Toray HSU-1515 User manual

Issued in June 2009

Revised in March 2014

TORAY Submerged UF

MEMBRANE ELEMENT

Instruction Manual

Model:

HSU-1515

issued by Toray Industries, Inc.

Water Treatment & Environment Division

2-1-1, Nihonbashi-Muromachi, Chuo-ku, Tokyo 103-8666 Japan

Tel: +81-3-3245-4557

Fax: +81-3-3245-4913

URL: http://www.toray.com

BJADJCAG

Content

I. Introduction......................................................................................................1

1. Characteristics of Toray Submerged UF Membrane Rack ...............................1

2. Applications of Toray Submerged UF Membrane Rack....................................2

II. For Your Safety................................................................................................3

1.Safety Instruction for Unpacking and Installation .............................................4

2. Safety Instruction for Filtration Operation........................................................6

3. Safety Instruction for Chemical Cleaning.........................................................8

4. Safety Instruction for Disposal.........................................................................9

III. Outline...........................................................................................................10

1. Outline of membrane.....................................................................................10

2. Outline of element......................................................................................... 11

3. Outline of rack...............................................................................................12

IV. Specifications and Configuration....................................................................13

1. Specifications of Membrane ..........................................................................13

2. Specifications and Configuration of Element .................................................14

3. Specifications and Configuration of Rack ......................................................16

4. Feed water and Cleaning Limits....................................................................20

V. Installation.....................................................................................................21

VI. Operation.......................................................................................................25

1. Advance preparation .....................................................................................25

2. Filtration........................................................................................................27

3. Backwash and Air-scrubbing.........................................................................29

4. Toray Maintenance Cleaning.........................................................................31

5. Air Diffuser Cleaning......................................................................................32

6. Temperature Correction Factor......................................................................34

VII. Integrity Test and Maintenance......................................................................35

1. Pressure Decay Test (PDT)...........................................................................35

VIII.Maintenance..................................................................................................38

IX. Storage of New Element and Rack after use..................................................42

1. Storage of New Membrane Element..............................................................42

2. Storage of Rack after use..............................................................................42

1

I. Introduction

Toray Submerged UF Hollow Fiber Membrane Rack is the submerged type hollow

fiber UF (ultra filtration) membrane rack developed with the polymer science and

the membrane fabrication technologies accumulated for a long time in Toray

Industries, Inc.

The membrane material is Polyvinylidene fluoride (PVDF). The nominal molecular

weight cut off of the membrane is 150,000 daltons. It has been confirmed that more

than 90% of 150,000 daltons model polymers is consistently removed.

The element, with Polyethylene (PE) protective cylinder, is submerged type. The

maximum operating trans-membrane pressure is 100 kPa (14.5 PSI). The flow

direction is outside to inside which is suitable for high turbidity water treatment

because the air-scrubbing can be adopted to remove suspended solid effectively.

1. Characteristics of Toray Submerged UF Membrane Rack

(1) High Filtration Flux

It provides high filtration flux and stable operation for the filtration of various

raw water sources. The membrane is made with a special spinning method,

which enables high permeability and high fouling resistance.

(2) Excellent Water Quality

It provides very good water quality for the filtrate, extremely low turbidity since

the membrane has 150,000 dalton nominal molecular weight cut off. The rack is

recommended to be applied in high turbidity water treatment, such as for

tertiary treatment of sewage water and industrial waste water reuse.

(3) High Mechanical Strength

The membrane has very high mechanical strength because it is made of PVDF

with the special spinning method developed by Toray. The rack provides high

integrity and durability under recommended operating conditions.

2

(4) High Chemical Durability

The membrane material is PVDF, which allows you to clean the membrane with

high concentrations of chlorine and with high concentrations of acid resulting in

better cleaning and longer sustainable membrane flux rates.

2. Applications of Toray Submerged UF Membrane Rack

- Drinking Water Production

Membrane Elements certified with NSF61

- Tertiary Treatment of Sewage Water

- Industrial Water Production

- Reuse of Industrial Waste Water

3

II. For Your Safety

- Please be sure to read and follow the instructions below before using. This

manual should be retained for future reference.

