torbo LOC2001 How to use

Short manual LOC2001

K004-9901

Operators must follow all rules and regulations for the

proper use of abrasive blasting equipment. Caution must

be also paid to the following:

• Any and all recommendations and instructions, espe-

cially basic safety instructions included in the opera-

tors manual!

• This equipment must be operated by trained and

skilled personnel only!

• The magnet of the remote control must always be se-

curely tied to the operators wrist!

• Protective clothing, helmet, hearing and respiratory

protection must always by worn!

• Before operating the equipment, make sure all com-

ponents are in working order!

• If further information is needed and not included on

this short version operators manual, please see the

main manual included with your equipment!

1. Machine setup procedures

• Close valve „P“ (11).

• Connect abrasive feed hose (7), water hose on cou-

pling (22), air hose on coupling (12) for soft cleaning

and on (12 and 13) for power cleaning, power cable

(5) on 12V DC, remote control (8) with additional cable

to coupling (6), and blast hose (14) with nozzle (9) to

coupling (10).

• Connect the remote (8) approx. 30 cm (12 inches) be-

hind the blast nozzle (9).

• Check all electrical, air, water, blast hose connections

and apply safety pins where required.

• Select the abrasive, start the compressor, open the

water supply and compressed air supply to the ma-

chine.

2. Filling the machine with abrasive/water

• Turn metering valve „S“ (20) to position „D”.

• Add the abrasive through the loading hopper into the

pressure vessel until abrasive flows from the overflow

hose (3).

• Close valves (3).

• Raise the loading hopper back, make sure the pres-

sure vessel is totally full of water, and pull up on the

vessel sealing disc (15).

• Lower the hopper to the vessel.

3. To start blasting

• Set valves (16, 19 & 20) to the recommended settings

(see back page).

• Attach magnet (8.4) to operators wrist and keep a firm

hold of the blast hose (11).

• To start blasting, put the magnet (8.4) into the correct

opening (8.3) of the remote control (8), activate push

button (8.1) to start.

• For wash down, set (20) to “0”.

• For drying (air only), set (19 & 20) to “0”.

• To switch off, remove magnet (8.4) from opening

(8.3).

4. Machine shut-down procedures

• Close valve (16) and turn off main switch (17) =

EMERGENCY-OFF.

• Open valve (3) and close compressed air valve at

compressor, turn off the compressor.

If the machine is to be shut down for an extended period

of time, the following measures must be taken:

• Close water supply feeding the machine, uncouple

hose (7), and empty vessel.

• Push the relief valve (18) until air flow stops.

• Remove power cable (5), water hose from coupling

(22), air hose from coupling (12 and 13).

• Remove remote control (8), and additional cable from

blast hose (14) and coupling (6) and blast hose (14)

from coupling (10)

