ElectroMaax Marine Watermaker Series Instruction manual

1V2

ElectroMaax Inc.

Marine Watermaker Series

SolarMaax 10

12 or 24 Volt System

INSTALLATION, OPERATION

&

MAINTENANCE MANUAL

Table of Contents

Toll Free: 1-866-945-8801

Fax: 1-905-563-8806

Web: www.electromaax.com

Email: sales@electromaax.com

US Customers

Electromaax

6405 Inducon Drive West

Unit 5

Sanborn NY 14132

Canadian and

International Customer

Electromaax

5552 King Street

Lincoln,

ON, L3J 1N6

2V2

Table of Contents

Introduction __________________________________________________ 3

General Warnings and Notices _____________________________________4

Specifications _________________________________________________ 5

Parts List ______________________________________________________ 7

Configurations _________________________________________________ 8

System Overview________________________________________________ 9

Installation Instructions___________________________________________10

Component Descriptions in order of water flow _______________________ 11

Intake Seacock ________________________________________________ 11

Sea Strainer ____________________________________________________11

Fresh Water Flush Filter Assembly__________________________________ 12

Feed Pump Assembly____________________________________________ 13

Prefilter Status Gauge ___________________________________________ 15

Accumulator Tank_______________________________________________ 15

Clark Pump 3G__________________________________________________ 16

RO membrane and Pressure Vessel _________________________________ 17

Control Panel __________________________________________________ 18

3 Way Service Valves ____________________________________________ 19

Brine Discharge Through Hull ____________________________________ 19

Optional Tank Selector Valve ______________________________________ 20

Handheld Salinity Sensor_________________________________________ 20

Mounting the Components________________________________________ 22

System Plumbing Diagram ________________________________________ 23

Low Pressure Tube Fittings________________________________________ 24

Electrical ______________________________________________________ 26

Commissioning _________________________________________________ 29

Normal Start Up and Run _________________________________________ 30

Shut Down and Flush Options _____________________________________ 31

Long Term Storage and Restart____________________________________ 32

Pre-Filter Service_______________________________________________ 33

Membrane Cleaning_____________________________________________ 34

Membrane Replacement_________________________________________ 35

Module Dimensions_____________________________________________ 40

Troubleshooting________________________________________________ 41

3V2

INTRODUCTION

The team at ElectroMaax thanks you for your purchase of our SolarMaax 10

reverse osmosis watermaker with Auto Flush, and the latest in energy recovery

technology; the Clark Pump 3G.

The addition of a low energy watermaker can be a life changing upgrade for your

cruising experience. Used properly, you will never have to go out your way just to

get questionable and/or expensive water or have to lift jerry cans out of the

dingy. The SolarMaax 10 can easily make enough for you and your crew to

shower every day, in addition it can pay for itself by being able to rinse salts off

your boat and gear, reducing maintenance and replacement costs.

The SolarMaax 10 design is based on decades of real-world product testing and

engineering from both Marine and Military applications ranging from supporting

military operations in the mountains of Afghanistan to serious offshore yacht

racing, as well as tranquil anchorages around the world.

We are confident that you will be completely satisfied with your new system and

stand behind our product with an industry leading warranty and customer

support.

4V2

GENERAL WARNINGS AND NOTICES

There are several things which the installer or operator of the SolarMaax 10 can do incorrectly,

which can seriously damage the SolarMaax 10 water maker, dramatically shorten the

operational life span of the system, and in some cases cause personal injury. Knowing the

things to avoid is critical to a good SolarMaax 10 installation and operation. We will cover the

following items again during the appropriate section later in the manual, however, due to their

importance it is worth giving the following items extra attention.

WARNING: THE SOLAR MAAX 10 IS DESIGNED TO BE USED IN TYPICAL SEA WATER.USING TASTE TO

TEST THE QUALITY OF THE PRODUCT WATER ONLY WORKS WITH A SEA WATER FEED.OPERATING IN FRESH

WATER WITHOUT STERILIZING THE PRODUCT COULD RESULT IN SICKNESS OR DEATH.

WARNING: WHEN DISASSEMBLING THE PRESSURE VESSEL,DO NOT TOUCH THE TREADS ON THE END OF

THE TUBE.THERE MAY BE FIBERGLASS SPLINTERS.