- Follow the safety precautions as they are intended to protect operators and

equipment from various risks such as physical harm and/or property

damage. The following table shows a level of potential risk for each

indicated symbol.

This symbol indicates an imminent hazardous situation

which will result in serious injury or death when the

instruction is not observed.

This symbol indicates a potentially hazardous situation

which will result in serious injury or death when the

instruction is not observed.

This symbol indicates a potentially hazardous situation

which might result in injury or property damage when

the instruction is not observed.

- The following table explains the information to be noted.

“Prohibited”

This symbol indicates a prohibited action or procedure.

“Instruction”

This symbol indicates an important action or procedure

which has to be taken without fail.

! DANGER

! DANGER

! WARNING

! WARNING

! CAUTION

! CAUTION

Prohibited

!

!

Instruction

4

1. Safety Instruction for Unpacking and Installation

Be sure to wear safety gear such as rubber gloves and safety glasses

for unpacking. The membrane is packaged in sodium hypochlorite

solution (100mg/L). If the solution happens to touch on the skin, wash

the affected part with running water. If the solution happens to get in the

eyes or mouth, wash the affected part with sufficient amounts of clean

running water for more than 15 minutes and see the doctor immediately.

When lifting rack, please attach chains or slings to it and raise it straight

upward calmly to prevent it from shaking. Please never allow any

person under lifted article.

When installing rack, please set up a foothold in advance. Please never

do the work above the rack. Use protective equipment to ensure the

safety of workers.

Be sure to wear safety gear such as a helmet and safety shoes to avoid

injury.

The preservative solution should be washed out before using the

element. After that, keep clean water on the element to prevent the

membranes from drying out (for example, sprinkle on the element with

water). Do not allow the element to dry even for a few hours.

The element should not be frozen.

! DANGER

! DANGER

!

!

Instruction

! WARNING

! WARNING

!

!

Instruction

! CAUTION

! CAUTION

Prohibited

Prohibited

!

!

Instruction

!

!

Instruction

5

Be careful not to damage or dent the element during handling.

IDF/ISO Clamp Union Fittings 1.5 are applied for connecting the

element of HSU-1515 to the piping. Do not overtighten the cramp as

damage to the element may occur.

Keep the connection surface free of any dirt or oils.

Be sure not to install the element upside down. Confirm the element

installed in the right direction.

Be sure to install the element vertically for effective air scrubbing.

Be sure to store the element transversely.

At transportation, storage and installation rack, please take appropriate

measures to protect rack from damage.

Do not put any heavy objects on the rack. Please take care to protect

the rack from collision with other objects.

Please take adequate measures to protect rack from sparks caused by

welding, fusion cutting or grinding throughout the entire process from

installation work to operation setup.

!

!

Instruction

!

!

Instruction

Prohibited

Prohibited

Prohibited

!

!

Instruction

!

!

Instruction

!

!

Instruction

6

2. Safety Instruction for Filtration Operation

Flush all the piping out with clean water and make sure no debris is

remaining in the piping prior to charging water to the element from the

piping.

Confirm that the preservative chemical in the element and the piping is

completely washed out before starting the filtration operation. The

preservative chemical is harmful to humans.

Prior to use, make certain elements are washed. Filtrate water should

be drained unless it meets the required quality.

Protect elements from direct sunlight and ultraviolet light. Ultraviolet

light can degrade element housing and membranes.

Constantly monitor filtrate water quality such as turbidity and/or the

number of particles during filtration, and stop the operation if abnormal

water quality is detected.

Do not exceed the maximum applicable trans-membrane pressure for

filtrating 100 kPa or for backwashing 200 kPa. Higher pressures can

damage the elements. Do not exceed the maximum temperature of 40

degree C . The higher temperature damages the elements.

Do not freeze the elements.

! DANGER

! DANGER

!

!

Instruction

! WARNING

! WARNING

!

!

Instruction

Prohibited

Prohibited

!

!

Instruction

!

!

Instruction

!

!

