Toro 07344 User manual

FormNo.3361-472RevA

1/3PlatformLift

forWorkmanHeavy-DutyUtilityVehicle

ModelNo.07344—SerialNo.2900000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

BeforeOperating.................................................3

WhileOperating...................................................3

Maintenance.........................................................3

SafetyandInstructionalDecals.............................4

Setup............................................................................6

1RemovetheSeat,ShroudandFender

Assemblies.......................................................7

2RemovingtheHood..........................................7

3InstalltheMainWireHarnessw/Relays..............7

4MounttheParkingBrakeSwitch.........................8

5MountRearLevelSwitch...................................9

6MountLiftontoVehicleFrame........................10

7ConnectWires.................................................12

8ReinstallHoodandReconnectBattery..............12

9MountCircularBubbleLevel...........................12

10InstallDecals.................................................12

ProductOverview......................................................14

Controls.............................................................14

Operation...................................................................15

CheckOilLevel..................................................15

CheckTirePressure............................................15

InstallingSafetyBlocks.......................................15

OperatingtheLift...............................................16

OperatingTips...................................................18

Maintenance...............................................................20

CheckSafetyCircuits..........................................20

BatteryCare.......................................................20

Schematics.................................................................22

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Safety

BeforeOperating

•Readandunderstandthecontentsofthismanual

beforeoperatingtheplatformlift.Becomefamiliar

withallcontrolsandknowhowtostopquickly.A

replacementmanualisavailableatwww .Toro.com.

•Donotallowchildrentooperatethelift.Donot

allowadultstooperateitwithoutproperinstruction.

•Keepallshieldsandsafetydevicesinplace.Ifa

safetydevice,shieldordecalmalfunctions,becomes

damagedorillegible,replaceitbeforeoperation

iscommenced.Toassureliftisinsafeoperating

condition,tightenloosenuts,boltsandscrews.

WhileOperating

•Donotusenearelectricalpowerlines.Neverallow

platformlifttotouchpowerlines.

•Donotuseplatformliftduringlightning,

thunderstorms,orhighwinds.

•Nevermovevehiclewhileplatformisraised.

•Alwaysapplyparkingbrakebeforeraisingplatform.

Wheelchockuseisrecommended.

•Neverreleaseparkingbrakewhileplatformisraised.

•Checksafetyinterlocksbeforeeachuseofplatform.

Seeoperator’smanualforsafetyinterlockcheck

instructions.

•Neverbypasssafetyinterlocks.

•Neverallowridersonplatforminanyposition.

•Alwaysparkvehicleonrm,levelsurfacebefore

raisingplatform.

•Neverexceed5degreemaximumangleofoperation.

•Neverraiseplatformifbubblelevelindicatoris

outsiderecommendedoperatingrange.

•Neverraiseplatformifoneormorevehicletiresare

underinated;checktirepressuredaily.

•Neverpullonobjectswhilereachingfromraised

platform.

•Neveruseplatformforcarryingorloweringtree

limbs,branchesorheavyorunevenloads.

•Neverexceedcapacityofplatformlift,oneperson

withequipmentnottoexceed600lbs.(272Kg).

•Alwayswearhardhatandeyeprotectionwhile

operatingplatformorwhileinareabelowplatform.

•Neverdroporthrowarticlesfromraisedplatform.

•Whenraisingplatformbealertforoverhead

obstructionswhichcouldcauseeye,headorcrushing

injuries.

•Standclearofscissorarmswhileplatformismoving.

•Makesureareaisclearofbystandersbeforelowering

platform.

Maintenance

•Alwaysremovekeyfromliftcontrolboxwhen

platformisnotinuse.

•Ensureliftisinsafeoperatingcondition.Keepnuts,

boltsandscrewstight.

•Neverworkunderraisedplatformwithoutliftsafety

blocksinstalled.

•Tobesureofoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmade

byothermanufacturerscouldbedangerous.Such

usecouldvoidtheproductwarrantyofTheToro®

Company.

3

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-3702

93-3710

93-3711

93-3701

93-3703

4

93-3704

93-3708

93-3706

93-3709

93-3705

93-3707

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Nopartsrequired–Removetheseat,shroudandfender

assemblies

2Nopartsrequired–Removethehood

MainWireHarnessw/Relays1

CableTie7

Screw,1/4x3/4inch2

Nut,1/4inch2

3

Fuse1

Installmainwireharnessw/relays

Parkingbrakeswitch1

4Screws2MounttheParkingBrakeSwitch

Rearlevelswitchbracket1

5Rearlevelswitchw/harness1Mountrearlevelswitch

ReinforcingPlate2

Spacertube2

FlangeHD.Capscrew,3/8-16x3inch2

FlangeHD.Capscrew,3/8-16x3–1/2

inch2

FlangeHD.Capscrew,3/8-16x1inch4

6

Flangenut,3/8-164

Mountliftontovehicleframe

7Nopartsrequired–Connectwires

8Nopartsrequired–Reinstallhoodandreconnectbattery

9CircularBubbleLevel1Mountcircularbubblelevel

OperationDecal1

10NoStepDecal2Installdecals

The1/3platformliftisdesignedtobeusedonlywitha

WorkmanVehicleandmustbemountedwiththewiring

harness,level,decals,switchesandallinterlockswitches

installed.The1/3platformliftwillonlyworkon

Workman3000–4000seriesvehicleswithserialnumbers

240000001andupandallWorkmanHD,HDXand

HDX-Dvehicles.

