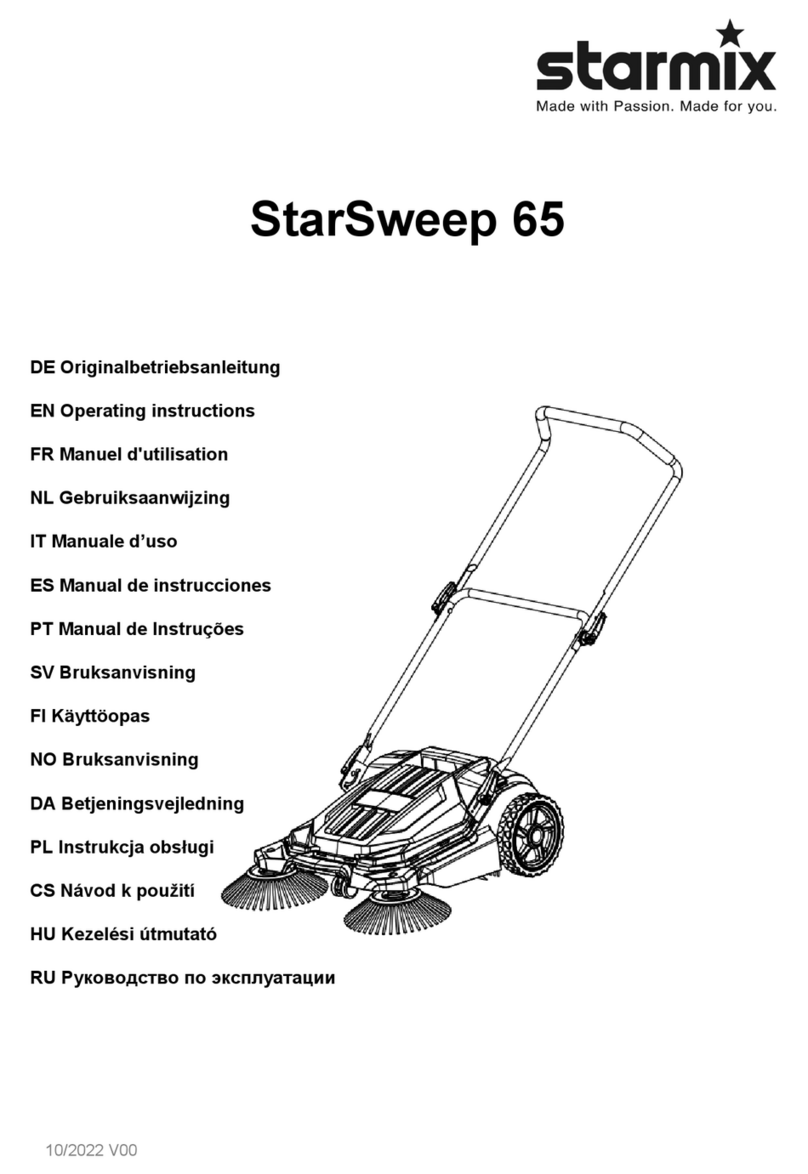

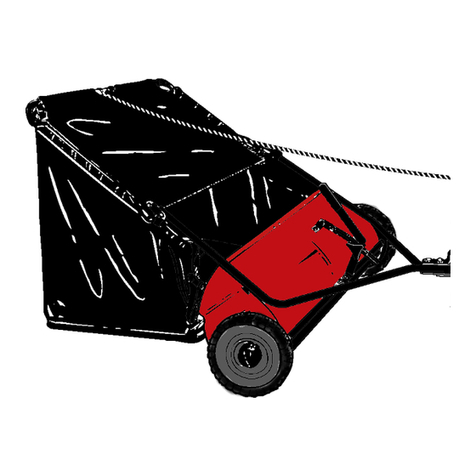

2.2 Operation of SWM 31/9

The unit operates with two brushes. The side brush takes dirt from the side into the reach of the main brush.

The main brush maintains its direction of rotation to throw the dirt into the hopper in forward direction of the

machine.

2.3 Overcoming Obstacles

In case of normal obstacles coming in the way of sweeping the unit should be pressed down at the handle.

This will cause the two brushes to lift off from the floor and the machine can easily surmount these

obstacles.

2.4 Emptying of Hopper

The hopper can be easily lifted by using the handle provided. The hopper is secured to the machine by

means of the frame. The hopper must be in direct contact with the brush compartment in order to prevent

leakage of dirt.

2.5 Renewal of Brush Assemblies

The main brush consists of a brush shaft with two brush core assemblies fastened with six self tapping

screws.

The brush cores can be replaced as below:

- Unscrew the self tapping screws

- Pull the brush core assembly to the front (broom viewed from user side) to remove it from the

brush shaft.

When reassembly of the brush ensures the split pins are fixed in the holes to guide the brush.

2.6 Rubber Gaskets

The rubber gaskets avoid dust leakage produced by the brush. Damaged or used gaskets that

fail must be replaced.

2.7 Greasing of the Main Wheels

For cleaning and greasing of the wheel axle and the gear ring, the main wheels must be

removed as described below.

1. Remove hood, remove the bolt and domed cap nut from the wheel and pull the main wheel.

2. Unscrew the gear cover and apply grease in the gear area.

3. Reposition the main wheel.

2.8 Replacement and Tensioning of the V-belt

1. Lift up the side brush arm

2. Loosen the clamp screw and pull out the side brush from the brush arm.

3. Place the V-belt through the brush arm and put it on the V-belt pulley on the brush shaft

4. Push the side brush back into the brush arm and re-tighten the clamp screw.

5. Place V-belt into the groove of the right-hand main wheel.

When the brush arm is put down, the V-belt must be tensioned so as to allow a perfect drive

transmission, if necessary re-tighten by shifting of the side brush arm bearing.

2.9 Replacement of the Side Brush

The side brush can be replaced after removing hex-bolts from the side brush.

2.9.a Regaining of Bristles

If the bristles have been bent inwards in transit the side brush must be placed on a flat base,

the bristles pointing outward and a weight must be placed on the plate. The bristles will regain

their correct position gradually.

If the bristles have been bent outwards, bring them together apply a rubber band around the

bristles and allow it to stay for sometime. The bristles will regain their correct position

gradually.

5