Clearfield FieldShield FLATdrop User manual

FieldShield FLATdrop

Installation Manual ______________________________________________________

Manual 018957 Rev C - July 2022

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

2

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

Table of Contents

Application 3

Description 3

Technical Specications 3

Opening Standard Flat Drop 4

Opening 900um Peelable FLATdrop 6

Pre-Connectorized SFF FLATdrop 7

Field Installable FlexConnector - SFF 8

Field Installable FlexConnector - Standrd FLATdrop 10

Placing FLATdrop MPO and Single-Fiber Assemblies 12

Connector Cleaning Procedure 16

Standard Warranty 21

Proprietary Notice 22

Technical Support 22

3

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

Application

Technical Specications

Description

FLATdrop options designed to save contractors and installers time

and space in almost any deployment environment. The peelable outer

sheath of FieldShield FLATdrops allow for easy access to the inner

ber elements (either 3mm or 900um) and each offer a large selection

of connector types in a pre-connectorized solution while allowing for up

to 100 feet of compact ber slack storage. Cleareld’s suite of at drop

solutions effectively meet the unique needs of your network deployment.

The FieldShield FLATdrop suite offers the rst pre-connectorized at

drop style cable to provide hardened environmental performance on a

peelable at drop style cable without the added cost or dependency on

the market’s existing bulky connector. Connectivity to access terminals

is achieved through the innovative FlexConnector, which snaps into the

FlexPort, providing an air-tight and water-tight connection.

The FieldShield FLATdrop suite offers the rst pre-connectorized at drop style cable to provide hardened environmental

performance on a peelable at drop style cable without the added cost or dependency on the market’s existing bulky con-

nector. Connectivity to access terminals is achieved through the innovative FlexConnector, which snaps into the FlexPort,

providing an air-tight and water-tight connection.

Standard Flat Drop

FieldShield Peelable FLAT-

drop (With and Without

Rip Cords)

FieldShield Peelable Small

Form Factor FLATdrop

Coil Diameter 12” 12” 8”

Slack Footprint of Sub-Unit N/A 100ft 100+ ft

Sheath Jacket Dims 8.3mm x 4.7mm 8.3mm x 4.7mm 5.4mm x 3mm

Sub-Unit 250μm 3mm 900μm

Connector Types SC/APC, SC/UPC, HFOC SC/APC, SC/UPC, HOFC,

Pushable

SC/APC, SC/UPC, HOFC,

Pushable

Deployment Environment Aerial, Buried, Conduit Aerial, Buried, Conduit Aerial, Buried, Conduit

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

4

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

Isolate the internal subunit from the jacket and strength

members. Cut away the excess jacket and strength mem-

bers.

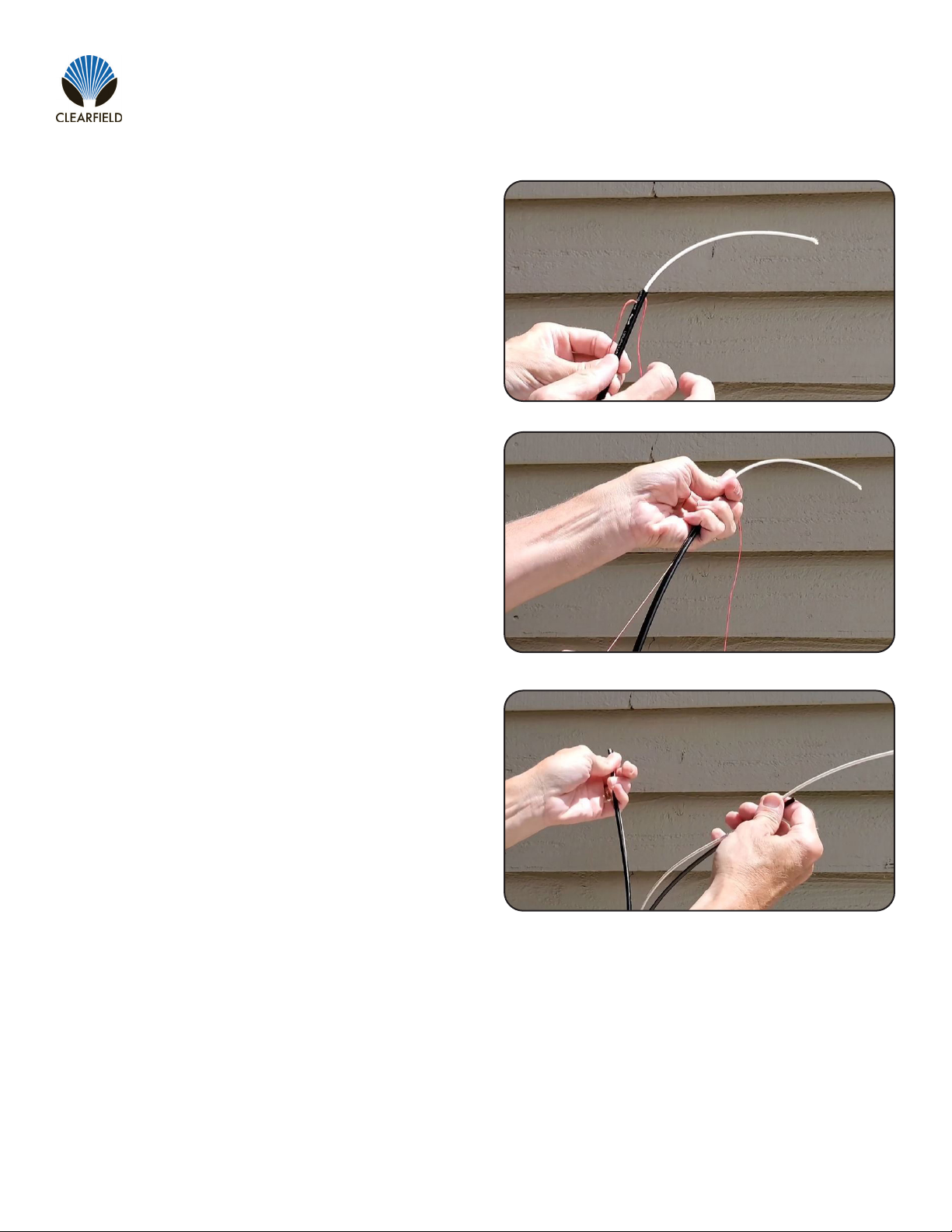

Opening Standard Flat Drop

1. Determine the amount of cable to be opened and enclose

your side cutting tool around the cable.

2. Pull the cutting tool along the length of the cable until you

reach the end of the jacket.

3.

