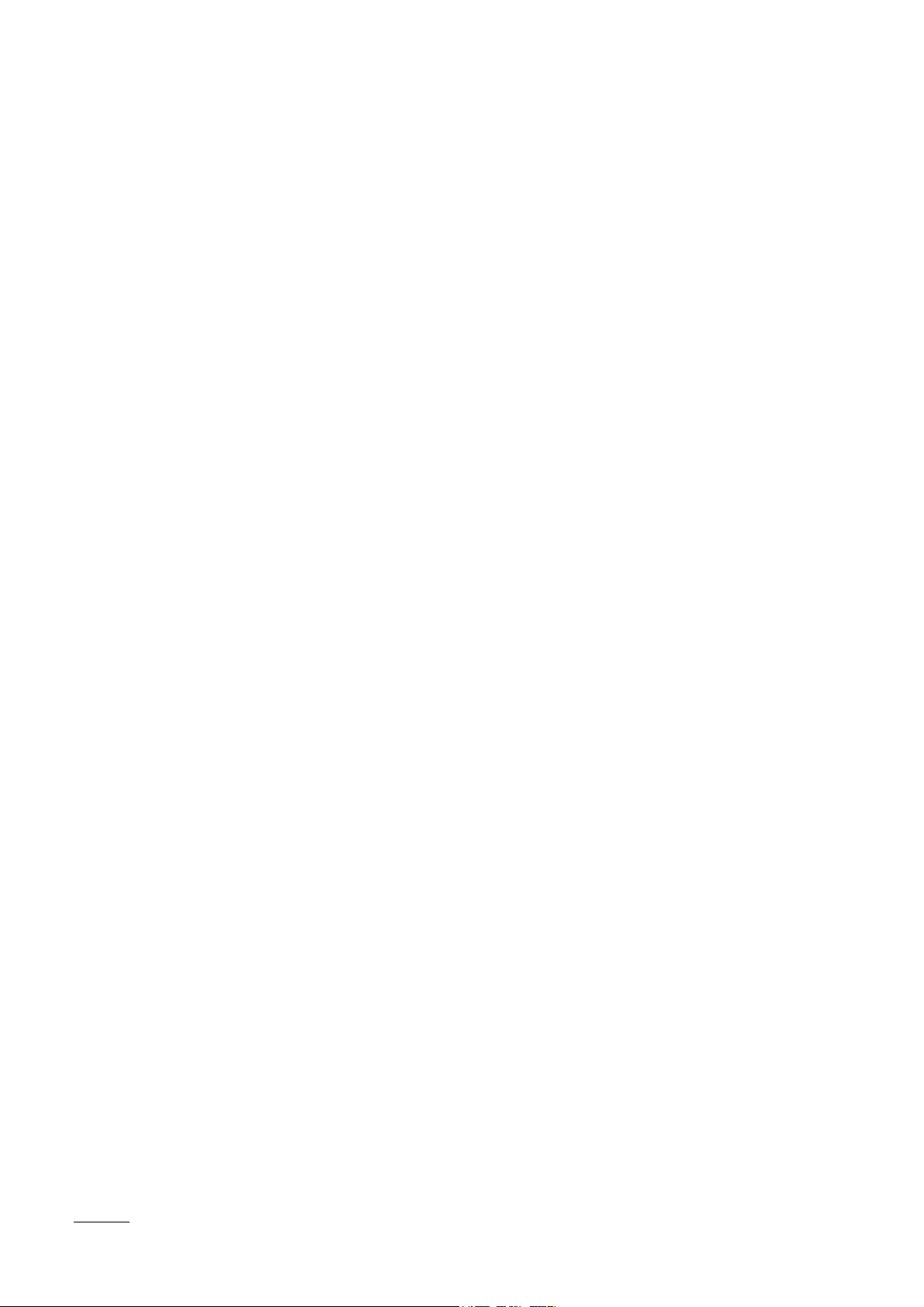

Engine: Perkins, 4-cycle, 3-cylinder, liquid-cooled,

vertical overhead valve, diesel engine with centrifugal

water pump. 13.4 kW governed to a maximum speed

of 3200 rpm. 676 cc displacement. Forced lubrication

gear pump. Mechanical centrifugal governor.

Mechanical fuel transfer pump. Fuel filter/water sepa-

rator with replaceable filter element. 12-volt (0.7 kW)

starter. Heavy-duty remote mounted air cleaner. Spin-

on oil

filter.

Radiator: Side-mounted radiator. Cooling system

capacity is 4.7 liters.

Electrical: 12-volt Group 55, 450 cold-cranking amps

at –18°, 75-minute reserve capacity at 27°C. 14-amp

alternator with regulator/rectifier. Seat switch, PTO

and traction interlock switches. Indicator light when

cutting units are running.

Fuel Capacity: 24.6 liters

Traction Drive: Three high-torque hydraulic wheel

motors. 3-wheel drive; two-position selector valve

located below the seat, push for 3-wheel drive and pull

for 2-wheel drive. Oil cooler and shuttle valve provide

positive closed-loop cooling.

Hydraulic Oil Capacity/Filter: Remote mounted, 8.7

liter oil reservoir. 25-micron remote-mounted spin-on

the filter.

Ground Speed: Infinitely variable speed selection in

forward and reverse

Mowing speed: 0–8 km/h

Transport speed: 0–13 km/h

Reverse speed: 0–3 km/h

Tires/Wheels: Two front traction tires, 20 x 10-8,

tubeless, 4-ply rating. Rear steering tire and tube: 20 x

8-8, 2-ply rating. Demountable front rims.