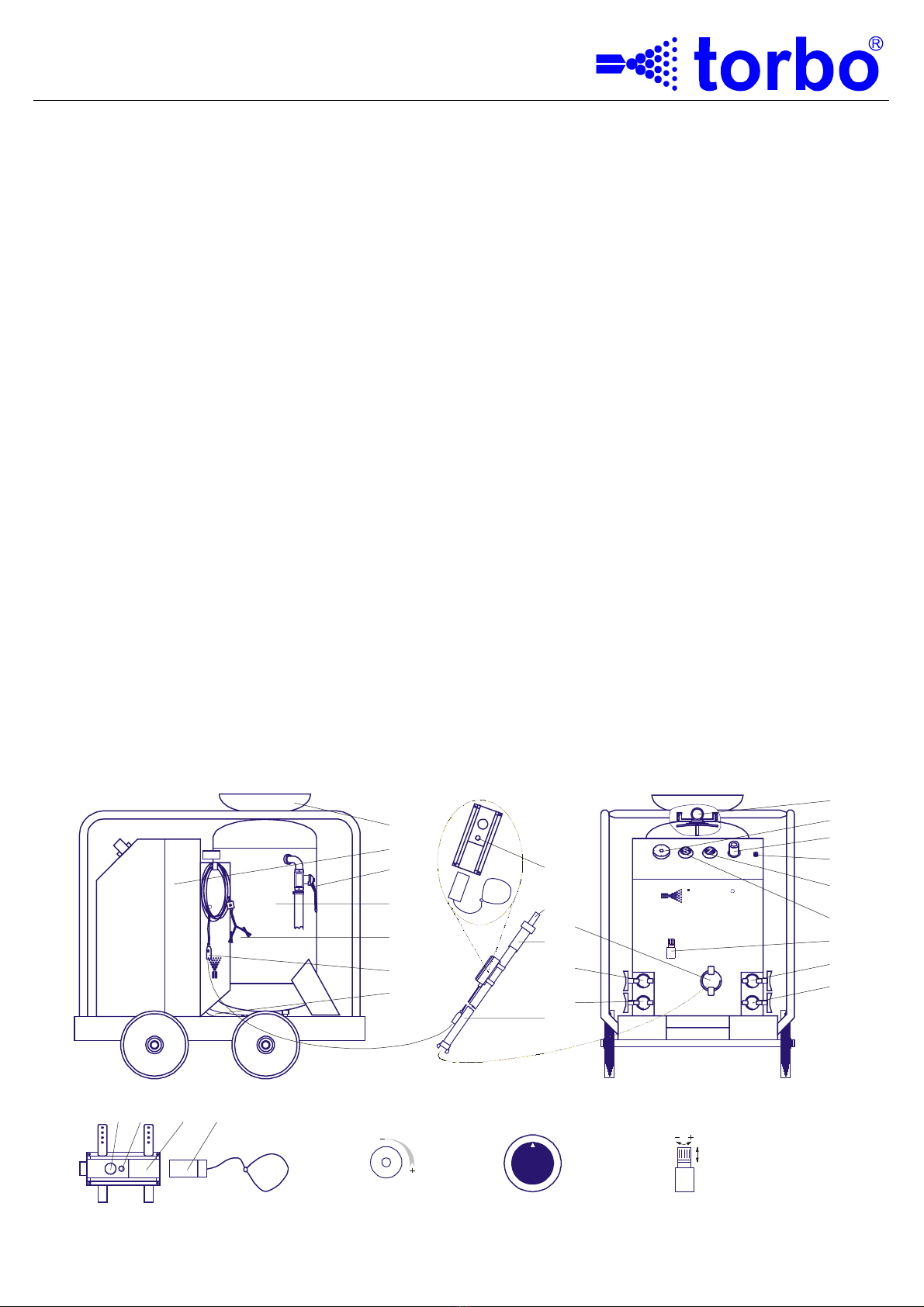

to orb

R

toorb

R

8.1 8.2 8.3 8.4

3

4

5

6

7

No. 19, 20

0,6

4

5

D

62

1

3

S

No. 16 No. 21

15

17

18

19

20

21

22

23

10

12

13

1

2

16

8

9

11

14

Short manual LOC2001

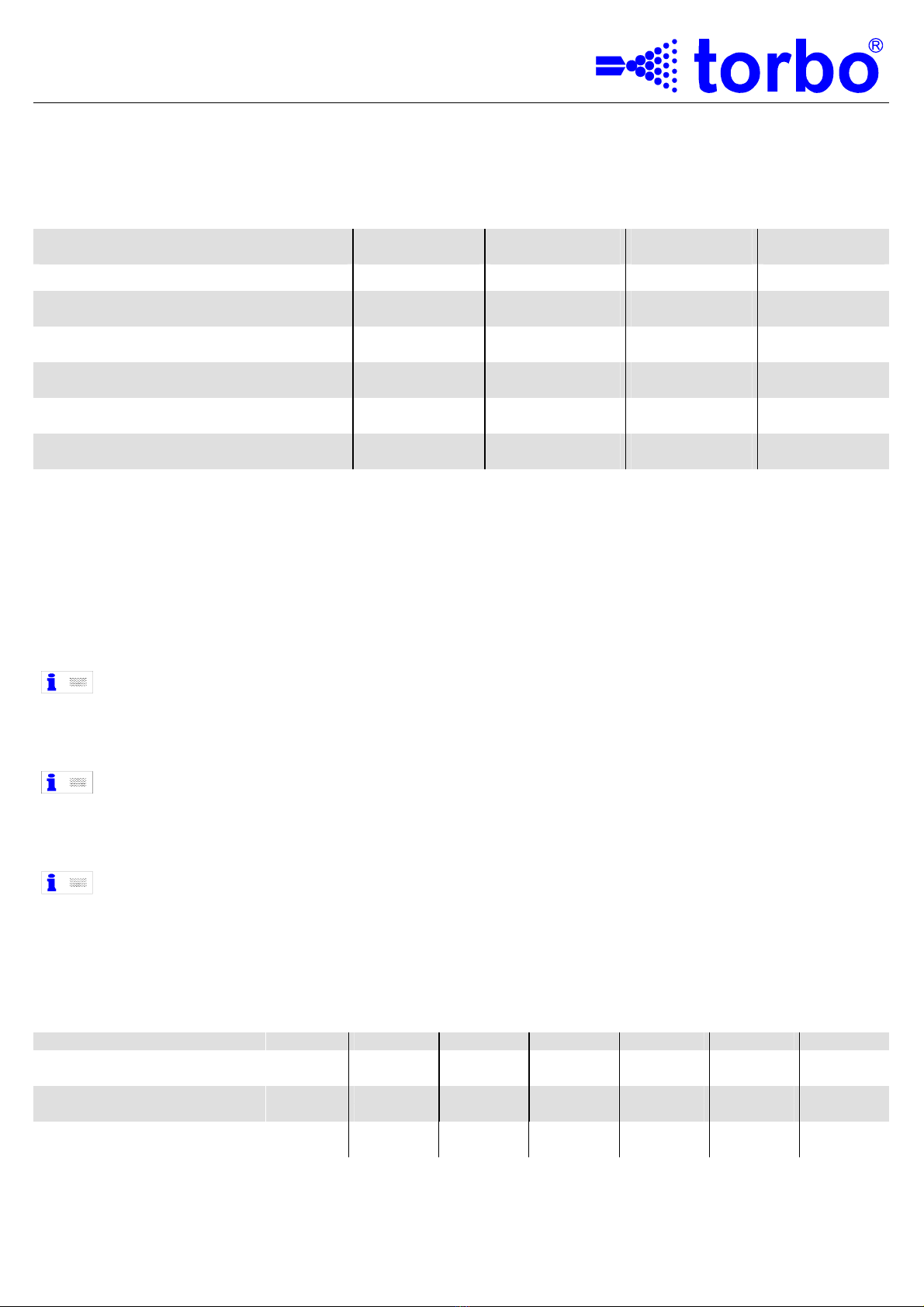

Adjustments and settings !

Table 1: Settings

Type of

Abrasive

Abrasive Metering

Valve Setting (20)

Blast-pressure

valve (16)

Blast nozzle

(9)

l/min PSI (bar) No (mm)

Cleaning up to 30 PSI (2 bar)

a) d) 0,4 / 0,6 / 0,8 /

1,0 / 1,5

8 to 30

(0,5 bis 2,0)

4, 5 or 6

(6 bis 10)

Cleaning up to 70 PSI (5 bar)

a) b) 0,6 / 0,8 / 1,0

1,5 / 2,0

15 to 70

(1,0 bis 5,0)

6 or 8

(10 to 12)

Blasting up to 180 cu ft./min. (5 m3/min)

b) c)

2,0 / 3,0

up to 140

(up to 10)

6 or 8

(10 to 12)

Blasting up to 250 cu ft./min. (7 m3/min)

b) c)

3,0 / 4,0

up to 140

(up to 10)

8 or 9

(12 up to 14)

Blasting up to 350 cu ft./min. (10 m3/min)

b) c)

4,0 / 5,0

up to 140

(up to 10)

9 or 10

(14 up to 16)

The data given in the table above are approx. values only and may differ from case to case.

Information for table 1

Column 2 “Type of Abrasive”

a) very soft abrasives without sharp edges, up to mesh 60 and with a hardness up to 4 Mohs.

b) glass beads, glass powder and other fine abrasives up to mesh 30 and with a hardness up to 8 Mohs.

