Toptech ACR II User manual

ACR II

Installation Guide

Part # 6057

July 11, 2018

2

ACR II Installation Guide: 20180711 Part # 6057

EC Declaration Of Conformity (Valid until April 20, 2016)

the product listed below conforms to the relevant provisions of the following directives:

2004/108/EC The Electromagnetic Compatibility Directive (and its amending directives)

2006/95/EC The Low Voltage Directive (and its amending directives)

Product: Process Control Equipment

Model name/number: ACR II

Compliance with the Essential Health and Safety Requirements has been assessed by reference to the following standards:

EN 61000-6-4: 2007 Generic emissions for industrial operating environments

EN 61000-6-2: 2005 Generic immunity for industrial operating environments

EN 60950-1: 2006 Information technology equipment. Safety. General requirements

Year of CE Marking: 2010

Name: William J. Porthouse Position: Director of Engineering & Production Date: 01-August-2010

EC Declaration Of Conformity (Valid after April 20, 2016)

the product listed below conforms to the relevant provisions of the following directives:

2014/30/EU The Electromagnetic Compatibility Directive (and its amending directives)

2014/35/EU The Low Voltage Directive (and its amending directives)

Product: Process Control Equipment

Model name/number: ACR II

Compliance with the Essential Health and Safety Requirements has been assessed by reference to the following standards:

EN 61000-6-4: 2007 Generic emissions for industrial operating environments

EN 61000-6-2: 2005 Generic immunity for industrial operating environments

EN 60950-1: 2006 Information technology equipment. Safety. General requirements

Year of CE Marking: 2010

Name: William J. Porthouse Position: Director of Engineering & Production Date: 19-Apr-2016

3

ACR II Installation Guide: 20180711 Part # 6057

ELECTRICAL CONSIDERATIONS AND REGULATORY REQUIREMENTS

This equipment is suitable for use in Class I, Division 2, Groups C and D locations.

This equipment is also suitable for use in EX Zone 2 Group IIB Locations OR non-hazardous locations.

WARNING ─ EXPLOSION HAZARD ─ SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR USE IN

CLASS I, DIVISION 2.

AVERTISSEMENT ─ RISQUE D’EXPLOSION ─ LA SUBSTITUTION DE COMPOSANTS PEUT RENDER CE

MATERIEL INACCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION 2.

WARNING ─ EXPLOSION HAZARD ─ DO NOT REPLACE COMPONENTS UNLESS POWER HAS BEEN SWITCHED

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT ─ RISQUE D’EXPLOSION ─ COUPER LE COURANT OU S’ASSURER QUE L’EMPLACEMENT

EST DESIGNE NON DANGEREUX AVANT DE REPLACER LE COMPOSANTS.

WARNING ─ EXPLOSION HAZARD ─ DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT ─ RISQUE D’EXPLOSION ─ AVANT DE DECONNECTER L’EQUIPMENT, COUPER LE COURANT

OU S’ASSURER QUE L’EMPLACEMENT EST DESIGNE NON DANGEREUX.

!

!

!

4

ACR II Installation Guide: 20180711 Part # 6057

Copyright Notice

Copyright © 2006 - 2018 Toptech Systems, Inc.

The information contained in this document is proprietary and confidential. No part of this document may be copied, reproduced, or

transmitted in any medium without the express written permission of Toptech Systems, Inc.

Disclaimer

Toptech Systems assumes no responsibility for damages resulting from installation or use of its products. Toptech Systems will not be liable

for any claims of damage, lost data, or lost time as a result of using its products.

A Unit of IDEX Corporation

logo is a registered trademark of Toptech Systems, Inc.

TMS™, TMS5™, TMS6™, RCU II Remote Control Unit™, Toptech MultiLoad II™, MultiLoad II -RCU™, RCU II™, FCM Flow Control

Module™, veriFID™, ACR™, ACR II™are trademarks of Toptech Systems, Inc.

Copyright © 2018 Toptech Systems, Inc. All Rights Reserved.