6

1

RemovetheSeat,Shroudand

FenderAssemblies

NoPartsRequired

Procedure

1.Positionvehicleonaclean,levelsurface,stopengine,

engageparkingbrakeandremovekeyfromignition

switch.Disconnectpositivecablefrombattery.

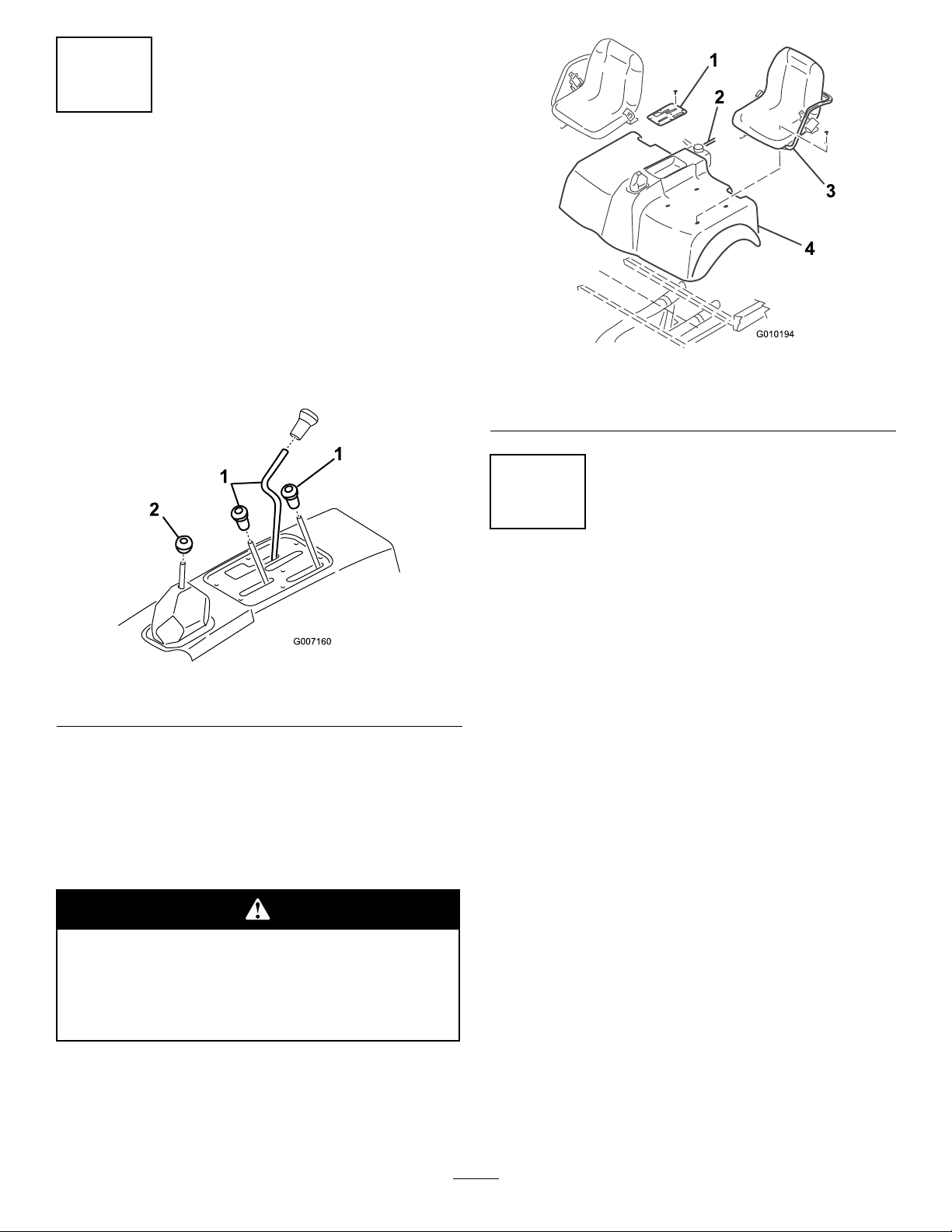

2.Unscrewandremoveallknobsfromconsolelevers

andfromthegearshiftlever(Figure2).