Instruction

7

The operating conditions, including the filtration flux and the periodical

physical cleaning, must be properly set-up otherwise the

trans-membrane pressure may rise too quickly. The operation range is

described in the latter section of this manual.

Do not overfeed air to the element. Excessive scrubbing air damages

the membranes and/or shortens the membrane life.

The air flow rate should be within the range below for each element.

HSU-1515: 1.5 – 3.0 Nm3/h

At the Integrity tests, such as Pressure Decay Test (PDT) or Diffusive

Air Flow (DAF) Test, keep the air pressure below 125 kPa. Keep the

source air pressure lower than 200 kPa, to prevent the element

damaged.

!

!

Instruction

!

!

Instruction

!

!

Instruction

8

3. Safety Instruction for Chemical Cleaning

Take special precautions when handling chemicals during chemical

cleaning. Wear the safety gear such as safety glasses and protective

gloves. If chemicals come in direct contact with your skin or your clothes,

treat the contacted part appropriately based on the MSDS.

Do not mix sodium hypochlorite with acid. Such mixture generates toxic

chlorine gas.

Stop operation whenever any anomaly occurs with the equipment or

any signs of an anomaly are observed.

In the chemical cleaning, strictly follow the procedure described in the

latter section of this manual. Otherwise you may damage the elements

or negatively affect the membrane performance.

! DANGER

! DANGER

!

!

Instruction

!

!

Instruction

! CAUTION

! CAUTION

!

!

Instruction

Prohibited

9

4. Safety Instruction for Disposal

When dispose the element, please apply a service of a qualified waste

disposing company. When the element is to be incinerated, please

apply the appropriate facilities in which hydrogen fluoride (HF) gas can

be neutralized. HF gas is generaterd with the incineration of membrane.

!

!