5

ACR II Installation Guide: 20180711 Part # 6057

Table of Contents

Electrical Considerations and Regulatory Requirements .......................................................................................3

CHAPTER 1 General...........................................................................................................................................7

1.1 Who Should Use This Guide ......................................................................................................................7

1.2 Information Alerts:.......................................................................................................................................7

1.2.1 Typographical Conventions:...................................................................................................................7

1.2.2 Product Support......................................................................................................................................7

1.2.3 Receiving and / or Returning Equipment:...............................................................................................7

1.3 Operating Characteristics...........................................................................................................................8

1.4 Electrostatic Discharge (ESD) Protection...................................................................................................9

CHAPTER 2 Installing the ACR II..................................................................................................................... 10

2.1 Tools Required ........................................................................................................................................ 10

2.1.1 Installation............................................................................................................................................ 10

2.1.2 Service and Repair .............................................................................................................................. 10

2.2 Cover Closure and Bolt Replacement..................................................................................................... 10

2.3 Mounting The ACR II Enclosure.............................................................................................................. 10

2.3.1 Drywall................................................................................................................................................. 10

2.3.2 Wood.................................................................................................................................................... 10

2.3.3 Concrete or Cinder Block Walls........................................................................................................... 10

2.3.4 Mounting Height Considerations ......................................................................................................... 11

2.4 Recommended Wire Sizes And Torque For All Terminal Blocks............................................................ 12

2.5 Electrical Supply Connections................................................................................................................. 13

2.5.1 Input Power......................................................................................................................................... 13

2.5.2 Equipment Ground............................................................................................................................... 16

2.5.3 Cable Entries ....................................................................................................................................... 16

CHAPTER 3 Data Communications Interface .................................................................................................. 17

3.1 Communications Protocol Selection and Connection ............................................................................. 17

3.1.1 RS-422/485.......................................................................................................................................... 17

3.1.2 RS-232................................................................................................................................................. 17

3.1.3 Host/TMS Communications (RS-485) ................................................................................................. 18

3.1.4 Host / TMS Communications (RS-232 2-wire) .................................................................................... 19

CHAPTER 4 DIGITAL I/O................................................................................................................................. 20

4.1 digital inputs............................................................................................................................................. 21

4.2 digital outputs........................................................................................................................................... 21

CHAPTER 5 Configuration ............................................................................................................................... 23

5.1 Preliminary Configuration ........................................................................................................................ 23

5.2 ACR II Communication Configuration:..................................................................................................... 24

CHAPTER 6 Service and Repair ...................................................................................................................... 26

6.1 ACR II Troubleshooting ........................................................................................................................... 26

6.2 Modular Design........................................................................................................................................ 27

6.2.1 LED Cable Connector Removal ......................................................................................................... 28

6.2.2 ACR-FID_Combo PC Board Removal................................................................................................. 29

6.2.3 LED PC Board Replacement............................................................................................................... 30

6.2.4 Prox Reader Thinline II Replacement.................................................................................................. 31

6.2.5 Prox Reader RP15 Replacement ........................................................................................................ 32

6.3 TB2 Proximity Reader Connection: ......................................................................................................... 37

6.3.1 Prox Reader Thinline II:....................................................................................................................... 37

6.3.2 Prox Reader RP15:.............................................................................................................................. 37

CHAPTER 7 Appendix...................................................................................................................................... 38

