Torini TC210 CLUBMAXX User manual

MANUAL

COMPETITION ENGINE

TC210 CLUBMAXX

CONFORMS TO

KARTING AUSTRALIA NATIONAL

HOMOLOGATION 109H

IN AUSTRALIA

2

TORINI.COM.AU

3

3

3

4

4

4

4

5

5

6

6

8

9

11

11

13

14

15

15

16

CONTENTS

ENGINE SAFETY PRECAUTIONS

Most accidents with engines can be prevented if you follow all instrucons in this manual and on the engine. Some of the

most common hazards are discussed below, along with the best way to protect yourself and others.

Petrol is extremely ammable, and gasoline vapor can explode. Refuel outdoors in a well-venlated area with the engine

stopped. Never smoke near fuel and keep other ames and sparks away. Always store petrol in an approved container. If

any fuel is spilled, make sure the area is dry before starng the engine.

Exhaust gas contains poisonous carbon monoxide. Avoid inhalaon of exhaust gas.

Never run the engine in a closed garage or conned area.

• The engines are designed to give safe and dependable service if operated according to instrucons. Read and understand

this owner’s manual before operang the engine. Failure to do so could result in personal injury or equipment damage.

• Know how to stop the engine quickly, and understand the operaon of all controls.

• Never permit anyone to operate the engine without proper instrucons.

• Keep children and pets far away from the area of operaon.

•

• The muer becomes very hot during operaon and remains hot for a while aer stopping the engine. Be careful not to

touch the muer while it is hot. Let the engine cool before storing it indoors.

• To prevent re hazards and to provide adequate venlaon for staonary equipment applicaons, keep the engine at

least 3 feet (1 meter) away from building walls and other equipment during operaon. Do not place ammable objects

close to the engine.

3

TORINI.COM.AU

RUN IN OIL RACING OIL

(Allows engine components to bed in)

(Fricon modied, an-foaming formula)

SERIAL NUMBER LOCATION

APPROVED ENGINE OIL

PRODUCT PARAMETERS

The engine’s serial number, type and variant

number are all stamped on the crankcase.

You will need this informaon when ordering

parts and when making technical inquiries.

LOCATION OF

1800±100

16

4

TORINI.COM.AU

MAINTENANCE STANDARDS

TORQUE VALUES

INTENDED USE

ENGINE SWITCH

• This engine has been manufactured as a compeon engine it falls outside the scope of the Product Emissions Standards

legislaon 2017 and may only be used in compeon racing consistent with the requirements of secon 9(2) of the PES

Rules.

• The engine switch must be in the

for the engine to run.

• Turning the engine switch to the

stops the engine.

STANDARD

5

TORINI.COM.AU

MAINTENANCE SCHEDULE

ENGINE OIL

HOURS

6 HOURS

Oil is the major factor aecng performance and service

life. Only use the recommended Torini Race Engine Oil it

has an fricon and an foaming addives specically

designed for splash fed race engines.

This is premium quality race engine oil, it has been developed over years of racing experience for air cooled, splash lubricated

engines. It contains enhanced fricon modiers and an-foaming agents blended specically for Torini race engines.

• Engine Oil Capacity:

0.5 L

RUN IN OIL RACING OIL

Part No. TRO1031 Part No. TRO1000

6

TORINI.COM.AU

RUN IN PROCEDURE

AIR CLEANER

unlike other kart engines , you will only run in your Torini race engine once in its enre racing life.

How you run it in could eect its performance for life, as the manufacturer our engineers recommendaon’s are listed

below.

• For the 1st 10-15 minutes drive moderately at varying speeds up to 3800rpm (half throle). It is crical to vary the RPM

for proper camsha, piston rings and moving component bed in.

• Stop and allow the engine to cool, check that there are no fuel or oil leaks.

• For the 2nd 10-15 minutes drive moderately at varying speeds up to 4800rpm (3/4 throle).

• Again stop and allow the engine to cool, during this period check the kart over ensuring that all fasteners are secure and

that the chain is correctly tensioned with sprockets aligned. (This is a good indicaon that the engine mount has not

moved)

• For the 3rd 10-15 minutes and thereaer drive at race pace or varying speeds up to WOT (Wide Open Throle) Failure to

correctly carry out this step, may inhibit proper piston ring bed in, resulng in poor ring seal, loss of potenal horsepower

and/or excessive blow-by. Along with your new engine, you have received 1lt of and you should have

used 500ml before starng your engine. Once you have completed the rst 3 x 15 mins runs we suggest changing this oil

and using the remaining 500ml of run in oil supplied. We then suggest you run the engine on track for a further 30-45

minutes at race pace, this will allow engine components to be fully bedded in.

