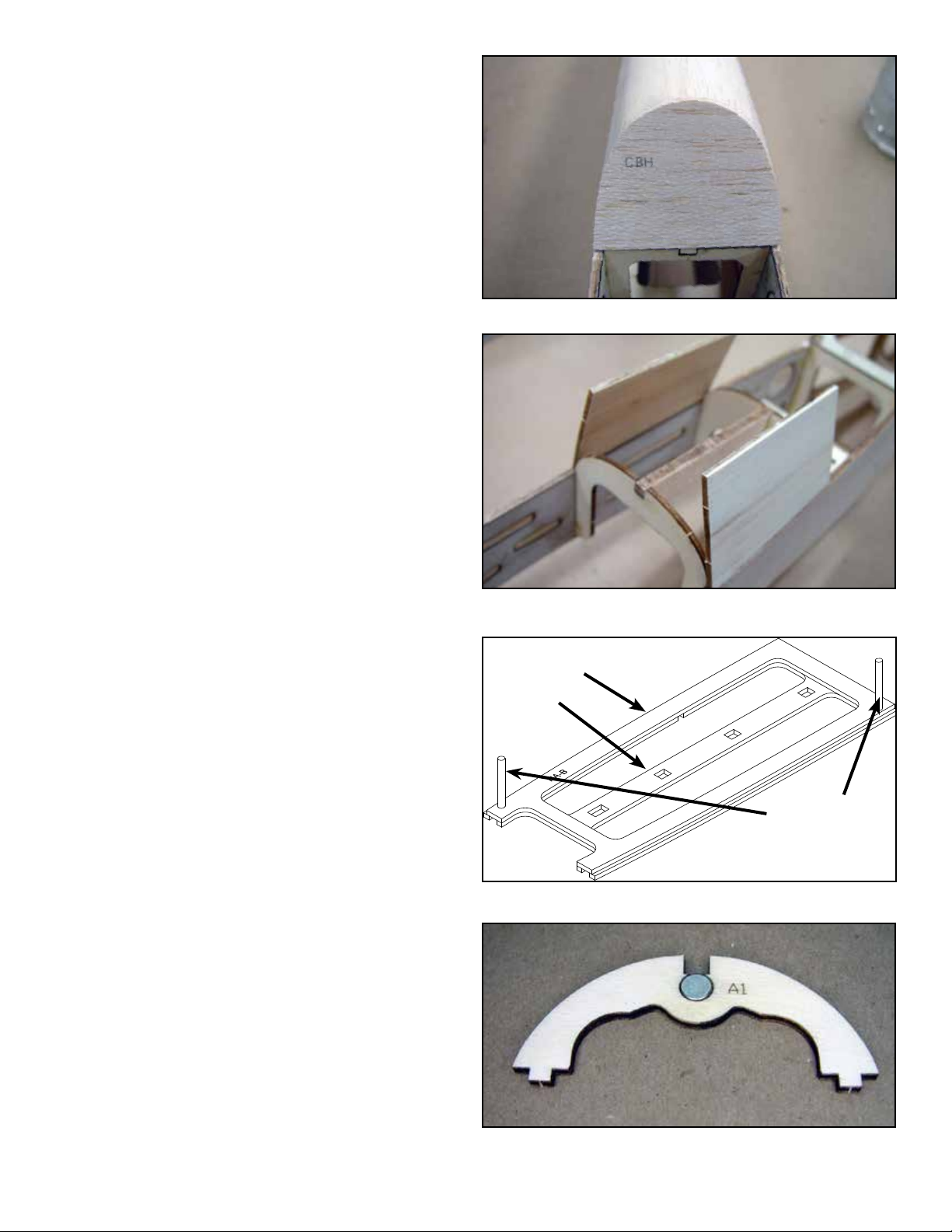

TopNotch Products Mooney M-18 User manual

TopNotch Products

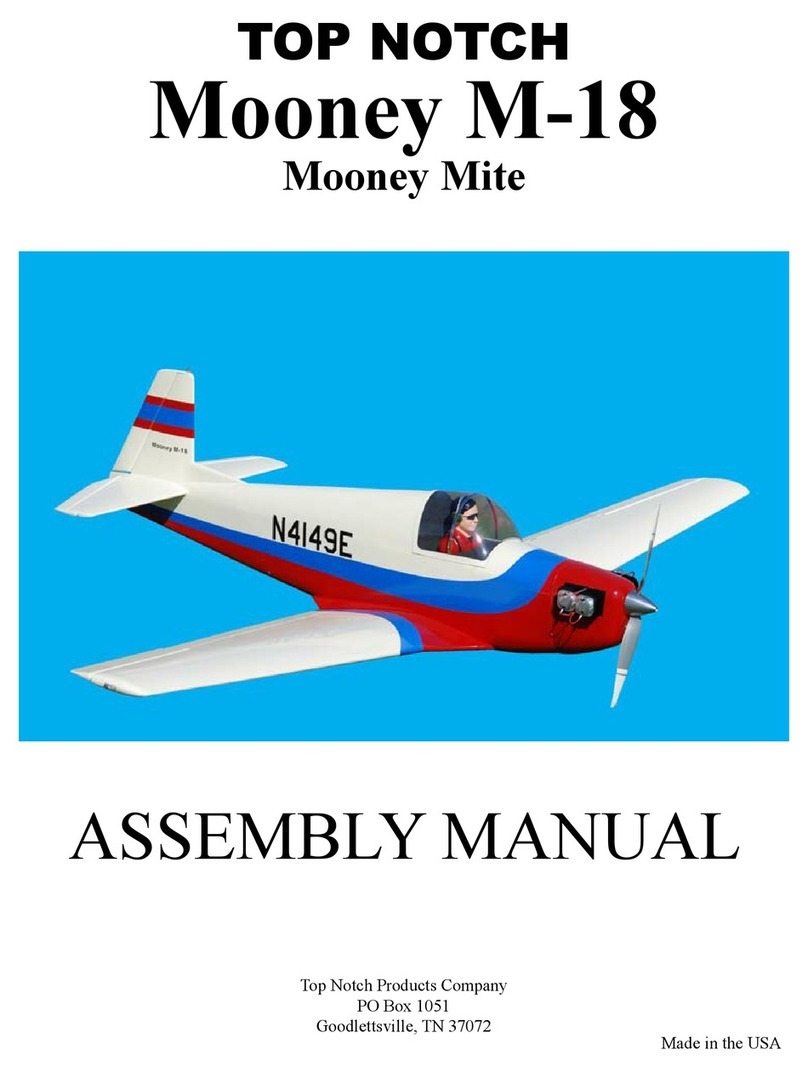

TopNotch Products SPUNKY User manual

TopNotch Products