NOTICE: NEVER ALLOW CHLORINATED WATER TO COME IN CONTACT WITH THE RO MEMBRANES.

OXIDANTS SUCH AS CHLORINE AND/OR BLEACH WATER WILL PERMANENTLY RUIN THE RO MEMBRANE.

NOTICE: NEVER RUN THE SolarMaax 10 IN OILY WATER.OIL WILL PERMANENTLY RUIN THE RO

MEMBRANE.

NOTICE: DO NOT INSTALL THE RO MEMBRANE MODULE IN AN AREA WHERE THE RO MEMBRANES CAN

BECOME HEAT SOAKED TO TEMPERATURES ABOVE 113°F/45℃

NOTICE: THE RO MEMBRANE MODULE IS SHIPPED CONTAINING A STORAGE/PRESERVATIVE SOLUTION

WHICH MUST BE PURGED

NOTICE: GOOD ELECTRICAL SUPPLY TO THE FEED PUMP IS MANDATORY FOR PROPER SYSTEM

OPERATION.

NOTICE: NEVER USE A 5MICRON” CARBON” FILTER IN PLACE OF THE SUPPLIED 5MICRON

PREFILTER ELEMENT.

NOTICE: ONLY USE THE STORAGE CHEMICAL SUPPLIED BY ELECTROMAAX.OTHER BRANDS MY DAMAGE

THE SYSTEM.

5V2

SOLARMAAX 10 SPECIFICATIONS

Production Rate:8-10 Gallons per hour, 30-38 liter per hour:

The production rate is set by the displacement of the Clark Pump 3G energy recovery device and the

feed flow rate. The SolarMaax 10 uses a 10% displacement Clark Pump 3G so 10% of the feed water

flow is turned into product water. Water temperature and salinity affects operating pressure but has

little effect on production rate. Changes in feed flow does have an effect, the more feed flow the more

product. Supplying good voltage to the feed pump gives the best production rate. Running the system

while the batteries are bulk charging gives highest production rates.

RO Membrane:

The SolarMaax 10 Watermaker is equipped with DOW Filmtec® RO Membrane(s)

Membrane Type: Polyamide Thin-Film Composite

Model: SW2521 or SW2540

Range of Operating Pressures: 650 to 1000 psi (45 to 69 bar)

Normal Operating Pressure: Set by feed water conditions and feed flow rate.

Salt Rejection rate: 99.4%

Maximum Operating Temperature: 113°F (45°C)

Minimum Storage/Operating Temp: 32°F (0°C)

Maximum Operating Pressure: 1,000 psi, (69 bar)

Maximum Pressure Drop: 15 psi (1 bar)

pH Range, Continuous Operation: 2-11

pH Range, short-term cleaning: 1-12

Free Chlorine Tolerance: <0.1ppm

Electrical Power Requirements:

8.0 –10.0 amps @ 12.5-14.4 VDC

4.0 –5.0 amps @ 25.0 –28.8 VDC

The Clark Pump Third Generation (3G) Hydraulic Pressure Intensifier:

Manufactured by ElectroMaax for marine and military use. The Clark Pump 3G uses the Feed/Boost

pump flow pressure to intensify the pressure of the flow through the RO membranes high enough for

reverse osmosis to occur. There are no electrical components.

Displacement: 10 %

Feed Flow range: 1.0 gpm (3.78 lpm) to 4.0 gpm (15.14 lpm)

Maximum Inlet pressure:

up to 125 psi (8.6 bar)

Maximum Working Pressure: 1000 psi (68.9 bar)

Maximum operating temperature:

113°F (45℃)

Maximum storage temperature: 140℉(60.0℃)

Pump Dimensions: 26.38” (67cm) W, 5.75” (14.6cm) D, 8.0” (20.32cm) H

Pressure Relief Valve: Manually open ½ turn for priming and servicing

Feed Pump:

6V2

Motor: Permanent magnet type, fully enclosed, fan cooled, 1/8 hp

Pump Body: Thermo plastic

Pump Type 3 chamber diaphragm

Typical Amp Draw: 8 to 10 amps, 12VDC 4 to 5 amps 24VDC

Recommended fuse size: 15 amps, 12VDC 7.5 amps, 24VDC

Flow Rate 1.8 gpm (6.8 lpm) open flow

Pressure Vessel:

Filament wound fiberglass/epoxy compound with non-metallic wetted surfaces. Easily removeable end

caps for membrane replacement with larger that standard internal porting and fittings for increased

energy efficiency.