Never use the Torini racing oil to run in your engine. The fricon modiers will prevent the bed in process from

occurring and you will never realise the full power potenal of the engine.

• Aer the rst 1-1.5 hours, your engine is now fully bedded-in, replace the run-in engine oil, with 500ml of the fricon

modied Torini Racing Oil. The oil contains enhanced fricon modiers and an-foaming agents blended specically

for your splash lubricated Torini race engine. The fricon modiers work with your piston coang to aide in both the

performance and life of your Torini race engine.

A dirty air lter will restrict air ow to the carburetor, reducing engine performance. If the engine is operated in dusty

areas, clean the air cleaner more oen than specied in the

Remove the foam lter from the main lter element.

Check both lter elements for signs of damage and replace as necessary.

Clean both the foam and main element in warm water with detergent or in

a nonammable or high ash point solvent and allow it to dry throughly.

Evenly apply lter oil to the main (fabric) lter element, as well as the foam

element, squeeze out as much excess oil as possible from the foam and

allow both lters to drain in a clean area overnight.

Place the foam air lter element over the fabric element, and reinstall the

assembled air lter ghten the hose clamp securely.

Keep the lters covered unl next use (lter oil is tacky so dirt and dust will

sck to it).

7

TORINI.COM.AU

SPARK PLUG INSTALLATION/REMOVAL

MUFFLER

VALVE CLEARANCE

Remove the spark plug cap.

Remove the spark plug with a spark plug wrench.

Visually inspect whether the insulator is cracked or chipped, if so, replace it with

a new one, if there are excessive deposits on it; clean it with a wire brush.

Measure the electrode gap with a feeler gauge. The correct gap is 0.70-0.80mm

(0.028 - 031 in). If necessary, adjust the gap by carefully tapping (for a too big

gap) the electrode or gently forcing up (for a too small gap) the electrode using

a sloed screwdriver.

Make sure the spark plug’s sealing washer is in good condion.

Install the spark plug and use a spark plug wrench to ghten it into the cylinder

head.

When installing the spark plug, in order to prevent cross-threading, rst use

hand to screw it in the direcon as shown by the arrow to install it into the

tapped hole in the cylinder head, then ghten with a plug wrench to compress

the sealing washer.

If installing a new spark plug, ghten 1/2 turn aer the spark plug seats.

If reinstalling the used spark plug, ghten 1/8-1/4 turn aer the spark plug seats.

Remove the valve cover bolts x 4, valve cover and gasket.

Set the piston just aer TDC on the compression stroke this ensures both valves are fully closed and the automac

decompressor is not interfering with seng the valve clearances.

Insert a feeler gauge between the rocker arm and valve to measure valve clearance.

If adjustment is necessary, proceed as follows:

Hold the rocker arm pivot with a wrench and loosen the pivot lock nut.

Loosen the rocker arm pivot and turn the rocker arm pivot to obtain the specied valve clearance.

Hold the rocker pivot with a wrench and ghten the lock nut 8 –10 Nm only.

Rotate the engine a few mes and recheck the valve clearance aer ghtening the lock nut.

IN

8

TORINI.COM.AU

CARBURETTOR

Check the screw head for

wear or damage before

installing.

Blow out the passage

using compressed air

and install.

Blow out the passage using

compressed air and install.

Blow out the passage using

compressed air and install.

Check for worn end of oat

valve and spring operaon

before installaon.

Check whether it is

correctly installed in the

groove.

Check for fuel leakage

aer installaon.

Check for smooth

movement by nger

aer installing

Check for fuel leakage

aer installaon.

9

TORINI.COM.AU

JETTING YOUR CARBURETTOR

(Cylinder head 230~240°C)

ENGINE IDLE SPEED - 2,000RPM

•

Using a screwdriver, turn clockwise

•

Using a screwdriver, turn an-clockwise

The carbureor is supplied with

. In many cases, this would be considered as a rich

seng but is done to protect against running the engine too lean

straight out of the box.

, in areas less than 300m above sea level

and with temperatures above 20°C, we suggest starng with a 94

Main Jet and a 40 Pilot Jet.

The carbureor mixes fuel and air at a precise rao, before it goes into the engine to be burnt.

When the fuel air mixture is correct, the engine performs at its best. However this precise fuel air rao is aected by a

number of outside inuences, most signicantly – altude (air pressure) and temperature, but is also aected to a lesser

degree by humidity.