TopNotch Products Seamaster II User manual

TopNotch Products

TopNotch Products Maverick User manual

TopNotch Products

TopNotch Products BUSH HAWK XP User manual

Popular Toy manuals by other brands

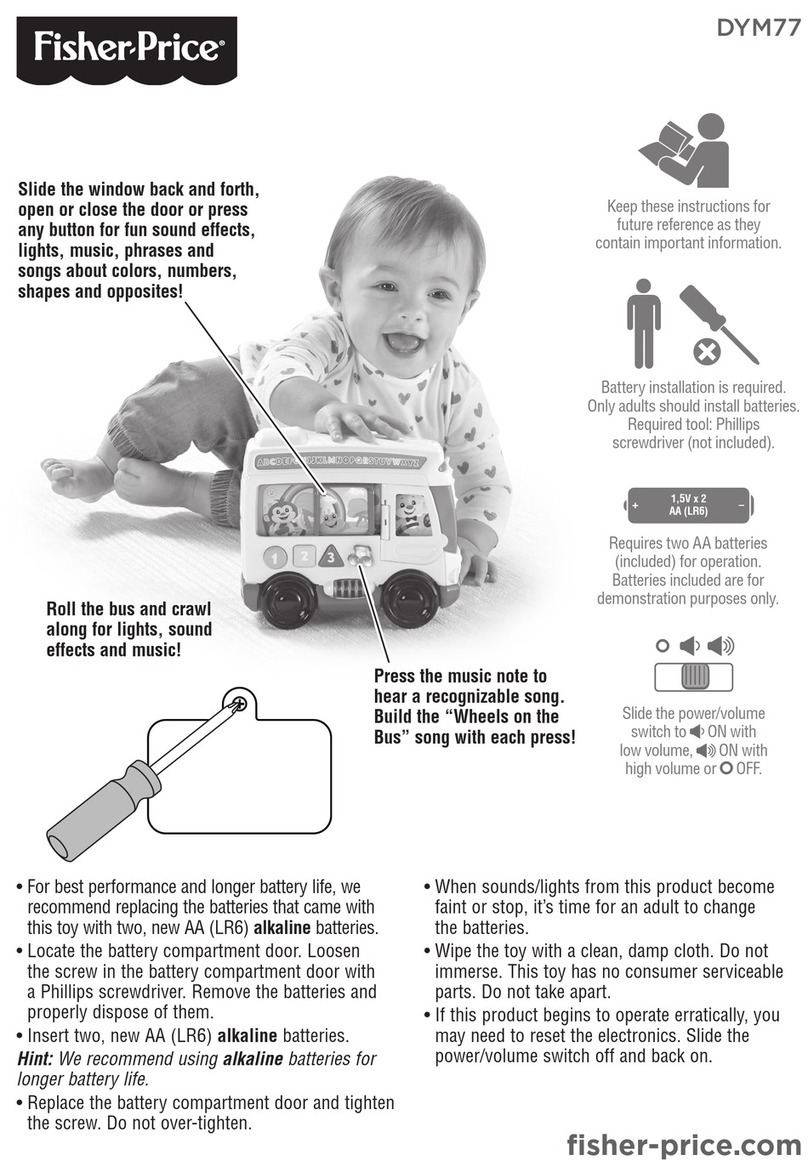