Without Rip Cords

5

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

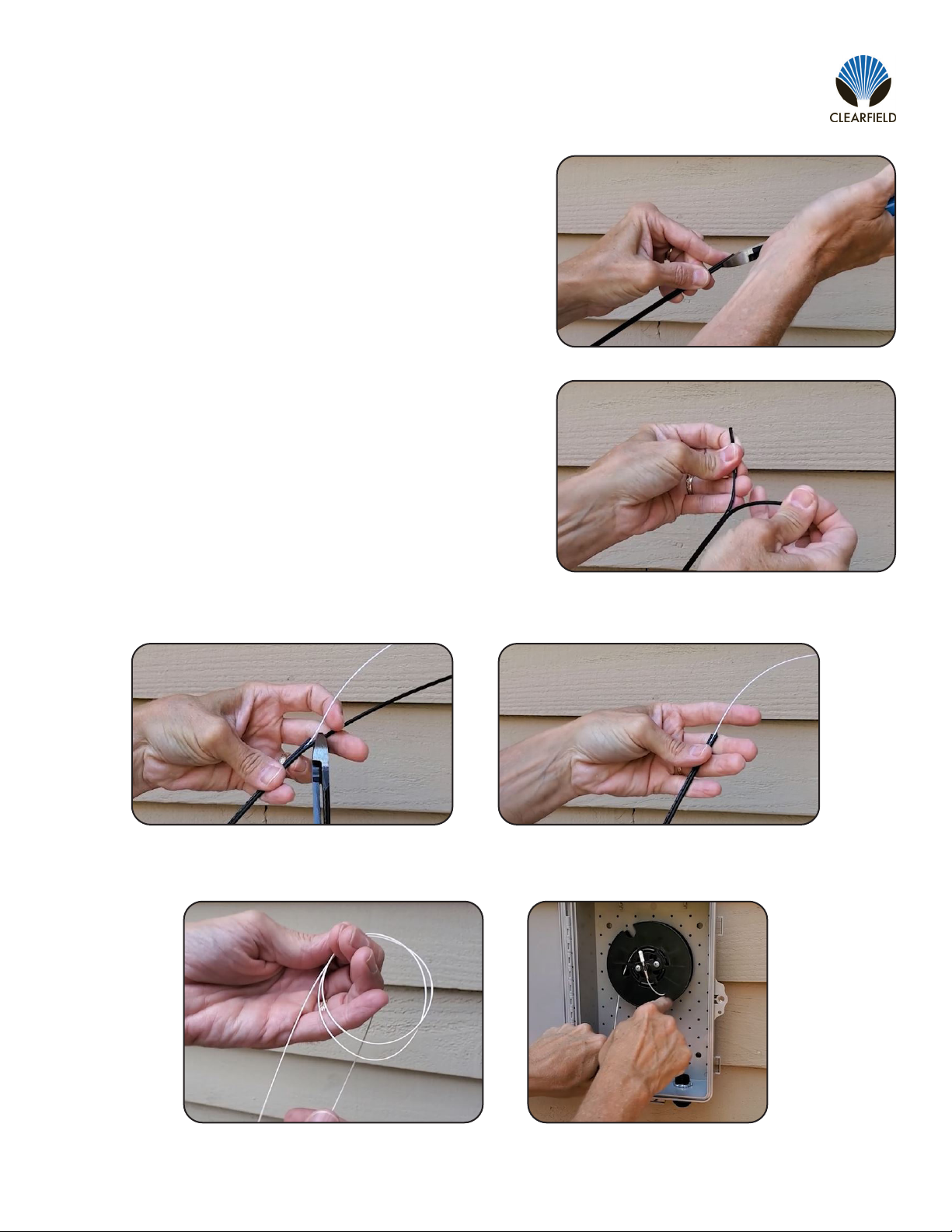

With Rip Cords

From the end of the cable, determine the length of cable

to be opened. Using a side cutting tool or blade, remove

approximately 6 inches of jacket to expose the rip cords.

1.

2.

3.

Tightly grip the rip cord and pull straight back along the

length of the cable.

Repeat on the other side to fully open the desired length

of cable. Cut away excess jacket, rip cords and strength

members.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

6

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

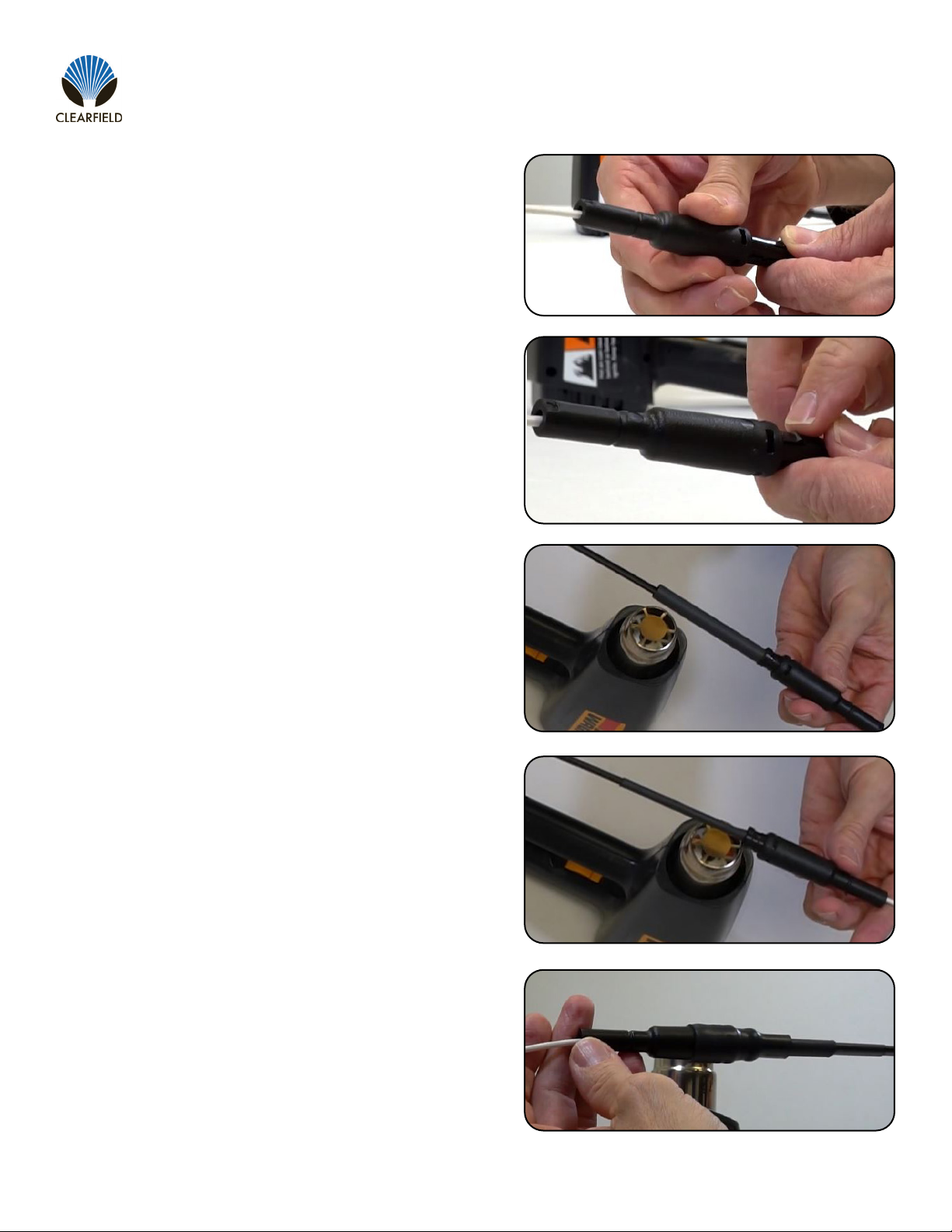

Opening 900um Peelable FLATdrop

1.