The factory supplied jeng is a starng point only; for opmum performance you will need to read the spark plug and

engine temperature under track condions to determine the opmum jet sizing required.

Racing on tracks that are more than 300 meters above sea level, or in a dierent temperature range (+ - 10°C), requires

that you re-jet your carbureor to compensate.

Going higher results in lower air pressure (lower air density). When racing at higher elevaons your engine is geng

less air, so it needs less fuel (a smaller jet) in order to maintain the correct fuel/air rao. Under such condions your

horsepower will also go down, this is both unavoidable and universal for all competors, you can gure on losing about

3% of your engine power for every 300m (1000 ) of elevaon.

Now if overnight it gets really COLD! You should also be thinking about re-jeng again! Cold air is dense air, and dense

air requires more fuel (a bigger jet). The jet you won the race with yesterday aernoon (when it was hot), will be too lean

now, you need a bigger jet to run properly when it’s cold. Air temperature makes that much dierence! If the temperature

is just 10 degrees colder than it was when last you raced, then you risk damaging the engine by running too lean, if you

don’t change to a larger main jet.

The Main Jet; is the most crical for ensuring full power operaon, correct engine temperature and thereby a long engine

life.

The Pilot jet and the low-speed idle mixture screw; work together, the pilot jet controls the amount of fuel available and

the low-speed idle mixture screw allows you to precisely control the idle mixture being allowed into the engine at idle.

The choke lever opens and closes the

choke valve in the carburetor.

START

RUN

10

TORINI.COM.AU

JET REMOVAL:

To recap a bigger main jet has a bigger hole in it, which lets more fuel into the engine making it richer! Straight forward

enough, but the main jet is also absolutely CRITICAL to high-speed engine operaon in another way. Not only does it

meter the amount of fuel going into the engine, it also controls the running temperature of the engine as well. If you run

too lean the engine will overheat causing damage.

A correctly sized main jet will let the engine make good power for a long me without overheang. The problem is that a

main jet just 1 size too small may make greater power, but the engine life will suer as the operang temperature becomes

extreme. A slightly rich mixture burns cooler than a lean one, so be sure the main jet is big enough.

Take out the Idle

Speed screw

1

Take out the center fuel

bowl bolt (10mm)

- and remove the

fuel bowl

1

Undo the Main Jet

Be careful not to drop the

progression tube (it may fall out

of the body) once the Main Jet is

removed.

Progression Tube

Fuel Bowl

Lever the Pilot Jet

up gently

Use a at blade screw driver

11

TORINI.COM.AU

CLUTCH INSTALLATION/REMOVAL

READING THE SPARK PLUG

RICH

The area you are interested in,

is known as the

RICH = Sooty,

Black in colour

= Light

Grey / tan in colour

= Extreme white

with aluminium specs

To obtain an accurate plug reading, run the

engine on track for at least 20 minutes, as a

new plug will not colour immediately. A spark

plug can only be read correctly, if the engine

is shut down immediately aer entering the

pit lane area; do not allow the engine to idle.

To prevent the cranksha from turning while aaching or removing the clutch, use a long sha Philips head screwdriver

and insert it under the top-plate, from the crankcase side.

Slide the p of the screwdriver through the hole in the crankcase and into the recess of the ywheel. (as shown below).

Begin by turning the ywheel to align the recess opposite the magnet with the crankcase hole, then insert the screwdriver

through the crankcase and turn the cranksha sha by hand unl contact is felt. This will prevent rotaon while undoing

or doing up the clutch retaining bolt, torque to 30-32 Nm.

12

TORINI.COM.AU

Clutch shown as viewed from the open end.

If the kart chaers or shakes,

either try a moderate or slow shoe

seng or white springs.

CLUTCH SETUP

The tension of the clutch spring and clutch shoe seng will determine the clutch engagement

speed and how much clutch slip you will get.

• Engine Idle Speed - 2,000RPM

• Red Spring Engagement Speed - 2,200RPM

• White Spring Engagement Speed - 2,700RPM

- Minor Clutch Slip

- Medium Clutch Slip

- Large Clutch Slip

Having the output or drive sprocket mounted outboard is the preferred orientaon

for a single engine kart.

The engine cranksha is connected to the input of the

clutch via a keyed sha, while the output sprocket is connected to the

axle by chain. Centrifugal force is used to engage the clutch shoes,

thereby transming power from the engine to the drive sha.

The clutch design allows for inboard or outboard

mounng of the output sprocket, 3 dierent shoe engagement

sengs, as well as 2 dierent spring tensions. This allows the clutch

to be “tuned” to suit your karts unique characteriscs. With correct

clutch setup and proper gearing, you will feel an even pull coming

out of the corners and constant acceleraon on the straights.