Figure2

1.Consolelevers2.Gearshiftlever

3.Remove(6)screwssecuringoutsideedgeofcenter

consolecoverplatetoframeandremovecoverplate

(Figure3).

4.Disconnectthereservoirhosefromtheradiatorand

plugorclampittoretaincoolant(Figure3).Remove

theoperatorshieldfromtheROPS.

Pressurizedhotcoolantescapingcancause

seriousburns.

Allowenginetocoolenoughtotouchbefore

removingoverowtubeorradiatorcap.

5.Removethecapscrewssecuringtheseatsandshroud

tomountingbrackets(Figure3).Removetheseats

andshroud.

Figure3

1.Consolecoverplate3.Seat

2.Reservoirhose4.Shroud

2

RemovingtheHood

NoPartsRequired

ForWorkman3000–4000series

vehicleswithserialnumbers240000001

andup

1.Removethe(6)screwsandnutssecuringthebumper

tothevehicleframeandremovethebumper.

2.Removethe(7)screwssecuringthefronthoodto

thevehicleframeandremovethehood.

ForWorkmanHD,HDXandHDX-D

vehicles

1.Positionthevehicleonalevelsurface,stopthe

engine,engagetheparkingbrakeandremovethe

keyfromtheignition.

2.Whilegraspingthehoodintheheadlightopenings,

liftuponthehoodtoreleasethelowermounting

tabsfromthebumperslots.

3.Pivotthebottomofthehoodupwarduntilthetop

mountingtabscanbepulledfromthedashslots.

4.Pivotthetopofthehoodforwardandunplugthe

wireconnectorsfromtheheadlights.

5.Removethehood.

7

3

InstalltheMainWireHarness

w/Relays

Partsneededforthisprocedure:

1MainWireHarnessw/Relays

7CableTie

2Screw,1/4x3/4inch

2Nut,1/4inch

1Fuse

ForWorkman3000–4000series

vehicleswithserialnumbers240000001

andup

1.Insertendofwireharness,withmaleandfemale

spadeterminalsonit,upthroughopeninginvehicle

oorboard,towarddashpanel,followingvehicle

wireharness.Secureharnesstovehiclewireharness

with(2)cableties.

2.Locatered/blackwireconnectedto"I"terminalof

ignitionswitch.Removewirefrom“I”terminaland

plugintoappropriatewireharnessterminal.Plug

remainingharnessterminalontoignitionswitch“I”

terminal.

3.Removefastenerssecuringwireharnesscoverto

undersideofvehicleoorandremovecover.

4.Routewireharnessrearwardtoconsolearea.

Harnessmustnotinterferewithanyhot(exhaust)or

movingparts.Securetheharnesswithcableties.

5.Mounttherelaystotheleftframechannelwith

2(1/4x3/4inch)screwsand(1/4inch)nuts

(Figure4).

Note:Ifthevehicleisequippedwithhighow

hydraulics,locateanothersuitablemountinglocation.

Figure4

1.Relays

ForWorkmanHD,HDXandHDX-D

vehicles

1.Insertendofwireharness,withmaleandfemale

spadeterminalsonit,upthroughopeninginvehicle

oorboard.

2.Locateanemptyslotinthefuseblock.Ifnoempty

slotisavailable,anadditionalfuseblock(Toropart

no.92–2641)willhavetobeadded.

3.Inserttheincludedfuseintotheemptyfuseblock

slotandconnectthewireharnessspadeterminalto

thecorrespondingspadeterminalonthefuseblock.

4.Removefastenerssecuringwireharnesscoverto

undersideofvehicleoorandremovecover.

5.Routewireharnessrearwardtoconsolearea.

Harnessmustnotinterferewithanyhot(exhaust)or

movingparts.Securetheharnesswithcableties.

6.Mounttherelaystotheleftframechannelwith

2(1/4x3/4inch)screwsand(1/4inch)nuts

(Figure4).

Note:Ifthevehicleisequippedwithhighow

hydraulics,locateanothersuitablemountinglocation.

8

4

MounttheParkingBrake

Switch

Partsneededforthisprocedure:

1Parkingbrakeswitch

2Screws

Procedure

1.Mounttheparkingbrakeswitchtotheparkingbrake

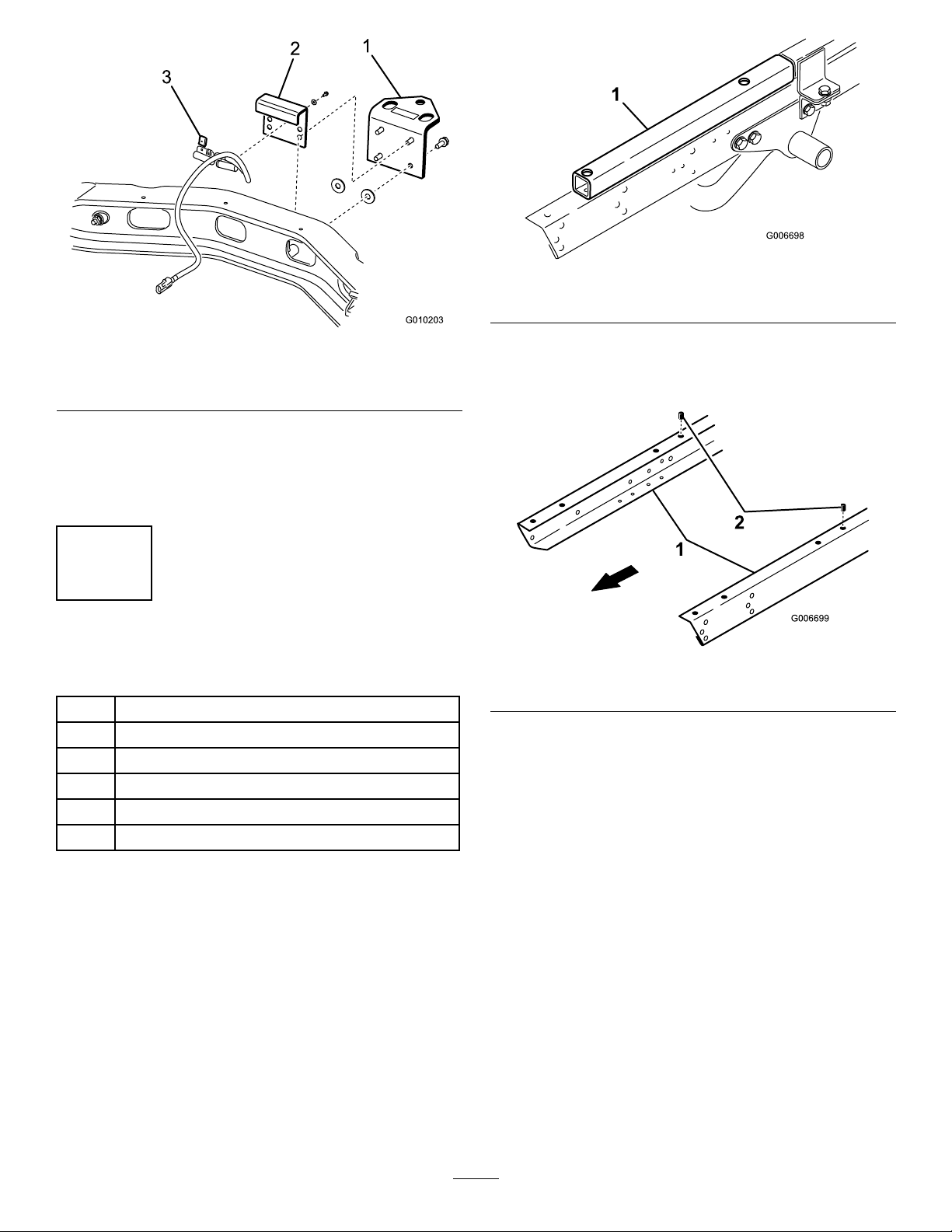

mountwithtwoscrewsasshowninFigure5.

Figure5

1.Switch

2.Plugswitchwireconnectorintoliftwireconnector

harness.

3.Removetheloopbackconnectorfromthevehicle

wireharnesslabeled1/3lift.Connecttheliftwire

harnesstothevehiclewireharenss.

5

MountRearLevelSwitch

Partsneededforthisprocedure:

1Rearlevelswitchbracket

1Rearlevelswitchw/harness

ForWorkman3000–4000series

vehicleswithserialnumbers240000001

andup

1.Removelocknutssecuringhitchplatetorearaxle

(Figure6).Usingtheuppersetofmountingholes,

looselymountthelevelswitchbrackettorearaxle

withlocknutsremoved.

Figure6

1.Hitchplate3.Switchharness

2.Levelswitchbracket

2.Routeswitchharnessforward,alongdifferential

lockcabletoleftsideofmachine.Harnessmustnot

interferewithanyhot(exhaust)ormovingparts.

Secureharnesstodifferentiallockcablewithcable

ties.

ForWorkmanHD,HDXandHDX-D

vehicles

1.Removecapscrewssecuringhitchplatetorearaxle

(Figure7).Usingthelowersetofmountingholes,

looselymount2washersandlevelswitchbracketto

rearaxlewithcapscrewsremoved.Thewashersare

tobepositionedbetweenthehitchplateandaxle.

9

Figure7

1.Hitchplate3.Switchharness

2.Levelswitchbracket

2.Routeswitchharnessforward,alongshiftcableto

leftsideofmachine.Harnessmustnotinterferewith

anyhot(exhaust)ormovingparts.Secureharnessto

shiftcablewithcableties.

