TableofContents

Preface................................................................................................................5

Chapter1:Safety............................................................................................1–1

SafetyInstructions.......................................................................................1–2

JackingInstructions.....................................................................................1–7

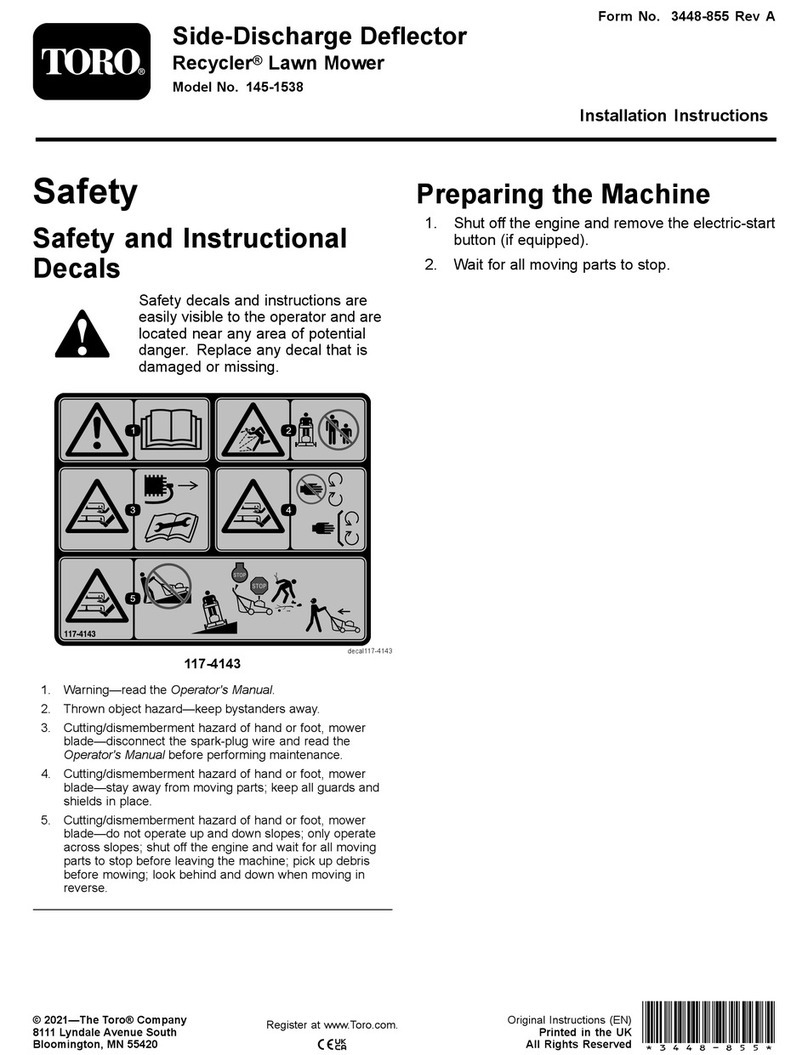

SafetyandInstructionalDecals....................................................................1–8

Chapter2:SpecicationsandMaintenance....................................................2–1

Specications...............................................................................................2–2

TorqueSpecications...................................................................................2–4