2.

3.

4.

Using a clipping tool, clip the ends of the cable at the peel-

able seams on each side, taking care not to cut the internal

subunit.

Pull the two jacket halves apart, opening the cable to the

desired length.

Cut away excess material.

The 900 micron sub-unit slack can then be wound onto slack reel for storage.

7

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

Pre-Connectorized SFF FLATdrop

Pre-connectorized Small Form Factor (SFF) FLATdrop

comes with protective shrink wrap around the pushable

connectorized end.

Carefully cut away the shrink wrap.

Remove the shrink wrap to expose pushable connector.

Slide back the protective tubing and ber designation

label back to the end of the cable jacket.

1.

2.

3.

4.

Note: When opening SFF cable to store slack, removing

the ramining two pieces of heat shrink must be done with

care. Score the two pieces of heat shrink on the outside,

opposite the 900 micron cable, to peel away.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

8

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

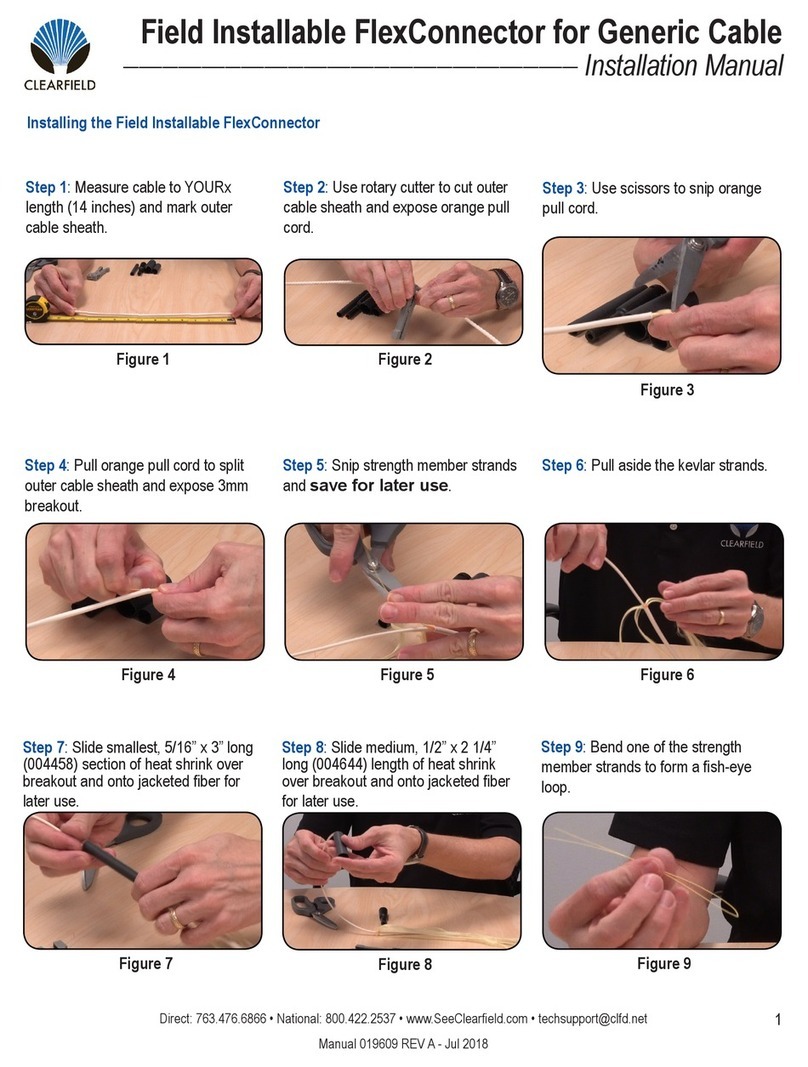

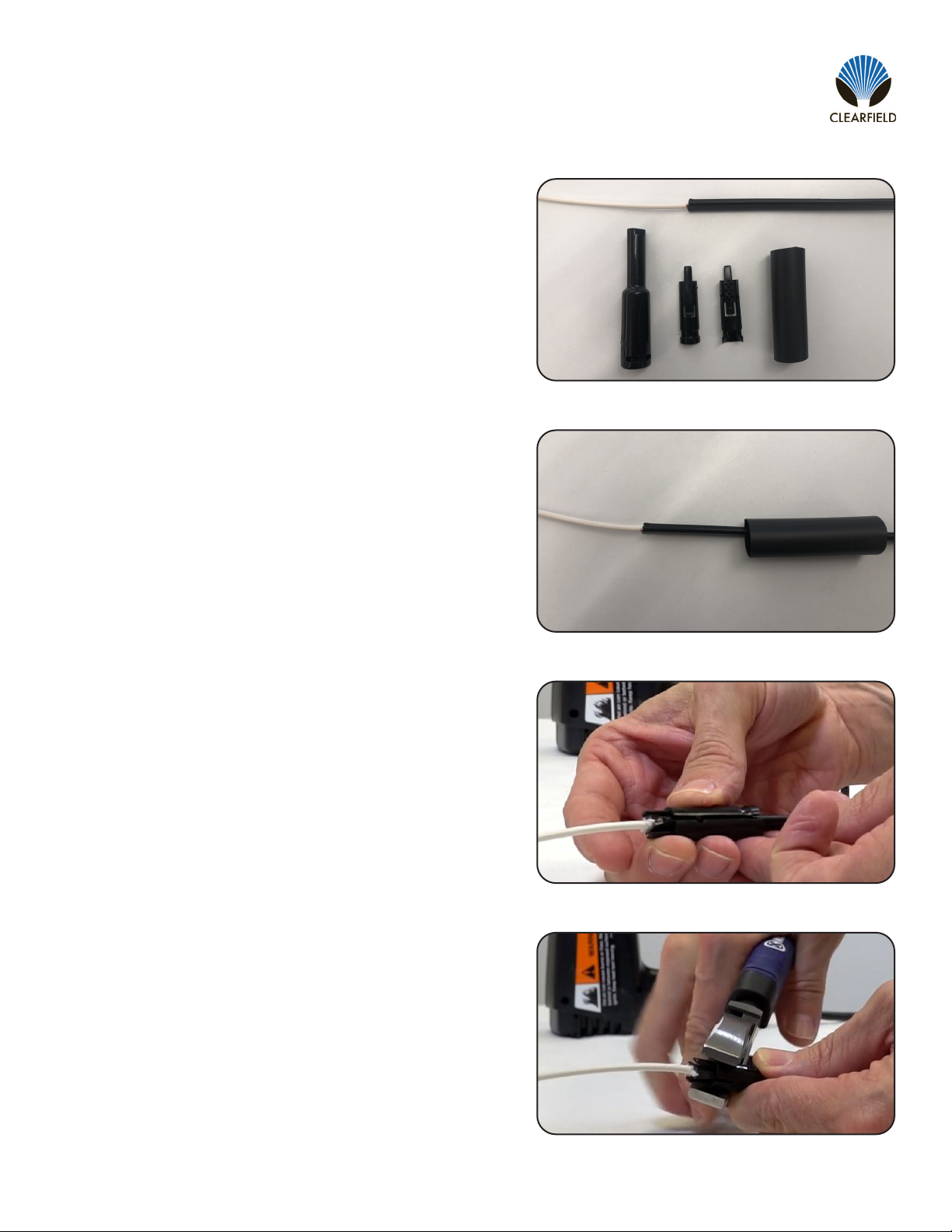

1. Open your cable to the desired breakout length.

Place both pieces of heatshrink over the end of the cable,

and push them down out of the way of the end of the jack-

et. These will be utilized later to seal the FlexConnector.