6

MountLiftontoVehicleFrame

Partsneededforthisprocedure:

2ReinforcingPlate

2Spacertube

2FlangeHD.Capscrew,3/8-16x3inch

2FlangeHD.Capscrew,3/8-16x3–1/2inch

4FlangeHD.Capscrew,3/8-16x1inch

4Flangenut,3/8-16

ForWorkman3000–4000series

vehicleswithserialnumbers240000001

andup

Note:Toinstalltheplatformliftinthemidposition,

theMidMountKitforthePlatformLift,PartNo.

93–3741mustbepurchasedandinstalled.

1.Removeanyaccessoriesmountedtotopofframein

forwardpositionsuchasa1/3bed,powerplatform,

H.D.HitchFrameextensiontubes(Figure8),etc.

Figure8

1.Hitchframeextensiontube

2.Locateandremovethethreadedinsertfromthe

mountingholeinleftandrightvehicleframe

channels,asshowninFigure9.

Figure9

1.Vehicleframechannel2.Threadedinsert

Note:Topreventliftscissorarmsfromexpanding,

pickuptheplatformliftfromthebottomwhen

positioningonframe.

3.Positionliftontoframealigningmountingholeswith

holesinframe(Figure10).

10

Figure10

1.Lift2.Reinforcingplate

4.Mounteachsideoflifttoframechannelswith

areinforcingplateand(2)3/8-16x1inchlarge

angeheadcapscrewsandangenuts(Figure10).

Reinforcingplatestobeusedinrearmountingholes

only.

ForWorkmanHD,HDXandHDX-D

vehicles

Note:Toinstalltheplatformliftinthemidposition,

theMidMountKitforthePlatformLift,PartNo.

93–3741mustbepurchasedandinstalled.

1.Removeanyaccessoriesmountedtotopofframein

forwardpositionsuchasa1/3bed,powerplatform,

H.D.HitchFrameextensiontubes,etc.(Figure8),

Figure11

1.Hitchframeextensiontube

2.Locateandremovethethreadedinsertfromthe

mountingholeinleftandrightvehicleframe

channels,asshowninFigure9.

Figure12

1.Vehicleframechannel2.Threadedinsert

3.Positionaspacertubeontoeachframechannel

aligningmountingholeswithholesinframe

(Figure13).

Figure13

1.Spacertube3.Reinforcingplate

2.Lift

Note:Topreventliftscissorarmsfromexpanding,

pickuptheplatformliftfromthebottomwhen

positioningonframe.

4.Positionliftontospacertubesaligningmounting

holeswithholesintubes(Figure13).

5.Mounttherearofeachsideoflifttotheframe

channelswithareinforcingplate,(2)3/8-16x3–1/2

11

inchangeheadcapscrewsandangenuts.Usethe

(2)3/8-16x3inchangeheadcapscrewsinfront

mountingholes(Figure13).

7

ConnectWires

NoPartsRequired

Procedure

1.Plugrearharnessintoconnectorfromfrontharness.

2.Plugtheconnectorfromtheliftintotheliftharness.

3.Connectgroundwirefromlifttoengineground.

4.Removenutfrompositivebatteryclamp,insert

positivewirefromliftontocableclampscrewand

looselysecurewithnut.

