2

All Rights Reserved

Printed in the USA

2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Warning

Important The engine in this product is not equipped

with a spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate this

engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other states

or federal areas may have similar laws.

Contents

Page

Contents 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

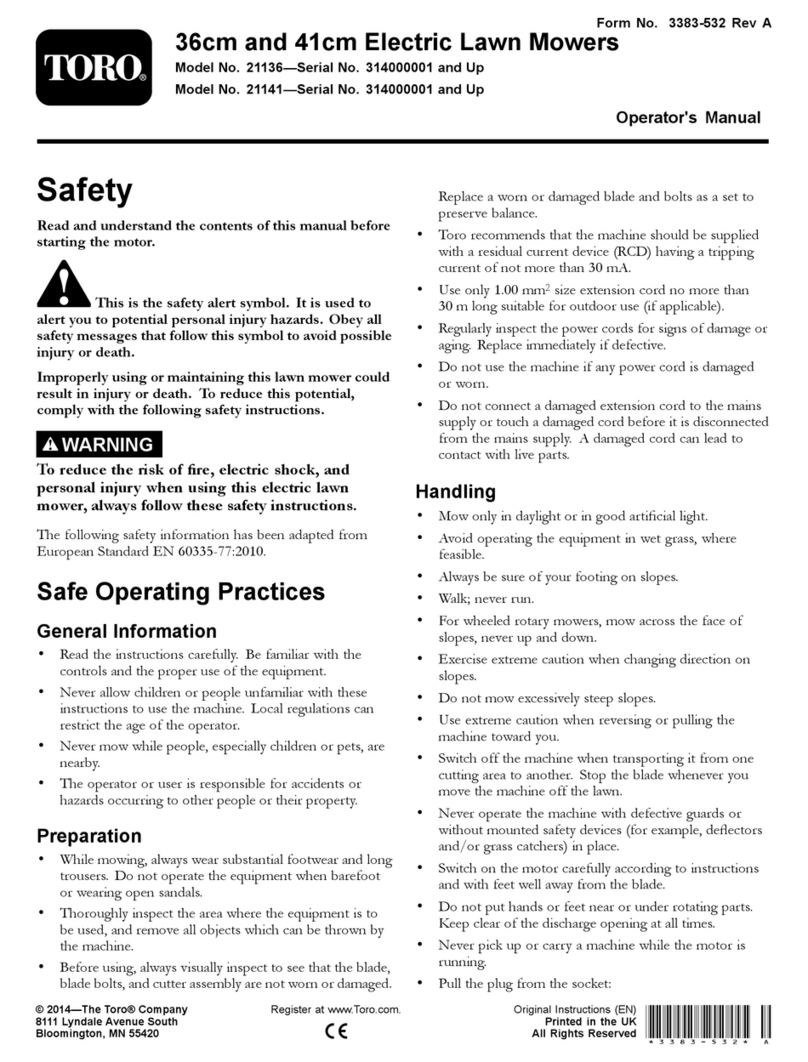

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Toro Mower Safety 4. . . . . . . . . . . . . . . . . . . . . . . .