6

ACR II Installation Guide: 20180711 Part # 6057

Table of Figures

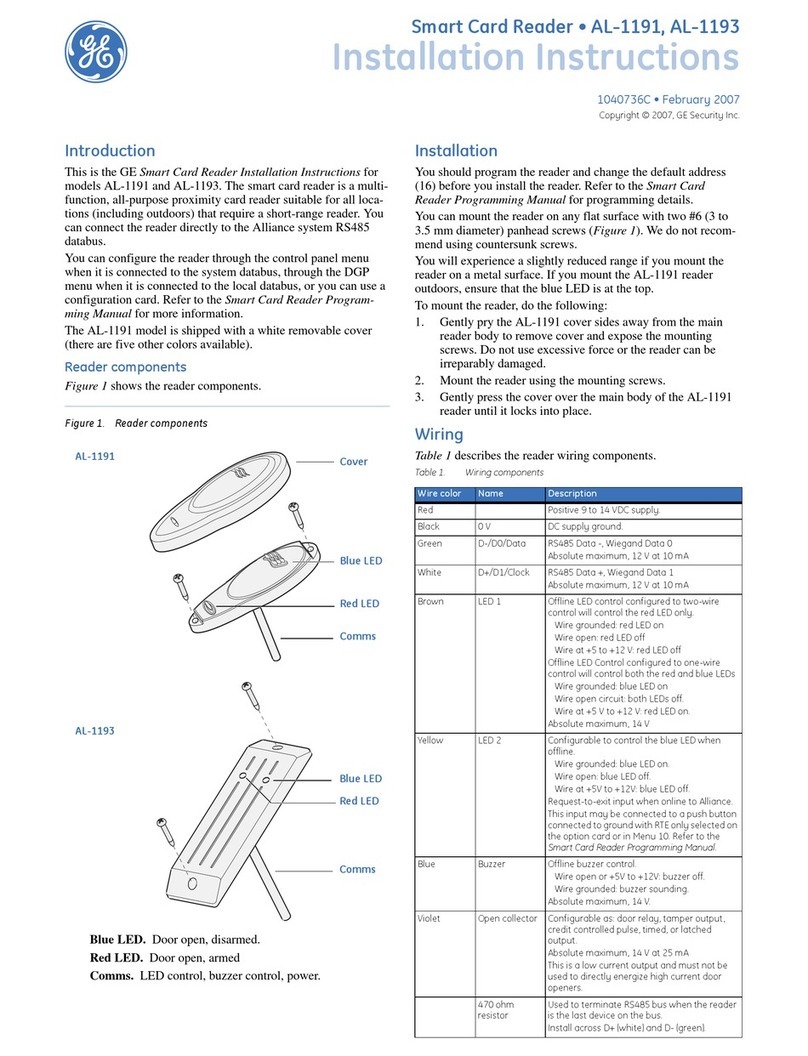

Figure 2.1 ACR II TERMINAL BLOCK RECOMMENDED WIRE SIZE AND SCREW TORQUE .................... 12

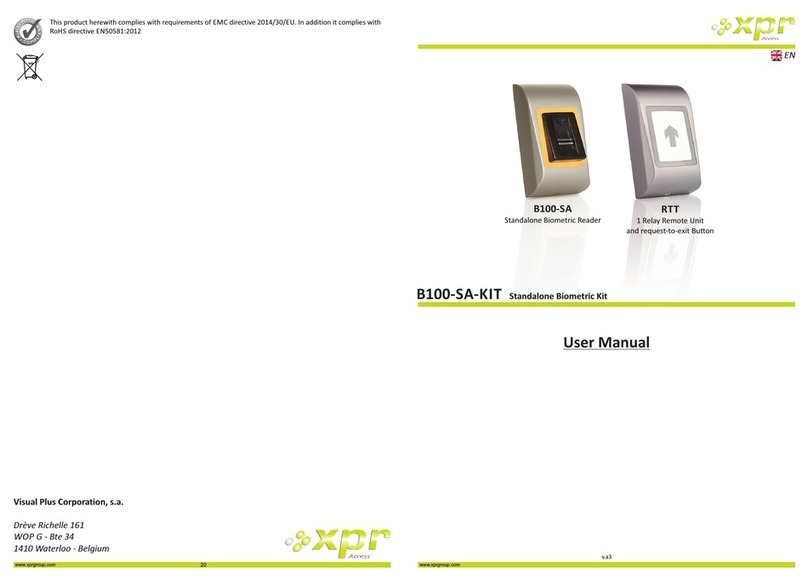

Figure 2.2 ACR-FID COMBO PC BOARD........................................................................................................ 14