Recommended tire pressure 97–138 kPa front tires and

55–69 kPa rear tire.

Frame: The frame consists of formed steel, welded

steel and steel tubing components. Tricycle vehicle

with 3-wheel traction drive and rear wheel steering.

Steering: Pinion and sector gear with solid drag link

to rear steer wheel arm.

Brakes: Service braking through the dynamic charac-

teristics of the hydrostat. Parking or emergency brake

is actuated by a ratchet hand lever on the operator’s

left-hand side.

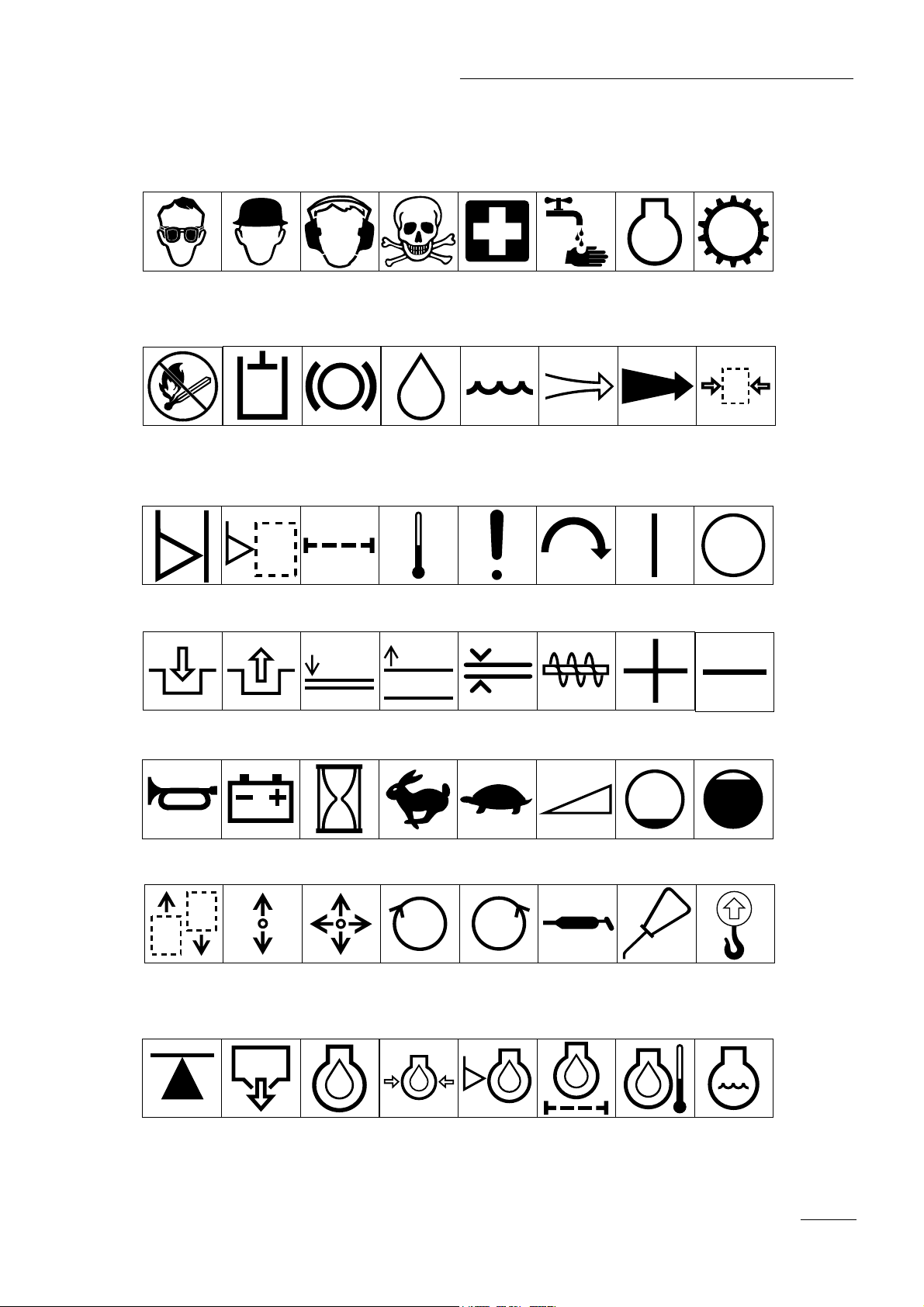

Controls: Foot-operated traction pedal and traction

pedal stop. Hand-operated throttle, ignition switch,

reel engagement switch, cold start button reel unit lift

lever, parking brake and seat adjustment, 2-position

selector valve for 2- or 3-wheel drive selection.

Gauges and Protective Systems: Hour meter, tem-

perature gauge, 4-light warning cluster gauge: oil pres-

sure, water temperature amps and glow plug. High

water temperature shutdown. Electric traction pump

declutching switch for cold start. Engine preheat

incorporated into the ignition switch.

Seat: Adjustable to operator weight, fore and aft, with

removable fold-up armrests.

Cutting Unit Lift: Hydraulic lift with an automatic

reel shut off.

Overall Dimensions:

Wheel tread width: 138

cm

Wheel base: 140

cm

Width: 194

cm

Length: 249

cm

Height: 112

cm

Weight: 562 kg with 5-blade cutting

unit 569 kg with 8-blade cutting

unit

9

Specifications