The most compact complete assembly available

Max pressure 1000 psi (69 Bar)

Burst pressure 3000 psi (207 Bar)

Prefilter and Auto Fresh Water Flush Filter housings:

Industry standard, 10 inch, plastic, filter housings. Accepting 9.75” by 2.5” high flow carbon filter

elements.

Clark Pump 3G and Pressure Vessel Assembly:

Dimensions: 16.3” (41.3 cm) W, 24.8” (63.0 cm) L, 9.1” (23.1 cm) H

Weight: 34.2 lbs. (15.5 kg)

Feed Pump Assembly:

Dimensions: 13.2” (33.5 cm) W, 8.63” (21.9 cm) D, 13.1” (33.2 cm) H

Weight: 11.2 lbs. (5.1 kg)

Shipping:

Level 1 with 21” Membrane: ships in 2 boxes

Box 1 –18”(45.7 cm) x 18”(45.7cm) x 14”(35.6) weight: 26 lbs.

Box 2 –29”(73.7cm) x 17”(43.2cm) x 12”(30.5cm) weight: 42 lbs.

Level 1 with 40” Membrane:

1 box 48”(122cm) x 18”(45.7cm) x 16”(40.6cm) weight: 65 lbs.

7V2

15) Handheld Salinity Sensor

16) Filter Wrench

17) Tubing Cutter

18) Tube Extractor Tool

19) Teflon Tape

20) Silicone Grease Packet

21) Container Memstor

22) 3/4” NPT to 3/4” Hose Barb –(Inlet Strainer)

23) 3/4” Check Valve –(Attached, Flush System)

24) 5/8” Tube Tee –(Flush system)

25) 2X 1/2” 3 way Service Valves (Service Access)

26) 3X 3/4” NPT to 5/8” Tube Fitting (Strainer and

Check Valve)

27) 3X 1/2” NPT to 5/8” Tube Fittings (Intake Service

Valve)

28) 4X 1/2” NPT to 1/2” Tube Fittings (Brine Service

Valve/Clark Pump)

29) 5/8” Tube Elbow Fitting (Clark Pump Stem Fitting)

30) 2X 1/4” Tube Fittings Elbow (Filter Gauge,

Attached)

31) 18X 5/8” locking rings

32) 8X 1/2” locking rings

33) 8X 1/4” locking rings

34) 1/2“NPT to 5/8” Tube Stem (Check Valve

attached)

35) 3/4” NPT to 1/2” NPT Bushing (Strainer,

Attached)

36) 3X 5/8” Tube Elbow Fittings (Feed line)

37) 2X 1/2” Tube Elbow Fittings (Brine line)

38) 4X plastic U clamps (Service Valve Mounts)

39) 3/4" NPT short nipple (Check Valve,

Strainer, Attached)

40) 2X 1/2” NPT Short Nipples (Service Valves)

41) 2X 1/8” NPT to 1/4” Tube Elbow Fittings

42) 1/2” Female Pipe to 1/2" Tube (1/2” Brine

Through Hull)

PARTS LIST:

1) Clark Pump and Pressure Vessel Assembly

2) RO Membrane Element

3) Feed Pump Assembly (Feed Pump, Prefilter, Pump Control Module)

4) Control Panel

5) Carbon Filter with Solenoid Valve for Automatic Fresh Water Flush

6) Accumulator Tank (depressurized for shipping)

7) 3/4” Sea Strainer and Mount Bracket

8) Prefilter Status Gauge

9) 30’ Coil 5/8” Tube, Black (Feed)

10) 10’ Coil 5/8” tube, Clear (Flush)

11) 20’ Coil 1/4” Tube, Black (Gauge)

12) 30’ Coil 1/2” Tube, Red (Brine)

13) 30’ Coil 1/4” Tube, Blue (Product)

14) 10” Coil Flush Valve 14/2 Power Cable

SMALL PARTS LIST:

8V2

CONFIGURATIONS:

The SolarMaax 10 can be purchased with 3 different Clark Pump/Membrane configurations. All

configurations are sent with the Clark Pump and the Membrane(s) mounted together on a base frame

and plumbed together with High Pressure hoses. If a frame assembly cannot be reasonably mounted as

a unit, the Clark Pump and Membrane can be separated for custom mounting. Usually, at least one new

custom length HP hose will need to be ordered to complete the install. Membrane flow must always be

horizontal or uphill.