Figure 2.3 ACR-FID COMBO PC BOARD CONNECTOR AND LED IDENTIFICATION................................. 15

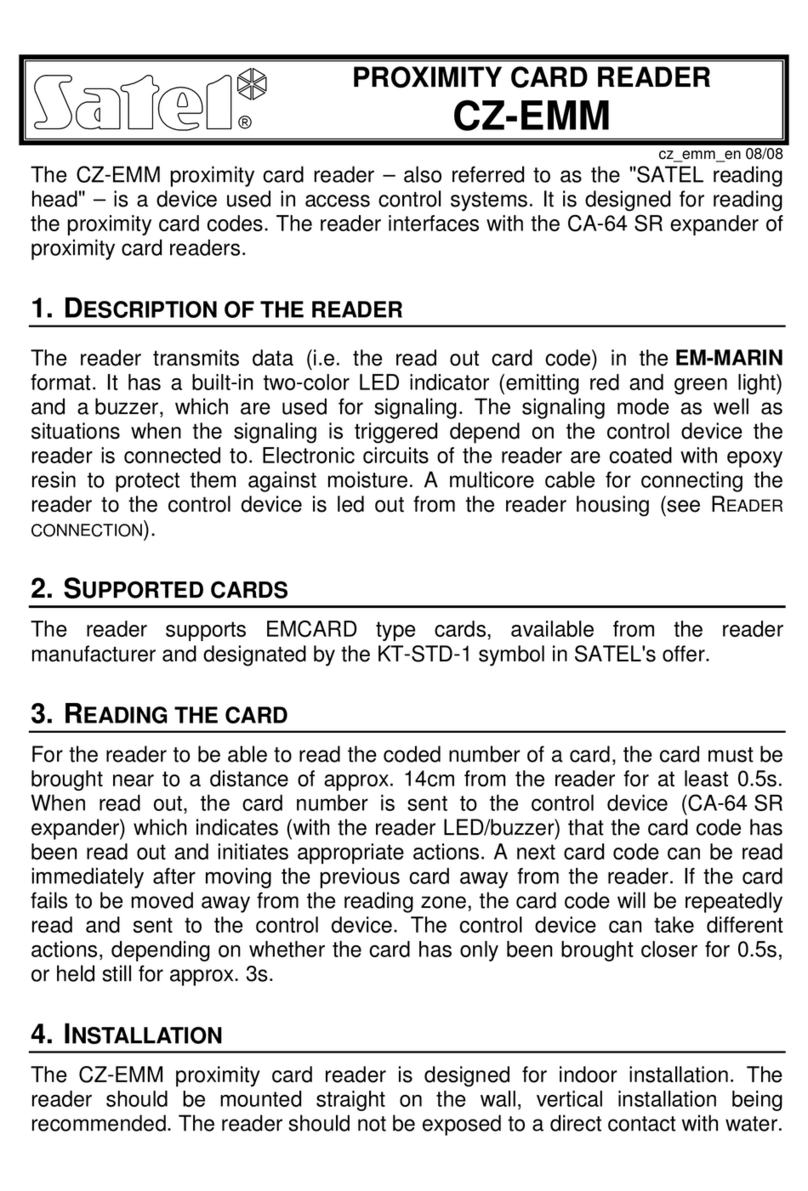

Figure 2.4 TB1 AC WIRING.............................................................................................................................. 16

Figure 3.1 4-WIRE, RS-485 CONFIGURATION............................................................................................... 18

Figure 3.2 2-WIRE, RS-485 CONFIGURATION............................................................................................... 18

Figure 3.3 RS-232 CONFIGURATION ............................................................................................................. 19

Figure 4.1 DIGITAL INPUT WIRING................................................................................................................. 21

Figure 4.2 DIGITAL OUTPUT WIRING............................................................................................................. 22

Figure 5.1 ACR-FID_COMBO SWITCH TABLES ............................................................................................ 24

Figure 5.2 ACR-FID_COMBO SW1-SW2......................................................................................................... 25

Figure 6.1 LED CABLE CONNECTOR............................................................................................................. 28

Figure 6.2 LED PC BOARD.............................................................................................................................. 30

Figure 6.3 PROX READER THINLINE II.......................................................................................................... 31

Figure 6.4 HINGE RETAINING SCREW .......................................................................................................... 32

Figure 6.5 REMOVING CARD HOLDER BACK............................................................................................... 33

Figure 6.6 PROX READER RP15 RETAINING SCREW ................................................................................. 33

Figure 6.7 BRASS INSERT ON CARD HOLDER BACK.................................................................................. 34

Figure 6.8 UNLOCK PROX READER RP15..................................................................................................... 34

Figure 6.9 PROX READER RP15 TAB CLEAR POSITION............................................................................. 34

Figure 6.10 PROX READER RP15 REMOVED ................................................................................................. 35

Figure 6.11 PROX READER RP15 TAB AND SLOT ......................................................................................... 35

Figure 6.12 HINGE RETAINING RING CUTOUT.............................................................................................. 36

Figure 7.1 UNIT OUTLINE DRAWING –MOUNTING TEMPLATE ................................................................. 38

Figure 7.2 UNIT OUTLINE DRAWING –FRONT VIEW................................................................................... 39

Figure 7.3 UNIT OUTLINE DRAWING –SIDE VIEW....................................................................................... 40

Figure 7.4 UNIT OUTLINE DRAWING –BOTTOM VIEW................................................................................ 41

Figure 7.5 PROX READER RP15 TAB –TOP LEVEL VIEW........................................................................... 42

Figure 7.6 PROX READER RP15 TAB –EXPLODED VIEW........................................................................... 43

Figure 7.7 PROX READER THINLINE II –TOP LEVEL VIEW........................................................................ 44

Figure 7.8 PROX READER THINLINE II EXPLODED VIEW........................................................................... 45

Figure 7.9 COVER –EXPLODED VIEW.......................................................................................................... 46

Figure 7.10 PARTS LIST .................................................................................................................................... 47

Figure 7.11 ACR II INSIDE VIEW....................................................................................................................... 48

Figure 7.12 RP15 - STATUS LIGHT................................................................................................................... 49

Figure 7.13 Thinline - STATUS LIGHT............................................................................................................... 49

Chapter 1 –General

7

ACR II Installation Guide: 20180711 Part # 6057

!