13

TORINI.COM.AU

EXHAUST PIPE INSULATION

CAUTION

Depending on the brand of chassis the header pipe of the exhaust will vary in

distance from the seat. We recommend regardless of distance to apply heat

insulaon to the header pipe in the following manner.

350mm

• Stop heat transfer from the exhaust through your seat

adding to driver comfort.

• Stop the potenal to accidentally burn a hole in your

driving suit.

Applying this kind of insulaon to 4 stroke kart engines

is common place.

14

TORINI.COM.AU

WET WEATHER KIT

Once mounted, the bracket itself can

be le on the engine for use at a moment’s

noce. Ensure hose clamp is done up

The Wet Weather Kit minimises water ingeson by the engine, whilst operang in rainy condions. The rear facing air

intake, uses the karts forward moon to prevent water droplets directly striking the lter intake area while at the same

me drawing dry air from one of the most shielded posions available.

• Prevents engine damage due to excessive water ingress into the engine.

• Designed for quick and easy installaon or removal under race condions.

• Maintains near normal engine performance.

Essenal to prevent engine damage whilst racing in wet condions -

15

TORINI.COM.AU

LONG TERM STORAGE

TROUBLESHOOTING

• Remove and drain fuel bowl, ush out the fuel lines and fuel pump.

• Set the piston to TDC (compression stroke) so valves are closed and valve springs are not compressed.

• Seal o air intake and the exhaust outlet, to prevent moist air entering the engine.

• Store in a clean dry environment.

HARD STARTING

Disassemble and clean

16

TORINI.COM.AU

LIMITED WARRANTY POLICY

This Limited Warranty applies only to new products* distributed by Austech Industries Pty Ltd (“Austech Industries”). It is a condion

of this Limited Warranty Policy that the purchaser read the owner’s manual for the product and only use the product to the extent or

for the purposes stated therein. The purchaser must also ensure that all servicing requirements are completed as listed in the owner’s

manual (said servicing is at the owner’s expense). We recommend that all servicing is completed by an authorised service agent and

that records of said servicing are retained by the purchaser as proof in the event of a warranty claim.

Whilst the owner’s manual, packaging, and/or other documentaon supplied with Austech Industries’ products may provide details in

respect of a Limited Warranty, the terms set out herein supersede these maers, and this Limited Warranty applies in their place. This

warranty is no less advantageous than otherwise described in such other documentaon.

Austech Industries agrees, subject to the terms and condions specied below, to repair or replace at Austech Industries’ cost, the

product purchased by you when the product does not perform in accordance with its specicaons during the limited warranty period,

due to any fault in manufacturing, materials and/or workmanship. Austech Industries is not liable to repair or replace products that

the purchaser uses in a manner that is inconsistent with the owner’s manual or in the circumstances set out in paragraphs 1.1 – 1.7

below.

The benets to the purchaser under this warranty are in addion to other rights and remedies under the Compeon and Consumer

Act 2010 (Cth).

The limited warranty period, within which a defect in the product must appear, commences from the date of purchase and ceases on

expiraon of the specied term below.

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entled to a replacement or

refund for a major failure and for compensaon for any other reasonably foreseeable loss or damage. You are also entled to have

the goods repaired or replaced if the goods fail to be of acceptable quality and the failure does not amount to a major failure.

* SP, Scorpion, Torini, are all brand names of products distributed by Austech Industries

Note # Units which are failing to perform in accordance with specicaons due to non-warrantable causes will be subject to freight,

repair and or quote charges.

• Torini Race Engine – 30 Days

To the extent permied by law and subject to this Limited Warranty, and as part of the terms of the sale of the equipment or part

thereof: Austech Industries shall not be liable for any form of loss, damage, cost, injury or harm of any kind (whether direct, indirect,

special or consequenal) howsoever arising from the use or supply of the equipment to the purchaser.

This Limited Warranty will not apply where the equipment or any part thereof:

This Limited Warranty may be claimed on in the following manner:

Fails due to an accident (including liquid spillage), abuse, misuse, neglect or normal wear and tear;

Has been used in a manner other than for which it was originally designed;

Has been tampered with or is otherwise than as supplied by Austech Industries;

Where any damage, malfuncon or other failure of the equipment or any part thereof resulted directly or indirectly from

unauthorized persons, adjusng or failing to adjust any part requiring normal maintenance and service (examples include

adjustment of tappets, air lter maintenance, lubricaon and ghtening of screws nuts and bolts);

Malfuncons due to the use of defecve or incompable accessories;

Is damaged by lightning or thunderstorm acvity; or

Has been transported to a country where no authorised Service Agents exist.