1. The basic single 21” membrane in a 26.5” pressure vessel. This configuration is ideal for

temperate to warm water operation and is the lightest in weight.

2. Double 21” membranes in series. One is mounted on top of the other to conserve space. Ideal

for temperate to cold water operation and where a 40” membrane would be hard to fit. This will

work in warm water with some increase in Product water TDS.

3. One 40” Membrane ideal for temperate to cold water operation. This is the most energy

efficient configuration. In warm waters the Product TDS will be higher than a 21” membrane.

9V2

SYSTEM OVERVIEW:

The SolarMaax 10 is simple to install. When all the components are connected in the right

order the system will perform as designed and give all the fresh water you need for years. Every

install is going to be different in where and how the components are mounted so forethought is

necessary for the ideal layout for your installation. If you are already familiar with watermakers

without an energy recovery device like the Clark Pump, please try to forget what you know as

much won’t apply to this system and lead you astray. Please read the instructions and don’t

make assumptions based on older types of systems.

Here is a simplified drawing of the SolarMaax 10 layout to familiarize yourself with how the

components go together:

Figure 1: Simplified Component and Plumbing Layout

When installing the SolarMaax 10 in your boat; here are the top factors to consider:

A. Make access for service, removal, and repair as easy as possible

B. Create a space where all the service valve service tubes can reach the service pail

C. Minimize the use of right-angle fittings to reduce water flow drag

D. Water will be spilled when servicing filters. Do not mount over sensitive equipment

E. Keep wire runs as short as possible and oversize the wire to minimize voltage drop

F. Though quiet for a watermaker, consider the noise when placing the components

10 V2

INSTALLATION INSTRUCTIONS:

Prior to beginning the actual installation process, please read the entire installation procedure

and take a moment to consider the following installations notes to insure the best

performance, life, ease of operation, and maintenance of your SolarMaax 10 system.

installation of your system. We are here to help you, so there’s no need to proceed with the

installation if you have any doubts or questions. We would much rather walk you through any

questions you have now, than after everything mounted in place and screw holes are drilled

into your boat! In this Manual, step by step instructions are numbered, Notes are lettered.

Installation Notes:

A. When selecting a mounting location, consider the parts that will require periodic access, such

as the Pressure Relief Valve on the Clark pump, pre-filters, membrane replacement, flush filter

and service valves

B. The boost/feed pump requires a, 15AMP fuse or breaker for 12 VDC, 7.5 amp for 24 VDC. Both

the high pressure and low-pressure water lines must be routed through the boat in such a way

that does not expose them to chafing or with tight radius bends that could cause the lines to

kink and inhibit flow.

C. Use only Teflon tape or Loctite #55 sealing cord in the installation of any water line fittings and

do not coat the first thread. Pastes type sealants are more likely to get into the system and

cause damage to the membrane and Clark Pump

D. The RO membrane can have its performance degraded by exposure to temperatures above

113°F (45°C). Select a mounting location where it will not be exposed to ambient temperatures

in excess of 113°F (45C) when the SolarMaax 10 is non-operational. If operating and being

cooled by sea water, higher ambient temperatures up to 120°F (49°C) are tolerable.

E. All of the assembly inlets and outlets are labeled clearly in the manual making the assembly

process as “plug and play” as possible. Refer to the installation schematic for a detailed

pictorial flow chart of the assembly.

F. As with most projects on a boat, the key to a good installation is planning and component

layout. We recommend that the components first be loosely (dry fit) in place for verification

of how the plumbing will go before permanently mounted.

G. Avoid sharp 90 degree fitting turns. The shortest length of tubing between two components

may not be the most efficient if it has to have hard 90-degree fittings. A longer but smoother

turning tube has less flow drag.