CHAPTER 1 GENERAL

1.1 WHO SHOULD USE THIS GUIDE

This guide is intended for individuals installing veriFID II equipment, engineering firms developing site electrical

drawings, and users troubleshooting system operation such as managers, system administrators, technicians, and

meter proving personnel.

1.2 INFORMATION ALERTS:

Important information to enhance understanding and make better use of the product.

Indicates potential damage to hardware or loss of data.

Potential for property damage or that personal injury may occur. Pay close attention and follow

instructions when you see this symbol.

1.2.1 TYPOGRAPHICAL CONVENTIONS:

Boldface: Indicates what you are to press on the keypad. Example: Key in 00000.

Italics: Emphasizes a key product or industry term.

Example: the display features a pick list style of item selection.

1.2.2 PRODUCT SUPPORT

Thank you for your purchase of this Toptech product. Should you require information or technical assistance

beyond that provided in this manual, please call Toptech’s Technical Assistance Center at 407-332-1774 x381.

You may also reach us online 24x7 at http://www.toptech.com/support. Additionally, you can email any issues you

have with our hardware to support.toptech@idexcorp.com. Information or technical assistance provided by the

Toptech Assistance Center may result in incidental charges on a time and materials basis.

1.2.3 RECEIVING AND /OR RETURNING EQUIPMENT:

The veriFID II should be immediately inspected after opening the packaging case. If any damage is visible notify

the carrier at once to establish liability. Contact Toptech Account Management to initiate timely repair or

replacement of the unit.

Account Management will issue a Return Materials Authorization (RMA) to return the product or parts requiring

repair. Do not return any material to Toptech without an RMA.

Account Management contact information: Account Management, Toptech Systems, 1124 Florida Central Pkwy,

Longwood, FL. Telephone: (407) 332-1774.

Prior to installation the veriFID II should be stored in its packing case and be protected from damage due to handling

and adverse weather conditions.

Chapter 1 –General

8

ACR II Installation Guide: 20180711 Part # 6057

1.3 OPERATING CHARACTERISTICS

For product outline and dimensions see Appendix Figures 6.1 to 6.4.

Operating voltage: 85 - 250 Vac, 47-63 Hz

Operating current: 100mA

Operating temperature: -40°F to 140°F (-40°C to 60°C)

Enclosure: Type 4, IP65

Weight: 10 lbs (4.6 kg)

Card reader :(Two options)

Card Reader Thinline II (Two options captive or non captive, Factory set) HID OEM

Card Reader RP15 (Two options captive or non captive, Factory set) HID OEM

Communications:

1 serial port: RS-232 OR RS-485

I/O:

Two Digital Inputs: 5-30Vdc

Two Digital Outputs: 0-250Vac, 0.1A MAX / 0-75Vdc, 0.1A MAX

Chapter 1 –General

9

ACR II Installation Guide: 20180711 Part # 6057

1.4 ELECTROSTATIC DISCHARGE (ESD) PROTECTION

The ACR II contains electronic components and assemblies subject to damage by ESD. The ACR II was designed

to protect against ESD while the unit is closed and in normal operation. Proper handling procedures must be

observed during the removal, installation, repair and other handling of printed circuit board assemblies, electronic

devices and components to include:

1) Service to be performed by authorized personnel only.

2) The person performing the service must be grounded by an ESD grounding strap.

3) While performing maintenance or repair, touch an unpainted metal of the ACR II surface prior to

touching or handling any printed circuit boards or electronic components.

4) Printed circuit board assemblies must be placed in and transported in conductive bags or other

conductive containers.

5) Printed circuit boards must not be removed from the conductive container until time of use.

6) All other “best” practices for protecting devices from ESD must be observed.