c) slag, sand, garnet and other abrasives up to mesh 12 (10), and with a hardness up to 8 to 9 Mohs.

d) Sodium Bicarbonate, (suitable for the removal of paint and coatings without damaging the substrate).

• In order to ensure a good flow of abrasive it is recommended to use an abrasive containing superfines and

fines of particles.

• To achieve a more delicate blast/clean, you may have to use additional water (valve 8).

Column 3 “ Abrasive Metering Valve Setting (20)“

• For blast/cleaning always test soft abrasives first.

• The abrasive is already mixed with 20% water. If you need more water for delicate cleaning, you may have to

use additional water (valve 19).

Column 4 „Blast-pressure valve (16)“

• For blast/cleaning always test with a low blast pressure first (valve 16)

• The blasting pressure at the machine and at the blast nozzle may differ with different length and different di-

ameter of blast hose.

Table 2: Max. compressor size in relation to blast nozzle.

Diameter blast nozzle size (17) mm (No.) 6 (4) 8 (5) 10 (6) 12 (8) 14 (9) 16 (10)

Compressor output (B) m³/min

cu ft./min.

1,8

65

3,2

115

5,0

180

7,2

255

9,8

345

12,8

450

Blasting hose size (C, 20) Inch 1/2 or 3/4 3/4 or 1 1 or 5/4 5/4 5/4 or 1 1/2 5/4 or 1 1/2

mm 13 or 19 19 or 25 25 or 32 32 32 or 38 32 or 38

Compressed-air hose size (B) Inch 3/4 1 or 5/4 5/4 1 1/2 or 2 2 2

mm 19 25 or 32 32 38 or 49 49 49