Safety Page 1 - 2 GreensPro 1200

Safety Instructions

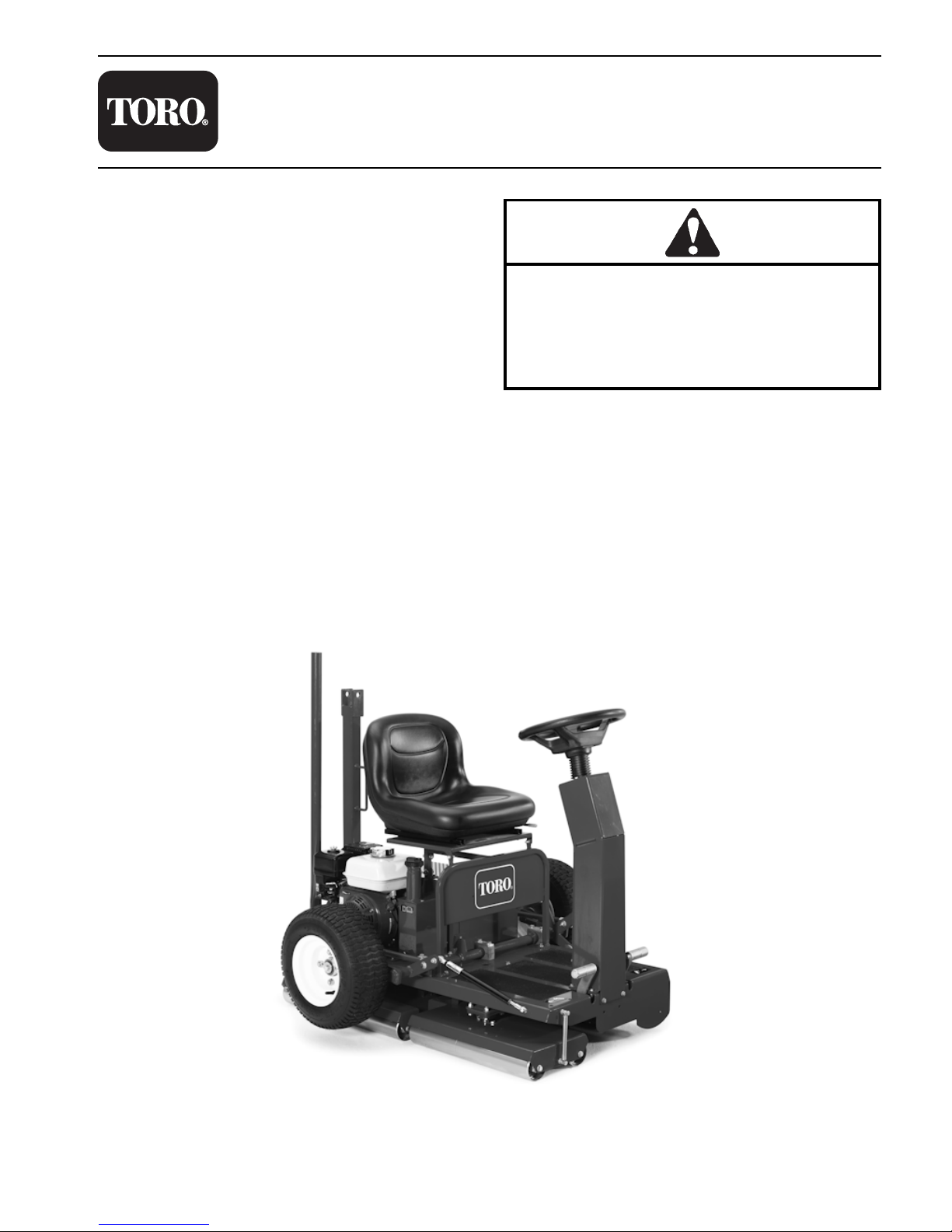

GreensPro 1200 machines have been tested and

certified by Toro for compliance with existing safety

standards and specifications. Although hazard control

and accident prevention are partially dependent upon

the design and configuration of the machine, these

factors are also dependent upon the awareness,

concern, and proper training of the personnel involved

in the operation, transport, maintenance, and storage

of the machine. Improper use or maintenance of the

machine can result in injury or death. To reduce the

potential for injury or death, comply with the following

safety instructions.

WARNING

Before Operating

1. Operate the machine only after reviewing and

understanding the contents of the Operator’s Manual. A

replacement Operator’s Manual is available on the

internet at www.toro.com.

2. Never allow children to operate the machine or allow

adults to operate it without proper instructions.

3. Become familiar with the controls and know how to

stop the machine and engine quickly.

4. Keep all shields, safety devices, and decals in place.

If a shield, safety device, or decal is malfunctioning,

illegible, or damaged, repair or replace it before

operating the machine.

5. Always wear substantial shoes. Do not operate

machine while wearing sandals, tennis shoes, or

sneakers. Do not wear loose fitting clothing, which

could get caught in moving parts and cause personal

injury.

6. Wearing safety glasses, safety shoes, long pants,

ear protection, and a hard hat is advisable and required

by some local safety and insurance regulations.

7. Keep everyone, especially children and pets, away

from the areas of operation.

8. Since gasoline is highly flammable, handle it

carefully.

a. Use an approved gasoline container.

b. Do not remove cap from fuel tank when engine is

hot or running.

c. Do not smoke while handling gasoline.

d. Fill fuel tank outdoors.

e. Wipe up any spilled gasoline.

f. Do not fill fuel tank higher than to the bottom of

fuel tank insert. Fuel may leak from filler neck when

machine is tilted for servicing if tank is overfilled.

While Operating

1. Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous

and could be deadly.

2. Always stand behind the machine when starting the

engine. Always sit in the operator’s seat when

operating the machine.

3. To start the engine:

a. Open fuel shutoff valve. Make sure spark plug

wire is connected to spark plug.

b. Move on/off switch to ON position. Set choke to

full choke position (cold start) and throttle to half

throttle.

c. Pull starter cord to start engine.

4. To stop the engine:

a. Reduce engine speed to SLOW.

b. Move on/off switch to OFF position to stop

engine.

5. Do not touch engine, muffler, or exhaust pipe while

engine is running or soon after it has stopped, because

these areas are hot enough to cause burns.

6. Whenever machine is left unattended, park machine

on a level surface and be sure engine is stopped.

7. Close fuel shutoff valve if machine is not to be used

for an extended period of time. Also, close fuel shutoff

valve if machine is to be transported.

To reduce the potential for injury or death,

comply with the following safety instructions.