2.

Place the two halves of the internal retaining clips around

the end of the cable jacket, with the end of the clips even

with the end of the cable jacket.

3.

Using a pliers, squeeze the two retaining clips together to

ensure the teeth bite into the jacket.

4.

Field Installable FlexConnector - SFF

9

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

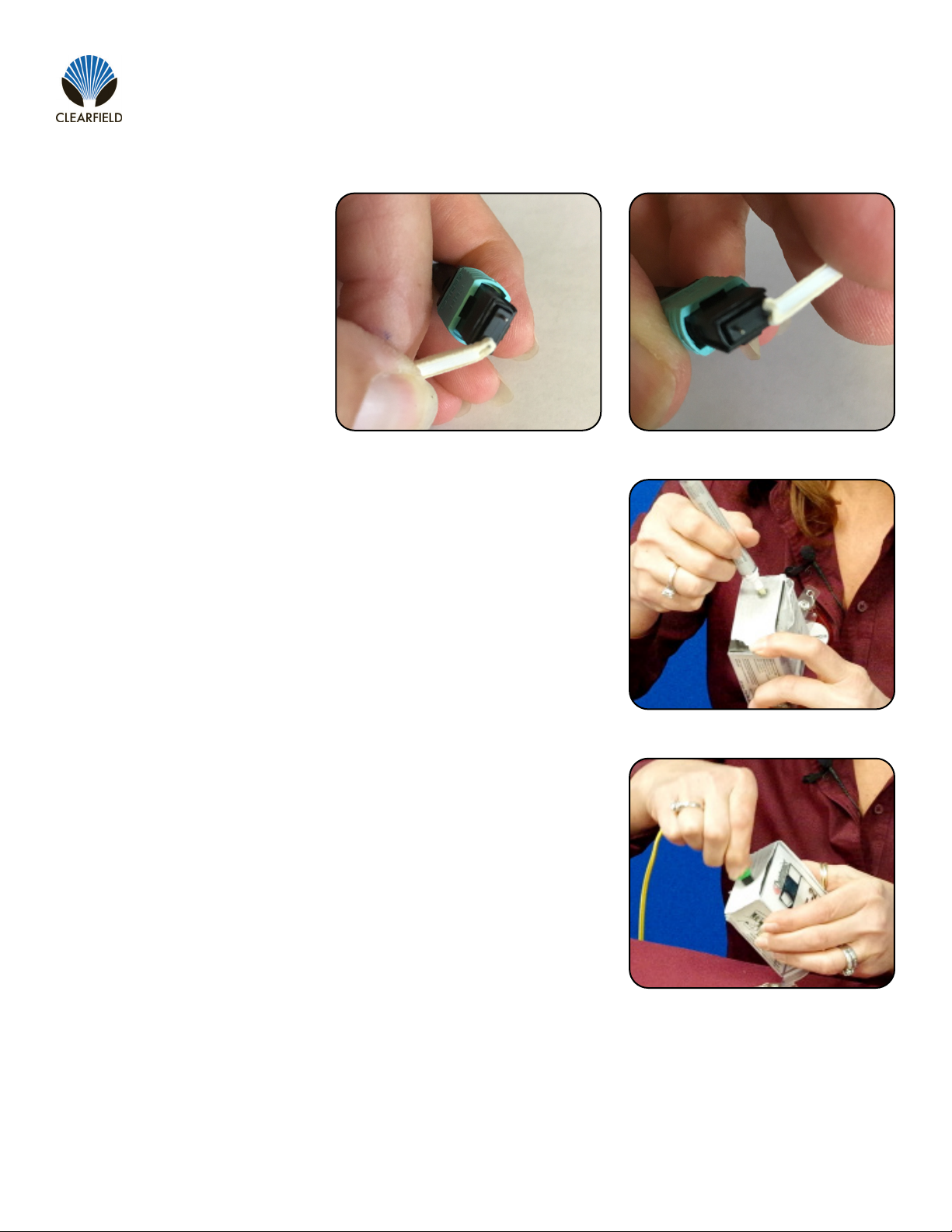

Align the holes in the FlexConnector with the retainer

clips and snap it into place.

Slide the FlexConnector over the end of the cable and

down to the two retaining clips.

5.

6.

Position the smaller, 5/16”, heatshrink just inside the

back portion of the retainer clips and shrink using a heat

gun.

7.

Position the 3/4” heatshrink about halfway over the

FlexConnector and shrink with the heat gun.

8.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

10

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

1. Open your cable to the desired breakout length.

Place the pieces of heatshrink over the end of the cable,

and push them down out of the way of the end of the jack-

et. These will be utilized later to seal the FlexConnector.

2.

Place the two halves of the internal retaining clips around

the end of the cable jacket, with the end of the clips even

with the end of the cable jacket.

3.

Using a pliers, squeeze the two retaining clips together to

ensure the teeth bite into the jacket.

4.

Field Installable FlexConnector - Standrd FLATdrop

11

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

Align the holes in the FlexConnector with the retainer

clips and snap it into place.

Slide the FlexConnector over the end of the cable and

down to the two retaining clips.

5.

6.

Position the 3/4” heatshrink about halfway over the

FlexConnector and shrink with the heat gun.

