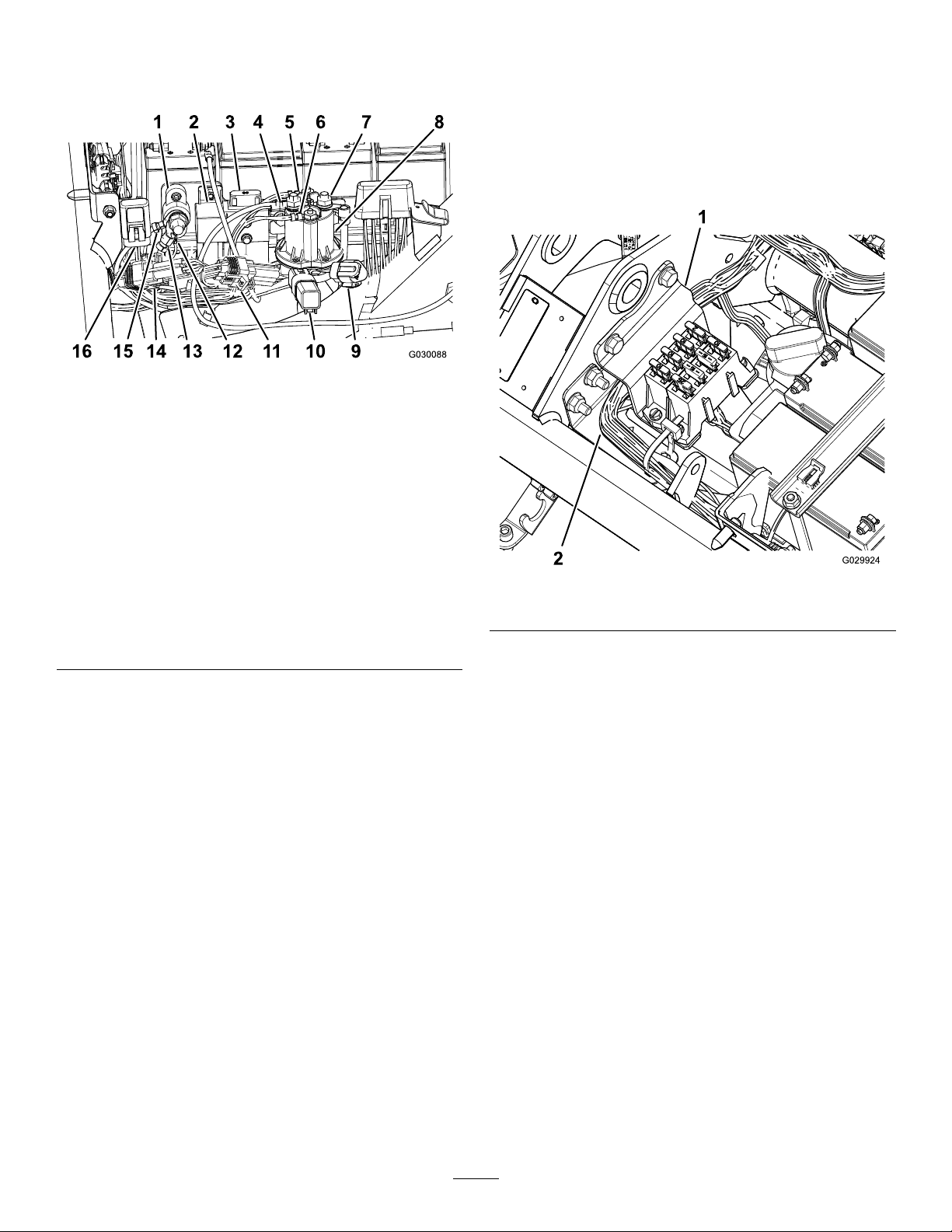

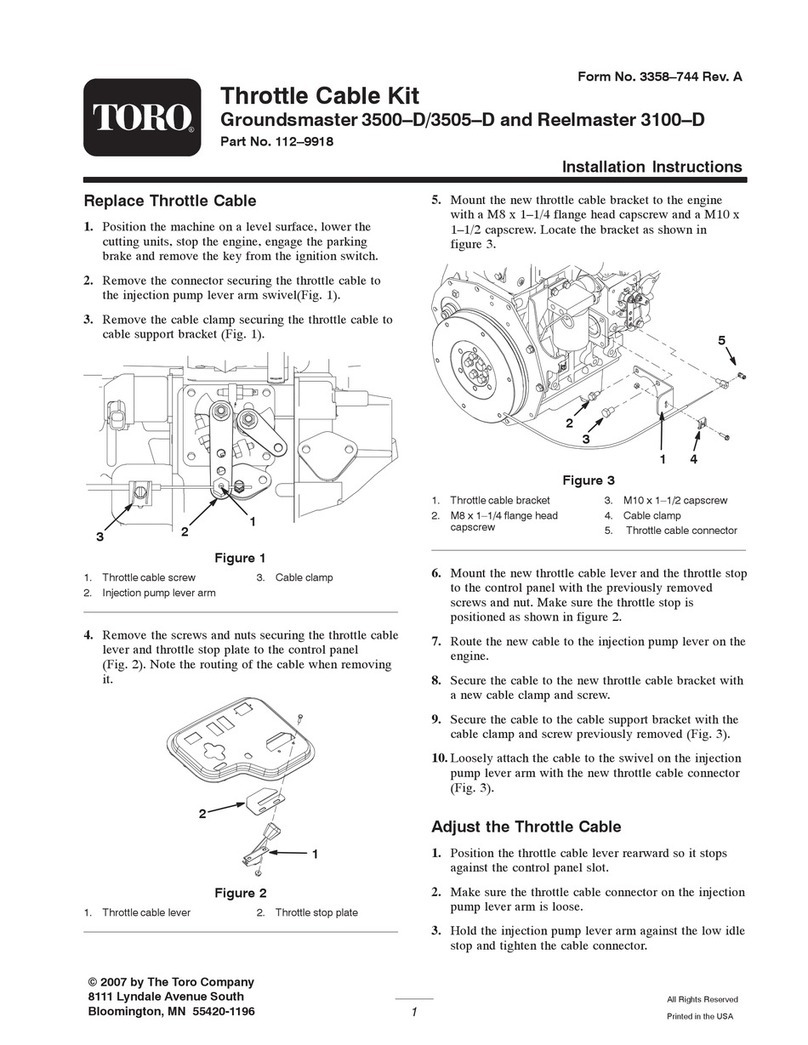

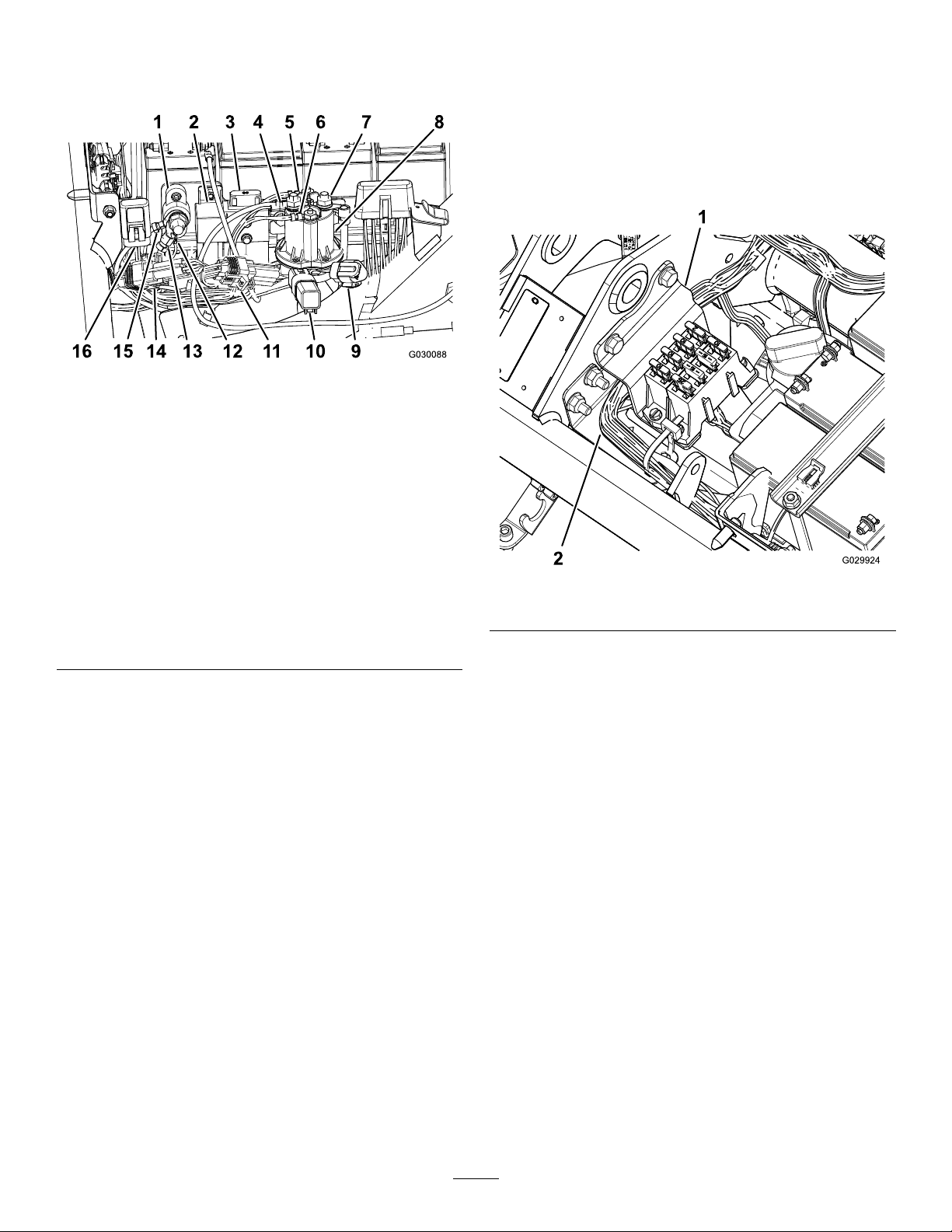

11.Removeanddiscardthecapfromthefuse(10A,58

V)asshowninFigure9.

Note:Thefusehasaredwireandayellowwire

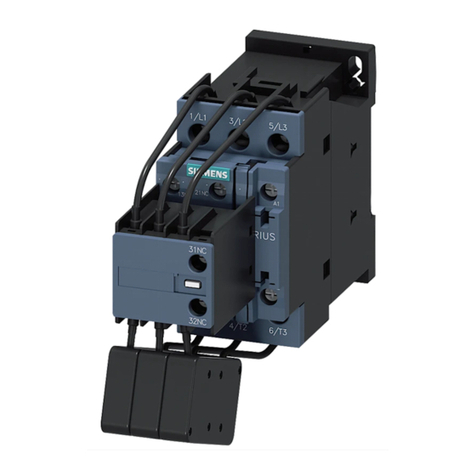

Figure9

1.Groundblock9.E-reels-CANdiagnostic

port

2.E-reelsenablerelay10.Protectiondiode

3.E-reelsfuse(60A,58V),

existing

11.IDmodule

4.Battery-sidepower(boot

notshown)

12.Harnessground

5.Main-contactor-coil

connector(white)

13.Harnessground

6.Main-contactor-coil

connector(brown)

14.CAN-interfacemodule

7.Switched-sidepower(boot

notshown)

15.E-reelsbatteriesground

8.Contactor(48VDC)16.Fuse(10A,58V)

12.Inserttheterminalwiththefuse(10A,58V)intothe

existingcapmountedontheframeofthemachine

(Figure9).

13.ConnecttheE-Reelsenablerelayconnector(P07)as

showninFigure9.

14.Connectthe90-degreeswitchedside(J07)connector

onthewireharnesstotherearterminalonthe

contactor(48VDC),andsecureittotheterminal

(Figure9).

15.Routethewireundertheangeonthecontactor(48

VCD).

16.Connectthe2main-contactor-coilconnectorstothe

contactor(48VDC)asshowninFigure9.

17.Connectthewiremarked“BatterySide”andthe

battery-disconnectwiretothefrontterminalofthe

contactor(48VDC)asshowninFigure9.

18.Slidetheinsulatorbootsfortheswitched-sidepower

connectorandthebattery-sideconnectoroverthe

terminalstocoverthem.

19.ConnecttheIDmodule(P08)asshowninFigure9.

