Contents

Safety.......................................................................4

GeneralSafety...................................................4

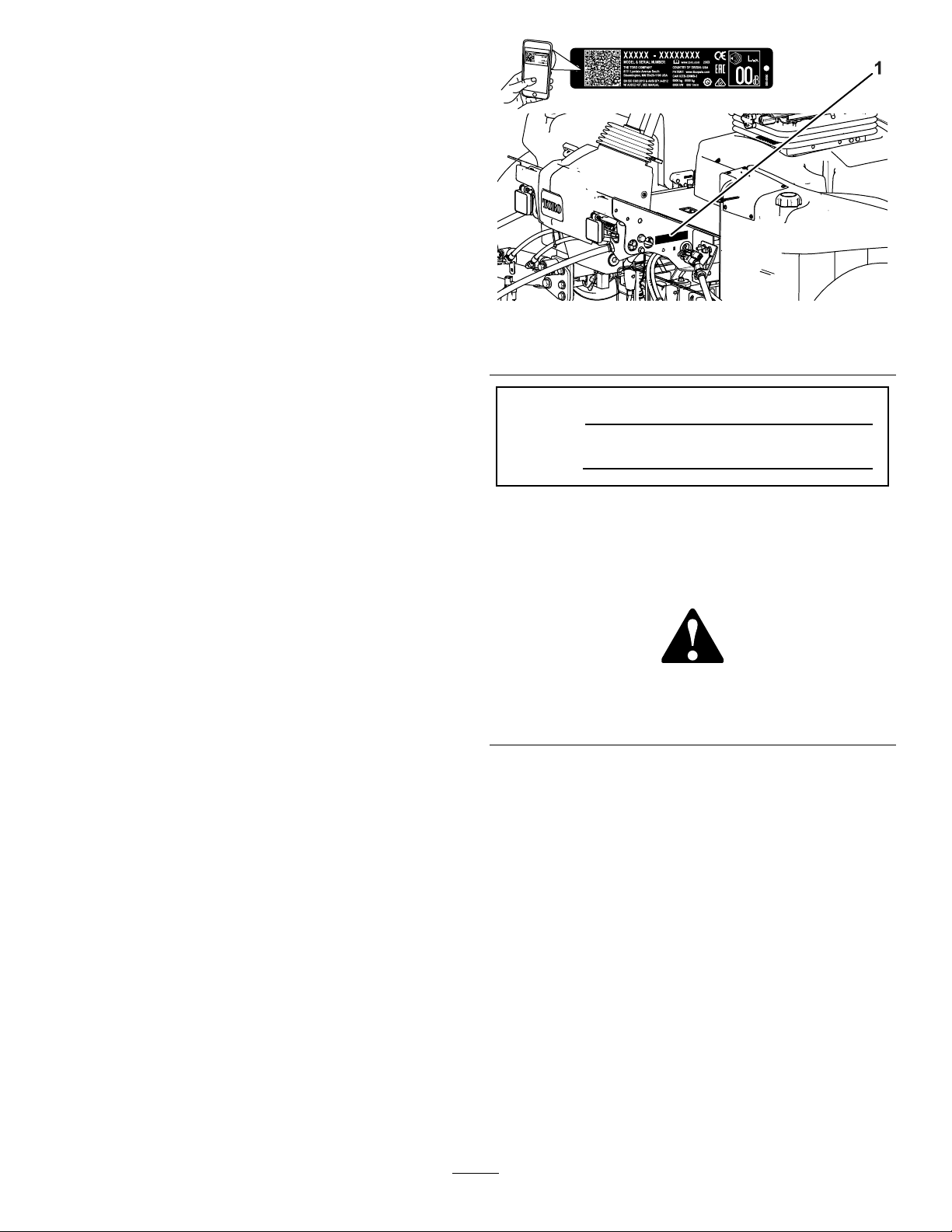

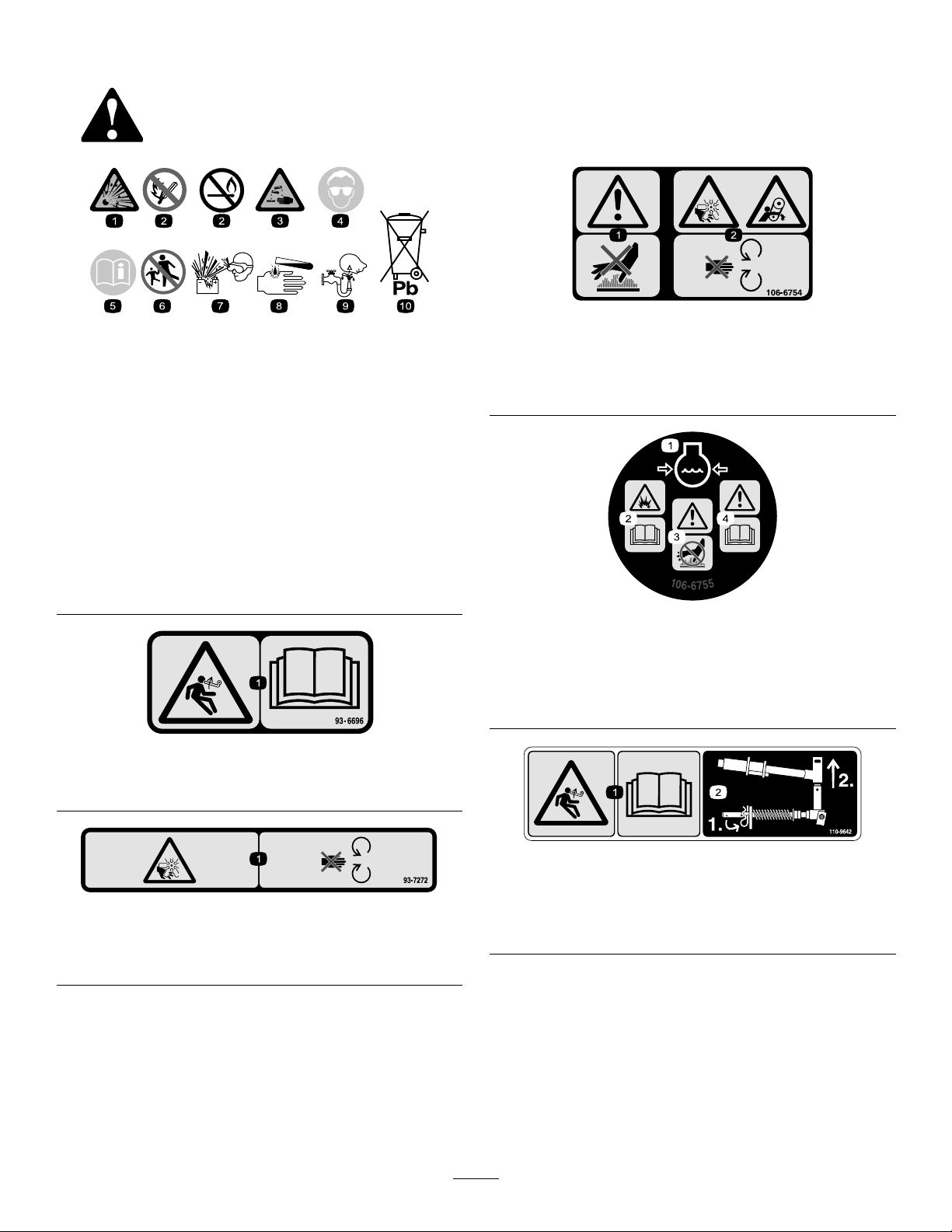

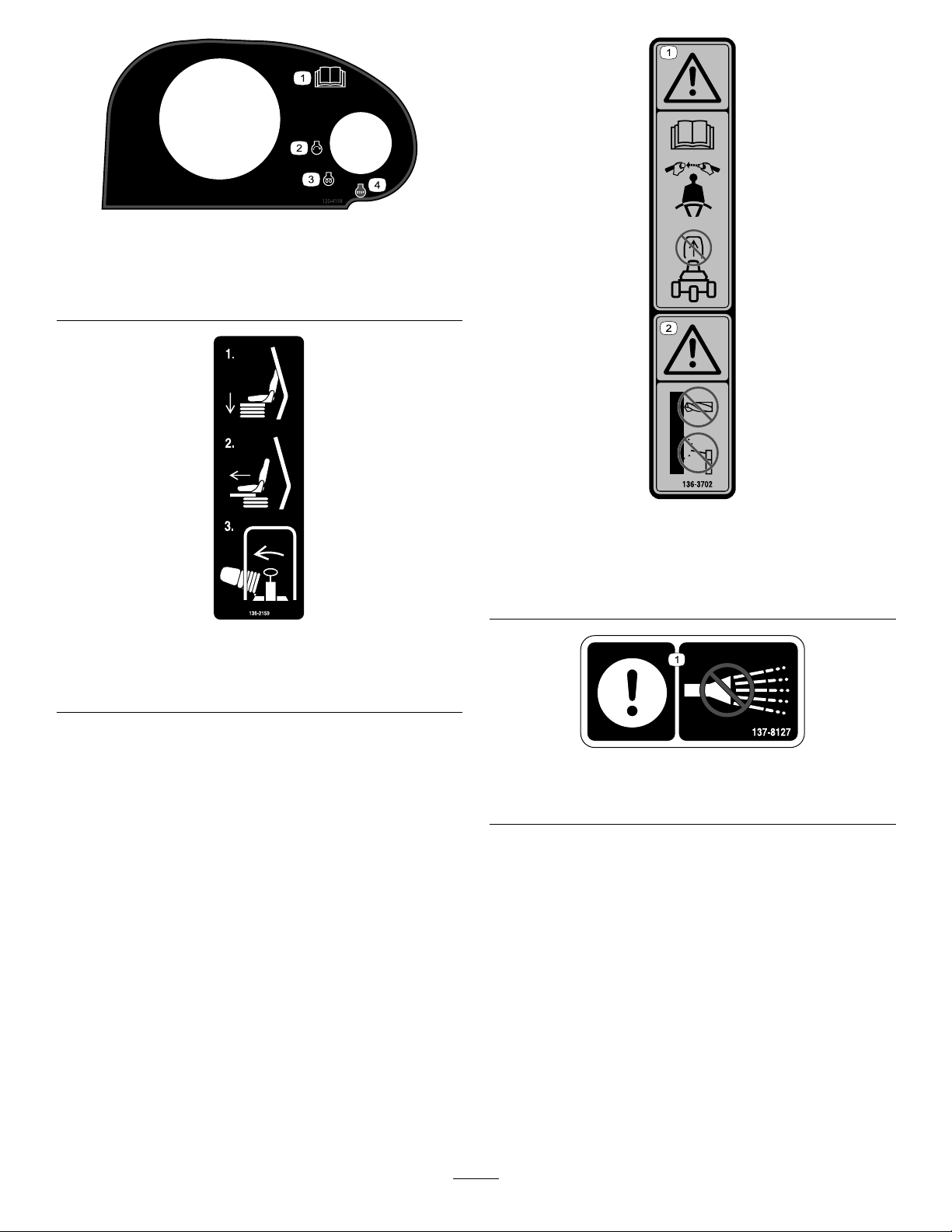

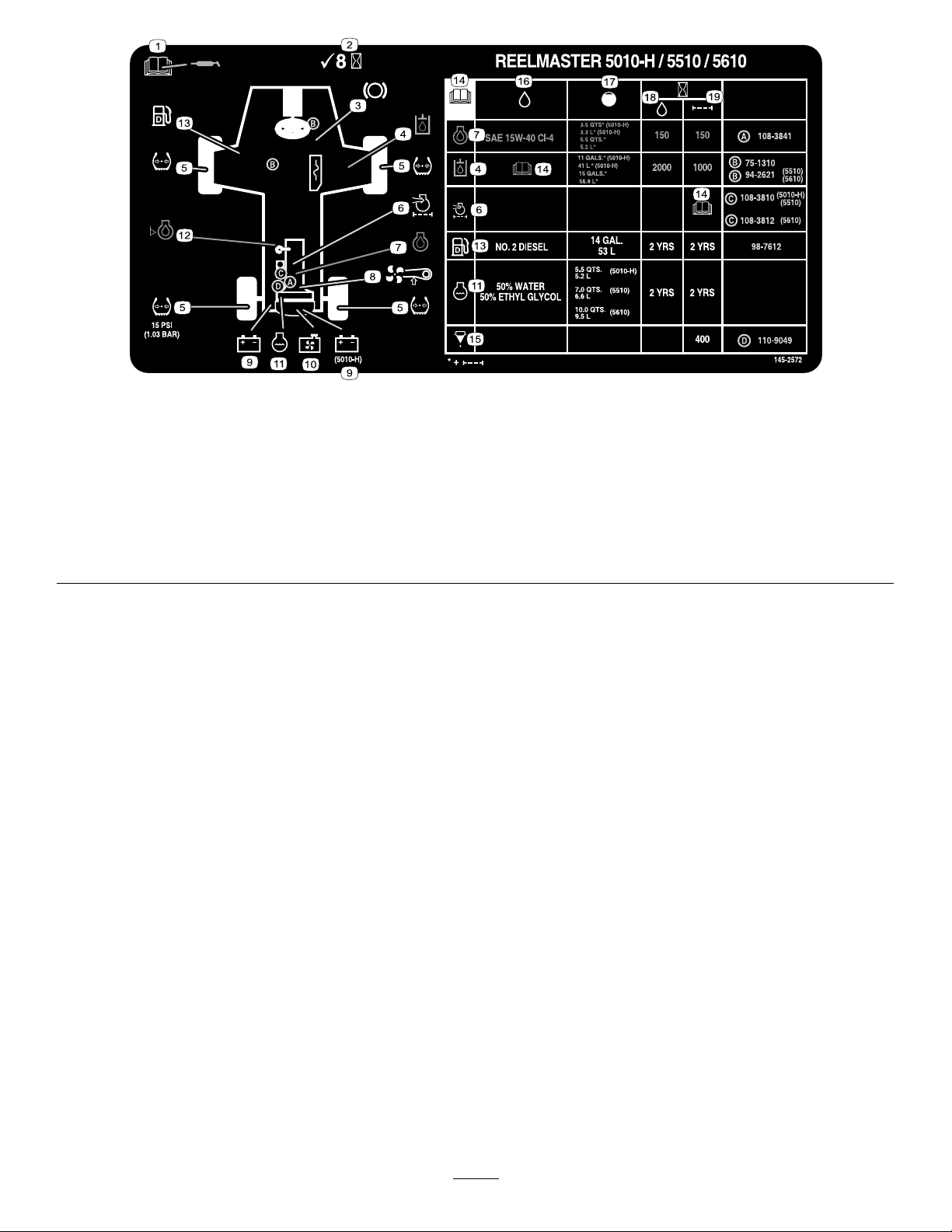

SafetyandInstructionalDecals..........................5

