3

SAFETY INSTRUCTIONS

The safety alert symbol means

CAUTION, WARNING or DAN

GER personal safety

instruction". Read and under

stand the instruction because

it has to do with safety. Failure to comply with

the instruction may result in personal injury.

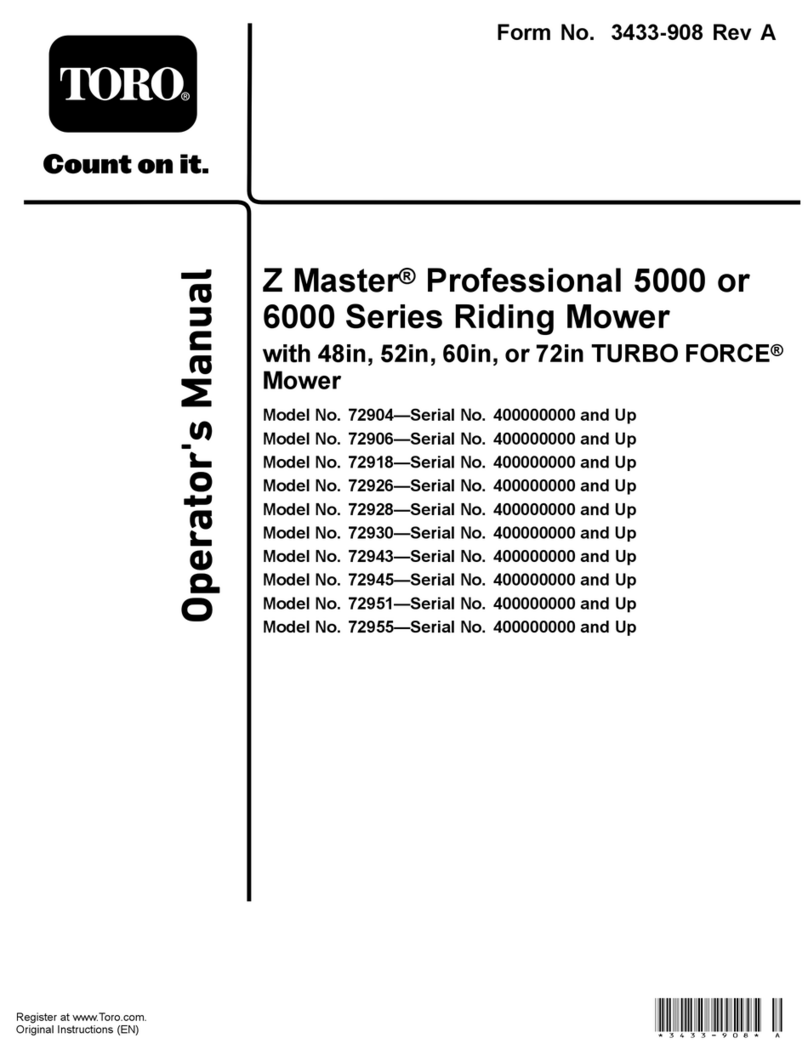

BEFORE OPERATING

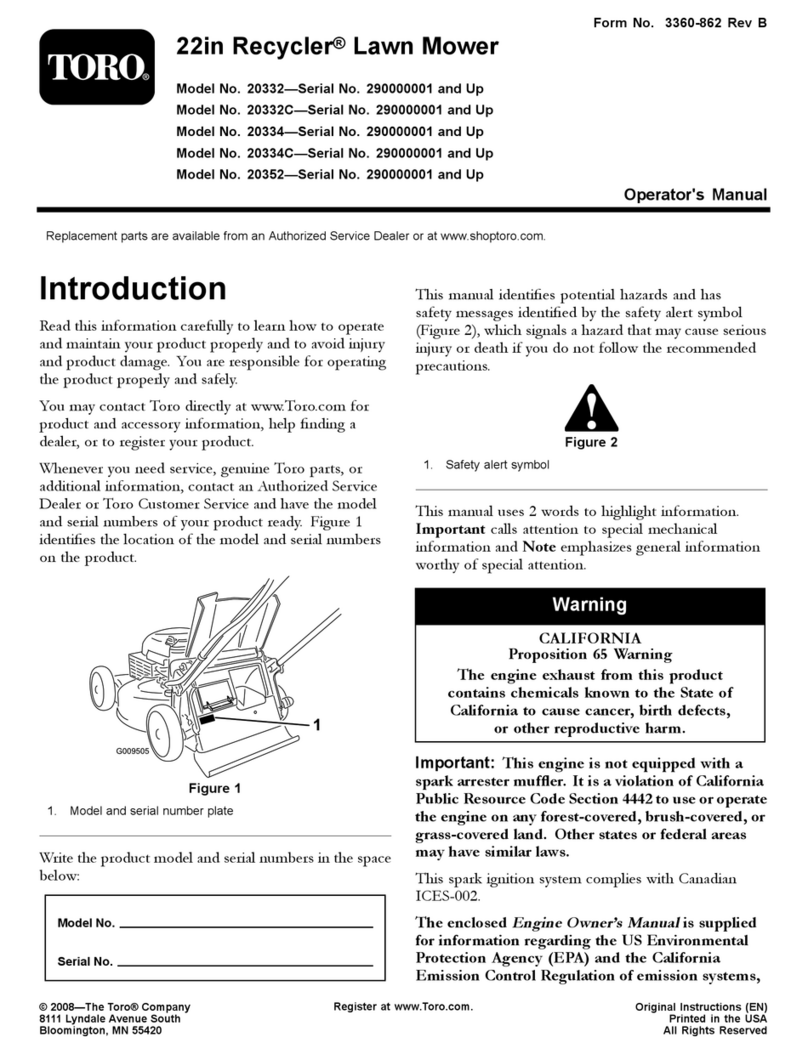

1. Read and understand the contents of this

Operator's Manual before operating the machine.

Become familiar with all controls and know how to stop

quickly. A free replacement manual is available by

sending complete Model and Serial Number to:

The Toro Company

8111 Lyndale Avenue South

Bloomington, Minnesota 55420-1196

2. Never allow children to operate the machine. Do

not allow adults to operate the machine without proper

instructions. Only trained and authorized persons

should operate this vehicle. Anyone who operates the

vehicle should have a motor vehicle license.

3. Never operate the machine when under the

influence of drugs or alcohol.

4. Keep all shields and safety devices in place. If a

shield, safety device or decal is illegible or damaged,

repair or replace it before operation is commenced.