20.ConnecttheCAN-interfacemodule(P10)asshown

inFigure9.

21.Connectthereel-speedswitch(P04)undertheseat.

22.Connectthe2terminals(CAN-businterconnectand

interfacetomainwireharness)onthenewwireharness

withthe2terminalsonthemainwireharnessunder

theseat.

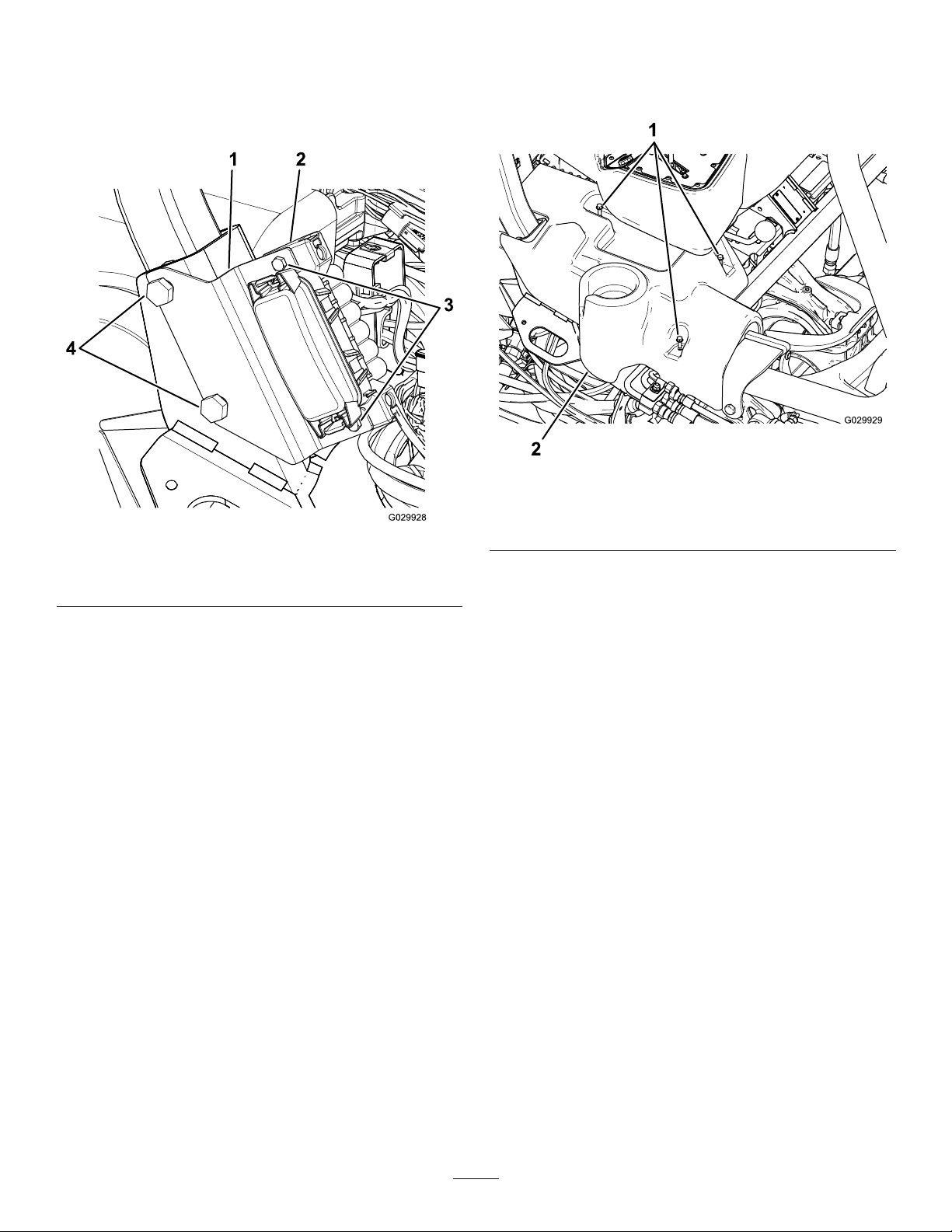

23.Installthefuseblock(Figure10).

Note:Routethewireharnessbehindthebracket.