Has not been used in accordance with Karng Australia Homogolaon No 109H

In order to make a claim under this Limited Warranty, the purchaser must deliver the equipment or any part thereof to an Austech

Industries authorised repair agent and pay all costs of transportaon and all costs incidental to making a claim under this Limited

Warranty. The purchaser must rst contact Austech Industries and request the delivery address of an authorised repair agent.

The purchaser must deliver to the repair agent wrien reasons why the purchaser considers that the purchaser has a claim under

this Limited Warranty and must provide all necessary details, including:

• The place, date and from whom the unit or part was purchased.

• The unit or part involved, Model and Serial Number.

• The defect, malfuncon or failure in respect of which the claim is being made.

• Proof of service of the unit or part (if applicable)

• Proof of purchase in respect of the unit or part.

If the Limited Warranty claim is valid, the repair agent will carry out repairs and return the product at no charge to the purchaser.

These repairs are limited to the Limited Warranty fault idened and as such will not include any other faults due to misuse,

abuse, failure to maintain, fair wear and tear or the replacement of serviceable items such as oil, spark plugs, air lters, fuel etc.

Table of contents

Popular Engine manuals by other brands

Intertec Data Systems

Intertec Data Systems ExVENT 30 Series operating instructions

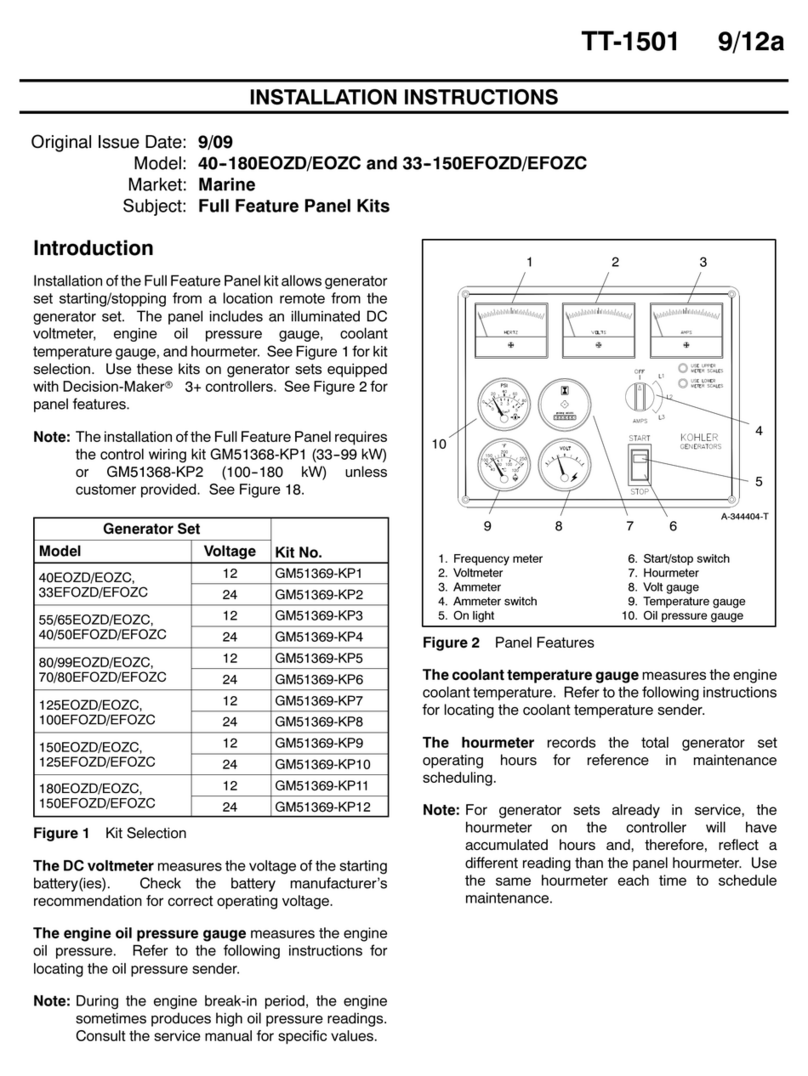

Kohler

Kohler 40EOZD installation instructions

Saito

Saito FG-57T instruction manual

SIMONINI

SIMONINI MINI 2 EVO Installation

Briggs & Stratton

Briggs & Stratton Automobile Parts Illustrated parts list

Sole Diesel

Sole Diesel MINI 17G instruction manual