Instruction

! WARNING

! WARNING

10

III. Outline

1. Outline of membrane

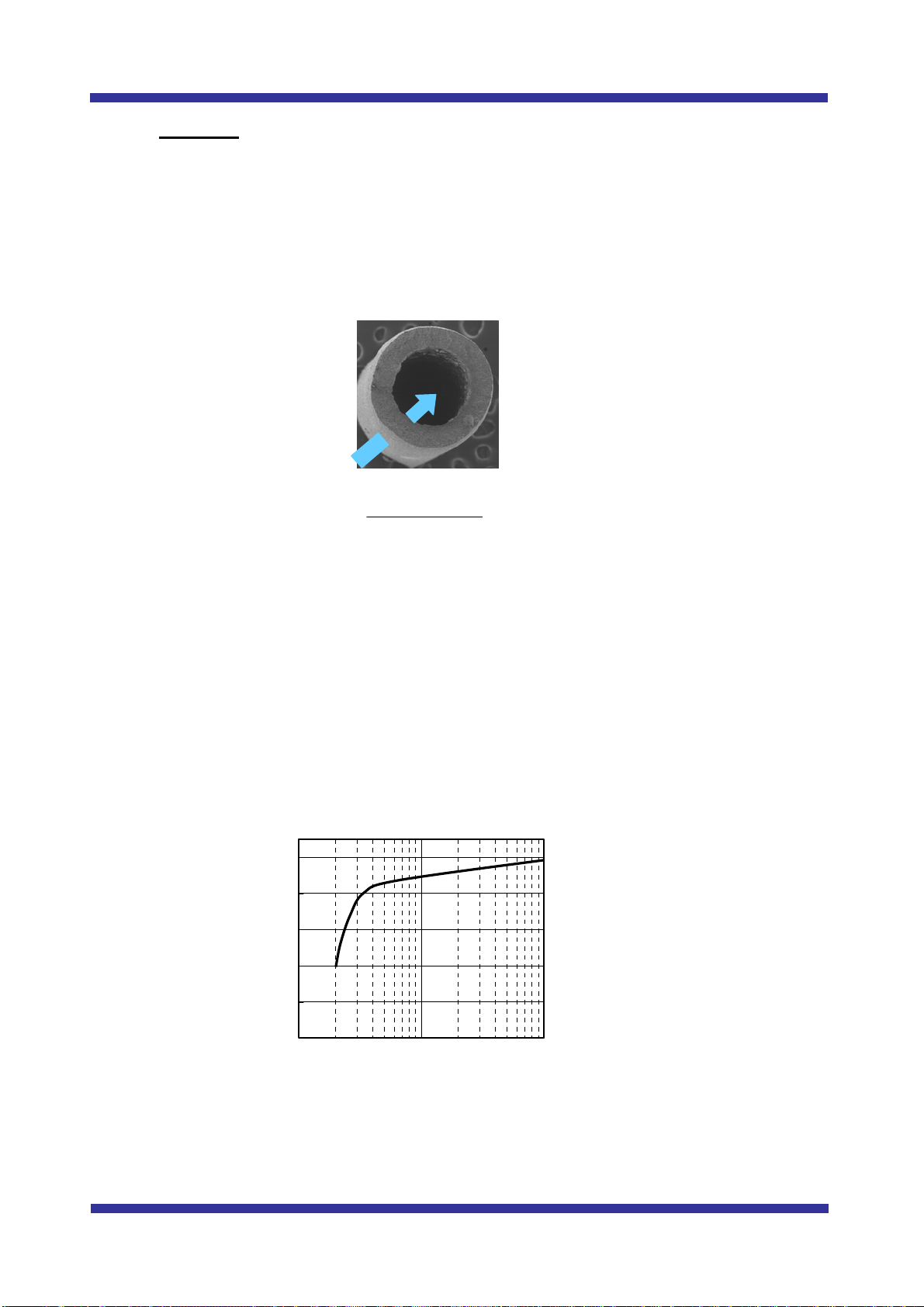

The hollow fiber membrane installed in this rack is made of PVDF (Polyvinylidene

fluoride). Cross section of the structure is shown in Fig. 1. Flow direction to the

hollow fiber membrane is outside to inside.

Fig. 1 Cross section picture of Toray PVDF hollow fiber

The diameter of the hollow fiber membrane is designed to be as follows:

For HSU-1515: Outside diameter is 1.4 mm. Inside diameter is 0.9 mm.

