The Groundsmaster 3500-D was tested and certified

by TORO for compliance with the B71.4-1999

specifications of the American National Standards

Institute. Although hazard control and accident

prevention partially are dependent upon the design

and configuration of the machine, these factors are

also dependent upon the awareness, concern, and

proper training of the personnel involved in the

operation, transport, maintenance, and storage of

the machine. Improper use or maintenance by the

operator or owner of the machine can result in

injury. To reduce the potential for any injury,

comply with the following safety instructions.

Supervisor’s Responsibilities

1. Make sure operators are thoroughly trained and

familiar with the operator’s manual and all the

labels on the machine.

2. Be sure to establish your own special

procedures and work rules for unusual

operating conditions (e.g., slopes too steep for

machine operation. Survey the complete

mowing site to determine the hills on which the

machine can be safely operated. When

performing this site survey, always use

common sense and take into consideration the

turf condition and the rollover risk.

To determine which hills or slopes on which the

machine may be safely operated, use the

inclinometer provided with each machine. To

perform a site survey, lay a 1.25 meter board on

the slope surface and measure the angle of the

slope. The board will average the slope but will

not take into consideration dips or holes. THE

MAXIMUM SIDE HILL ANGLE SHOULD

NOT BE GREATER THAN 25 DEGREES.

Before Operating

3. Operate the machine only after reading and

understanding the contents of this manual and

viewing the operator’s training video supplied

with the machine. A free replacement manual is

available by sending complete model and serial

number to:

The Toro Company

8111 Lyndale Ave. S.

Bloomington, MN 55420-1196.

4. Only trained operators, skilled in slope

operation and who have read this manual and

viewed the operator’s training video should

operate the machine. Never allow children to

operate the machine or adults to operate it

without proper instructions.

5. Become familiar with the controls and know

how to stop the machine and engine quickly.

6. Do not carry passengers on the machine. Keep

everyone, especially children and pets, away

from the areas of operation.

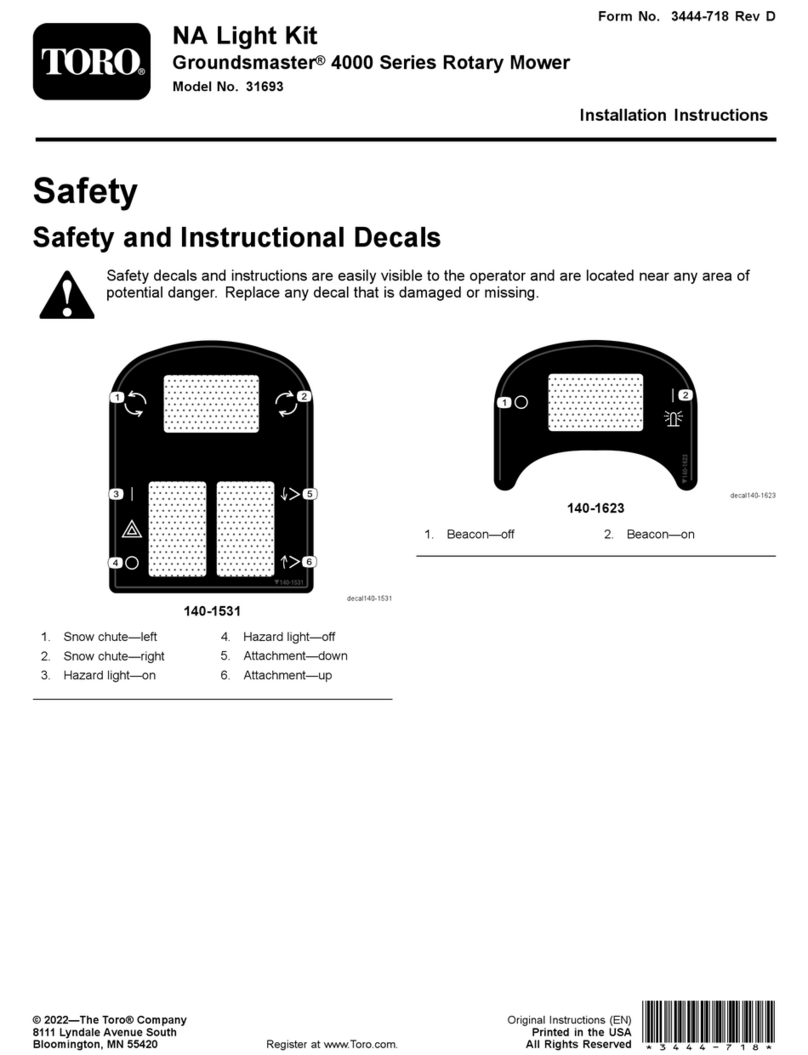

7. Keep all shields, safety devices and decals in

place. If a shield, safety device or decal is

damaged, malfunctioning or illegible, repair or

replace it before operating the machine.

8. Always wear substantial shoes. Do not operate

machine while wearing sandals, tennis shoes or

sneakers. Do not wear loose fitting clothing

because it could get caught in moving parts and

possibly cause personal injury.

9. Wearing safety glasses, safety shoes, long pants

and a helmet is advisable and required by some

local ordinances and insurance regulations.

10. Make sure the work area is clear of objects

which might be picked up and thrown by the

blades.

11. Fill fuel tank with diesel fuel before starting

engine. Avoid spilling any fuel. Since fuel is

highly flammable, handle it carefully.

A. Use an approved fuel container.

B. Do not remove cap from fuel tank when

engine is hot or running.

C. Do not smoke while handling diesel fuel.

D. Fill fuel tank outdoors and not over one

inch from the top of the tank, (bottom of

the filler neck). Do not overfill.

– 3 –

Safety