H. The electrical connections should be performed by a person with proper knowledge and

experience in the installation of 12 and 24 vdc systems.

I. Voltage drop at the unit will degrade performance. Use the recommended wire size or larger.

J. For further assistance, Email first to bring our techs up to speed with the issue at

11 V2

COMPONENTS IN ORDER OF WATER FLOW:

In this section, each component’s function and how it is installed is explained

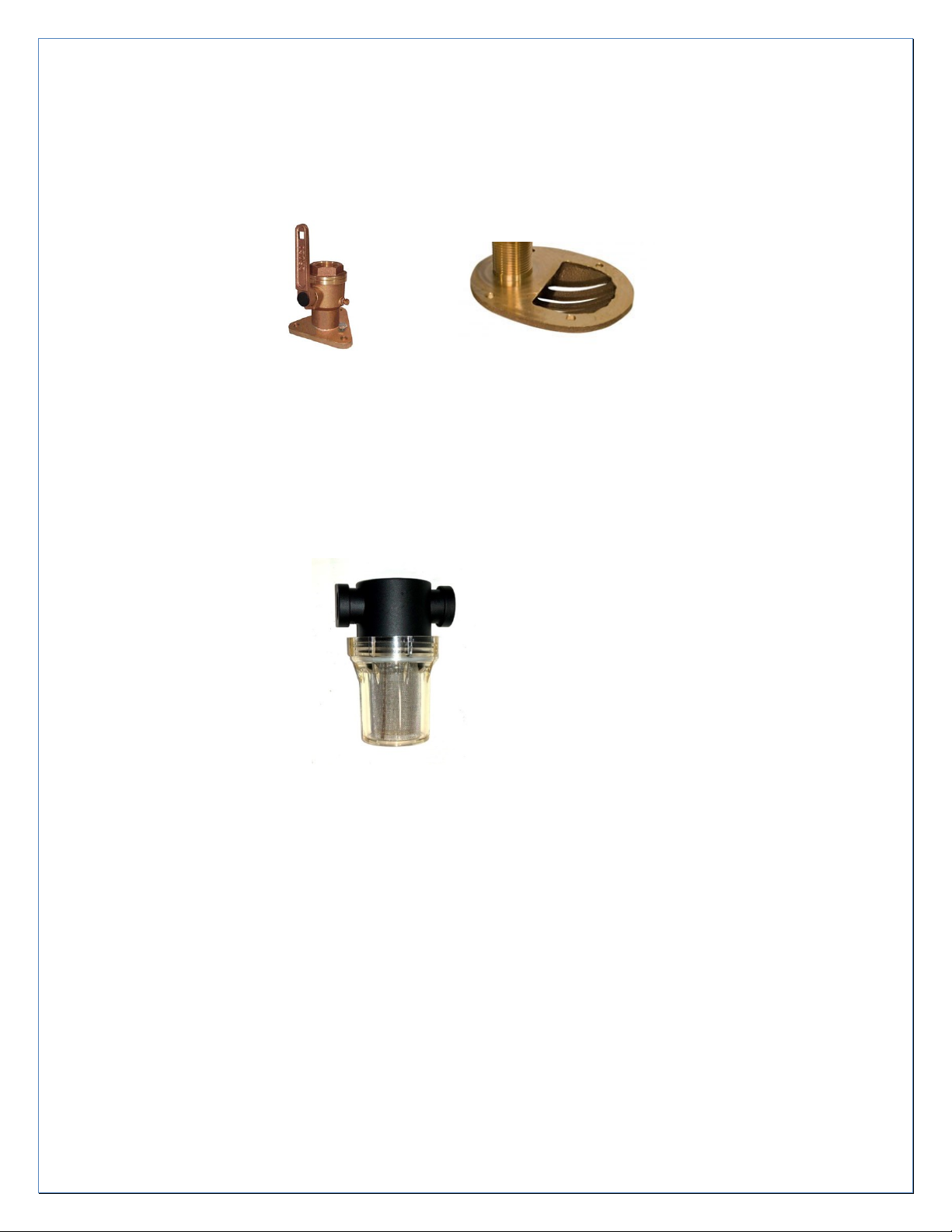

INTAKE SEACOCK:

Figure 2: ¾” Intake Seacock and Scoop, Owner Supplied

Install a dedicated ¾” seacock with a forward-facing scoop, placed as low and in the middle of

the boat as possible. Avoid placing the seacock near or downstream of a head outlet or sink

drain. Have a yard do the installation during a haul out. Sharing a through hull with another

system is not recommended, but in certain cases is acceptable. Use ¾” hose barbs that match

the valve material and ¾” ID hard walled reinforced below waterline rated hose leading to the

Sea Strainer. The Seacock and Hose are not included in the SolarMaax 10 kit

SEA STRAINER:

Figure 3: ¾” Sea Strainer and Mounting Bracket

The Sea Strainer is used to protect the check valves in the Feed Pump from being jammed by

debris. The Sea Strainer is placed between Intake Thru-hull Valve and the Feed Pump. Ideal

placement is just above the waterline but in can be placed above or below. Water will be spilled

when servicing; avoid mounting over sensitive equipment. Use ¾” hard wall reinforced rubber

hose between the Intake Through Hull and Sea Strainer. Make sure there is enough room below

the bowl for removal clearance. After selecting a location, screw down the mount bracket.

Identify the flow direction by the arrow on the housing then install the hose and tube fittings

through the bracket into the strainer body. The fittings hold the strainer body in the bracket.

When servicing the strainer, be careful not to lose the bowl gasket. Make sure the Strainer Bowl

is screwed tight, so no air is allowed to enter.

Arrow on housing shows flow direction

12 V2

FRESH WATER FLUSH ASSEMBLY:

Figure 4: Fresh Water Flush Assembly

The Auto-Flush function is used to flush seawater out of the system after use. A carbon filter is

used to remove any chlorine that may be in the ships water tank that will damage the

membrane. Mount vertically using the integral mounting bracket. Be sure to leave at least 2

inches below the assembly to allow for opening filter housing. Fresh water will be spilled

during filter replacement. The inlet is connected to the ships pressure water system with owner

supplied hose/tube and Tee-fitting to match the ships plumbing. The outlet from Flush Filter is

plumbed to a Tee placed in the feed line before the feed pump. Replace the Carbon Filter every 6

months of use or when the system is brought out of long-term storage. The connections to the

electrical “Flush Valve” at the Flush Filter Assembly are NOT polarity sensitive. The wires can

connect to either spade at the valve and the PCM.

Figure 5: Fresh Water Flush Check Valve

Carbon Filter

(We ship with filter

installed)

Carbon Filter (we ship with

filter installed)

Ships Fresh

Water Pressure

To Flush Tee

Use the 10’ Flush Valve

Cable between the

PCM outputs (right)

and the Flush Valve

(left)

The Flush Check Valve keeps the pressurized filtered flush

water from going out the intake through hull and directs

it to the Feed Pump. Its ideal placement is close to the

Flush Tee so there is no place for salt water to sit

between the valve and the Tee. Fittings included allow

for an inline placement or connected directly to the Tee

using the 3/4” NPT to Stem fitting that will push into the

Tee making it a single assembly.

13 V2

FEED PUMP ASSEMBLY

Figure 6: Feed Pump Assembly

The Pump Assembly has a 3 chambered positive displacement diaphragm Feed Pump similar to

marine and RV demand pumps but generates higher pressure. It is self-priming but can’t prime

against a head pressure. The Pressure Relief Valve on the Clark Pump must be open at least a ½

turn for the Pump to prime. Mount on a horizontal surface in a dry location with access to the

rotary manual pump switch and room for the pre-filter wrench to loosen the sump. Have

enough space around it to dissipate the heat and/or place vents below and above the pump to

allow for convection currents to take away the heat. If the components have to be separated,

mount the pump with the pump head down, the Prefilter with at least 2 inches of space under

Sump removal and the Pump Control Module in a dry area close to the Feed Pump.