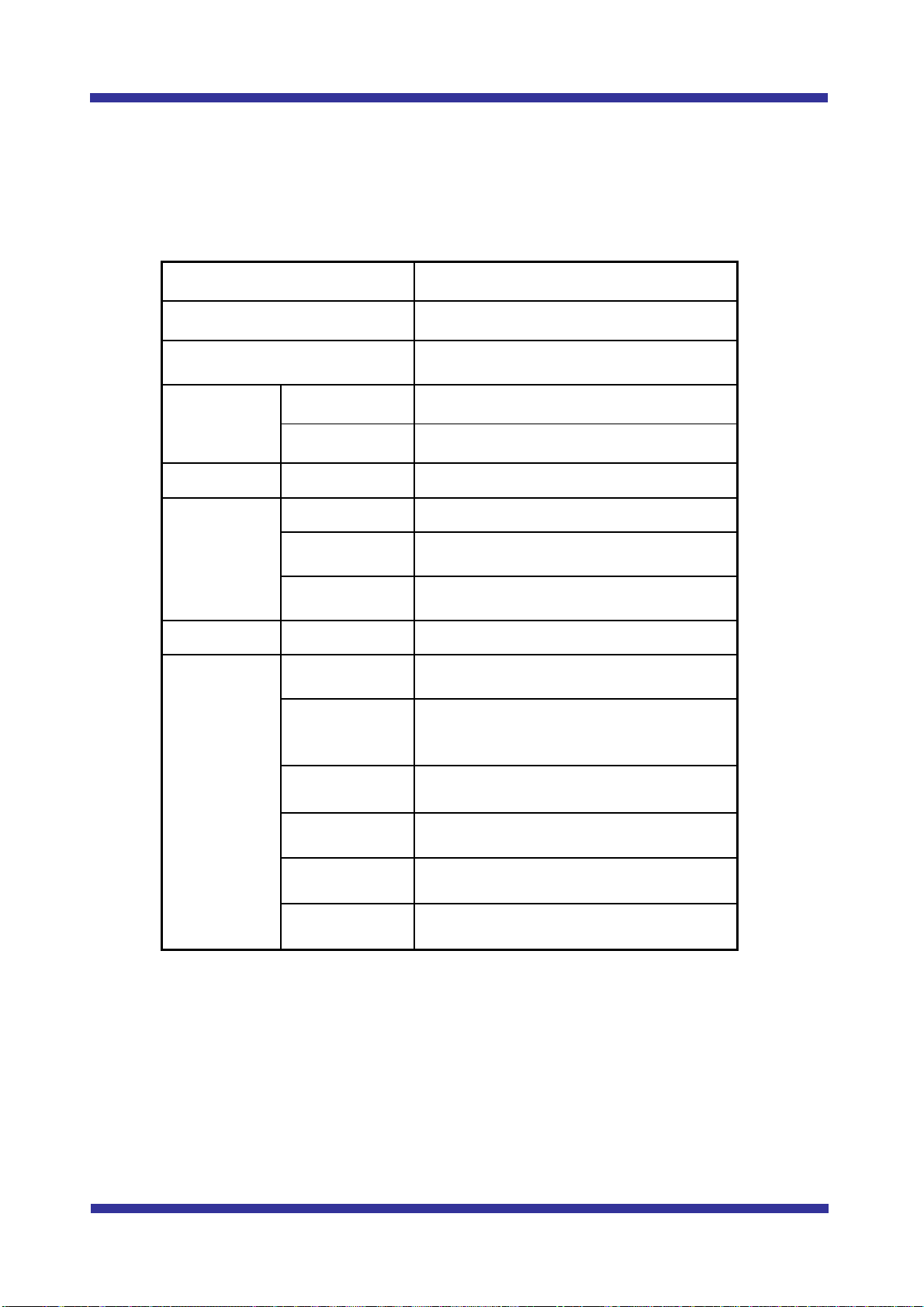

Molecular weight cut off (MWCO) of the HSU membrane is shown in Fig. 2. The

MWCO is determined by dextran solution having molecular weight of 70,000,

200,000 and 500,000. The concentrations of the dextran are measured by the

Refractive Index Detector.

0

20

40

60

80

100

10,000 100,000 1,000,000

MW of Dextran

Rejection (%)

Fig.2 Molecularweightcut off (MWCO) of the HSU membrane

Flow Direction

(Outside-in) Cross Section

Flow Direction

(Outside-in) Cross Section

11

The membrane is manufactured with special spinning method developed by

TORAY and the nature of the membrane surface is modified for high fouling

resistance. As a result, this membrane enables very high filtration flux compared to

other PVDF membranes. In addition, the physical strength of the membrane fiber is

so high that it hardly gets breakage during the normal operation for many years.