Setup........................................................................9

1PreparingtheMachine.....................................9

2AdjustingtheControl-ArmPosition...................9

3InstallingtheCuttingUnits..............................10

4UsingtheCutting-UnitKickstand....................17

5ApplyingtheProductionYearDecal...............18

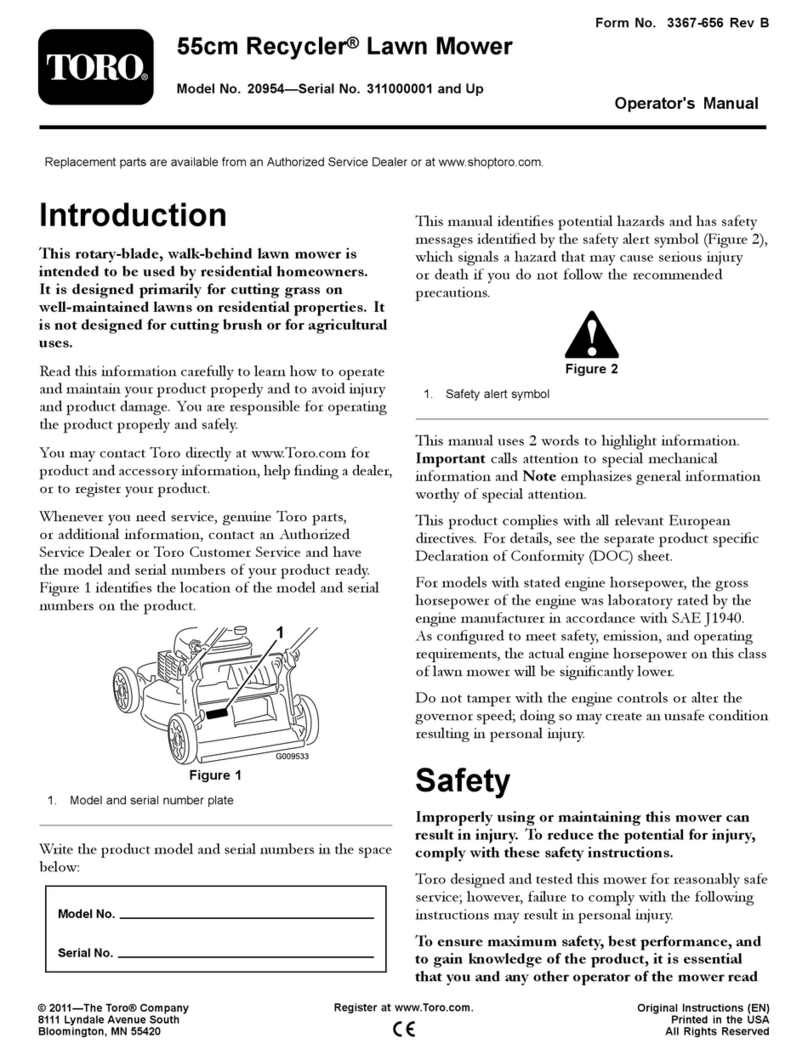