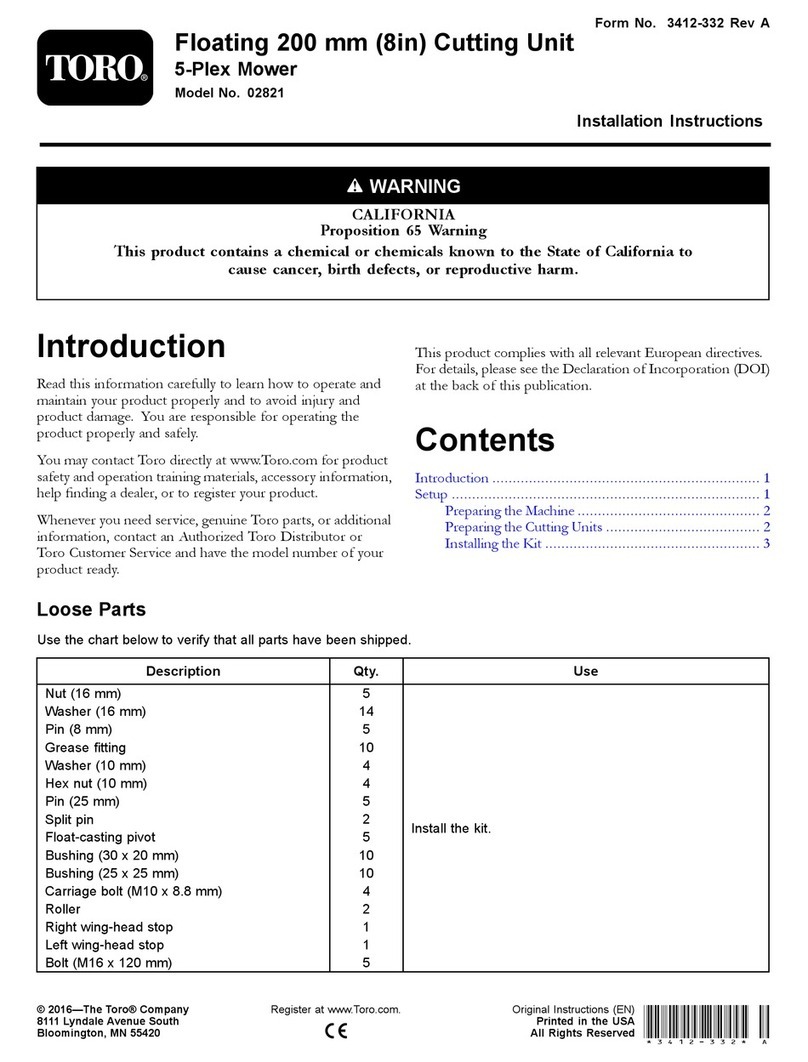

ShopSupplies..............................................................................................2–9

SpecialT ools..............................................................................................2–11

Chapter3:DieselEngine.................................................................................3–1

Specications...............................................................................................3–2

GeneralInformation.....................................................................................3–3

ServiceandRepairs.....................................................................................3–8

Chapter4:HydraulicSystem...........................................................................4–1

Specications...............................................................................................4–3

GeneralInformation.....................................................................................4–4

HydraulicSchematics.................................................................................4–13

HydraulicFlowDiagrams............................................................................4–14

SpecialT ools...............................................................................................4–27

Troubleshooting..........................................................................................4–34

TestingtheHydraulicSystem......................................................................4–39

ServiceandRepairs...................................................................................4–68

Chapter5:ElectricalSystem...........................................................................5–1

GeneralInformation.....................................................................................5–3

SpecialTools.................................................................................................5–6

InfoCenterDisplay........................................................................................5–8

Troubleshooting..........................................................................................5–28

ElectricalSystemQuickChecks..................................................................5–41

Adjustments................................................................................................5–43

TestingtheElectricalComponents..............................................................5–49

ServiceandRepairs.................................................................................5–104

Chapter6:Chassis..........................................................................................6–1

Specications...............................................................................................6–2

GeneralInformation.....................................................................................6–3

SpecialTools.................................................................................................6–4

Adjustments..................................................................................................6–6

ServiceandRepairs...................................................................................6–13

Chapter7:CuttingDeck..................................................................................7–1

GeneralInformation.....................................................................................7–2

FactorsThatCanAffectCuttingPerformance...............................................7–3

ServiceandRepairs.....................................................................................7–4

Chapter8:OperatorCab.................................................................................8–1

GeneralInformation.....................................................................................8–2

ServiceandRepairs.....................................................................................8–4

AppendixA......................................................................................................A–1

ElectricalDrawingDesignations....................................................................A–2

HydraulicSchematic.....................................................................................A–3

ElectricalSchematic-Platform.....................................................................A–4

ElectricalSchematic-Engine.......................................................................A–5

ElectricalSchematic-Cab(page1of2)........................................................A–6

ElectricalSchematic-Cab(page2of2)........................................................A–7

ElectricalSchematic-Attachments...............................................................A–8

ElectricalSchematic-DebrisCollection........................................................A–9

WireHarnessDrawing-Platform................................................................A–10

WireHarnessDiagram-Platform................................................................A–11

Groundsmaster360Page7Preface

16225SLRevC