Chapter 2 –Installing the ACR II

10

ACR II Installation Guide: 20180711 Part # 6057

CHAPTER 2 INSTALLING THE ACR II

2.1 TOOLS REQUIRED

2.1.1 INSTALLATION

- ¼” Flat Head screw driver is required for tightening cover screws

2.1.2 SERVICEAND REPAIR

- #2 Philips screw driver for circuit board removal

- #2 Philips screw driver for card reader removal

- ¼ Flat Head screw driver for hinge removal

- 5/16 Nut driver to remove LED PCB and PROX bracket stainless steal.

2.2 COVER CLOSURE AND BOLT REPLACEMENT

When closing the cover gently lift on the bottom of the cover when in position for starting one or two of the right

corner screws. This is done to assist in alignment of the cover and base holes for starting the screws. The enclosure

cover is secured to the housing by four 6mm slotted/Philips screws. When the screws are removed, the front cover

will swing left and hang from its hinges. The screws are captive and will remain with the cover.

2.3 MOUNTING THE ACR II ENCLOSURE

Exterior dimensions of the standard ACR II enclosure are shown in the Appendix, see figures 7.2-7.4. There is only

one mounting orientation possible reference figure 7.1 for ACR II Mounting Template. The cable entries are located

at the bottom of the unit.

Appropriate fasteners must be selected to support the minimum weight of 10 lbs (4.6 kg). Toptech offers the

following mounting suggestions for three typical surfaces: drywall, wood or concrete/cinder block.

2.3.1 DRYWALL

Insert four fasteners through the corner mounting holes, shown in Figure 7.2. For the fasteners, use #12 x 1” (M5

x 25 mm) Phillips pan head sheet metal screws inserted in #12 (M5) self-tapping nylon anchors.

Place one #12, 3/8” OD (M5, 10 mm 0D) flat washer under the head of the screw before inserting the screw into

the mounting hole.

2.3.2 WOOD

Follow the instructions above for Drywall installation, but substitute #12 x 1” (M5 x 25 mm) wood screws for the four

sheet metal screws. Do not use the self-tapping nylon inserts.

2.3.3 CONCRETE OR CINDER BLOCK WALLS

Follow the instructions above for Drywall installation, but substitute a 1/4 ” x1 1/4” Tapcon masonry fastener for the

four sheet metal screws. Do not use the self-tapping nylon inserts.

Drill pilot holes for the Tapcons using a 3/16” x 3 ½” masonry drill bit.

Chapter 2 –Installing the ACR II

11

ACR II Installation Guide: 20180711 Part # 6057

2.3.4 MOUNTING HEIGHT CONSIDERATIONS

The following factors should be taken into consideration when deciding where to mount the ACR II

control Unit.

The ACR II unit should be positioned for convenient access to the front panel and mounted in a

vertical, upright position. Try to mount the unit approximately five feet above the floor so that

the card reader can be accessed from a comfortable position.

The ACR II is housed in a Type4, IP65 enclosure. It should never be submersed in liquid.

Chapter 2 –Installing the ACR II

12

ACR II Installation Guide: 20180711 Part # 6057

2.4 RECOMMENDED WIRE SIZES AND TORQUE FOR ALL TERMINAL BLOCKS

Three sizes of terminal blocks are used in the veriFID II product: 7.62 mm pitch (supply power), 5.08 mm pitch (line

voltage switching), and 3.81 mm pitch (serial communication, or dc voltages). All sizes, orientations, and

manufacturer brands have different torque and wire size specifications. Please follow the recommendations in

Figure 2.1 below. The manufacturer may be determined by looking for the logo molded into the terminal block,

usually on the side.

Figure 2.1 ACR II TERMINAL BLOCK RECOMMENDED WIRE SIZE AND SCREW TORQUE

[mm] [AWG] [Nm] [LBin]

Phoenix 7.62 Straight 30 - 12 .6 - .8 5 - 7

On-Shore

Technology

7.62 Straight 24 - 12 0.40 3.5

Sauro 7.62 Straight 30 - 12 0.8 7

Phoenix 5.08 Straight 30 - 12 .6 - .8 5 - 7

On-Shore

Technology

5.08 Straight 24 - 12 0.40 3.5

Sauro 5.08 Straight 30 - 12 0.8 7

Phoenix 3.81 Straight 30 - 14 0.5 4

On-Shore

Technology

3.81 Straight 28 - 16 0.19 1.7

TB1

TB6

Terminal

Block Pitch

Allowable

Wire Size

TB3-TB5

Manufacturer

Orienta-

tion

Logo

Recommended

Screw Torque

Location

Chapter 2 –Installing the ACR II

13

ACR II Installation Guide: 20180711 Part # 6057

!

