9

INTRODUCTORY COMMENT

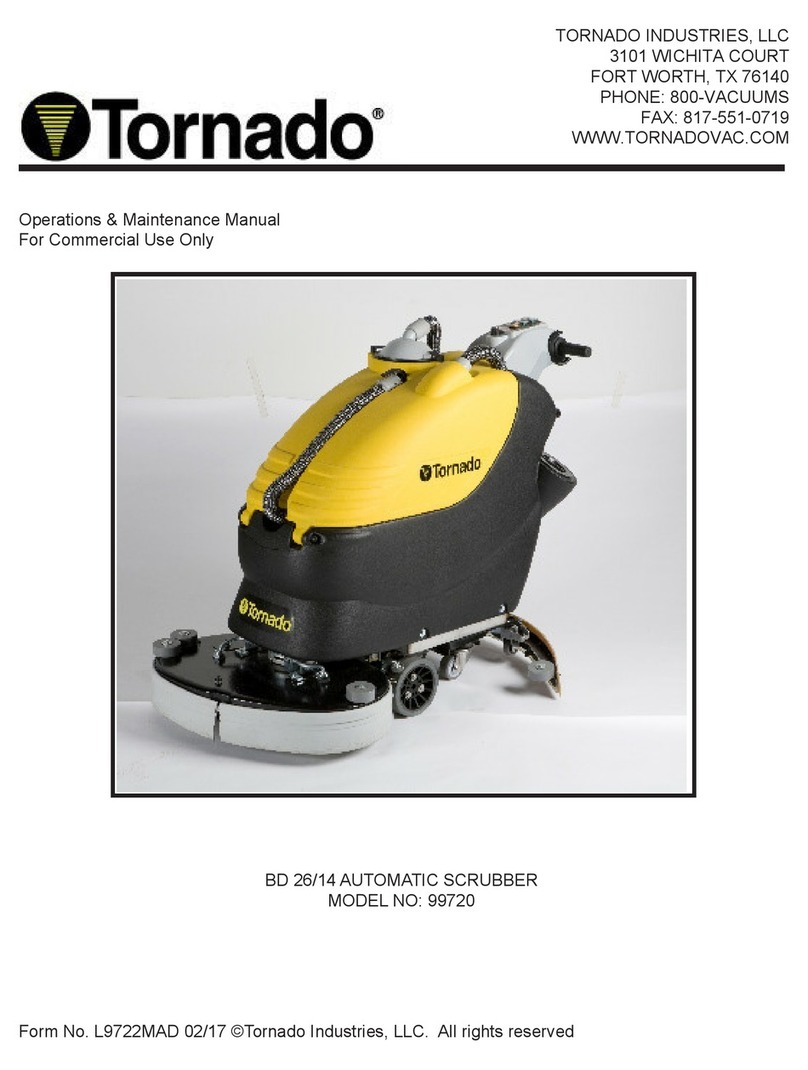

Thank you for choosing our machine. This oor

cleaning machine is used for the industrial and

commercial cleaning and is able to clean any

type of oor. During its movement, the combined

action of the brushes and the detergent solution

removes the dirt which is recovered through

the rear suction assembly, giving a perfectly

dry surface. The machine must be used only

for such purpose. It gives the best performance

if it is used correctly and maintained in perfect

efciency. We therefore ask you to read this

instruction booklet carefully whenever difculties

arise in the course of the machine’s use. In

case of need, we ask you to contact our service

department for all advice and servicing as may

prove necessary.

GENERAL RULES OF SECURITY

The rules below have to be followed carefully in

order to avoid damages to the operator and to

the machine.

- Read the labels carefully on the machine. Do

not cover them for any reason and replace them

immediately if damaged.

- The machine must be used exclusively by

authorized staff that has been instructed for its

use.

- During the working of the machine, pay at-

tention to other people and especially to the

children.

- In case of danger release the accelerator pedal

so to activate the parking brake.

- Leaving the machine in parking position, take

off the key from the instrument board.

- Do not mix different detergents, avoiding harm-

ful odors.

- Storage temperature: between -25°C and

+55°C.

- Perfect operating temperature: between 0°C

and 40°C.

- The humidity should be between 30 and 95%.

- Do not use the machine in explosive atmo-

sphere.

- Do not use the machine as a means of trans-

port.

- Do not use acid solutions in such concentra-

tions that could damage the machine and/or the

persons.

- Do not use the machine on surfaces covered

with inammable liquids or dusts (for example

hydrocarbons, ashes or soot).

- In case of re, use a powder re-extinguisher.

Do not use water.

- Do not strike shelvings or scaffoldings, where

there is danger of falling objects.

- Adapt the working speed to the oor condi-

tions: particularly, slow down before narrow

curves have to be faced.

- Do not use the machine on areas having a

higher gradient than the one stated on the

number plate.

- The machine has to carry out simultaneously

the operations of washing and drying. Differ-

ent operations must be carried out in restricted

areas prohibited to non-authorized personnel.

Signal the areas of moist oors with suitable

signs.

- If the machine does not work properly, check

by conducting simple maintenance procedures.

Otherwise, ask for technical advice an autho-

rized assistance centre.

- Where parts are required, ask for ORIGINAL

spare parts to an authorized dealer.

- Use only ORIGINAL brushes indicated in the

paragraph “RECOMMENDED BRUSHES".

- For any cleaning and/or maintenance

operation take off the power supply from the

machine.

- Do not take off the protections which require

the use of tools to be removed.

- Do not wash the machine with direct water

jets or with high water pressure nor with cor-

rosive material.

- Every 200 working hours have a machine

check through an authorized service depart-

ment.

- In order to avoid scales on the solution tank

lter, do not ll the detergent solution many

hours before the machines’ use.

- Before using the machine, check that all

panels and coverings are in their position as in-

dicated in this use and maintenance catalogue.

- Restore all electrical connections after any

maintenance operation.

- Provide for the scrapping of the material of

normal wear following strictly the respective

rules.

- When, your machine has to stop activity,

provide for the appropriate waste disposal

of its materials, especially oils, batteries and

electronic components, and considering that

the machine itself has, where possible, been

constructed using recyclable materials.

SYMBOLOGY

Symbol denoting the switch for the

water opening and the signal lamp

that the water is open.

Symbol denoting the functioning

of the solution valve adjusting the

ow of the detergent solution.

Indication of the maximum tempera-

ture of the detergent solution. It is

placed near the lling hole of the

solution tank.

Symbol denoting the push button and

the signal lamp of the manual mode.

Symbol denoting the push

button and the signal lamp of the

Automatic mode.

Symbol denoting the push

button and the signal lamp of the

break wash mode.

Symbol denoting the signal lamp of

the starting of the brushes rotation.

Symbol denoting the push button to

visualize on the display the brushes

pressure set.

Symbol denoting the functioning of

the adjustment knob of the brushes

pressure.

Symbol denoting the push button

and the signal lamp up/down of the

squeegee.

Symbol denoting the switch and the

signal lamp of the suction motor.

Symbol denoting the charge level of

the batteries.

Symbol denoting the push button

to visualize the hour meter on the

display.

Symbol denoting the push button and

the signal lamps for the speed selec-

tion.

Symbol denoting the drive selector

forwards/backwards.

Symbol denoting the signal lamp of

the parking brake on.

Symbol denoting the open book.

Indicates that the operator has to

read the manual before the use of the

machine.

Warning symbol.

Read carefully the sections marked

with this symbol, for the security of

both the operator and the machine.

https://harrissupplyind.com-ToOrderPartsCall608-268-8080