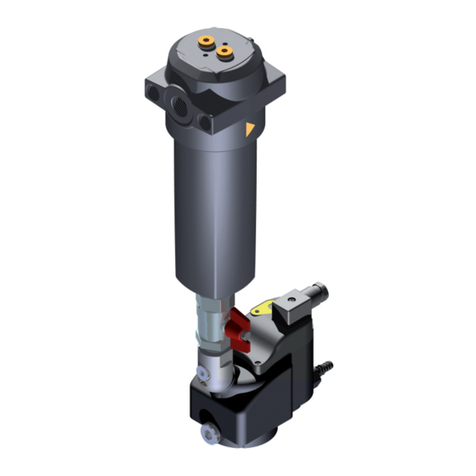

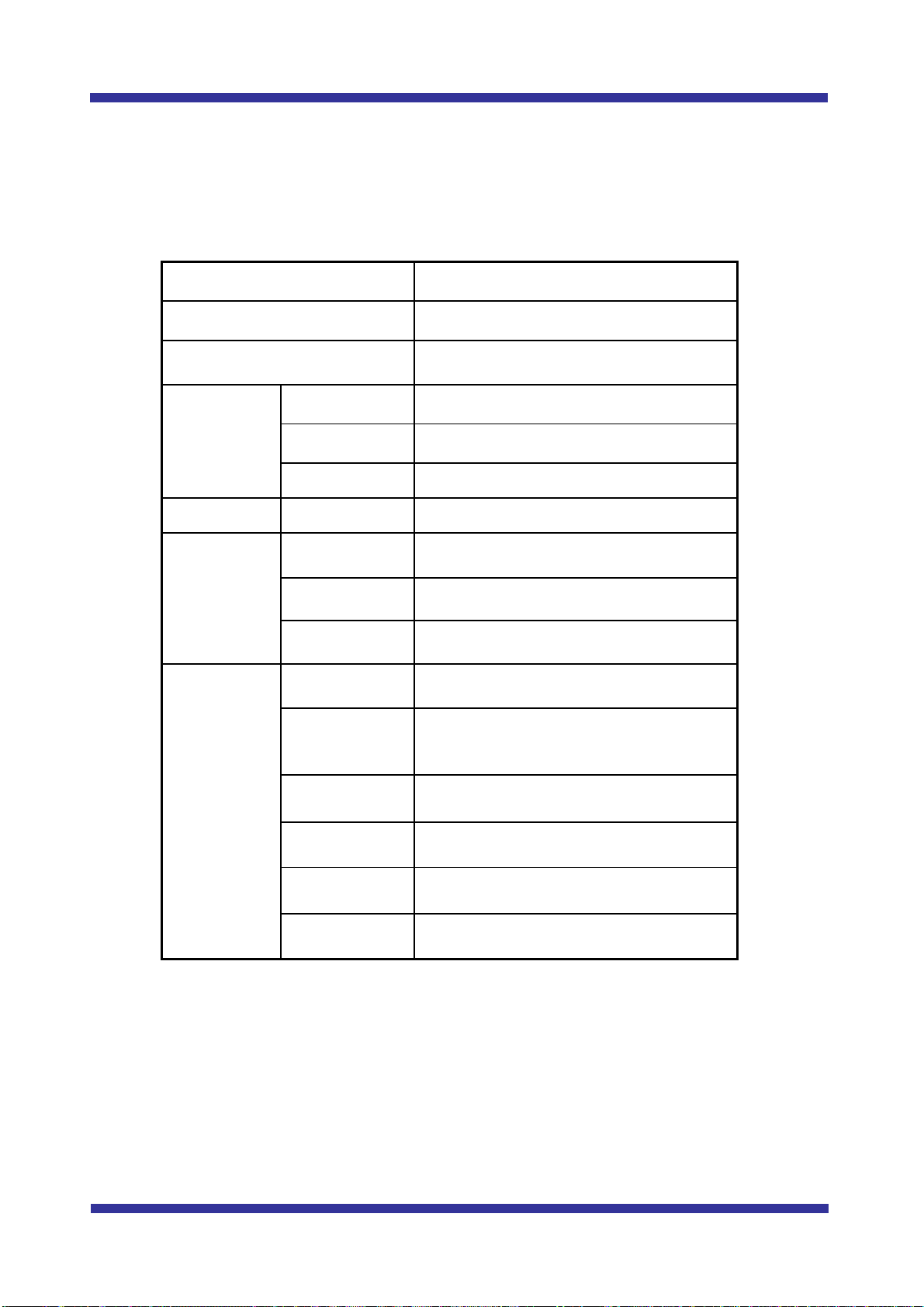

2. Outline of element

TORAY PVDF Hollow Fiber Membrane Element “HSU-1515” is submerged type

which is shown Fig. 3.

Effective membrane area of an element is as follows:

HSU-1515: 20 m2

HSU-1515: suitable for high turbidity water, large-scale water treatment plants.

Fig. 3 Picture of element (HSU-1515)

12

3. Outline of rack

“Rack” contains a number of membrane elements stacked at equal clearance and

two air diffusers. Each element is connected to the permeated water manifold.

The air diffuser consists of a number of holes to supply scouring air to each

membrane element.

This rack is used submerged in water to be treated.

Rack image is shown Fig. 4.