Fisher-Price

Fisher-Price DYM77 manual

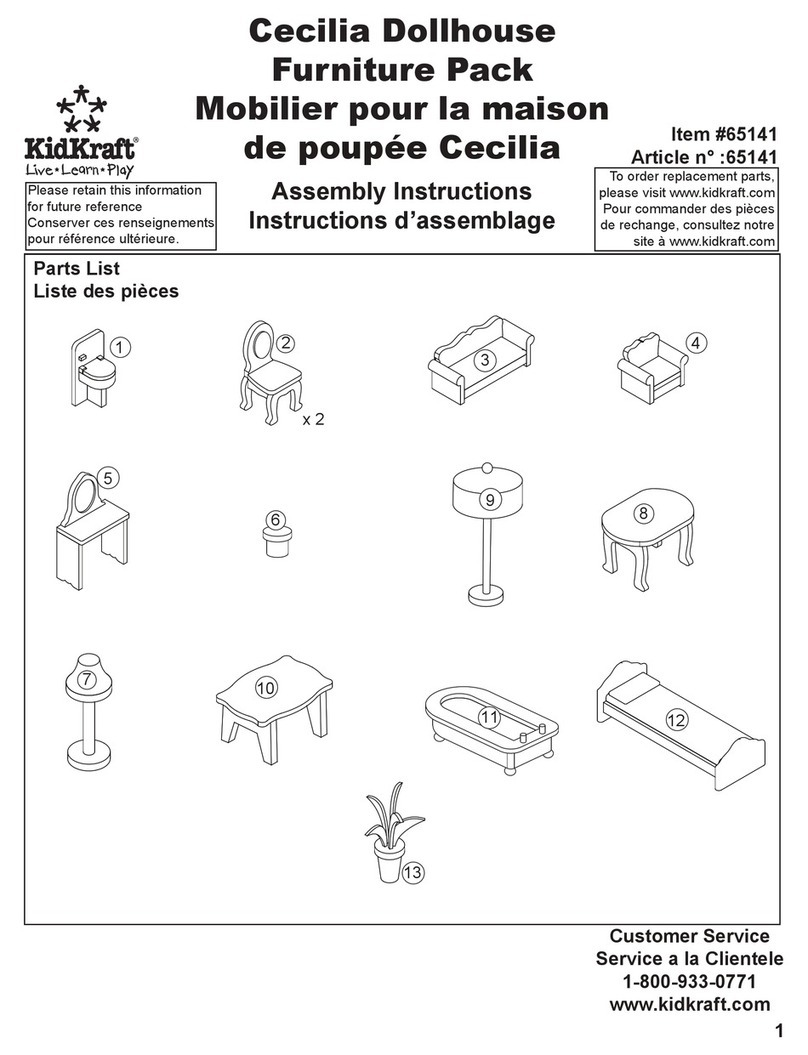

KidKraft

KidKraft 65141 Assembly instructions

Fisher-Price

Fisher-Price H5698 instructions

Mattel