2.5 ELECTRICAL SUPPLY CONNECTIONS

The ACR II is equipped for 85 -250Vac operation.

Use field wiring rated 75ºC or greater.

Do not route AC and DC wiring in the same conduit.

All wiring must enter the ACR II enclosure through conduit via entries in the bottom of the enclosure. All conduits

must be terminated at the enclosure by use of appropriately rated conduit hubs or glands.

Wires must be stripped ¼” and fully inserted into terminal block with no bare conductor exposed. See section 2.4

for recommended wire size and torque values.

The unit requires a safety ground connection as described in section 2.5.2 below.

A service loop is recommended for all wires and cables entering the enclosure.

Do not allow service loop cables to overlap the circuit boards. Coil any cable length in the

bottom of the enclosure. Keep AC wiring separated from all other wiring in the enclosure.

Wiring must comply with all local electrical codes.

2.5.1 INPUT POWER

Provide over current protection using a 15 Amp circuit breaker or equivalent. The breaker also serves as a means

of disconnection from the operating supply as required by UL/ISA/IEC 60950-1 and CAN/CSA-C22.2 NO. 60950-

1.The disconnect device may not be blocked or be made difficult to operate by the ACR II or any other device. Note

that installation of disconnects are typically prohibited in Class I, Division 2 locations.

Power required: 85 –250 Vac, 47 –63 Hz. The power connector (TB1) is located in the right hand corner of the

ACR-FID_COMBO board as shown in figure 2.2. Select supply wire rated 300V or better with a flammability rating

of at least VW-1. See figure 2.3 for wiring guide for TB1.

Chapter 2 –Installing the ACR II

14

ACR II Installation Guide: 20180711 Part # 6057

Figure 2.2 ACR-FID COMBO PC BOARD

TB1

AC INPUT, pin 1 Line, pin 2 Neutral and pin 3 Ground.

TB2

CARD READER

TB3

232 COM, pin1 RX, pin 2 TX and pin 3 GND.

TB4

485 COM, pin 1 RDA, pin 2 RDB, pin 3 TDA and pin 4 TDB.

TB5

DIGITAL INPUTS (5-30Vdc), pin1 IN1 +, pin 2 IN1 -, pin 3 IN2 +, and pin 4 IN2 -.

TB3 PIN 1

SW1

SW2

TB6 PIN 1

TB2 PIN 1

5V LED

TX LED

J3

RX LED

J2

OUT 1

LED

IN1 LED

IN2 LED

OUT 2

LED

TB4 PIN 1

TB5 PIN 1

TB7 PIN 1

TB1 PIN 1

Chapter 2 –Installing the ACR II

15

ACR II Installation Guide: 20180711 Part # 6057

Figure 2.3 ACR-FID COMBO PC BOARD CONNECTOR AND LED IDENTIFICATION

TB6

SWITCHED OUTPUTS (0-250Vac, 0.1A MAX / 0-75Vdc, 0.1A MAX), pin1 OUT1 +Vdc or AC Line, pin2 OUT1 -

Vdc or AC Neutral, pin 3 OUT2 +Vdc or AC Line, pin 4 OUT2 –Vdc or AC Neutral.

TB7

AC POWER OUT TO HEATER (NOT USED IN ACR II)

J2

LEDS (FRONT PANEL LED INDICATORS)

J3

VeriFID SENSOR CABLE (NOT USED IN ACR II)

SW1

BAUD RATE (S1-3), PARITY (S4-5), DIAG-ON (S6) (COM TEST SIGNAL), CAPTIVE- ON (S7) (NOT USED IN

VerFID MODE), OPEN PROTOCOL ENABLE (S8)

SW2

ADDRESS (S1 LSB) (S8 MSB)

TX LED

TURNS ON DURING COM TRANSMITION (GREEN)

RX LED

TURNS ON DURING COM RECEIVING (YELLOW)

5V LED

ON INDICATES COM IS POWERED UP (RED)

IN1 LED

This LED will turn on (GREEN) when IN1 (TB5 pin 1(+) and pin 2(-)) has 5-30Vdc applied to it.

IN2 LED

This LED will turn on (GREEN) when IN2 (TB5 pin 3(+) and pin 4(-)) has 5-30Vdc applied to it.

OUT 1 LED

This LED will turn on (GREEN) when OUT 1 (TB6 pin 1 and 2) is turned on.