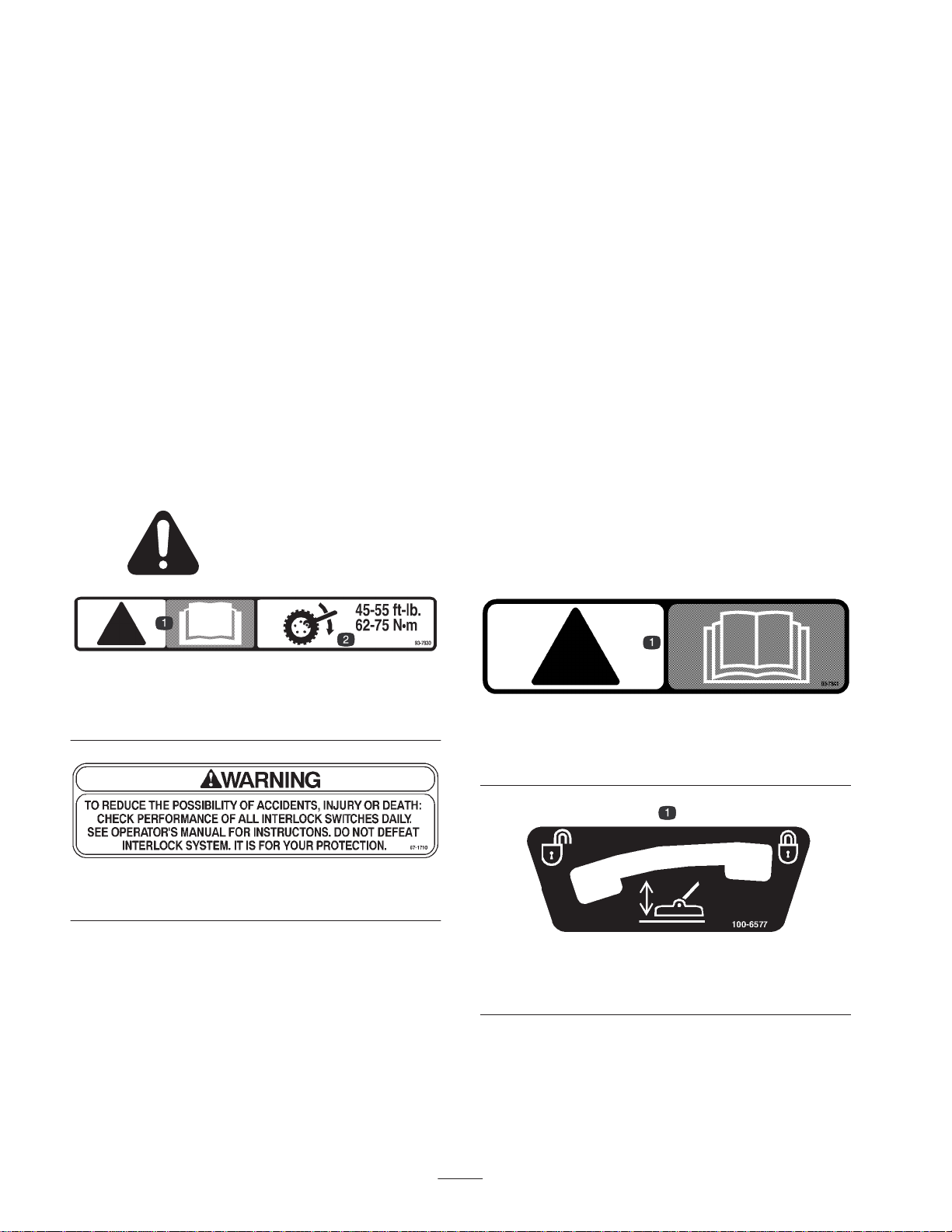

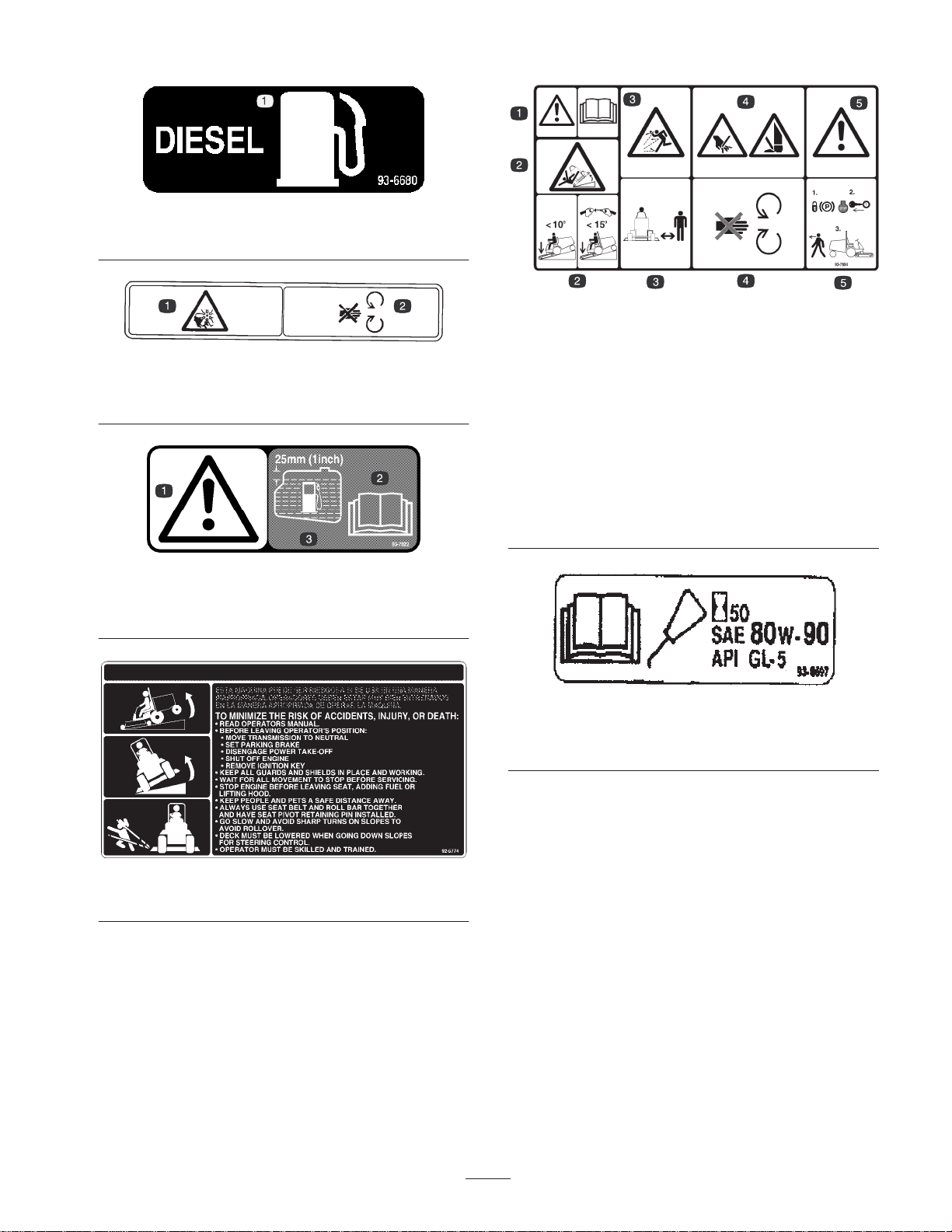

Safety and Instruction Decals 6. . . . . . . . . . . . . . . . .

Specifications 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 12. . . . . . . . . . . . . . . . . . . . .

Measurements 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Equipment 13. . . . . . . . . . . . . . . . . . . . . . . .

Setup 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Rear Wheels 15. . . . . . . . . . . . . . . . . . . . . . . .

Install Steering Wheel 15. . . . . . . . . . . . . . . . . . . . . .

Install Seat 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3Install Seat Belt 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Install Manual Tube 17. . . . . . . . . . . . . . . . . . . . . . . .

Install Rops 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect Battery 18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Tire Pressure 18. . . . . . . . . . . . . . . . . . . . . . . .

Install Rear Weight 18. . . . . . . . . . . . . . . . . . . . . . . . .

Before Operating 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Engine Oil 19. . . . . . . . . . . . . . . . . . . . . . . . . .

Check Cooling System 19. . . . . . . . . . . . . . . . . . . . . .

Check Hydraulic System Fluid 19. . . . . . . . . . . . . . .

Fill Fuel Tank 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Rear Axle 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Check Bidirectional Clutch Lubricant 21. . . . . . . . . .

Page

Controls 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting/Stopping Engine 24. . . . . . . . . . . . . . . . . . . .

Bleeding Fuel System 24. . . . . . . . . . . . . . . . . . . . . .

Checking Interlock System 25. . . . . . . . . . . . . . . . . .

Operating Characteristics 25. . . . . . . . . . . . . . . . . . . .

Pushing Or Towing Traction Unit 25. . . . . . . . . . . . .

Lubrication 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing Bearings And Bushings 26. . . . . . . . . . . . .

Service Interval Chart 28. . . . . . . . . . . . . . . . . . . . . .

Maintenance 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 29. . . . . . . . .

Daily Maintenance Checklist 30. . . . . . . . . . . . . . . . .

Maintenance 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Air Cleaner Maintenance 31. . . . . . . . . . . . .

Servicing Air Cleaner 31. . . . . . . . . . . . . . . . . . . . . . .

Cleaning Radiator And Screen 31. . . . . . . . . . . . . . . .

Changing Engine Oil And Filter 32. . . . . . . . . . . . . .

Servicing Fuel System 32. . . . . . . . . . . . . . . . . . . . . .

Bleeding Air From Injectors 33. . . . . . . . . . . . . . . . .

Alternator Belt 33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting Throttle 34. . . . . . . . . . . . . . . . . . . . . . . . .

PTO Belt 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PTO Clutch Adjustment 34. . . . . . . . . . . . . . . . . . . . .

Adjusting Transmission For Neutral 35. . . . . . . . . . .

Adjusting the Parking Brake Interlock Switch 35. . .

Changing Hydraulic Oil And Filter 36. . . . . . . . . . . .

Adjusting Service Brakes 37. . . . . . . . . . . . . . . . . . . .

Changing Rear Axle Lubricant 37. . . . . . . . . . . . . . .

Changing Bidirectional Clutch Lubricant 38. . . . . . .

Rear Wheel Toe–in 38. . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Battery 38. . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Harness Service 38. . . . . . . . . . . . . . . . . . . . .

Fuses 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Schematic 39. . . . . . . . . . . . . . . . . . . . . . .

Electrical Schematic 40. . . . . . . . . . . . . . . . . . . . . . . .

Storage 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Unit 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 44. . .