Manual Feed Pump Switch

Filter Status Gauge

connections on the

inlet and outlet of

the prefilter

5 Micron Filter

Element inside the

Pre-Filter Sump

Feed Pump

Pump Control Module (PCM)

14 V2

Mounting the Feed Pump Assembly

Figure 7: Feed Pump Assembly Foot Mount Drawing

To mount the Feed Pump Assembly, remove the 4 rubber feet by removing the 4 5/16” nuts

and use the following drawing to pre-mount the feet first then locate the pump module back

onto the 4 rubber feet.

15 V2

FILTER STATUS GAUGE:

Figure 8: Pre-Filter Status Gauge

The Pre-Filter is equipped with a “Status Gauge” to indicate when replacement is required….it is

connected using ¼” tubing from both inlet and outlet of filter. Note flow direction through

Status Gauge. Mount where it can easily be seen during operation. Double sticky foam or Alien

tape works good for mounting or can be fastened to a bulkhead

ACCUMULATOR TANK:

Figure 9: Accumulator Tank

The Accumulator Tank must be pressurized to 60 psi before use. It is mounted as close to the

Clark Pump as possible. Mount so the Schrader Valve (bicycle tire valve) is accessible to check

pressure. It is used to smooth out the feed flow to the Clark Pump 3G when the pump “shifts”

direction internally. Without it the Feed/Boost Pump might cycle off and on during a shift with

the pressure switch on the pump reacting to the pressure spike. Due to shipping restrictions the

Accumulator is not pressurized and requires being pressurized to 60 psi (4 atm). Use a bicycle

pump to fill to a higher pressure, and then use an accurate tire pressure gauge to set to 60 psi.

If the Clark Pump 3G shifts are affecting the Feed/Boost Pump, check the pressure while the

system is off and the Pressure Relief Valve open.

Water Flow is

Non-directional

16 V2

Pressure Relief Valve

CLARK PUMP 3G

Figure 10: Front View

Figure 11: Rear View

The Feed Pressure Gauge is shipped separately. Mount gauge to the inlet port as shown using the Teflon

Tape provided. Plastic Pipe Threads are only threaded in snug and will bottom out and leak if over

tightened. Locate the Clark Pump 3G and membrane assembly for easy access to the Pressure Relief

Valve and access to the pressure vessel for membrane replacement. The Clark Pump 3G can be mounted

in any orientation but if the Pressure Vessel is mounted vertical, the inlet of the pressure vessel needs to

be on the bottom to purge air from the top. The Clark Pump 3G has two brine discharge ports to choose

from. Both are plugged at the factory for shipping. Remove the plug for the one that best suits the

plumbing arrangement and leave the other side plugged. The Pressure Relief Valve is all plastic and is

only finger tightened. Do not over tighten. Leave the Pressure Relief Valve open ½ turn for the initial

commissioning. Before first start up, have the Black Feed Tube to the Clark Pump ready but not

connected.

High Pressure inlet

From Pressure Vessel

Feed Inlet with

shipping plug

High Pressure Outlet

To Pressure Vessel

Brine Out Ports, Left and Right

Usually only one is used

High Pressure Fittings

Swivel 360°

Inlet Pressure Gauge assembly

17 V2

PRESSURE VESSEL AND RO MEMBRANE ASSEMBLY:

Figure 12: Pressure Vessel and RO Membrane Assembly

The RO Membrane Element is shipped in the Pressure Vessel. The Clark Pump and Pressure

Vessel assembly have been flushed with a storage solution, drained and the inlet and outlet

of the Clark Pump and the membrane product outlet plugged to keep the membrane wet.

The Membrane should never be allowed to dry out. On first start up, the residual storage

solution needs to be purged before making water.

The Pressure Vessel with the RO Membrane inside it, is designed to be as compact as possible

for tight installations. It is specifically designed for low water flow drag for energy efficiency,

minimal metal exposed to salt water and ease of membrane replacement. If mounted with one

end up, place the Inlet end below the Outlet end with the flow going uphill to help purge air.

The stainless steel flare fittings threaded into the plastic endcaps have straight threads and O-

ring seals. They are only lightly tightened into the plastic after they bottom out. Do not over

tighten! If there is a leak between the fitting and the endcap, there is a problem with the O-ring

seal. Tightening will not help.

The Product Outlet End Cap can be positioned at either end as desired. See Membrane

Replacement for end cap removal and reinstallation. The Product Outlet Fitting is a 1/4” Push

to Fit for the product tubing. There is a 1/4” plastic plug in the product port for shipping.

