IB 340133 (10-02)10

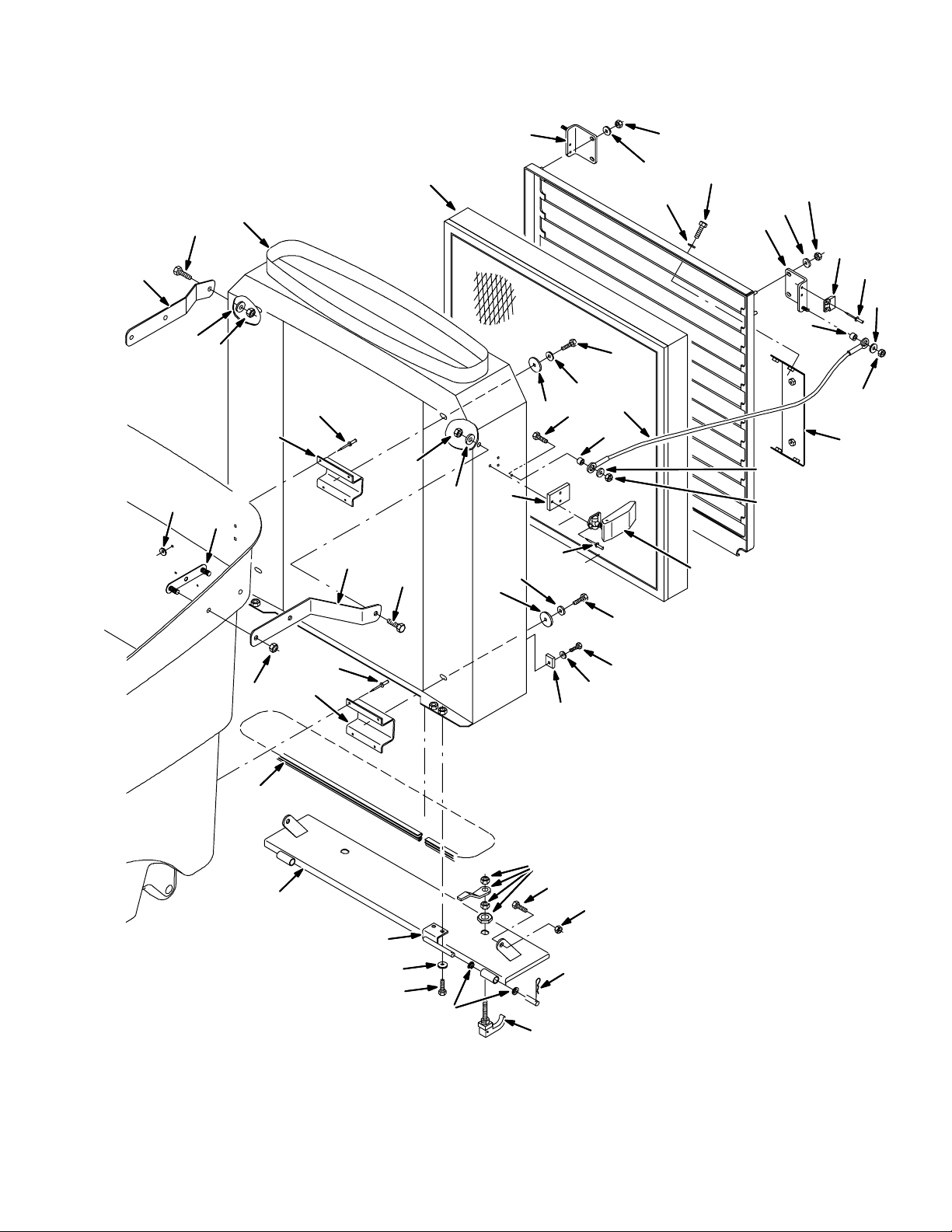

BILL OF MATERIALS FOR DUST FILTER HOUSING GROUP (S.N. 000000--001535)

NOTE: Dust Filter Kit, Tennant Part Number 367613 includes Fig. 4 and Fig. 5

Ref.

Tennant

Part No.

Machine Serial

Number Description Qty.

1368405 (000000--001535 )Housing Assy, Dust Filter 1

2 367985 (000000--001535 ) Bracket, Mtg, Upper 2

3 367982 (000000--001535 ) Bracket, Mtg, Lower 2

4 80218 (000000--001535 ) Rivet, Pop .196dx.76x38dhd 22

5 08793 (000000--001535 ) Washer 16

601685 (000000--001535 )Washer, Flat, .31 Ss 8

7 30013 (000000--001535 ) Washer, Flat, .31 Fender 4

8 09010 (000000--001535 ) Screw, Hex, M08--1.25 X 25, Ss 6

9 367994 (000000--001535 ) Door, Filter, Mtg 1

10 368221 (000000--001535 ) Bracket, Mtg, Rh 1

11 368254 (000000--001535 )Bracket, Mtg, Lh 1

12 01684 (000000--001535 ) Washer, Flat, .25 Ss 16

13 08712 (000000--001535 ) Nut, Hex, Lock, M06--1.0, Nl,Ss 8

14 368586 (000000--001535 ) Kit, Ci, Filter Latch 1

15 368253 (000000--001535 ) Plate, Latch (Repl. by 368586) 2

16 87821 (000000--001535 )Rivet, Pop 4

17 368542 (000000--001535 ) Filter Panel, [In A Box] 1

18 368318 (000000--001535 ) Guide, Centering, Door 2

19 01683 (000000--001535 ) Washer, Flat, #10 Ss 2

20 55845 (000000--001535 ) Screw, Hex, Fmg, M05--0.8 X 16 2

21 19676 (000000--001535 )Cable, Lanyard 2

22 80491 (000000--001535 ) Sleeve 4

23 15678 (000000--001535 ) Screw, Hex, M06--1.0 X 16, Ss 6

24 368263 (000000--001535 ) Bracket, Mtg, Label 1

25 368341 (000000--001535 ) Hinge Wldt, Door 2

26 08716 (000000--001535 )Screw, Hex, M06--1.0 X 20, Ss 4

27 368340 (000000--001535 ) Seal, Door 1

28 368339 (000000--001535 ) Door Wldt, By--Pass 1

29 15877 (000000--001535 ) Bearing, Flange 4

30 08178 (000000--001535 ) Pin, Cotter 2

31 65695 (000000--001535 )Latch 2

32 09740 (000000--001535 ) Screw, Hex, M08--1.25 X 20, Ss 2

33 08713 (000000--001535 ) Nut, Hex, Lock, M08--1.25,Nl,Ss 8

34 368222 (000000--001535 ) Strip, Backing 2

35 368402 (000000--001535 ) Bracket, Support, Rh 1

36 368403 (000000--001535 )Bracket, Support, Lh 1