Toro 4250 User manual

Other Toro Lawn Mower manuals

Toro

Toro Recycler 20996 User manual

Toro

Toro Z Master 74925 User manual

Toro

Toro 30739 User manual

Toro

Toro 78253 User manual

Toro

Toro TimeCutter SW 4200 User manual

Toro

Toro Super Recycler 20792 User manual

Toro

Toro 74253CP User manual

Toro

Toro 73590 User manual

Toro

Toro TITAN HD 1500 User manual

Toro

Toro Recycler 22287 User manual

Toro

Toro 72211 User manual

Toro

Toro Super Recycler 21681 User manual

Toro

Toro Recycler 20373 User manual

Toro

Toro ProLine 22160 User manual

Toro

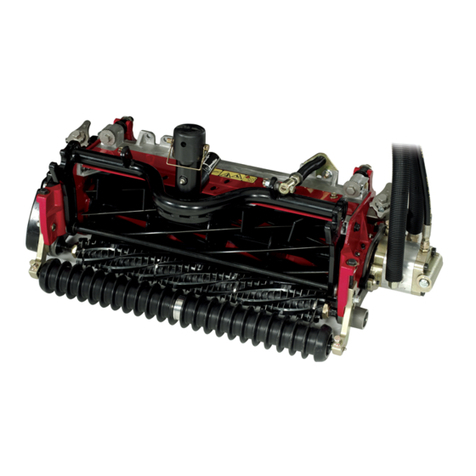

Toro 03200 Reelmaster 3100-D User manual

Toro

Toro Recyler 20379 User manual

Toro

Toro 21012B User manual

Toro

Toro 20337 User manual

Toro

Toro 22162 User manual

Toro

Toro 74176 User manual

Popular Lawn Mower manuals by other brands

TALEN TOOLS

TALEN TOOLS AVR HGM30 manual

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual