Contents

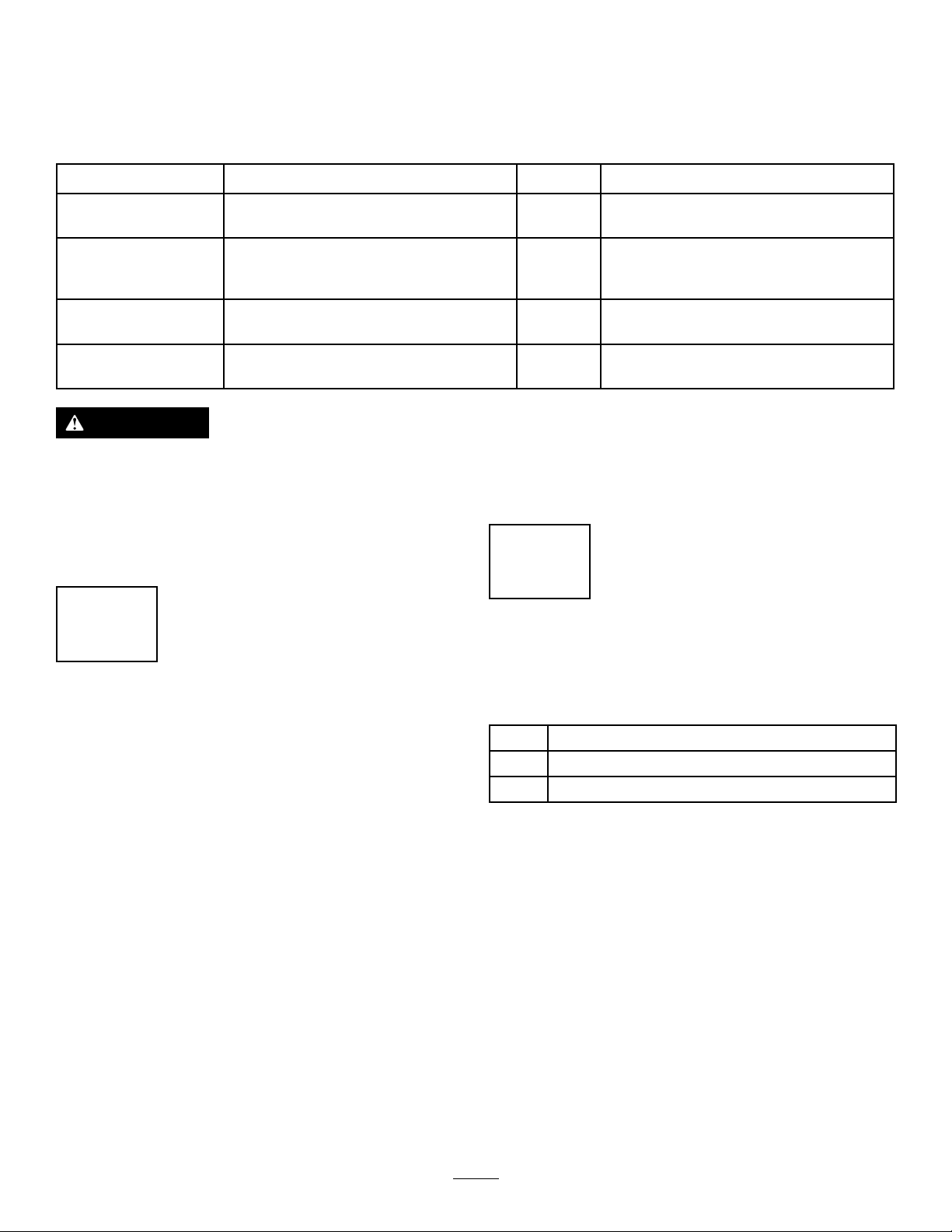

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Cutting Unit Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