OUT 2 LED

This LED will turn on (GREEN) when OUT 2 (TB6 pin 3 and 4) is turned on.

Chapter 2 –Installing the ACR II

16

ACR II Installation Guide: 20180711 Part # 6057

!

!

Figure 2.4 TB1 AC WIRING

2.5.2 EQUIPMENT GROUND

A safety ground should be attached to terminal block TB1 to maintain electrical safety in the event of a fault

condition. Follow the terminal block wiring instructions in section 2.5.1, and see figure 2.4.

Note that the external ground connection is not provided for the attachment of the protective conductor (the safety

ground). Rather, it is provided only as a supplemental bonding connection where local authorities permit or require

such a connection, for example, as a means of equipotentiality. The wire connection is on the bottom right side

exterior surface. The following wire sizes may be used: 10 AWG (5.26 mm2) or 11 AWG (4.17 mm2).

Do not connect the power supply dc common to earth ground.

2.5.3 CABLE ENTRIES

Two 1/2” NPT conduit hubs are provided for the installation of conduit and cables.

WARNING: If there are unused holes, blanking elements appropriate for the type enclosure must

be used.

L

2

1

G

N

3

TB1

Ground

Line

Neutral

Chapter 3 –Data Communications Interface

17

ACR II Installation Guide: 20180711 Part # 6057

CHAPTER 3 DATA COMMUNICATIONS INTERFACE

The ACR II has one serial communication port (see Figure 2.2). This allows for communication with a Host device

(such as TMS) with a choice of either 232 or 485.

3.1 COMMUNICATIONS PROTOCOL SELECTION AND CONNECTION

3.1.1 RS-422/485

RS-422/485 communications protocol is designed for multi-point (i.e. computer to multiple devices, also called multi-

dropped) communications up to 4,000 feet (1,220 Meters).

RS-422 requires 4-wires (2 twisted pair) for full duplex communications and utilizes a transmit pair of wires (TDA &

TDB) and a receive pair of wires (RDA & RDB).

RS-485 requires 2-wires (1 twisted pair) for half duplex communications and utilizes a single pair of wires (TDA/RDA

& TDB/RDB) for transmit and receive.

This manual will typically refer to both RS-422 and RS-485 as simply RS485 2 wire or RS485 4 wire.

A ground wire is not required, though some devices may have a terminal block for a ground.

Wire used must meet the following characteristics:

24 AWG stranded.

4-wire, two twisted pair with overall shield.

2-wire, one twisted pair with overall shield.

30 pF maximum between conductors.

1,000 ohm impedance.

Maximum length: 4,000 feet (1,220 Meters)

Maximum stub length: 15 feet.

All exposed shields must be properly insulated to prevent short circuits.

All shields must be continuous, soldered, and properly insulated.

3.1.2 RS-232

RS-232 protocol is designed for point-to-point (i.e., computer to a single device) communications limited to 50 feet

requiring a minimum of 3 wires –transmit, receive and ground. Additional wires are required for hardware

handshaking when using printers and data loggers.

Wire used must meet the following characteristics:

24 AWG.

3 conductor with overall shield (data only) or 8 conductor with overall shield (full handshaking).

30 pF maximum between conductors.

If a service loop is used, the maximum wire length in the service loop should not exceed 3 inches

[75mm].

Separate AC and DC wiring by at least 3 inches [75mm]. Do not allow excess wire in the service

loop to overhang printed circuit board.

Chapter 3 –Data Communications Interface

18

ACR II Installation Guide: 20180711 Part # 6057

3.1.3 HOST/TMS COMMUNICATIONS (RS-485)

Figure 3.1 4-WIRE, RS-485 CONFIGURATION

Figure 3.2 2-WIRE, RS-485 CONFIGURATION

Chapter 3 –Data Communications Interface

19

ACR II Installation Guide: 20180711 Part # 6057

3.1.4 HOST /TMSCOMMUNICATIONS (RS-232 2-WIRE)

Figure 3.3 RS-232 CONFIGURATION

Chapter 4 –Digital I/O

20

ACR II Installation Guide: 20180711 Part # 6057

CHAPTER 4 DIGITAL I/O

The ACR II has two digital inputs and two digital outputs. All input and output circuits are totally independent from

each other with no shared common.

If a service loop is used, the maximum wire length in the service loop should not exceed 3 inches

[75mm].

Separate AC and DC wiring by at least 3 inches [75mm]. Do not allow excess wire in the service

loop to overhang printed circuit board.

Table of contents