ProductOverview...................................................18

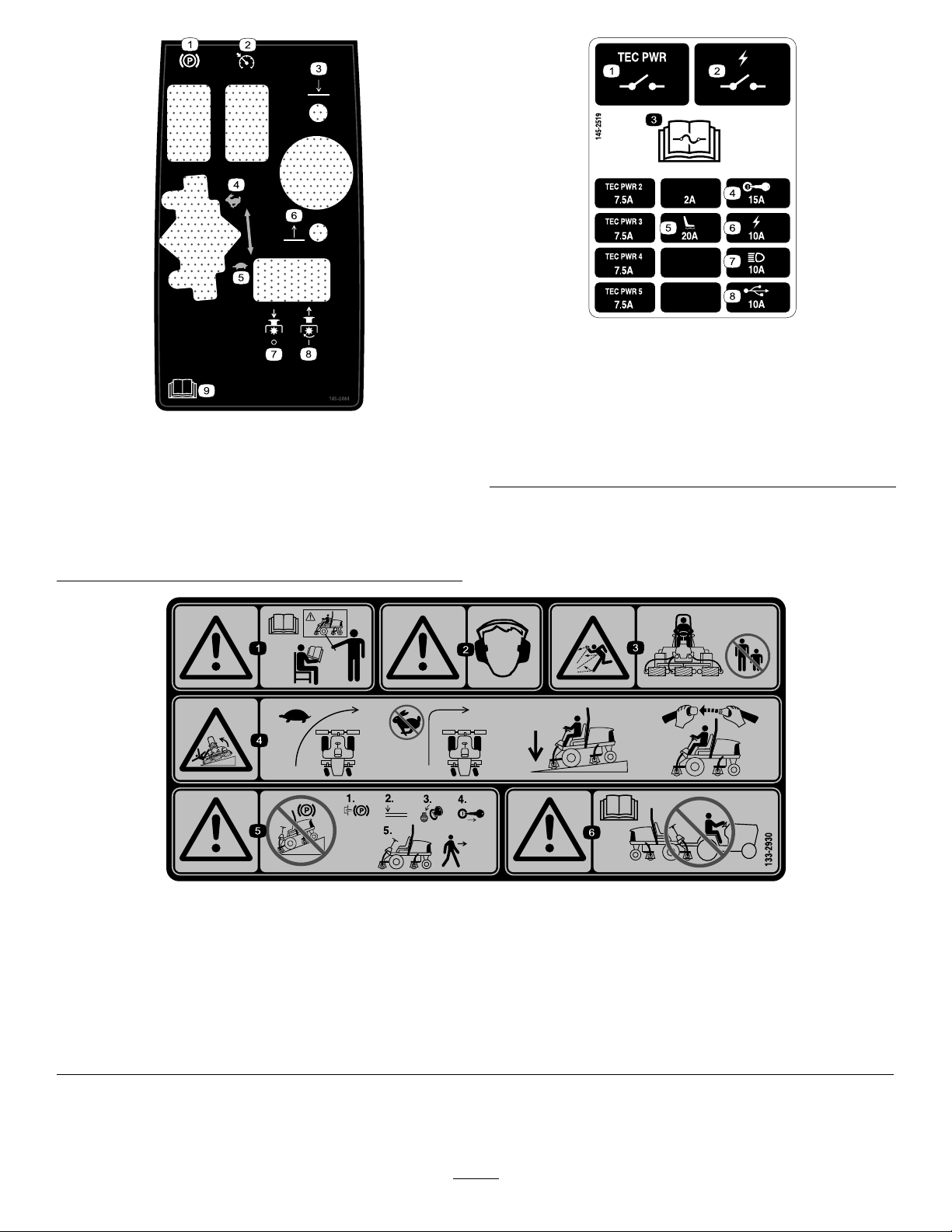

Controls...........................................................18

SeatControls................................................20

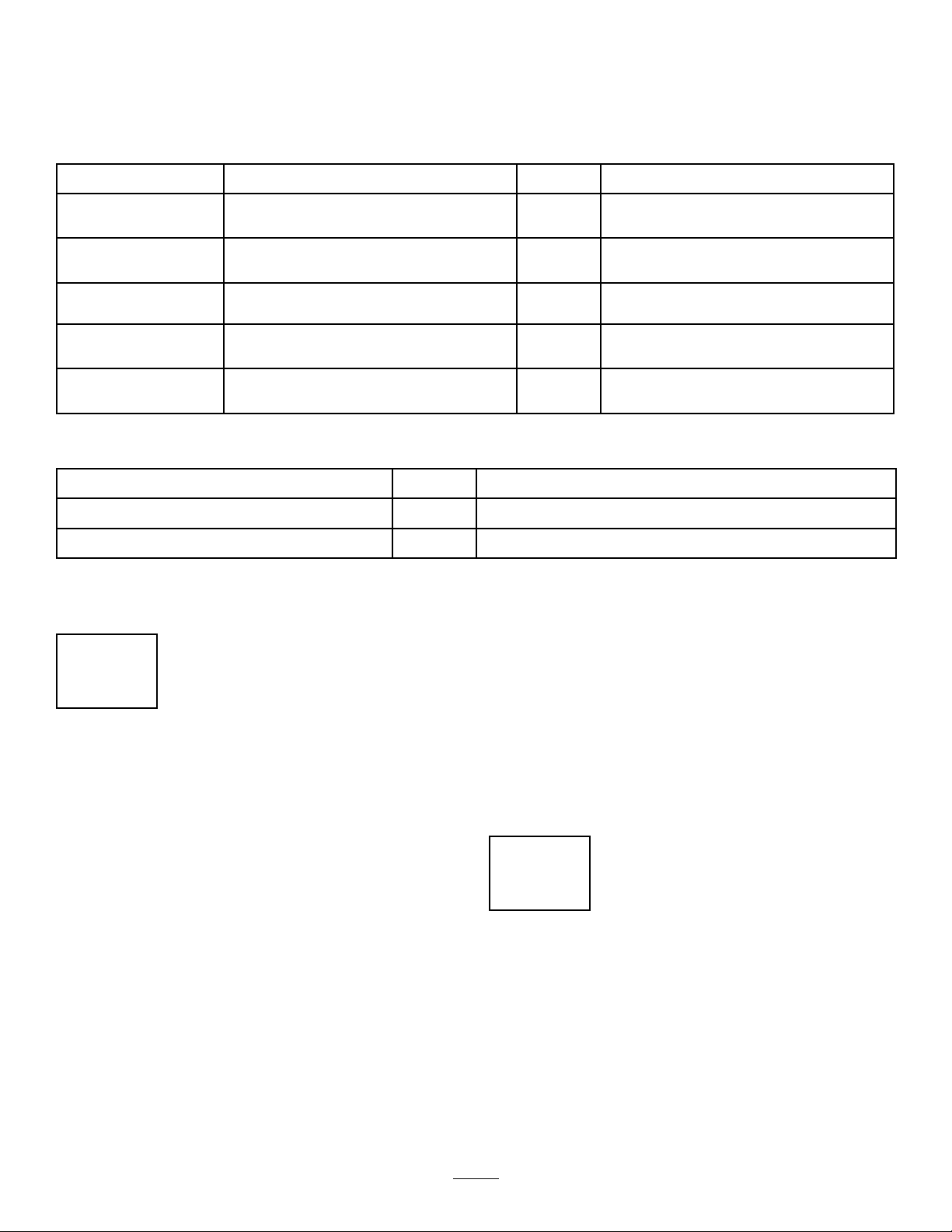

Specications..................................................21

Attachments/Accessories.................................21

BeforeOperation.................................................22

BeforeOperationSafety...................................22

PerformingDailyMaintenance..........................22

FuelSpecication.............................................22

FuelTankCapacity...........................................23

AddingFuel......................................................23

CheckingtheInterlockSwitches.......................23

UsingtheInfoCenterLCDDisplay....................24

UsingtheMenus...............................................25

ProtectedMenus..............................................26

CheckingtheHydrostaticBraking

Distance........................................................28

UnderstandingDisplayedTraction

Speeds..........................................................29

DuringOperation.................................................29

DuringOperationSafety...................................29

UnderstandingtheOperatingCharacteristics

oftheMachine..............................................30

OperatingtheMachine.....................................30

UsingtheTractionPedal...................................30

UsingtheVirtualPedalStop(VPS)