7.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

12

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

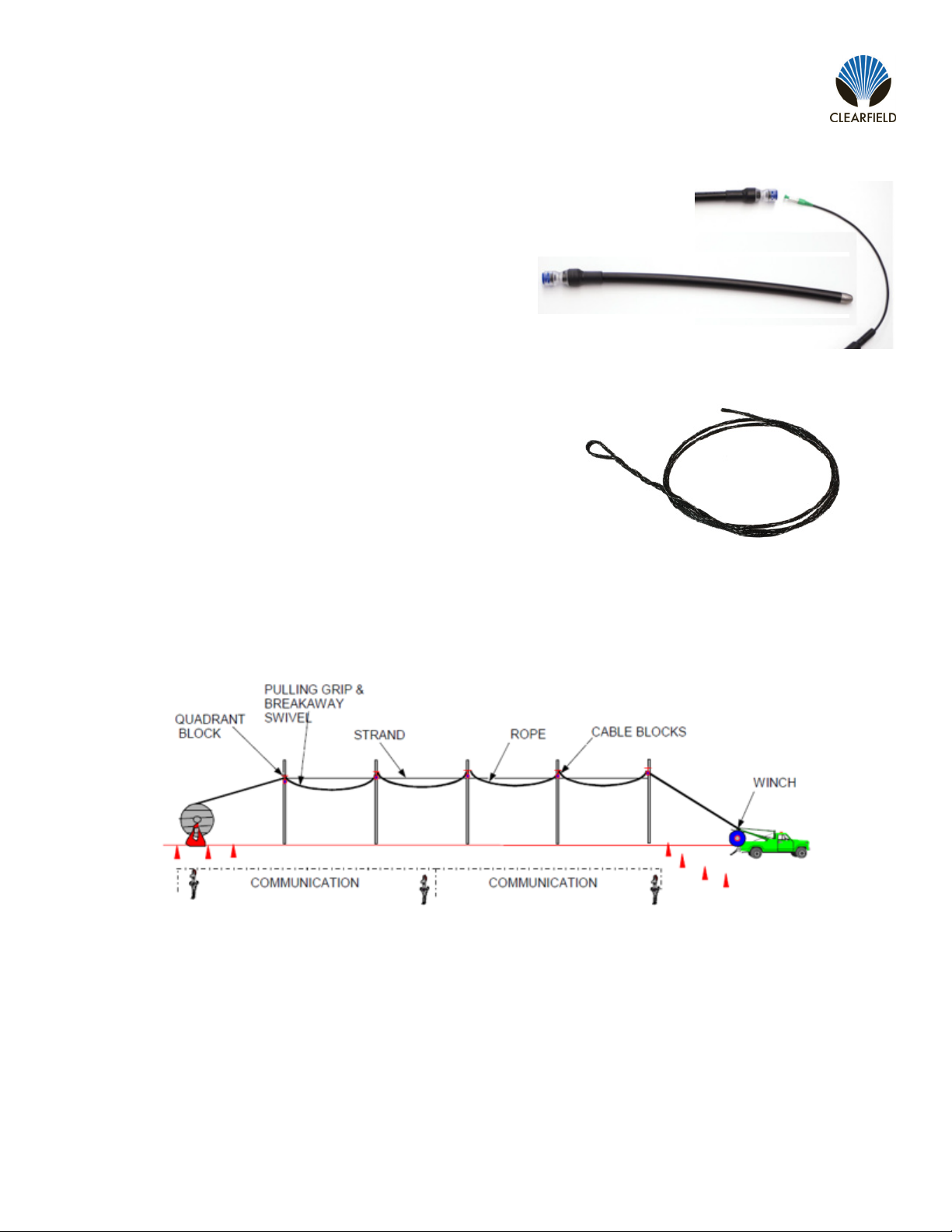

Placing FLATdrop MPO and Single-Fiber Assemblies

-Before starting:

• Do a visual inspection of the cable

• Remove the corregated tubing

• Place assembly into pull tool

-DO NOT ASSEMBLE THE CONNECTOR

-Use pulling tool for pulling through conduit

-Aerial placing utilizing the stationary reel method.

• Place temporary cable blocks

• Utilize the Cleareld pulling tool

• Lash toward reel

• Slack storage per local practice

FLATdrop Pulling Tool

P/N: FS-PUL-YOURX

SFF Pulling Sock

P/N: FS-PUL-5-9MM

13

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

Note: DO NOT assemble the connector prior to pulling/placing ber.

When placing a FLATdrop with an assembly (MPO or Single-Fiber) cables be sure to utilize the pulling tool. Failure to do so

could damage the assembly and render the cable useless.

First, remove cable ties from corrugated tube. Then, starting at the FLEXconnector end of tubing, unwrap the tubing to

expose the FLEXConnector and then gently pull the assembly free from the tubing. Do not yank it from the tubing.

Ship along connector

pieces will be tied to the

individual drops

MPO and Single-Fiber

Begin removing corrugated

tubing at end closest to the at

drop (over the FLEXconnector)

The FS-PROTECT-TOOL can be used to protect the YOURx breakout during deployment, when a pulling line is

not required.

FS-PROTECT-YOURX

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

14

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

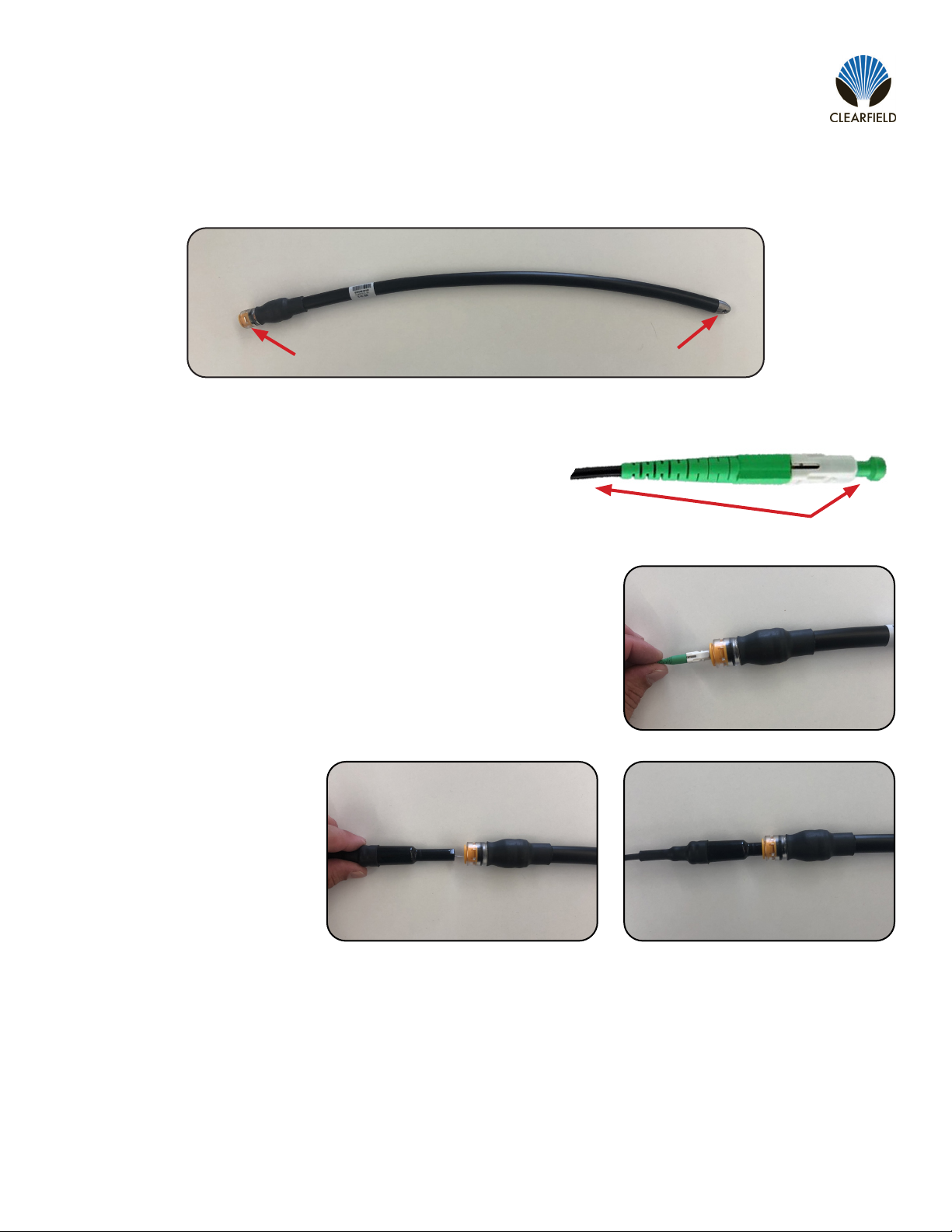

Pulling FLATdrop MPO and Single-ber assemblies using the FS-PUL-YOURX

FS-PUL-YOURX

Coupler Pulling Carrot

If using a single-ber connector, prior to inserting into the pulling

tool, snip off the dust cap “tail” close to the back edge of the dust

cap and at the cap itself to remove it from the cable. Do not remove

the dust cap. Snip here to remove tail

Insert the bullet for MPO assembly or the single-ber connector gently, holding

onto the boot/crimp tube. Do not push the bullet into the pulling tool using the

cable sheath or ber damage could occur.