Remove it just before connecting the product tube during installation. Do not let a membrane

dry out.

The flow through a membrane is directional due to a seal placed on one end of the membrane

to make it the inlet end. The seal directs the flow through the membrane and stops any flow

around the outside. If the placement of this seal is somehow lost, remove one end of the

Pressure Vessel. Grab and shake the end of the membrane. If it wobbles around easily the seal

is at the other end. If it hardly moves the seal is at that end.

18 V2

CONTROL PANEL:

The SolarMaax 10 is equipped with a basic electronic control system which has a manual override.

The manual override allows for emergency operation of the system in event of an electronic failure.

The Operator Control Panel (OCP) communicates with the Pump Control Module (PCM) to control the

Feed Pump and Auto Flush Mode as required.

Figure 13: Owner Control Panel (OCP)

OCP has the following features / functions, interfacing with the Pump Control.

A. ON / OFF button with LED to indicate motor status

B. Manual 3-way valve to direct product flow to tank or testing port

C. Analog flow gauge

D. Product test port

E. Auto & Manual Flush control with indicator LED

The Control Panel is surface mounted using the supplied standoffs. Place it so it is easily accessed, and

the test port tube can be led to drain somewhere safe. For ease of service, the Panel and the 3 Way

Service Valves should be located close to each other so all three Service Tubes can reach the Service Pail.

19 V2

3-WAY SERVICE VALVES:

Figure 14: 3-way Service Valves

Two 3-way service valves are provided for access to the seawater Feed Line and Brine Discharge

Line. They are used to facilitate membrane storage and cleaning procedures. They should be

place so their alternant Service Tubes can reach a Service Pail at the same time.

A. The Intake Service Valve can be placed anywhere between the strainer and the Feed

Pump. It can be hard mounted directly to the sea strainer with the fittings supplied

B. The Discharge Service Valve is placed anywhere in the Brine Discharge Line including

mounting directly on the Clark Pump 3G brine outlet port.

Note the common port; the valve will always introduce a 90 degree turn in the water flow.

There is no straight through position.

DISCHARGE THROUGH HULL:

Figure 15: Brine Discharge Through Hull Fittings (Owner Suplied)

The red Brine Discharge Tube from the 3 way Brine Service Valve is led to a dedicated Owner

Supplied through 1/2” hull fitting just above the waterline. It is possible to tee it into an existing

drain above the waterline but there is a good chance it will cause gurgling noise and flood the

boat if the drain through hull valve is closed. Sharing a discharge is highly discouraged for those

reasons.

Common Port

20 V2

TANK FILL SELECTOR VALVE:

Figure 16: Optional Tank fill Selector Valve

If more than one tank needs to be filled, a Product Water 3-way Valve can be installed in the

product line from the panel. A Product Water 3-way Valve is a specific type of valve that cannot

block the Product flow in any valve position (non-dead heading)

Caution: Do not use any type of selector valve that can block the flow any way, even

momentarily, or damage to the system will happen. The valve can be mounted in a panel or

fastened to a wall by drilling out the mounting holes.

TDS TESTER AND TESTING PRODUCT WATER QUALITY:

Figure 17: Hand Held TDS Tester

A good RO membrane will produce product water that is well below the upper limit of 500

parts per million (ppm) of Total Dissolved Solids (TDS) of which is mostly salt in seawater. On

startup, the first flow out of a membrane that’s been operating in salt water will have a high

TDS reading (taste salty) because of osmosis inside the membrane while it’s been

depressurized. This first low-quality water will quickly be flushed out so there is a waiting

period after start up to test the product. The Held Salinity/TDS Meter can accurately determine

the quality of the product water and be compared to an actual “taste” test. For most people, a

simple taste test is sufficient to determine if the water is drinkable. Most people can start to

taste the salt when the TDS is getting close to the upper limit of 500 ppm, but some cannot

taste it even if it’s well above 500 ppm and would not be considered good. To “TEST” the

product do the following steps on the next page.

Product Flow Inlet

To Tank 1

To Tank 2

This manual suits for next models

1

Table of contents

Other ElectroMaax Water Filtration System manuals