Figure10

1.Bracket2.Wireharness

24.Connecttheground-terminalconnectors(J06andJ08)

tothegroundblock(Figure9).

25.Usecabletiestosecurethewirestothemainwire

harnessandtothemachineframe.

Important:Ensurethatthewiresareawayfrom

movingparts.

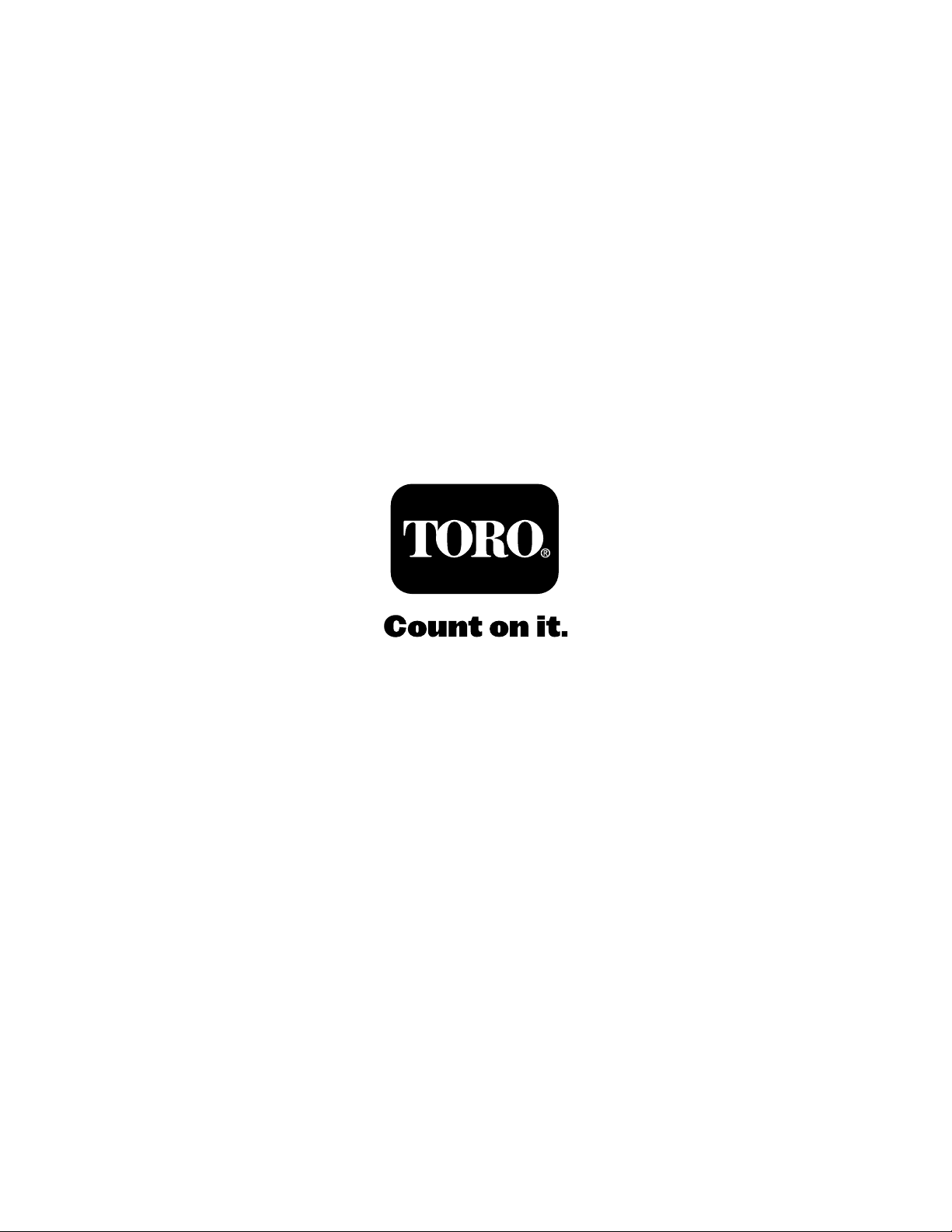

26.Securethewireharnesstothemachineframebehind

andinfrontofthefuel-tankbracket.

27.Usecabletiestosecurethenewwireharness.

Important:Ensurethattheseatassemblydoes

notcrushthewires.

4