Feature.........................................................31

OperatingtheCruiseControl............................31

UnderstandingtheAccelerationMode..............32

UnderstandingtheWarm-UpMode...................32

UnderstandingToroSmartPower™.................33

StartingtheEngine...........................................33

ShuttingOfftheEngine.....................................33

CuttingGrasswiththeMachine........................33

SettingtheReelSpeed.....................................34

AdjustingtheLift-ArmCounterbalance.............34

AdjustingtheLift-ArmTurnaround

Position.........................................................35

AdjustingtheTurf-Compensation

Spring...........................................................35

UnderstandingtheDiagnosticLight..................36

OperatingTips.................................................36

AfterOperation....................................................37

AfterOperationSafety......................................37

HaulingtheMachine.........................................37

IdentifyingtheTie-DownPoints........................37

PushingorTowingtheMachine........................38

Maintenance...........................................................40

MaintenanceSafety..........................................40

RecommendedMaintenanceSchedule(s)...........40

DailyMaintenanceChecklist.............................42

Pre-MaintenanceProcedures..............................43

PreparingforMaintenance...............................43

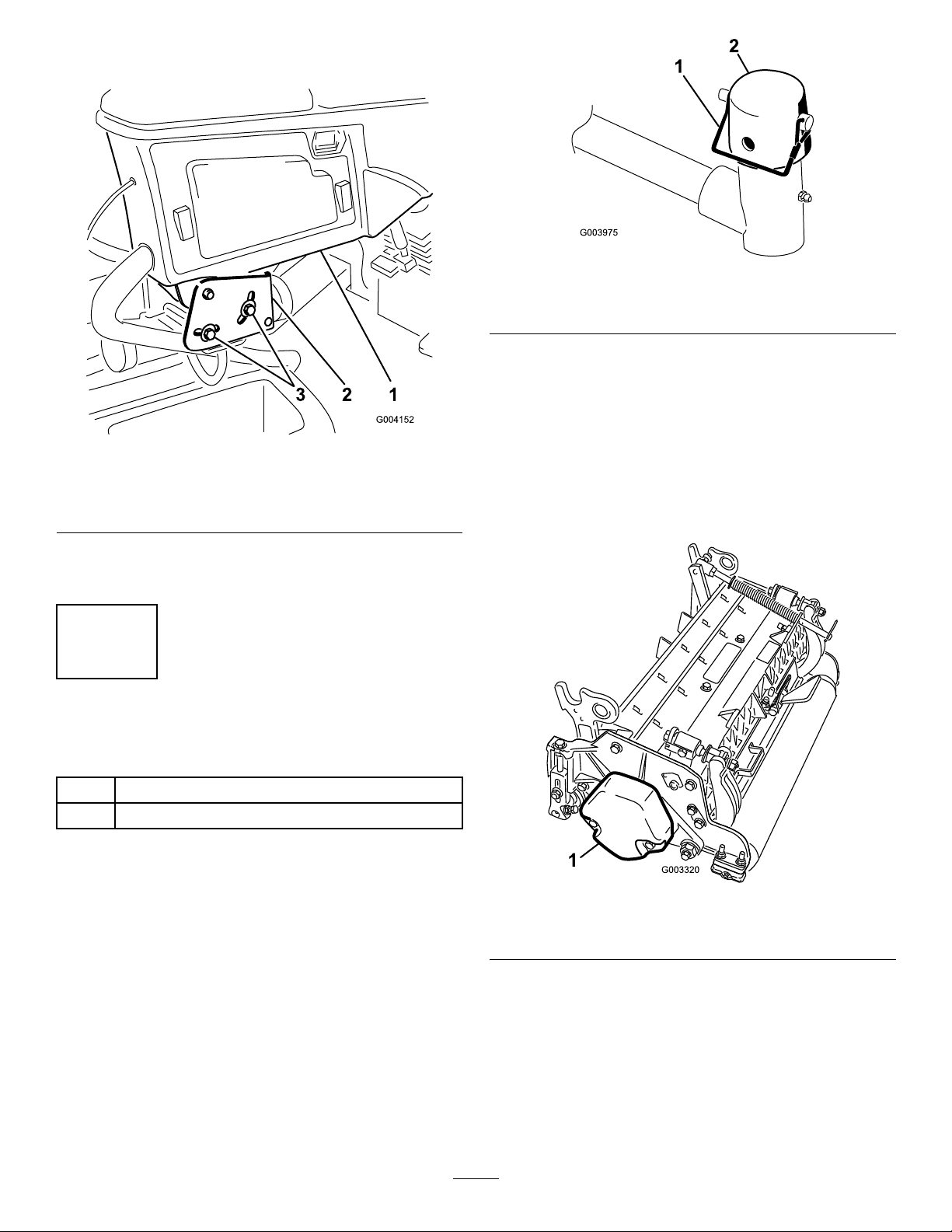

OpeningtheHood............................................43

ClosingtheHood..............................................43

OpeningtheScreen..........................................43

ClosingtheScreen...........................................43

TiltingtheSeat..................................................44

LoweringtheSeat.............................................44

JackingPointLocations....................................44

Lubrication..........................................................45

GreasingtheBearingsandBushings................45

EngineMaintenance...........................................46

EngineSafety...................................................46

CheckingtheAirFilter.......................................46