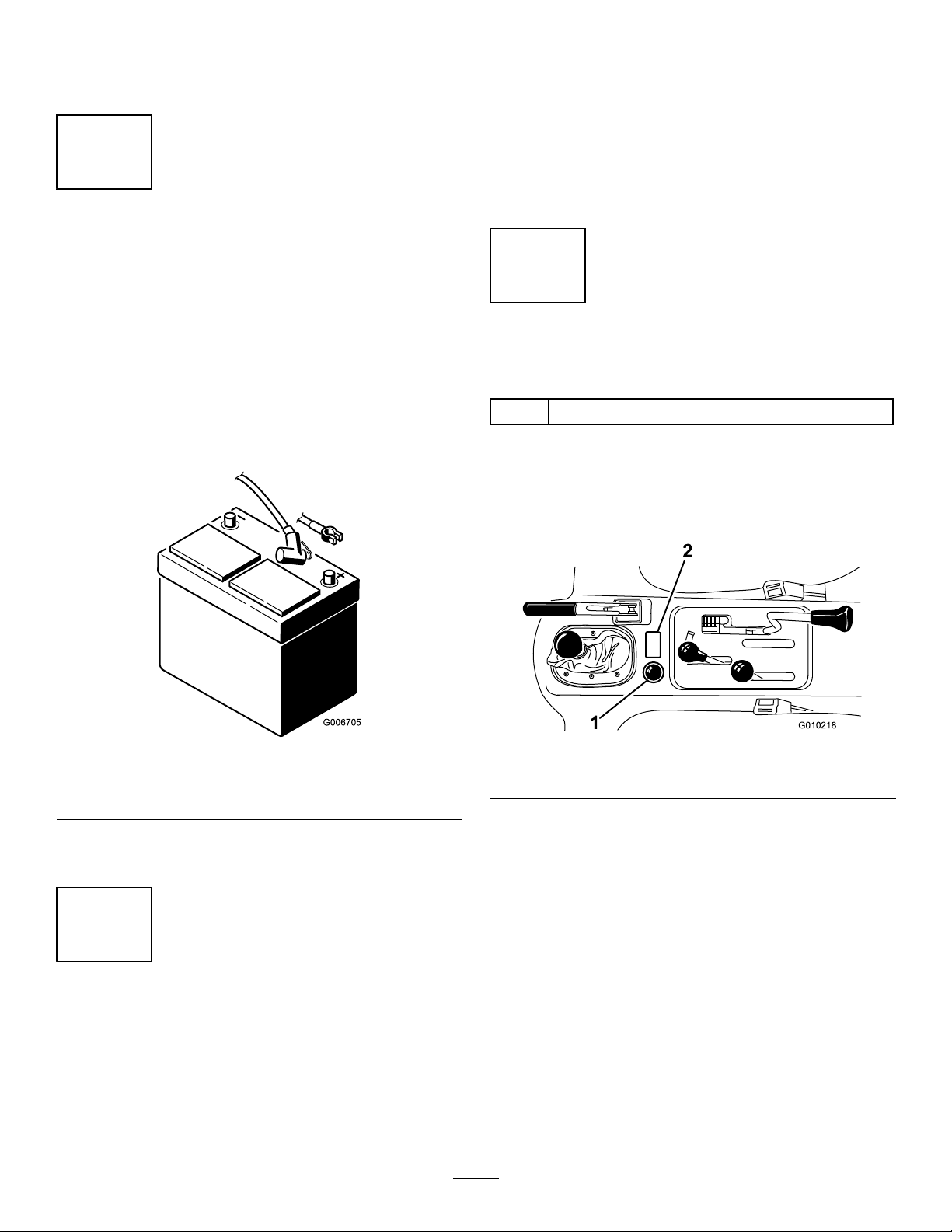

G006705

Figure14

1.Positiveliftwire2.Positivebatterycable

clamp

5.Makesurewiringisclearofallhotorrotatingparts.

Securewithcabletiesasrequired.

8

ReinstallHoodandReconnect

Battery

NoPartsRequired

Procedure

1.Reinstallhoodtoframe.

2.Reinstallshroud,seats,seatframeandconsolecover

plate,ifapplicable.

3.Reinstalloverowtubetoradiator.Checkcoolant

levelandreplenish,ifrequired.

4.Reinstallpositivebatterycabletobattery.

5.Sliderubberbootoverpositiveterminaltoprevent

possibleshort-outfromoccurring.

9

MountCircularBubbleLevel

Partsneededforthisprocedure:

1CircularBubbleLevel

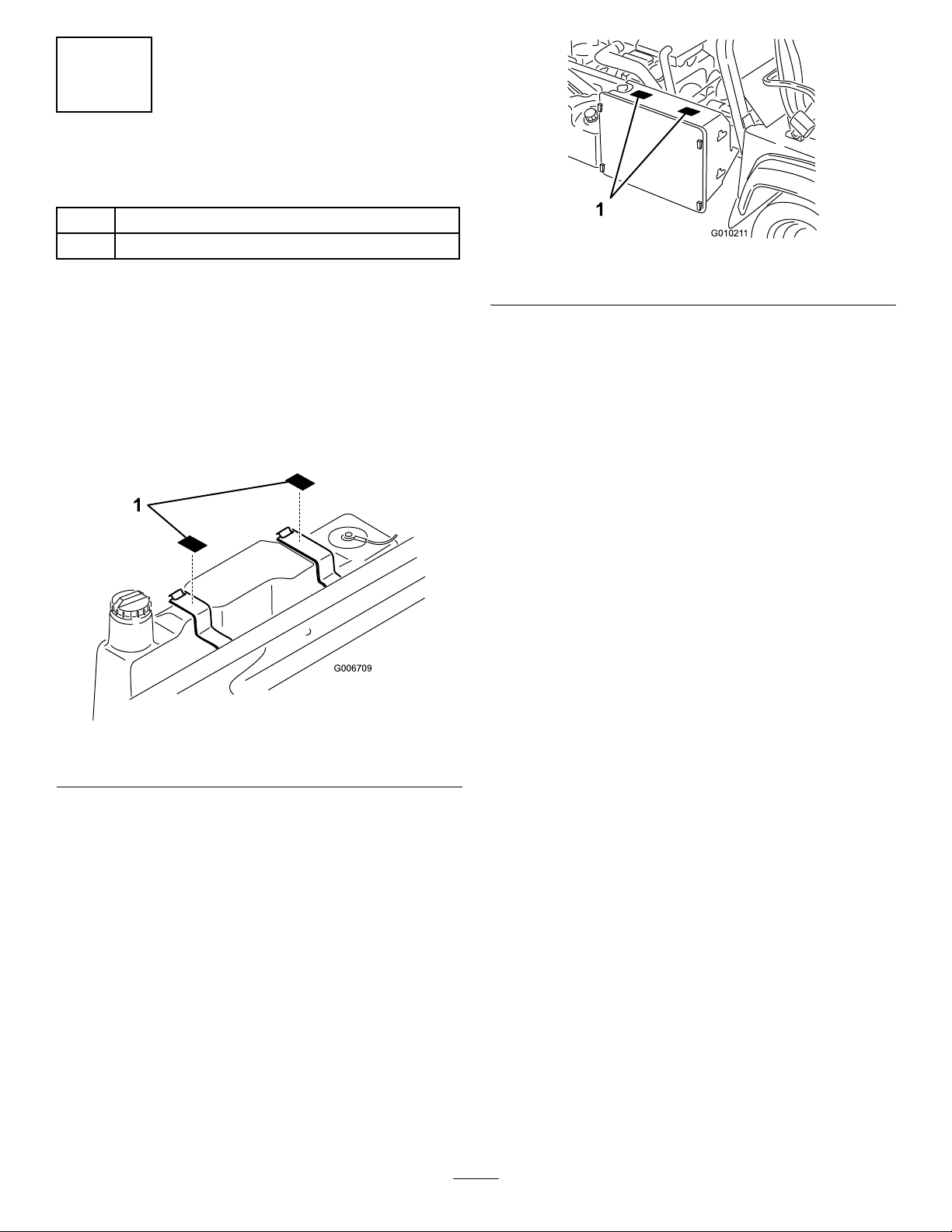

Procedure

Afxcircularleveltotopofconsolecoverpositioning

asshowninFigure15.

G010218

1

2

Figure15

1.Circularlevel2.Operationdecal

12

10

InstallDecals

Partsneededforthisprocedure:

1OperationDecal

2NoStepDecal

ForWorkman3000–4000series

vehicleswithserialnumbers240000001

andup

1.Afxoperationdecaltotopofconsolecover

positioningasshowninFigure15.

2.Afxa"NoStep"decaltotopofeachfueltank

mountingstrap,asshowninFigure16.

Figure16

1.No—Stepdecal

ForWorkmanHD,HDXandHDX-D

vehicles

1.Afxoperationdecaltotopofconsolecover

positioningasshowninFigure15.

2.Afxthe"NoStep"decalstotopofradiator,as

showninFigure17.

G01021 1

1

Figure17

1.No—Stepdecal

13

ProductOverview

Controls

UpButton

Press"UP"buttontoraiselift(Figure18).

DownButton

Press"DOWN"buttontolowerlift(Figure18).

KeySwitch

Rotatekeyswitchtoauthorizeuseoflift.Removekey

fromliftpendantcontrolswitchtopreventoperation

whenunattended.(Figure18).

