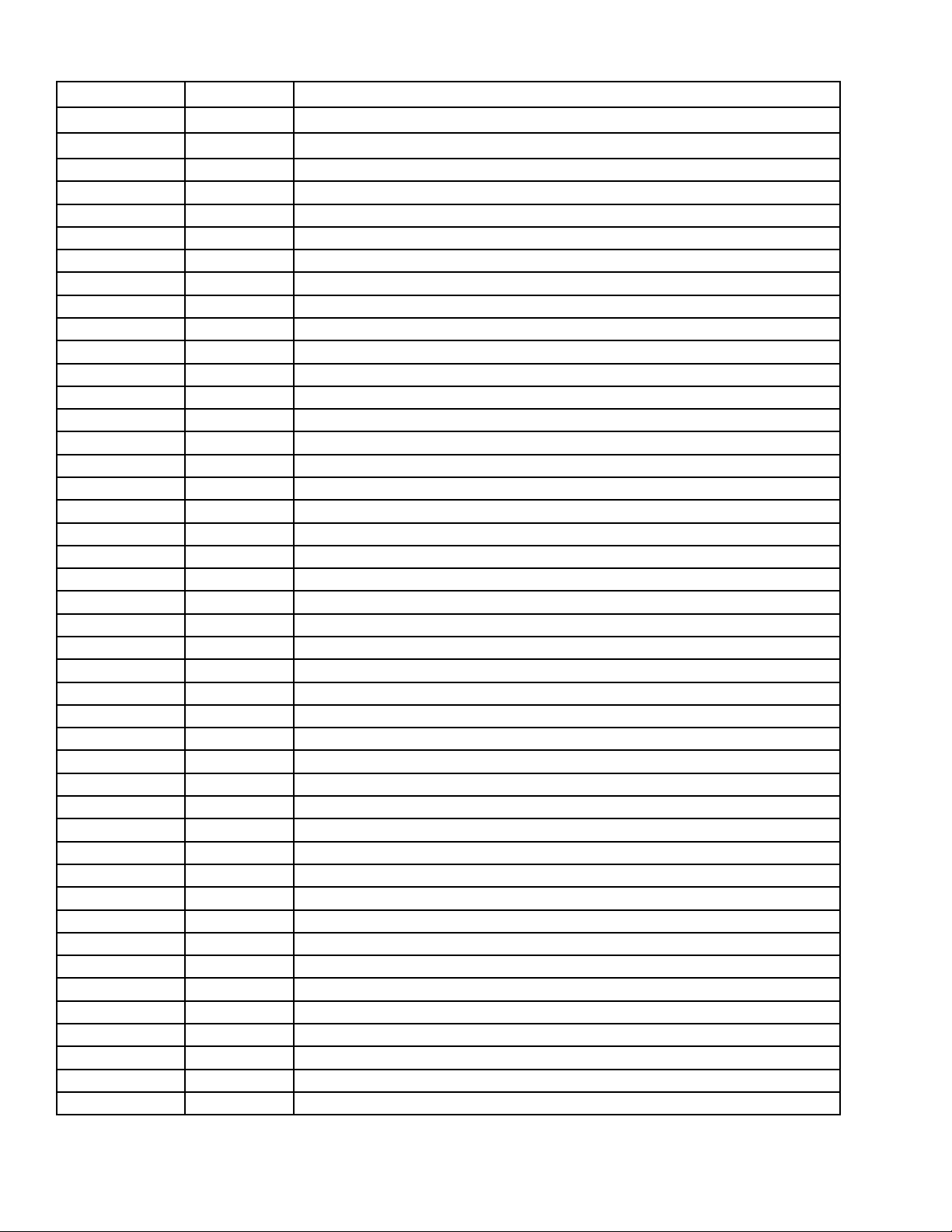

TableofContents

Preface................................................................................................................5

Chapter1:Safety............................................................................................1–1

SafetyInstructions.......................................................................................1–2

JackingInstructions.....................................................................................1–6

SafetyandInstructionalDecals....................................................................1–7

Chapter2:SpecicationsandMaintenance....................................................2–1

Specications...............................................................................................2–2

TorqueSpecications...................................................................................2–5

ShopSupplies............................................................................................2–11

SpecialT ools..............................................................................................2–13

Chapter3:Troubleshooting.............................................................................3–1

GEARS–TheSystematicApproachtoDening,DiagnosingandSolving

Problems......................................................................................................3–2

OperatorAdvisories......................................................................................3–3

DialogueMessages......................................................................................3–5

MachineFaults.............................................................................................3–7

UsingtheInfoCenterDisplayforTroubleshooting.......................................3–39

Troubleshooting..........................................................................................3–41

GeneralOperationProblems(Model04580)...............................................3–42

GeneralOperationProblems(Model04590)...............................................3–43

AftercutAppearance...................................................................................3–46

GroomingPerformance..............................................................................3–48

UniversalGroomerProblems(Optional).....................................................3–49

BatteryChargerErrorandFaultCodes(Model04590)................................3–50

Chapter4:Engine(Model04580)....................................................................4–1

GeneralInformation.....................................................................................4–2

ServiceandRepairs.....................................................................................4–3

Chapter5:ElectricalSystem...........................................................................5–1

GeneralInformation.....................................................................................5–3

ElectricalSystemOperation..........................................................................5–4

ElectricalSystemQuickChecks..................................................................5–18

Adjustments................................................................................................5–20

TestingtheElectricalComponents..............................................................5–23

Batteries(Model04580)............................................................................5–103

Batteries(Model04590)............................................................................5–111

ServiceandRepairs.................................................................................5–120

Chapter6:Chassis..........................................................................................6–1

GeneralInformation.....................................................................................6–2

Adjustments.................................................................................................6–3

ServiceandRepairs.....................................................................................6–9

Chapter7:DPACuttingUnits..........................................................................7–1

GeneralInformation.....................................................................................7–2

Adjustments.................................................................................................7–3

ServiceandRepairs.....................................................................................7–6

Chapter8:UniversalGroomer(Optional)........................................................8–1

GeneralInformation.....................................................................................8–2

ServiceandRepairs.....................................................................................8–3

AppendixA......................................................................................................A–1

ElectricalDrawingDesignations....................................................................A–2

ElectricalSchematic–3360..........................................................................A–3

ElectricalSchematic–3370..........................................................................A–4

ElectricalSchematic–3370(continued).......................................................A–5

WireHarnessDrawing–3360......................................................................A–6

WireHarnessDiagram–3360......................................................................A–7

WireHarnessDiagram–3360(continued)...................................................A–8

WireHarnessDrawing–3370......................................................................A–9

Greensmaster®eTriFlex3360and3370Page7Preface

19239SLRevB