Milli-Q EQ 7000 User manual

Table of contents

Other Milli-Q Water Filtration System manuals

Popular Water Filtration System manuals by other brands

BRUEL & KJAER

BRUEL & KJAER 1623 instruction manual

Watts

Watts OneFlow+ OFPSYS Installation, operation and maintenance manual

KAESER KOMPRESSOREN

KAESER KOMPRESSOREN AQUAMAT CF3 Instructions for installation and operation

Viqua

Viqua S2Q-PV owner's manual

Vulcan-Hart

Vulcan-Hart SCALEBLOCKER SPS600V Installation & operation manual

A.O. Smith

A.O. Smith ADR75-V-ET-1 user manual

Hydac

Hydac OLS 10 Operating and maintenance instructions

STODDART

STODDART SPWA.PCRO1 Specification, installation and operation manual

Good

Good PuROTwist RO Installation & service guide

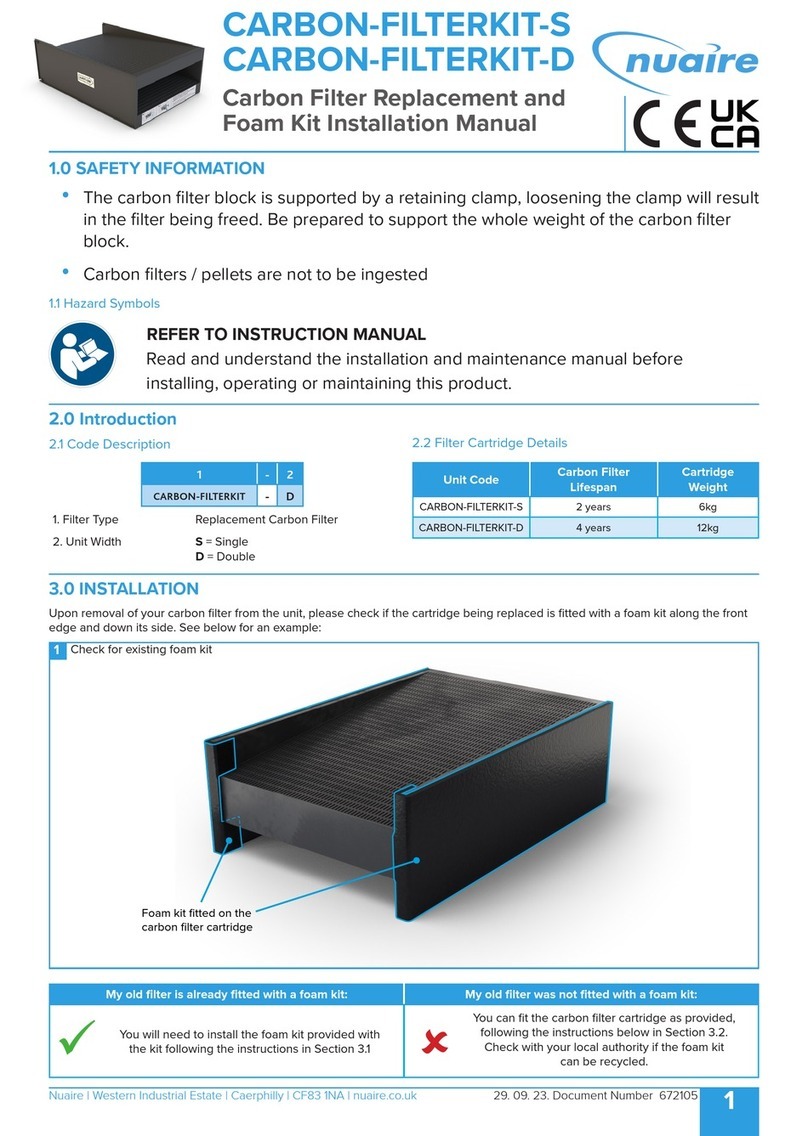

NuAire

NuAire CARBON-FILTERKIT-S installation manual

Savio

Savio Livingponds F070 Operating Manual & Specifications

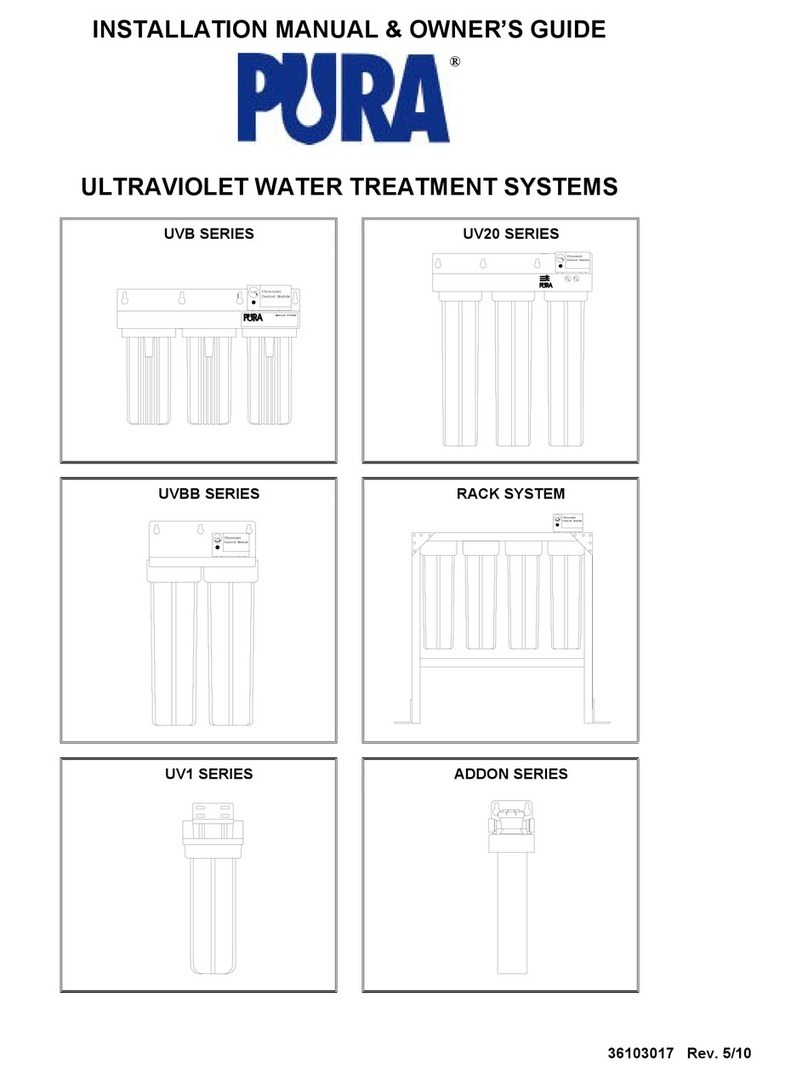

Pura

Pura UVB SERIES Installation manual & owner's guide

Ispring

Ispring RCS5T Installation instructions & operating manual

Panasonic

Panasonic TK-AS45 instruction manual

Air-Zone Inc.

Air-Zone Inc. XT-1800W operating instructions

wateroam

wateroam ROAMfilter Plus user guide

SpectraPure

SpectraPure CSPDI-180 Installation and operating manual

Water Right

Water Right Clear Flo Installation, operation & service manual