Gently slide the single-ber/

MPO assembly connector into the

coupler on the pulling tool until the

coupler has engaged the FLEXcon-

nector at a hard stop.

You are now ready to pull the FLATdrop to its desired location. Tie the pulling device to the carrot on the end of the pulling

tool. Cleareld recommends a max pulling force of 50 lbs

When you have reached to desired location, compress the ring holding the FlexConnector to release it. Gently pull the

FLEXconnector from the coupler along with the assembly.

Note: Do not yank it out of the pulling tool or ber damage may occur.

15

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

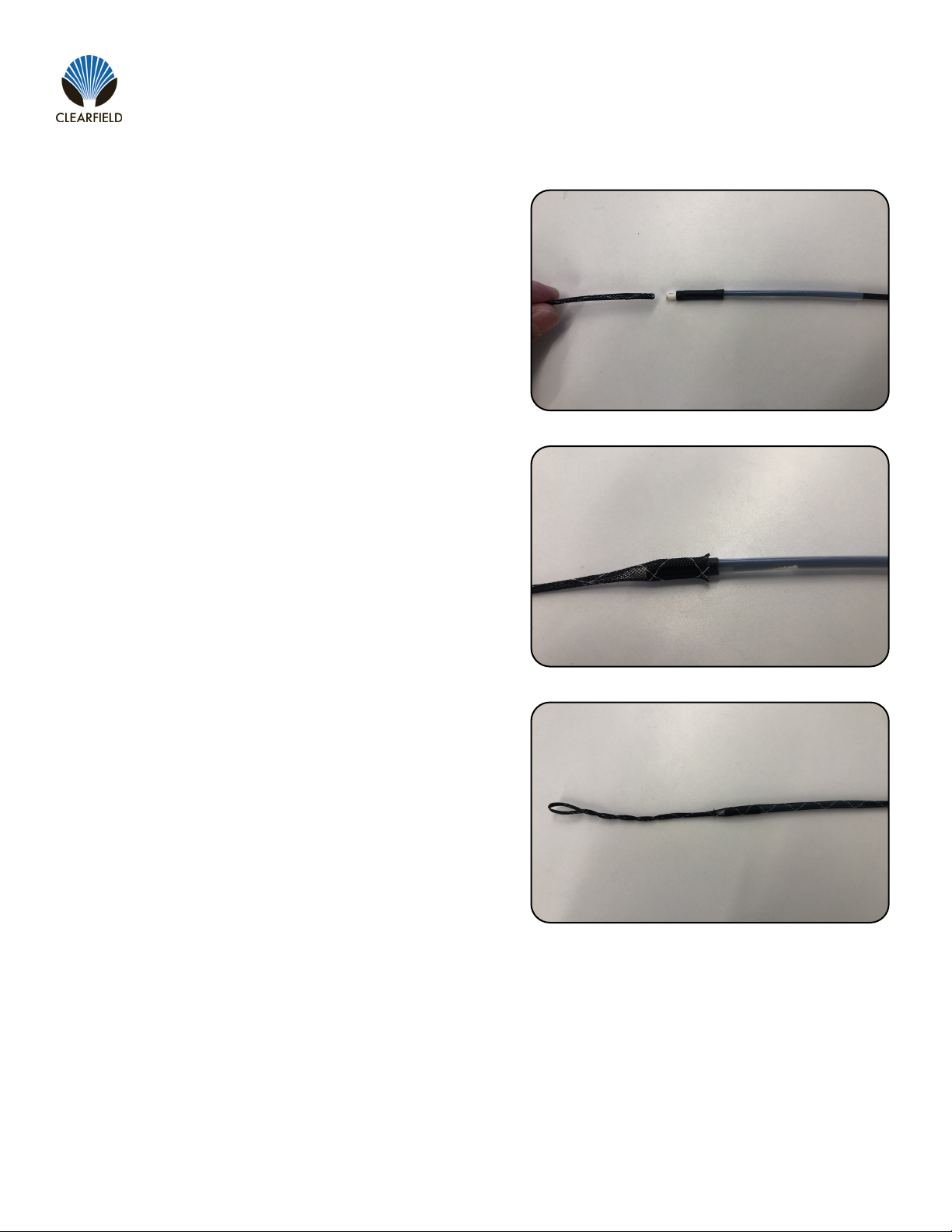

Pulling SFF Single-ber assemblies using the Pulling Sock

1. The SFF assembly will feed into the pulling sock. If nec-

essary, clean up the end of the pulling sock with a pair of

snips or a side-cutter.

You are now ready to pull the SFF to its desired location. Tie the pulling device to the loop on the end of the sock.

When you have reached to desired location, remove the pulling sock by pushing up on the back end of the sock to release

the compression.

Note: Do not attempt yank it out of the pulling sock or ber damage may occur.

2. Insert the end of the SFF into the pulling sock, pushing the

sock onto the pre-terminated end.

3. Continue feeding the sock onto the cable until it reached

the end of the pulling sock. When removing the sock, re-

member to push up from the back end of the sock instead

of attempting to pull it off.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

16

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

Inspect Then Connect

These are Cleareld recommended products/applications. Use the product

you feel will complete your cleaning procedures. Create a “best practice” for

your company and follow those procedures.

The use of Chemtronics end face and bulkhead cleaning products and

techniques ensures a clean end face, no matter the type of contamination.

Before cleaning any connector, be sure you know what type of contaminate

you are cleaning (dry, uidic, or combination). All the available products are

good, it’s the process that you need to be aware of. Using a dry cleaning

method to clean “dirt” can lead to scratching of the end face. Learn the

process of cleaning properly.

Note: It is NOT recommended to use isopropyl alcohol to clean the end face.