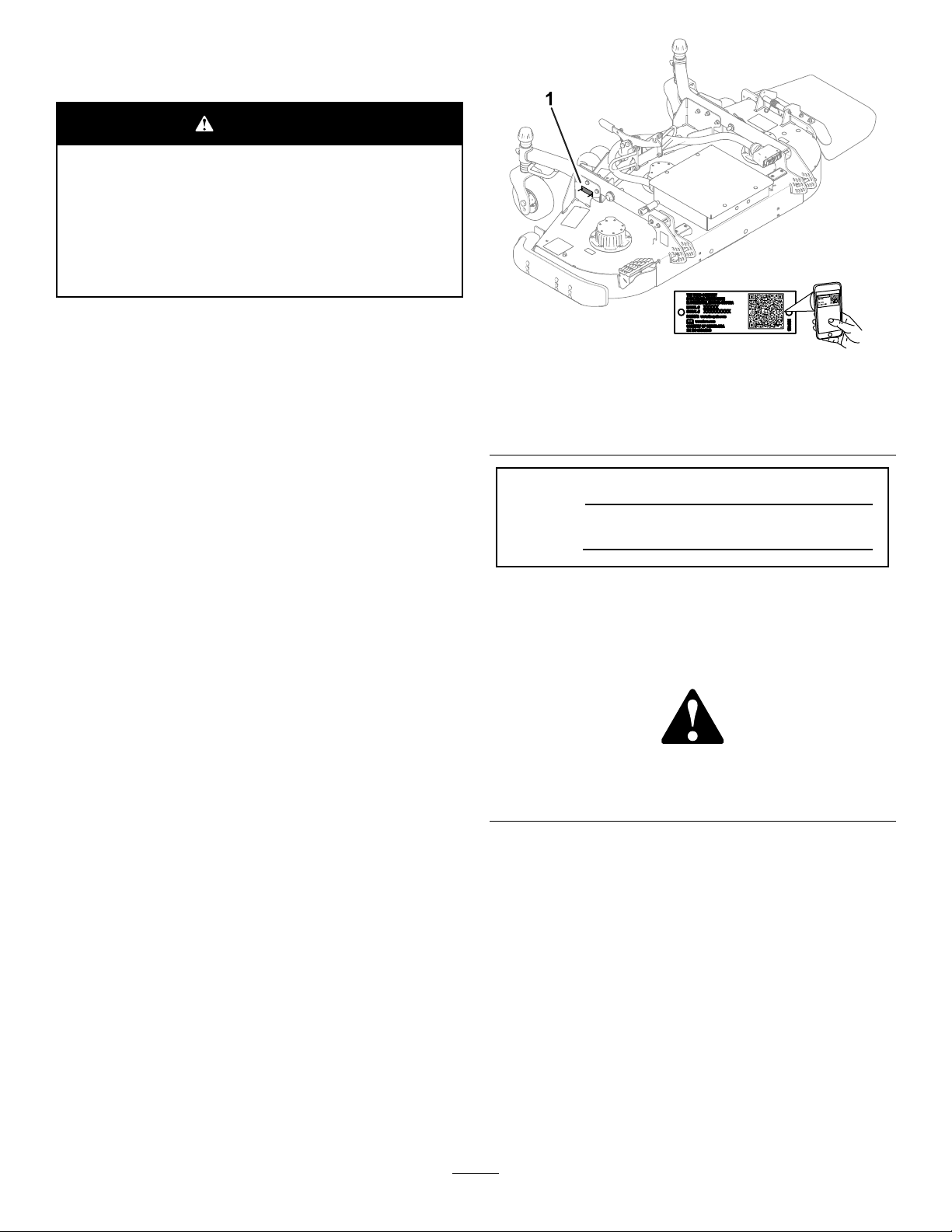

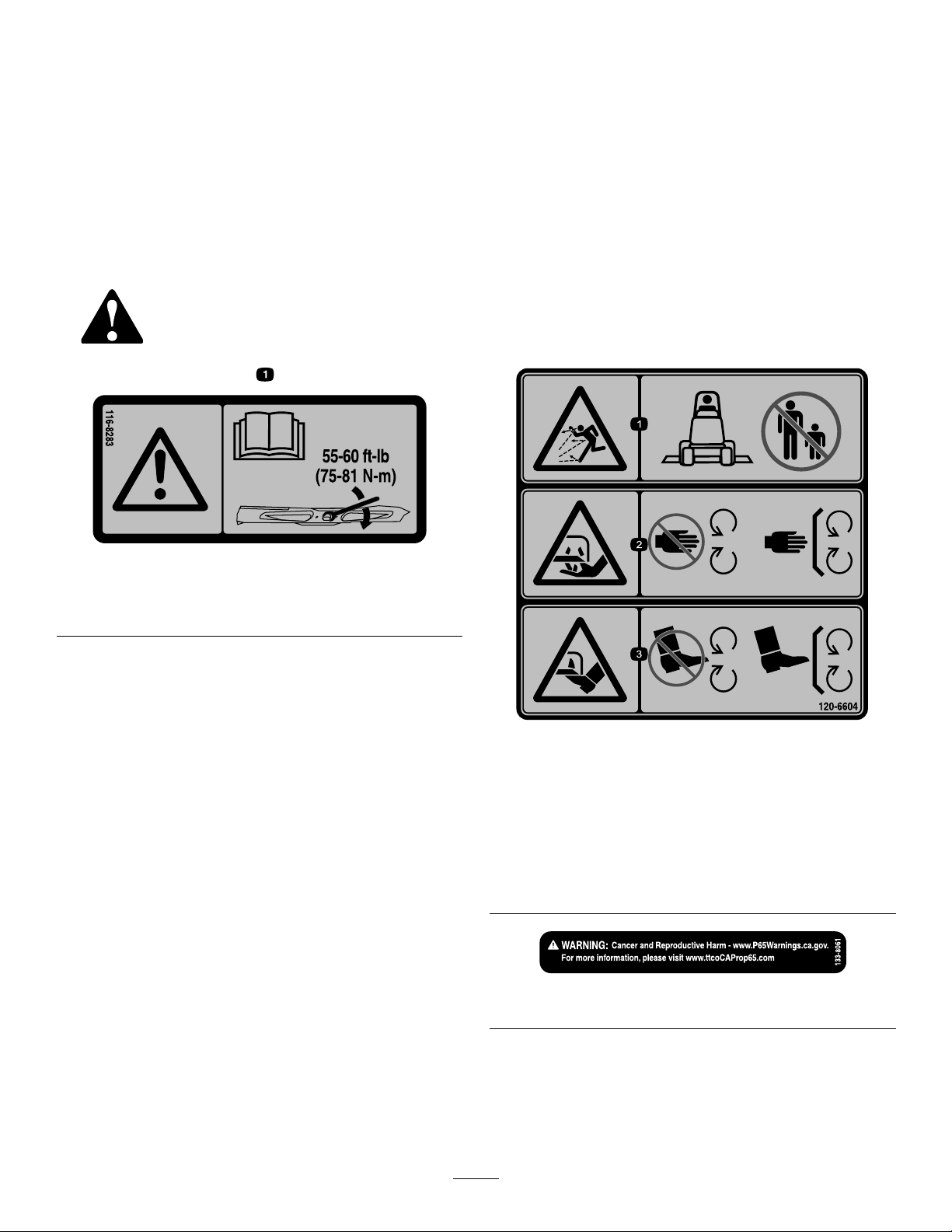

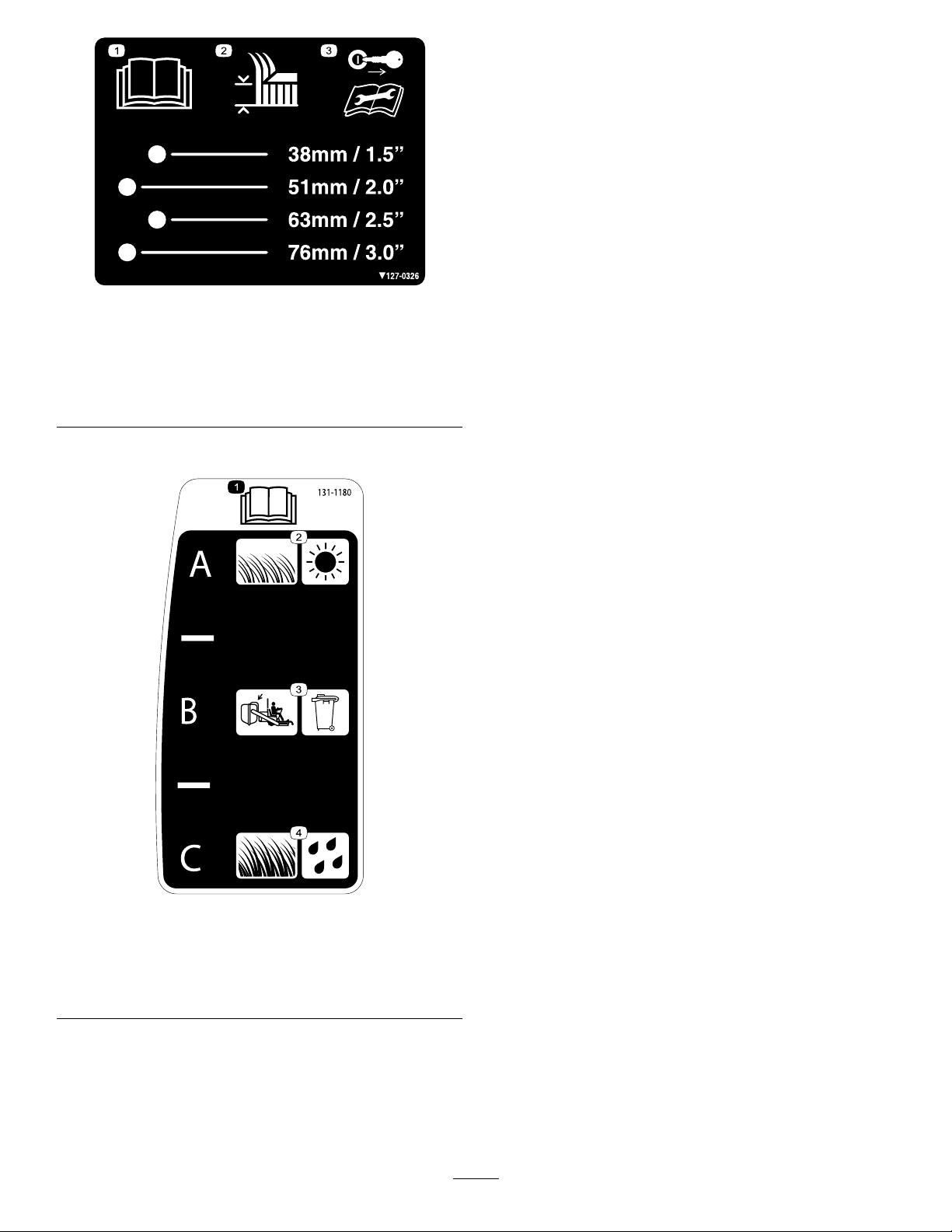

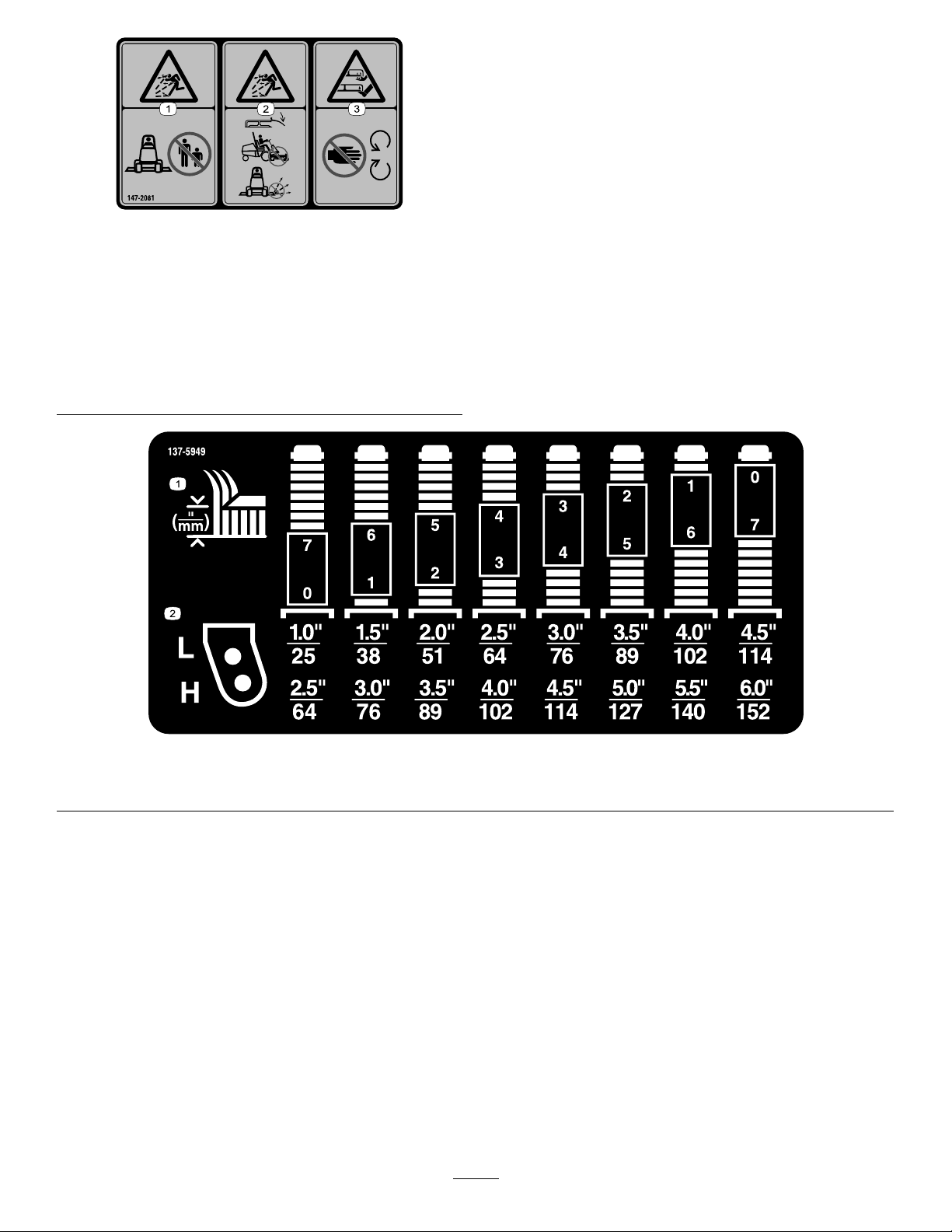

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Preparing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Installing the Cutting Unit to the T raction

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Leveling the Cutting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Greasing the Cutting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Attachments/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Evaluating the Quality of Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Leveling the Cutting Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Adjusting the Height of Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 1

Adjusting the Cutting-Unit Pitch . . . . . . . . . . . . . . . . . . . . . . . . 12