Mattel MERMAID FUN Kelly 52885 instructions

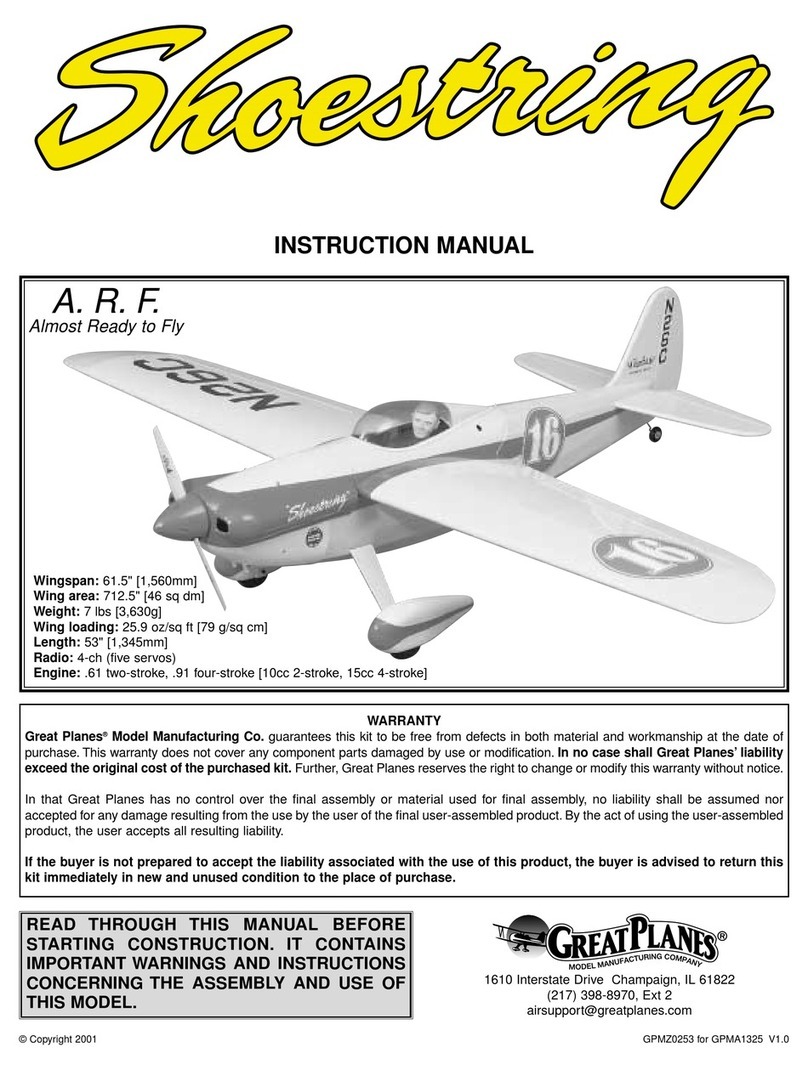

GREAT PLANES

GREAT PLANES Shoestring ARF instruction manual

Lightmybricks

Lightmybricks LEGO Gingerbread House 10267 Lighting Kit instructions