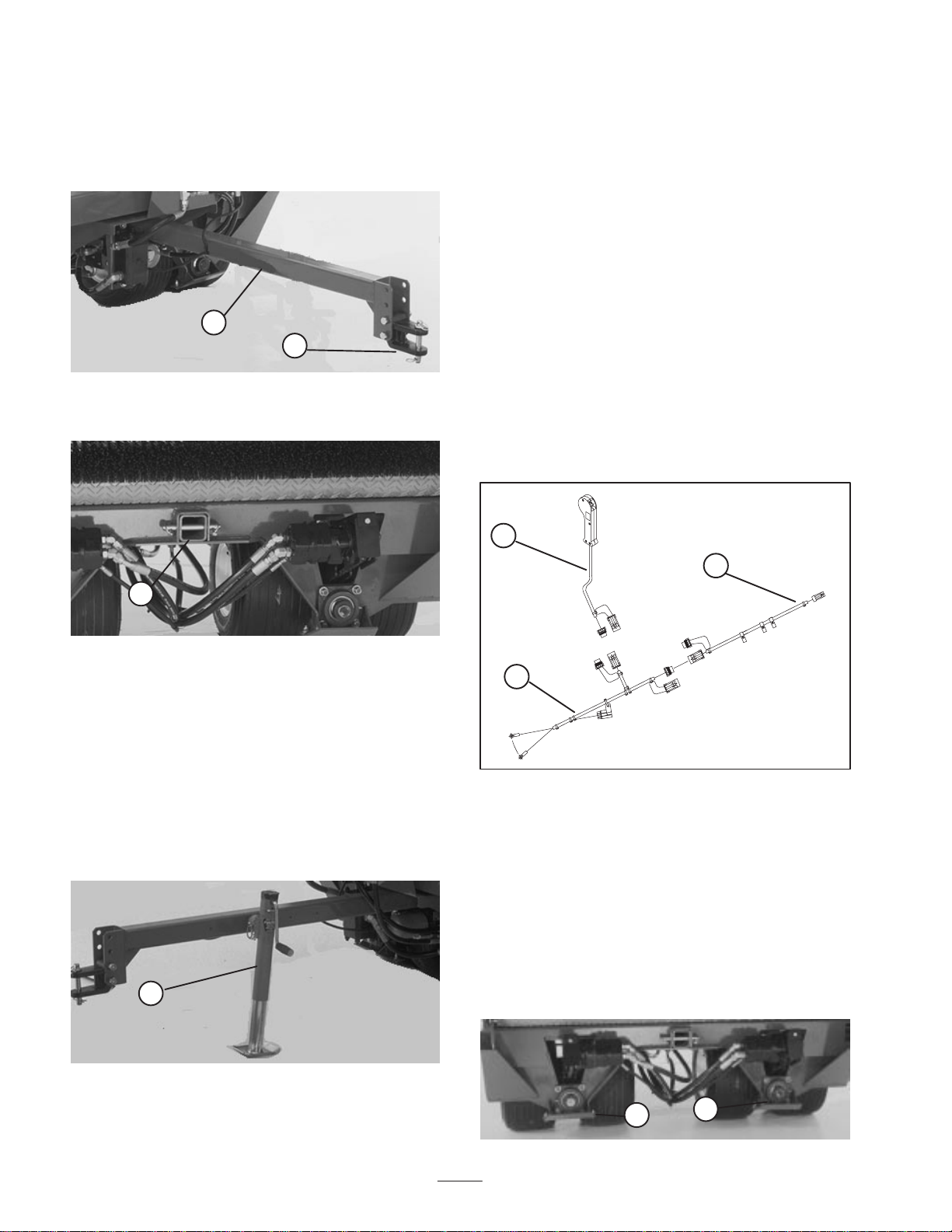

5. Tighten any loose nuts, bolts and screws to assure

machine is in safe operating condition. Make sure

Topdresser tongue mounting pins, hitch pins and

tongue jack are in place and secure.

6. Do not modify this equipment in any manner.

7. Do not operate machine while wearing sandals,

tennis shoes, sneakers or shorts. Also, do not wear

loose fitting clothing which could get caught in moving

parts. Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes and a helmet is

advisable and required by some local ordinances and

insurance regulations.

WHILE OPERATING

8. Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous

and could possibly be deadly.

