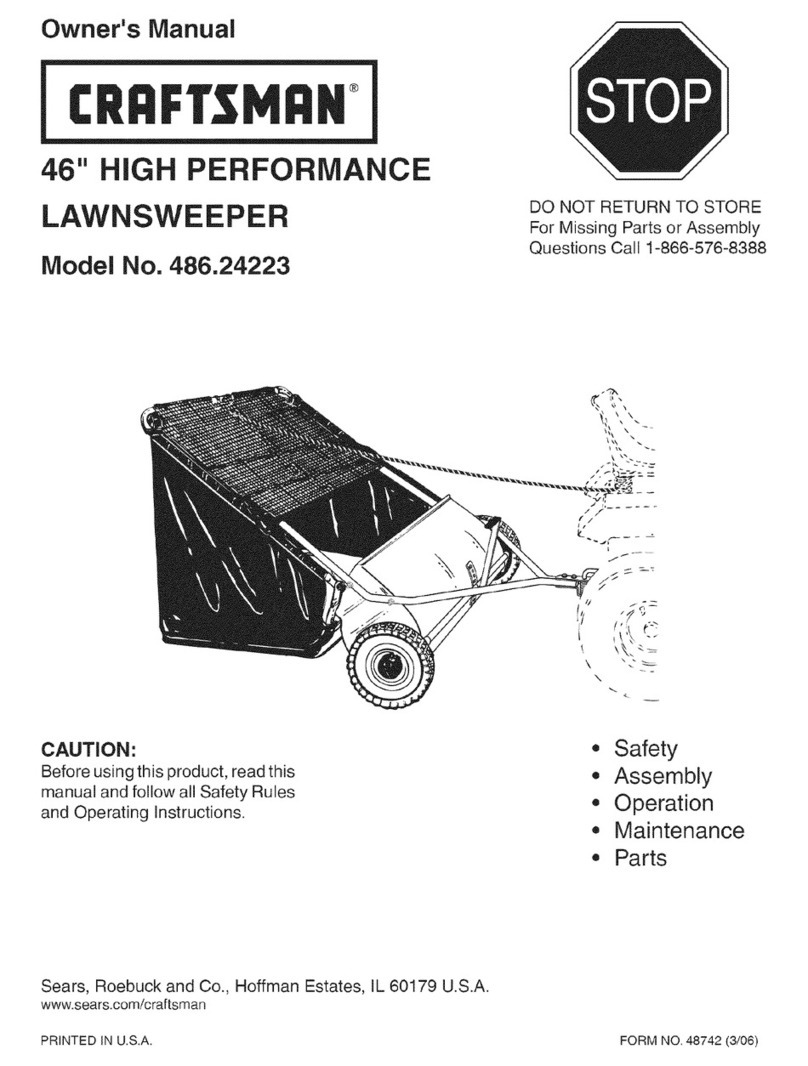

Craftsman 486.240383 User manual

Other Craftsman Lawn Sweeper manuals

Craftsman

Craftsman 486.240320 User manual

Craftsman

Craftsman 486.24222 User manual

Craftsman

Craftsman 486.242223 User manual

Craftsman

Craftsman 486.24207 User manual

Craftsman

Craftsman 486.242221 User manual

Craftsman

Craftsman 486.24212 User manual

Craftsman

Craftsman 486.24221 User manual

Craftsman

Craftsman 486.24211 User manual

Craftsman

Craftsman 486.242223 User manual

Craftsman

Craftsman 24222 - 42 in. High Speed Sweeper User manual

Craftsman

Craftsman 486.242291 User manual

Craftsman

Craftsman 486.24209 User manual

Craftsman

Craftsman 486.242231 User manual

Craftsman

Craftsman 486.24237 User manual