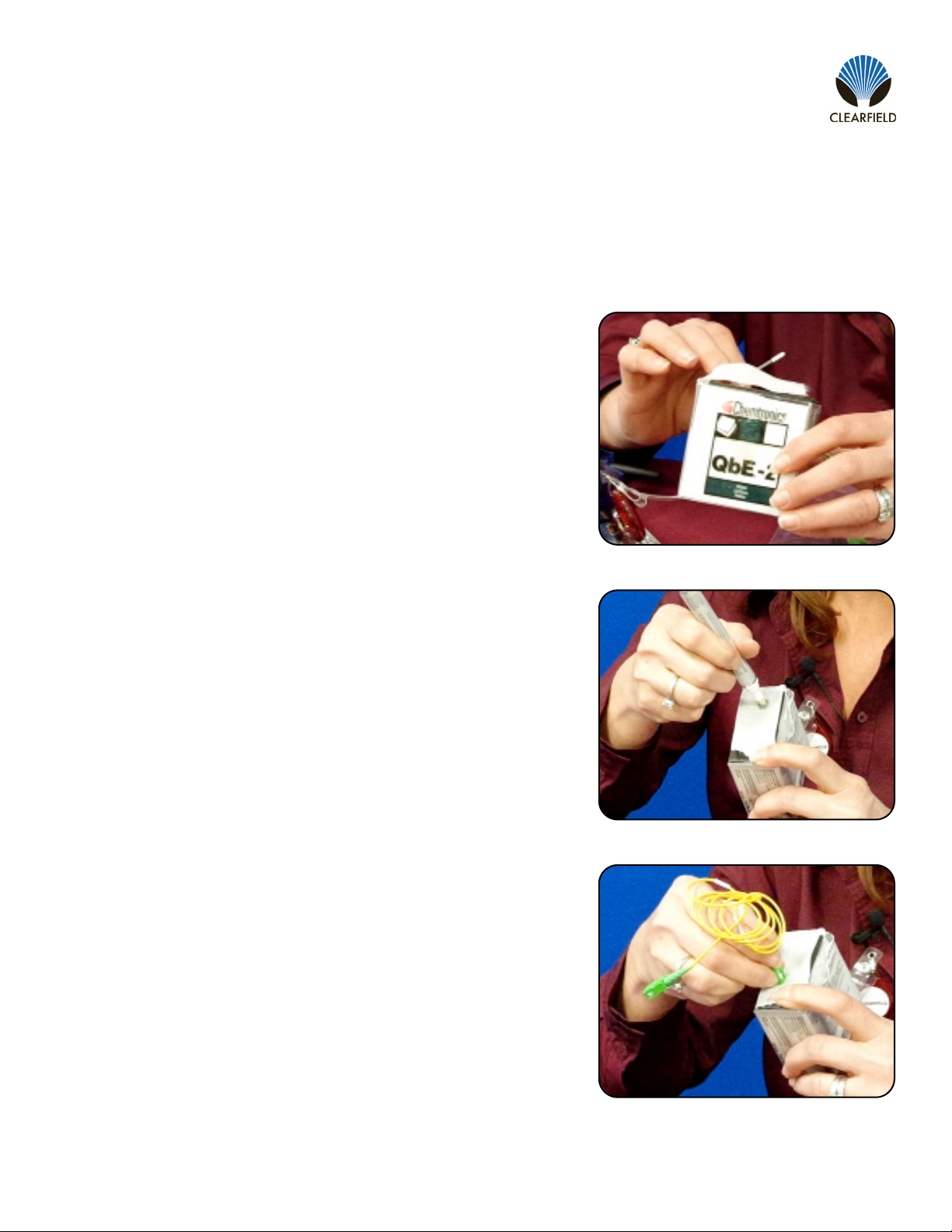

Cleaning an SC/LC Connector

Cleaning the End Face

• Place one wiping paper on QbE-2 FiberSafe™ Cleaning Platen.

(Figure 1)

• Apply small amount of precision cleaner (about 1” in diameter) with

Electro-Wash MX pen on to one end of the wipe. (Figure 2)

• Hold end face at a 90 degree angle. For APC connection, adjust by

slightly tilting the container or end face. Angle is correct when no drag is

felt on the end face. (Figure 3)

• Draw end face from wet to dry part of the wipe 3 times. Use just enough

pressure to ensure complete contact between end face and the wipe.

Note: DO NOT retrace previous step.

Figure 1

Figure 2

Figure 3

Connector Cleaning Procedure

Whether factory terminated or eld spliced, clean connectors are essential for proper system operation. Even the smallest

dust particle can cause transmission problems, so for optimal network performance inspect, and if necessary, clean

connectors and adapters prior to mating.

17

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

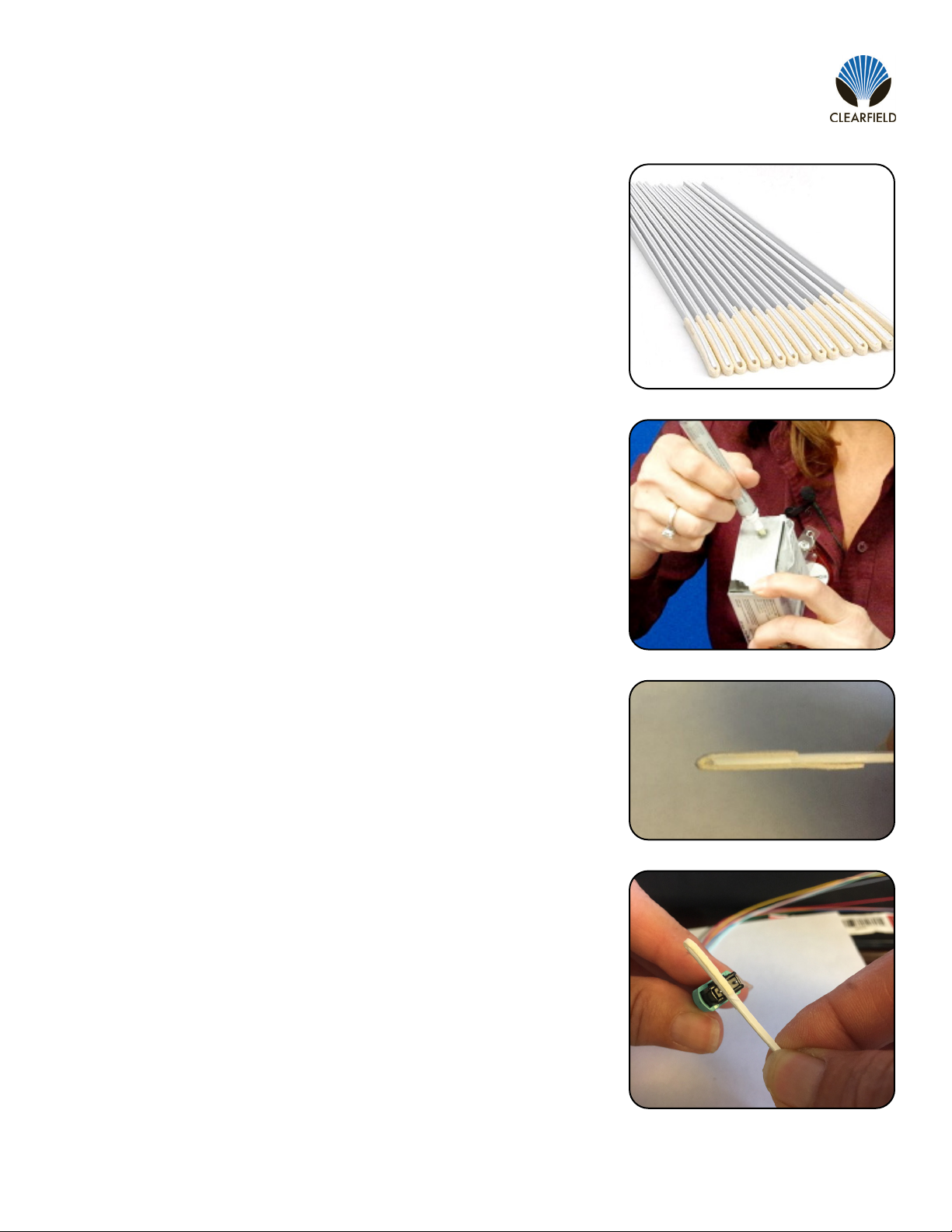

Cleaning the Ferrule

• Lightly moisten the ber optic swab (2.5mm/38542F or 1.25mm/38040)

by spotting a small amount (about 1”) of Electro-Wash PX or

Electro-Wash MX pen onto the QbE. Hold the swab, 1 side down to the

wetted area and hold for a count of 1-2-3-4-5. (Figure 4)

Figure 4

Figure 5

Figure 6

Cleaning the Mate Through an Adapter AND the Adapter Itself

• Lightly moisten the ber optic swab (2.5mm/38542F or 1.25mm/38040)

by spotting a small amount (about 1”) of Electro-Wash PX or

Electro-Wash MX pen onto the QbE. Hold the tip of the swab onto the

wetted area and hold for a count of 1-2-3-4-5.