ServicingtheAirCleaner..................................47

ResettingtheAirFilterServiceIndicator............48

OilSpecication................................................48

CheckingtheLeveloftheEngineOil.................48

CrankcaseOilCapacity....................................48

ChangingtheEngineOilandFilter....................49

FuelSystemMaintenance...................................50

FuelMaintenance.............................................50

StoringFuel......................................................50

ServicingtheFuel-WaterSeparator..................50

BleedingtheFuelSystem.................................51

InspectingtheFuelLinesand

Connections..................................................51

DrainingandCleaningtheFuelTank.................51

CleaningtheFuel-PickupTubeScreen.............52

PrimingtheFuelSystem...................................54

ElectricalSystemMaintenance...........................55

ElectricalSystemSafety...................................55

Disconnectingthe12VBattery.........................55

Connectingthe12VBattery.............................55

Chargingthe12VBattery.................................56

Servicingthe12VBattery.................................56

Replacinga12VFuse-BlockFuse...................56

ReplacingtheTECFuse...................................57

DriveSystemMaintenance..................................58

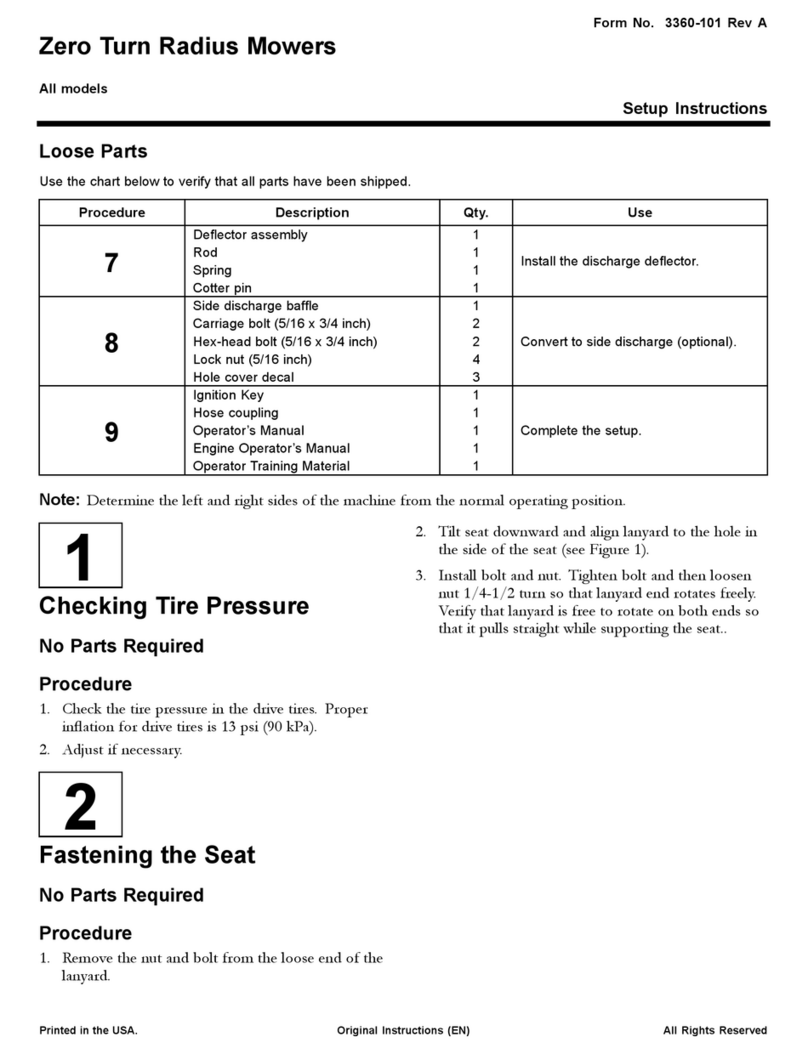

CheckingtheTireAirPressure..........................58

CheckingtheTorqueoftheWheel

Nuts..............................................................58

CheckingtheRear-WheelAlignment................58

AdjustingtheRearWheelT oe-in.......................58

CoolingSystemMaintenance..............................59

CoolingSystemSafety.....................................59

CoolantSpecication........................................59

CheckingtheCoolantLevel..............................60

RemovingDebrisfromtheCooling

System..........................................................60

BeltMaintenance................................................61

ServicingtheAlternatorBelt.............................61

HydraulicSystemMaintenance...........................62

HydraulicSystemSafety...................................62

3