TableofContents

Preface................................................................................................................5

Chapter1:Safety............................................................................................1–1

SafetyInstructions.......................................................................................1–2

SafetyandInstructionalDecals....................................................................1–5

Chapter2:SpecicationsandMaintenance....................................................2–1

Specications...............................................................................................2–2

TorqueSpecications...................................................................................2–5

ShopSupplies............................................................................................2–11

SpecialT ools..............................................................................................2–13

Chapter3:Troubleshooting.............................................................................3–1

GEARS–TheSystematicApproachtoDening,DiagnosingandSolving

Problems......................................................................................................3–2

OperatorAdvisories......................................................................................3–3

MachineFaults.............................................................................................3–5

BatteryChargerErrorandFaultCodes.........................................................3–8

ElectricalSystemProblems..........................................................................3–9

AftercutAppearance...................................................................................3–11

FactorsAffectingGrooming........................................................................3–12

GroomingReelMechanicalProblems.........................................................3–13

Chapter4:TractionandReelDriveSystems...................................................4–1

GeneralInformation.....................................................................................4–2

Adjustments.................................................................................................4–3

ServiceandRepairs.....................................................................................4–5

Chapter5:ElectricalSystem...........................................................................5–1

GeneralInformation.....................................................................................5–2

ElectricalSystemOperation..........................................................................5–4

Adjustments................................................................................................5–20

TestingtheElectricalComponents..............................................................5–21

ServiceandRepairs...................................................................................5–42

Chapter6:Controls,WheelsandAccessories................................................6–1

GeneralInformation.....................................................................................6–2

Adjustments.................................................................................................6–3

ServiceandRepairs.....................................................................................6–4

Chapter7:DPACuttingUnits..........................................................................7–1

GeneralInformation.....................................................................................7–2

Adjustments.................................................................................................7–3

ServiceandRepairs.....................................................................................7–4

Chapter8:UniversalGroomer(Optional)........................................................8–1

GeneralInformation.....................................................................................8–2

ServiceandRepairs.....................................................................................8–3

AppendixA......................................................................................................A–1

ElectricalDrawingDesignations....................................................................A–2

ElectricalSchematic.....................................................................................A–3

WireHarnessDrawing..................................................................................A–4

WireHarnessDrawing..................................................................................A–5

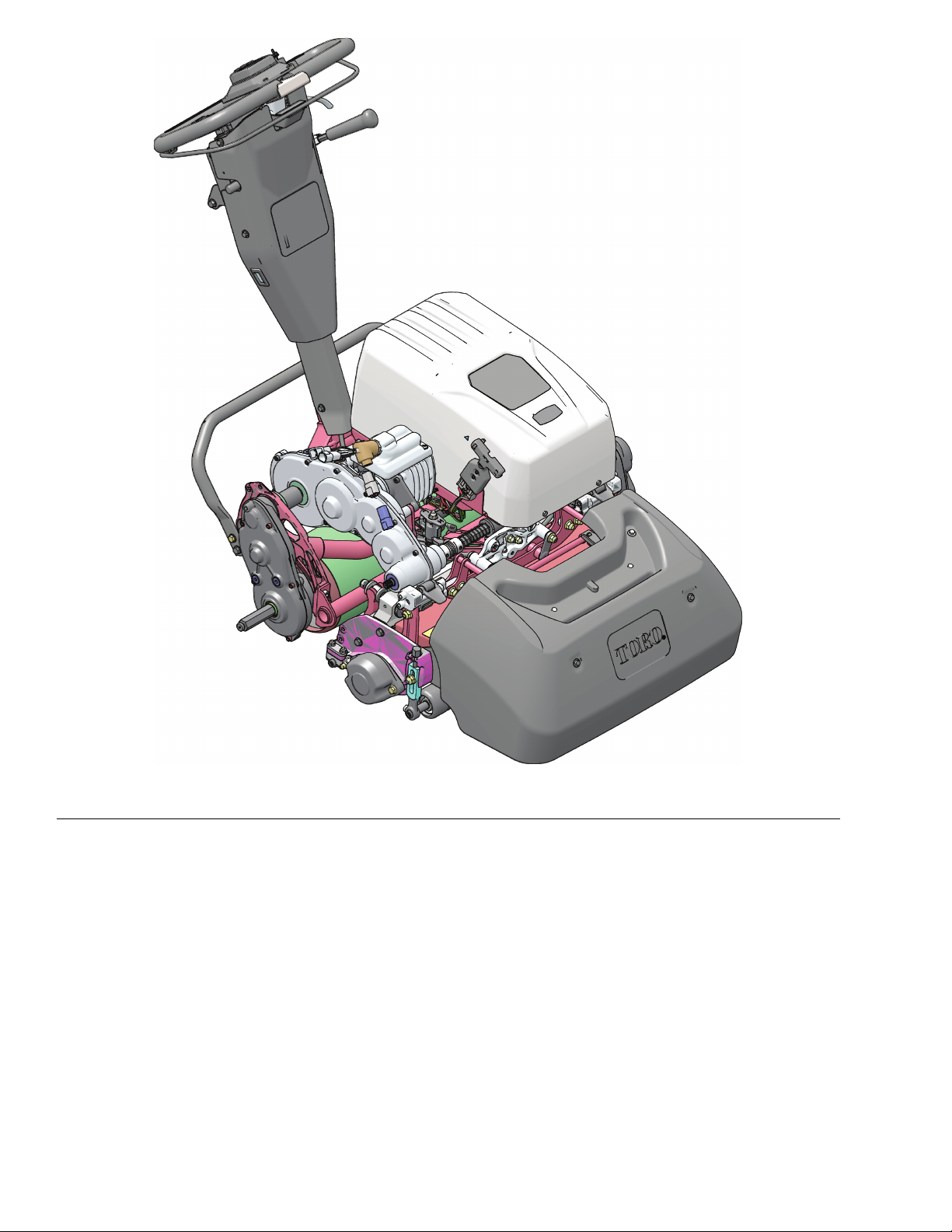

PrefacePage8Greensmaster®eFlex1021

20248SLRevA