Fig. 4 Image of “Rack” (4 units of R16 Model are submerged in tank)

Permeate

Backwash

Feed

Air Drain

Drain

Permeate

Backwash

Feed

Air Drain

Drain

13

IV. Specifications and Configuration

1. Specifications of Membrane

Table 1. Specifications of membrane *1)

Membrane Type HSU

Nominal Molecular Weight Cut Off 150,000 *2)

Membrane material PVDF

Filtrating

Trans-Membrane

Pressure

Maximum *3) 100 kPa

Normal Operation Not higher than 100 kPa

Backwashing

Trans-Membrane

Pressure

Maximum *4) 200 kPa

Normal Operation Not higher than 150 kPa

Storage and Operating

Temperature Range 0 - 40 degree C

Operating pH Range 1 – 10

*1): Please note that the specifications are subject to changes from time to time.

*2): The nominal molecular weight cut off is determined with the model test of dextran.

*3): TMP (

Trans-Membrane Pressure) should be below 100 kPa at any time even

during the filtration.

*4): TMP (Trans-Membrane Pressure) should be below 200 kPa at any time even

during the backwash.

14

2. Specifications and Configuration of Element

(1) Specifications of element

Table 2. Specifications of element *1)

Element Type HSU-1515

Membrane Type HSU

Membrane Surface Area

(Outer Surface) 20 m2

Dimensions Diameter 147 mm

Length 1,327 mm

Weight Wet Condition 18 kg

Materials

Cap ABS

Protective

Cylinder PE

Potting

Material Epoxy or equivalent

Connections Top Center IDF/ISO Clamp Union Fitting 1.5s

Operating

Conditions

Max. Feed

Water Flow 2.0 m3/h

Max.

Backwash

Flow 3.0 m3/h

Max. Air Flow 4.5 Nm3/h

Normal Air

Flow 1.5 – 3.0 Nm3/h

Filtration

Method Submerged, Outside to inside

Maximum

Temperature 40 degree C

*1): Please note that the specifications are subject to changes from time to time.

15

(2) Configuration of element

Fig. 5 Configuration of element

(a): Nozzle

(b): Nut

Connections

Pipe fitting

outer

diameter

mm

Connectors

(a) 50 IDF/ISO Clamp

Union Fitting 1.5s

Filtrate Outlet

(b)

Inlet of Backwash Water

(a)

Feed

Drain

Feed

Drain

Drain

Air

Feed

Air Air

Lowest Water Level

in Filtration

180

1327

156

Filtrate Outlet

(b)

Inlet of Backwash Water

(a)

Feed

Drain

Feed

Drain

Drain

Air

Feed

Air Air

Lowest Water Level

in Filtration

180

1327

156

180

1327

180

1327

156

16

3. Specifications and Configuration of Rack

(1) Specifications of Rack

Table 3. Specifications of Rack Module “R16“ *1)

No. of Elements / Rack 16 elements

Element Type HSU-1515

Total Membrane Area

(Outer Surface) 320 m2

Dimensions

Height 1,800 mm

Length 1,587 mm

Width 365 mm

Weight Wet Condition Max. 500 kg

Materials

Element PVDF, ABS, PE,

Epoxy or equivalent

Rack 304SS *2)

Pipe 304SS *2), PP, HIVP

Operating

Conditions

Max. Feed

Water Flow 32 m3/h

Max.

Backwash

Flow 48 m3/h

Max. Air Flow 72 Nm3/h

Normal Air

Flow 24 – 48 Nm3/h

Filtration

Method Submerged

Outside to inside

Maximum

Temperature 40 degree C

*1): Please note that the specifications are subject to changes from time to time.

*2): 316SS is available as option.

17

Table 4. Specifications of Rack Model “R08“ *1)

No. of Elements / Rack 8 elements

Element Type HSU-1515

Total Membrane Area

(Outer Surface) 160 m2

Dimensions

Height 1,800 mm

Length 851 mm

Width 365 mm

Weight Wet Condition Max. 250 kg

Materials

Element PVDF, ABS, PE,

Epoxy or equivalent

Rack 304SS *2)

Pipe 304 SS*2), PP, HIVP

Operating

Conditions

Max. Feed

Water Flow 16 m3/h

Max.

Backwash

Flow 24 m3/h

Max. Air Flow 36 Nm3/h

Normal Air

Flow 12 – 24 Nm3/h

Filtration

Method Submerged

Outside to inside

Maximum

Temperature 40 degree C

*1): Please note that the specifications are subject to changes from time to time.

*2): 316SS is available as option.

18

(2) Configuration

Rack Model “R16”

Table of contents

Other Toray Water Filtration System manuals

Popular Water Filtration System manuals by other brands

AquaScape

AquaScape SIGNATURE Series Instruction and maintenance

BWT

BWT bestaqua 14ROC Installation and operating instructions

Waterco

Waterco HYDROCHLOR ST owner's manual

HEISSNER

HEISSNER FPU10100-00 Instructions for use

Wateraid

Wateraid Smarttap User's manual & warranty information

cleansui

cleansui AJP407-D instruction manual

Davey

Davey EMX3600 Installation & operation instructions

Miltenyi Biotec

Miltenyi Biotec autoMACS Pro user manual

Matheson

Matheson 6124 instructions

AquaScape

AquaScape 77011 installation instructions

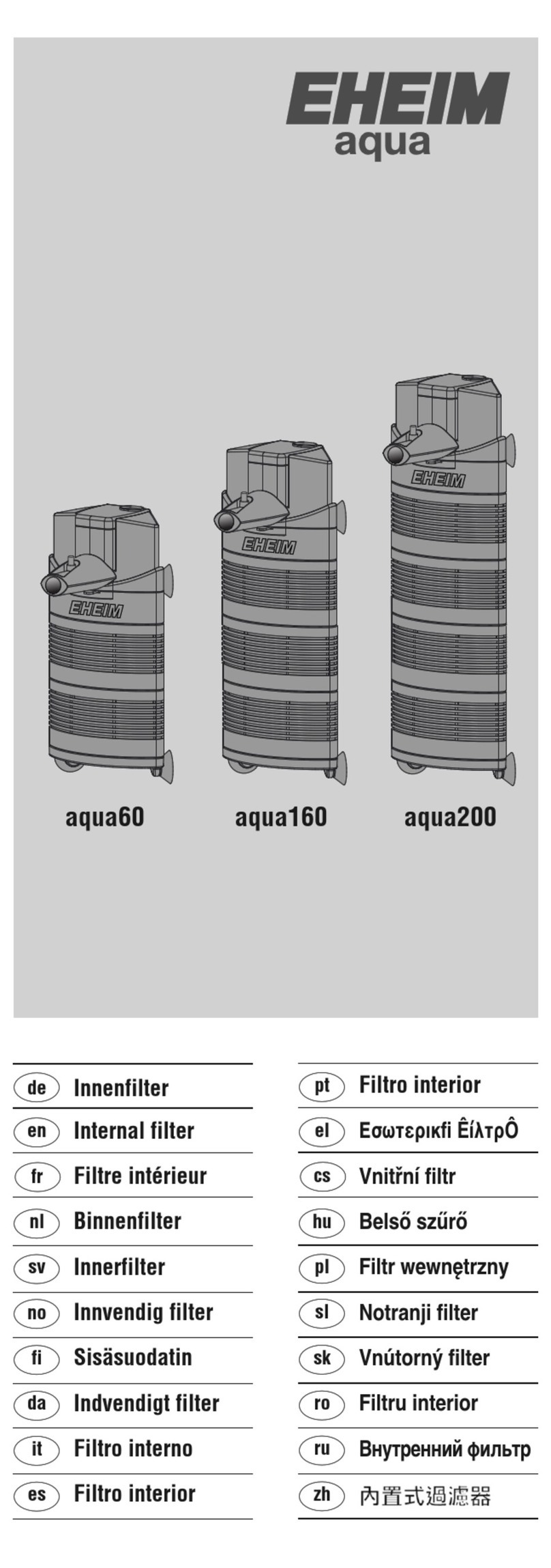

EHEIM

EHEIM aqua160 Original operating manual

ElectroMaax

ElectroMaax Marine Watermaker Series Installation, operation & maintenance manual