• Insert the swab into the adapter to the connector, press lightly against

the connector, twist 2-3 times, remove and discard.

• Dry with a second dry swab.

• Inspect, repeat cleaning if necessary, and test for signal strength.

• Use additional swabs to clean inside the actual adapter. Moisten

swab, like above, and insert through hole and remove while twisting.

(Figure 6)

• Insert swab into side of ferrule, wet side to the ceramic ferrule and

circle around 2-3 times and remove. Turn swab to dry side and repeat.

(Figure 5)

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

18

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

Male Connector

• Use of Chemtronics MTP Connector Cleaning Swabs (CC505F) is rec-

ommended. Even after cleaning with a probe cleaner, you should always

clean the pins with this (or an equivalent) type swab. Cleans ALL MTP/

MPO connector end faces. This swab also cleans the “pins” of the male

connector

• Lightly “spot” a QbE-2 wipe on the platen with Electro-Wash PX Fiber

Optic Cleaner, the FiberWash or MX Pen.

• Lightly touch short side of the MTP/MPO Connector Swab to the wetted

area (3-5 secs) to absorb some cleaning solution (DO NOT over saturate

the swab).

• Wipe connector areas to be cleaned, sliding pad from bottom of pad

across and forward to tip of swab, from 1 side to the other, turn over and

use long side to dry in same movement.

Cleaning an MPO/MTP Connector

19

FieldShield FLATdrop

__________________________________________________________ Installation Manual

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

Manual 018957 Rev C - July 2022

• Use the hole on end of pad to

clean one alignment pin, then

press the end of the swab

into the other pin to clean.

• Check your work with a ber

scope. This can take several

attempts to get the endface

clean.

Female Connector (without pins)

• Cleaned like a single ber connector, using a cleaning platform. The

receptacles will be cleaned as long as you are using a combination clean-

ing process as recommended.

• Again, using a platen, moisten the platen with cleaning solvent on one

end to accommodate 3 swipes of the MPO female endface.

• Holding the connector (If APC, slightly at an angle to accommodate for 8°

angle) swiping with medium pressure, from the wet area into the dry area

3 times, without wiping over previous area.

• Inspect, and if clean, make the connection. If NOT, repeat above steps

until clean or if determined that the end face is damaged (based on stan-

dards of 5 cleanings per connection), replace.

Direct: 763.476.6866 • National: 800.422.2537 • www.SeeCleareld.com • [email protected]

20

FieldShield FLATdrop

Installation Manual _________________________________________________________

Manual 018957 REV C - July 2022

Cleaning Using a Probe-Style Cleaning Tool

• The probe style cleaning tools are capable of cleaning a connector end face separately or through the adapter.

• Slightly engage probe by pulling back but do not allow to click. Lightly “spot” a QbE-2 wipe on the platen with Elec-

tro-Wash PX Fiber Optic Cleaner, this will help alleviate “over saturation” of the material.

• Lightly touch the tip of probe and release.

Wipe

Material

Wet

End

Face

Dry

• Insert connector or insert probe though adapter and click 2-3 times to move past the wet area and allow material to dry

wipe.

• Inspect connector, repeat if necessary (following standards)

• If cleaning a male connector, clean the pins (see above)

Table of contents

Other Clearfield Cables And Connectors manuals

Popular Cables And Connectors manuals by other brands

Alvey

Alvey Adventurer 40GDZ quick start guide

Foxun

Foxun SX-SP28-Audio operating instructions

Kenwood

Kenwood CA-U1EX instruction manual

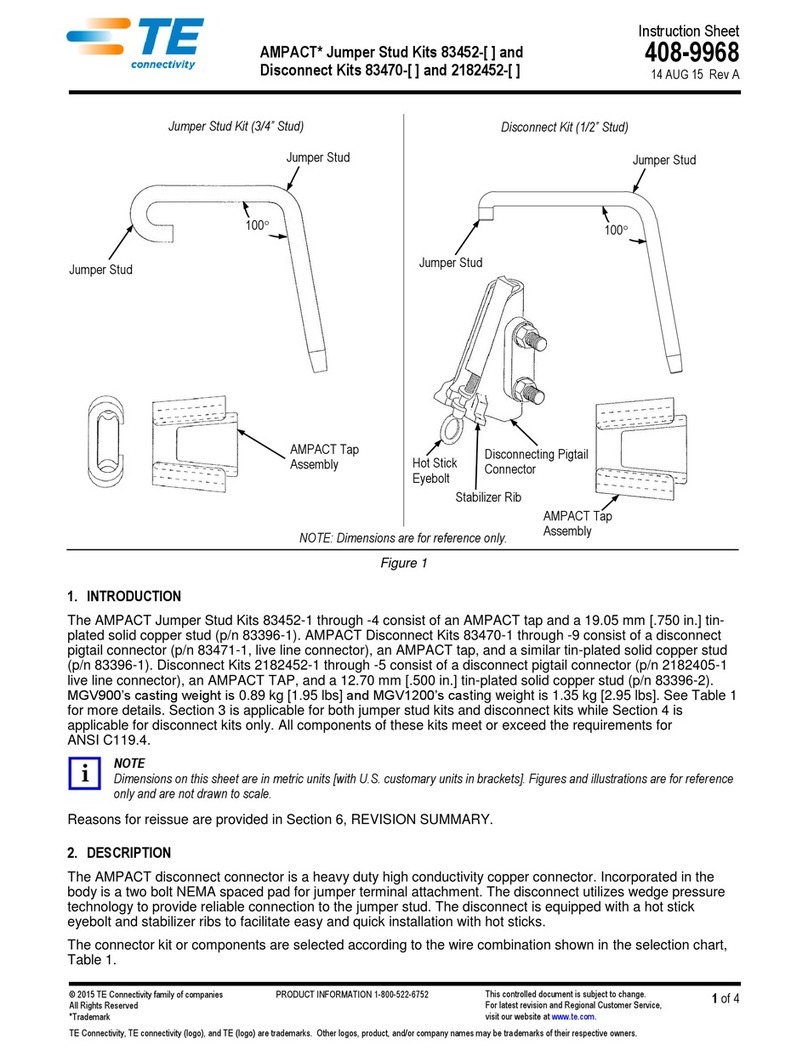

TE Connectivity

TE Connectivity AMPACT 83452 Series instruction sheet

Cadenceberge

Cadenceberge CADHV-HCA25 user manual

National Instruments

National Instruments NI SHC68 user guide