Craftsman

Craftsman 486.242211 User manual

Craftsman

Craftsman 486.242211 User manual

Craftsman

Craftsman 486.241320 User manual

Craftsman

Craftsman 486.241322 User manual

Craftsman

Craftsman 486.242112 User manual

Craftsman

Craftsman 486.241321 User manual

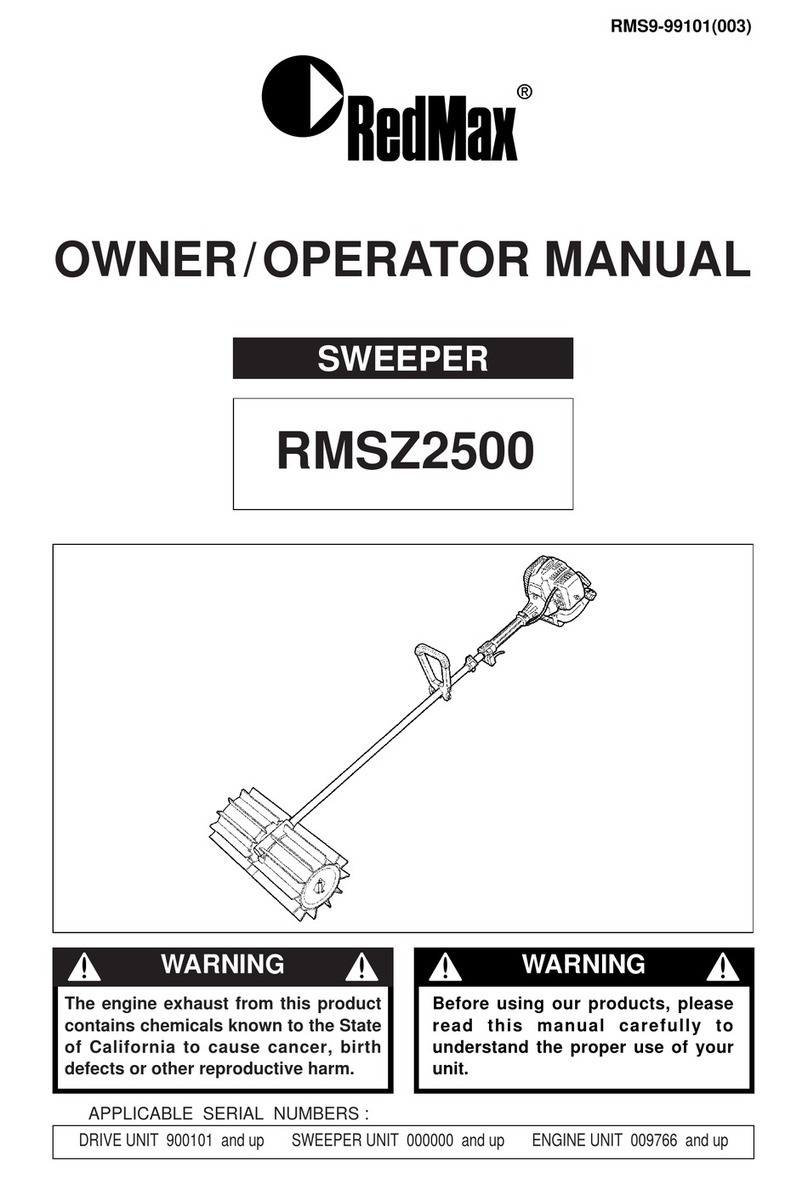

Popular Lawn Sweeper manuals by other brands

Smithco

Smithco 72-000-A Operator's manual

Parker

Parker Suburbanite 895803 Owner/Operator & Parts Manual

Agri-Fab

Agri-Fab 45-0290 owner's manual

Agri-Fab

Agri-Fab 26" Leaf/Lawnsweeper 45-02181 owner's manual

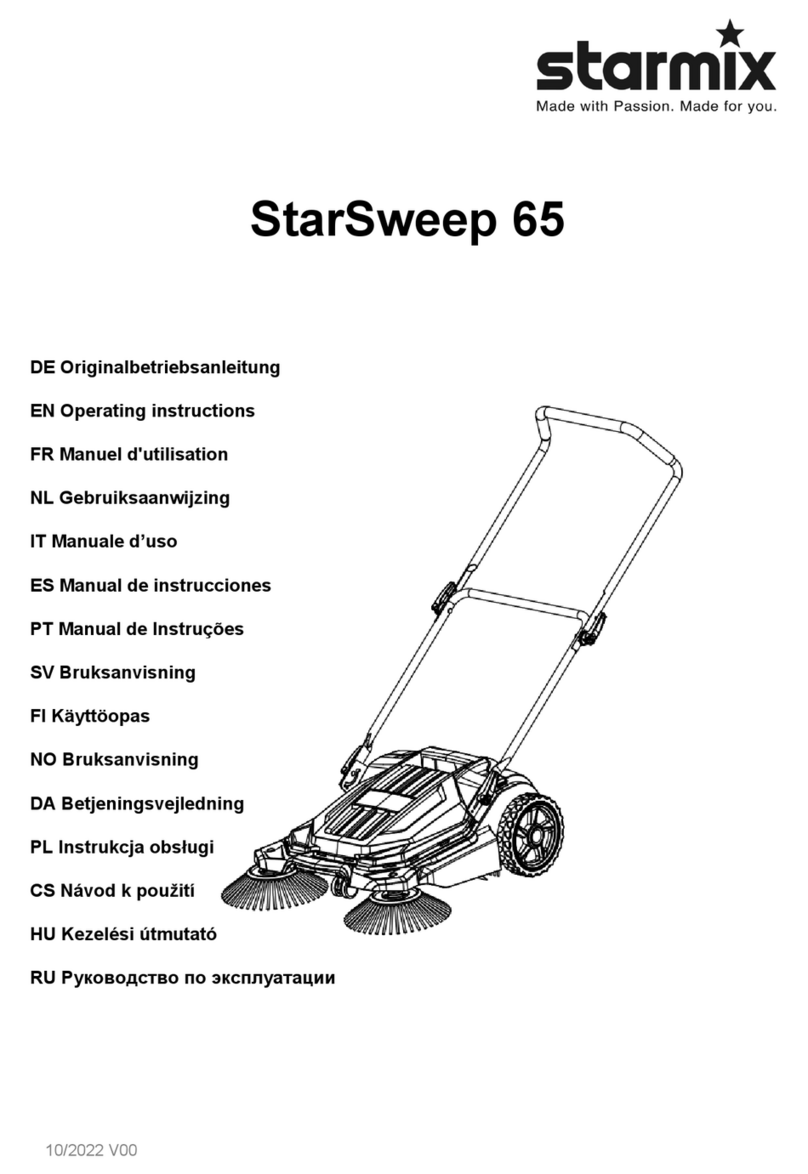

Starmix

Starmix haaga Series Original operating instructions

MasterCraft

MasterCraft HS 700 S operating instructions