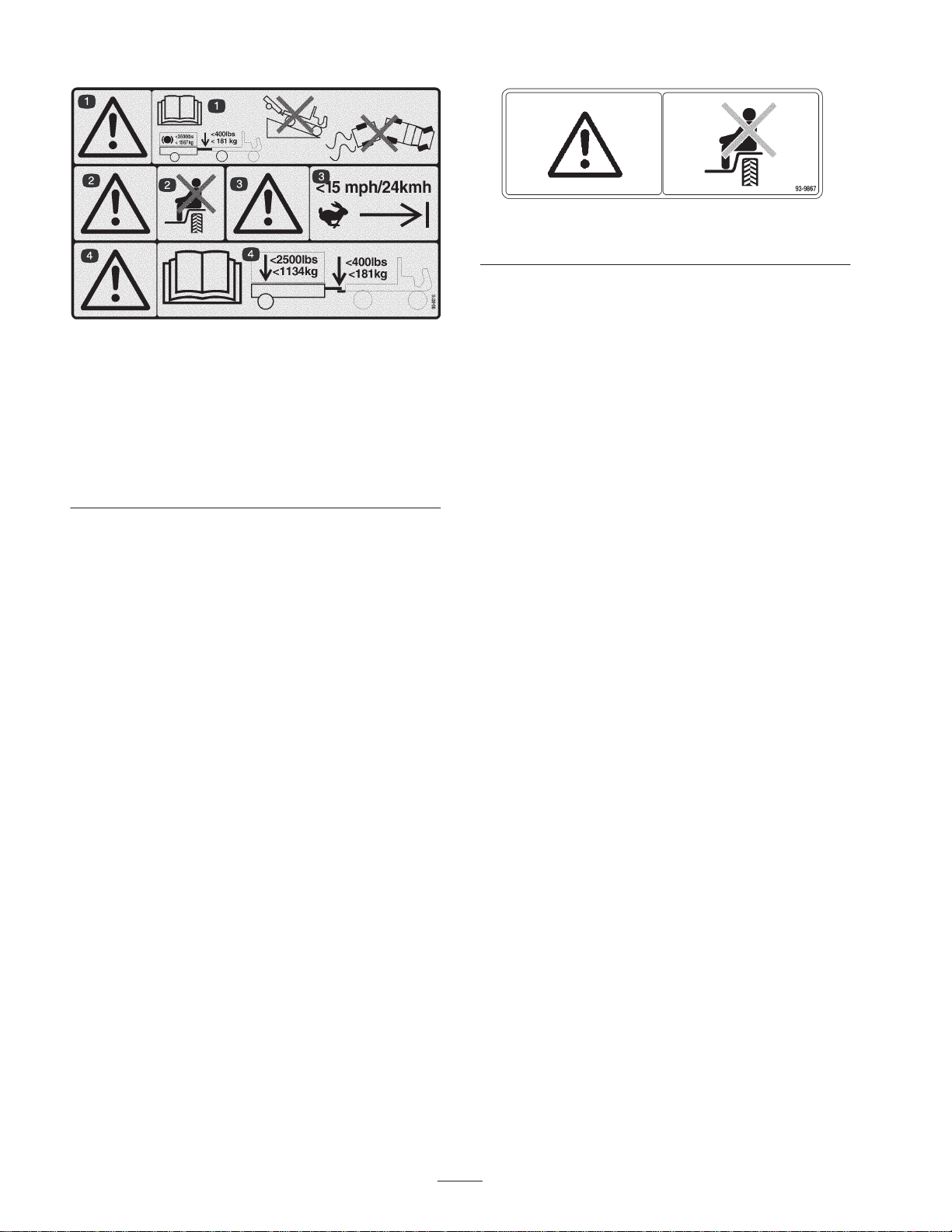

9. NEVER carry passengers on the Top Dresser and

keep everyone away from the areas of operation.

10. Keep hands and feet out of hopper when unit is

operating or engine is running on tow vehicle.

11. Operator and passenger should remain seated

whenever the tow vehicle is in motion.

12. Using the machine demands attention. Failure to

operate tow vehicle safely may result in an accident,

tipover of tow vehicle and serious injury or death. Drive

carefully. To prevent tipping or loss of control:

A. Use extreme caution, reduce speed and

maintain a safe distance around sand traps,

ditches, creeks, ramps, any unfamiliar areas or

other hazards.

B. Watch for holes or other hidden hazards.

C. Use caution when operating tow vehicle on a

steep slope. Normally travel straight up and down

slopes. Reduce speed when making sharp turns or

when turning on hillsides. Avoid turning on hillsides

whenever possible.

D. Use extra caution when operating tow vehicle on

wet surfaces, at higher speeds or with a full load.

Stopping time will increase with a full load. Shift into

a lower gear before starting up or down a hill

E. Avoid sudden stops and starts. Do not go from

reverse to forward or forward to reverse without

coming to a complete stop.

F. Do not attempt sharp turns or abrupt maneuvers

or other unsafe driving actions that may cause a

loss of control.

G. Before backing up, look to the rear and assure

no one is behind. Back up slowly.

H. Watch out for traffic when near or crossing

roads. Always yield the right of way to pedestrians

and other vehicles. This machine is not designed

for use on streets or highways. Always signal

your turns or stop early enough so other persons

know what you plan to do. Obey all traffic rules and

check for local regulations on the operation of the

topdresser on or near highways.

I. Always watch out for and avoid low over-hangs

such as tree limbs, door jambs, over-head

walkways, etc. Make sure there is enough room

over head to easily clear the tow vehicle and your

head.

J. If ever unsure about safe operation, STOP

WORK and ask your supervisor.

13. When loading with sand, distribute load evenly.

Operate tow vehicle with extra caution when the hopper

is full of sand. Keep load balanced to prevent it from

shifting.

MAINTENANCE

14. Before servicing or making adjustments to the

topdresser, stop engine of tow vehicle, set parking

brake and remove key from engine to prevent

accidental starting of the engine.

15. Perform only those maintenance instructions

described in this manual. If major repairs are ever

needed or assistance is desired, contact an Authorized

TORO Distributor.