Adjusting the Anti-Scalp Rollers . . . . . . . . . . . . . . . . . . . . . . . . 13

Adjusting the Skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting the Flow Baf e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Positioning the Flow Baf e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the Side Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Operating T ips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Recommended Maintenance Schedule(s) . . . . . . . . . . . 16

Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Greasing the Castor-Arm Bushings . . . . . . . . . . . . . . . . . . 17

Removing the Cutting Unit from the T raction

Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Servicing the Bushings in the Castor

Arms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Servicing the Cutting Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacing the Grass Deector . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Checking the Electrical Cables . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cleaning under the Cutting Unit . . . . . . . . . . . . . . . . . . . . . . . . 22

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Safety

General Safety

This product is capable of amputating hands and

feet and of throwing objects. Always follow all safety

instructions to avoid serious personal injury

•Read and understand the contents of this

Operator ’ s Manual before starting the machine.

•Use your full attention while operating the

machine. Do not engage in any activity that

causes distractions; otherwise, injury or property

damage may occur .

•Do not put your hands or feet near moving

components of the machine.

•Do not operate the machine without all guards

and other safety protective devices in place and

functioning properly on the machine.

•Keep clear of any discharge opening.

•Keep bystanders and children out of the operating

area. Never allow children to operate the machine.

•Before you leave the operator ’ s position, do the

following:

– Park the machine on a level surface.

– Lower the cutting unit(s).

– Disengage the drives.

– Ensure that the parking brake is engaged.

– Shut of f the machine and remove the key .

– W ait for all movement to stop.

Improperly using or maintaining this machine can

result in injury . T o reduce the potential for injury ,

comply with these safety instructions and always

pay attention to the safety-alert symbol , which

means Caution, W arning, or Danger—personal safety

instruction. Failure to comply with these instructions

may result in personal injury or death.

3