Figure18

1.Pendantcontrol3.DOWNbutton

2.UPbutton4.Keyswitch

EmergencyLoweringValveKnob

Pushinredknobonsolenoidvalveandrotate180

degreescounter-clockwisetoactivateemergency

loweringvalve.Tostopliftandreturntonormal

operation,pushbuttonin,rotate180degreesclockwise

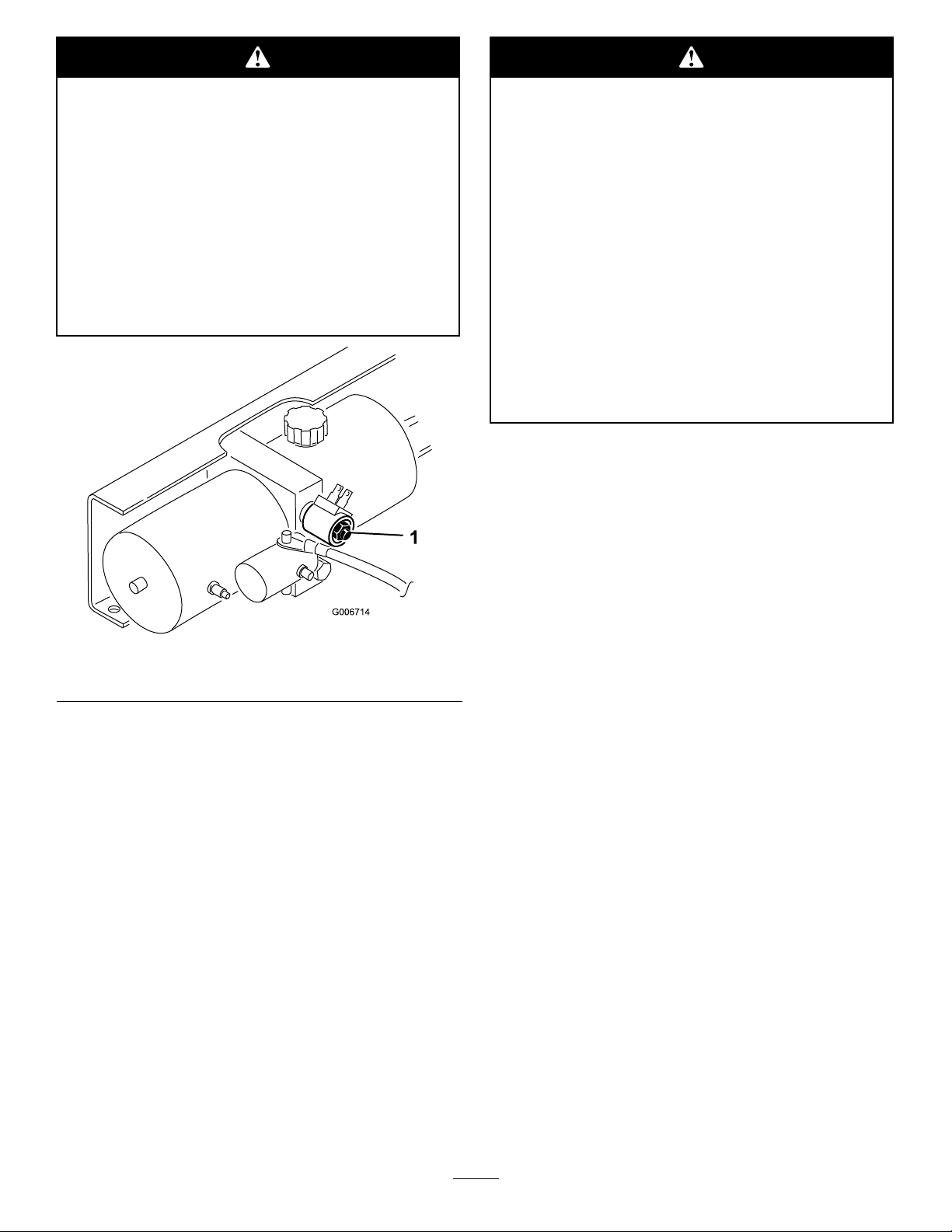

andrelease(Figure19).

Figure19

1.Emergencyloweringvalveknob

14

Operation

CheckOilLevel

TheliftreservoirislledatthefactorywithDTE13

hydraulicoil.Checklevelbeforeliftisrstoperatedand

every8hoursordaily,thereafter.Capacityofsystem

is1.5qt.

1.Positionthevehicleonalevelsurface.

2.Raiseliftandinstallsafetyblocks.Refertothe

InstallingSafetyBlockssectionandtheOperation

chapter.

Note:Ifliftcannotberaised,duetolackofoilin

reservoir,itmayberaisedwithahoistandsafety

blocksinstalled,toexposereservoirbreathercap.

3.Cleanareaaroundreservoirbreathercap(Figure20).

Figure20

1.Reservoircap

4.Unscrewbreathercapfromtopofreservoir.

5.Insertacleanrodorstickintoreservoirandcheck

uidlevel.Fluidshouldbewithin2inchesfromtop

ofreservoir.Iflevelislow ,addenoughDTE13

hydraulicoiltoachievetheproperlevel.DONOT

OVERFILL.

Note:IfDTE13hydraulicoilisnotavailable,

DTE24orDextronllATFmaybesubstituted.

Fluidsmaybemixed,afterinitialllofreservoir.

Note:AlwaysuseDTE13,DTE24,orequivalent

ISOViscosityGrade32oilswhenreservoirmustbe

completelyrelledorifcoldweatherisexpected.

Theuseofotheruidsmayinhibittheoperation

ofthelift.

CheckTirePressure

Checktirepressureevery8hoursordailytoassure

properlevels.

Refertothevehicleoperator’smanualforpropertire

inationspecication.

InstallingSafetyBlocks

1.Positionthevehicleonalevelsurface.

2.Setparkingbrakeandchockwheels.

3.Rotatevehiclekeyswitchto"Off"position.

4.Whilestandingnexttomachine,grasppendant

controlandrotateliftkeyswitchto"On"position.

Checkoverheadclearanceandforanyobstructions.

5.Press"UP"buttontoraiselifthighenoughtoinstall

safetyblocks.Standclearofscissorarmswhile

platformismoving.

Contactwithmovingscissorarmscancause

personalinjury.

•Standclearofscissorarmswhileplatform

ismoving.

•Makesureareaisclearofbystandersbefore

loweringplatform.

•Neverworkunderraisedplatformwithout

liftsafetyblocksinstalled.

•Alwaysremovekeyfromliftcontrolbox

whenplatformisnotinuse.

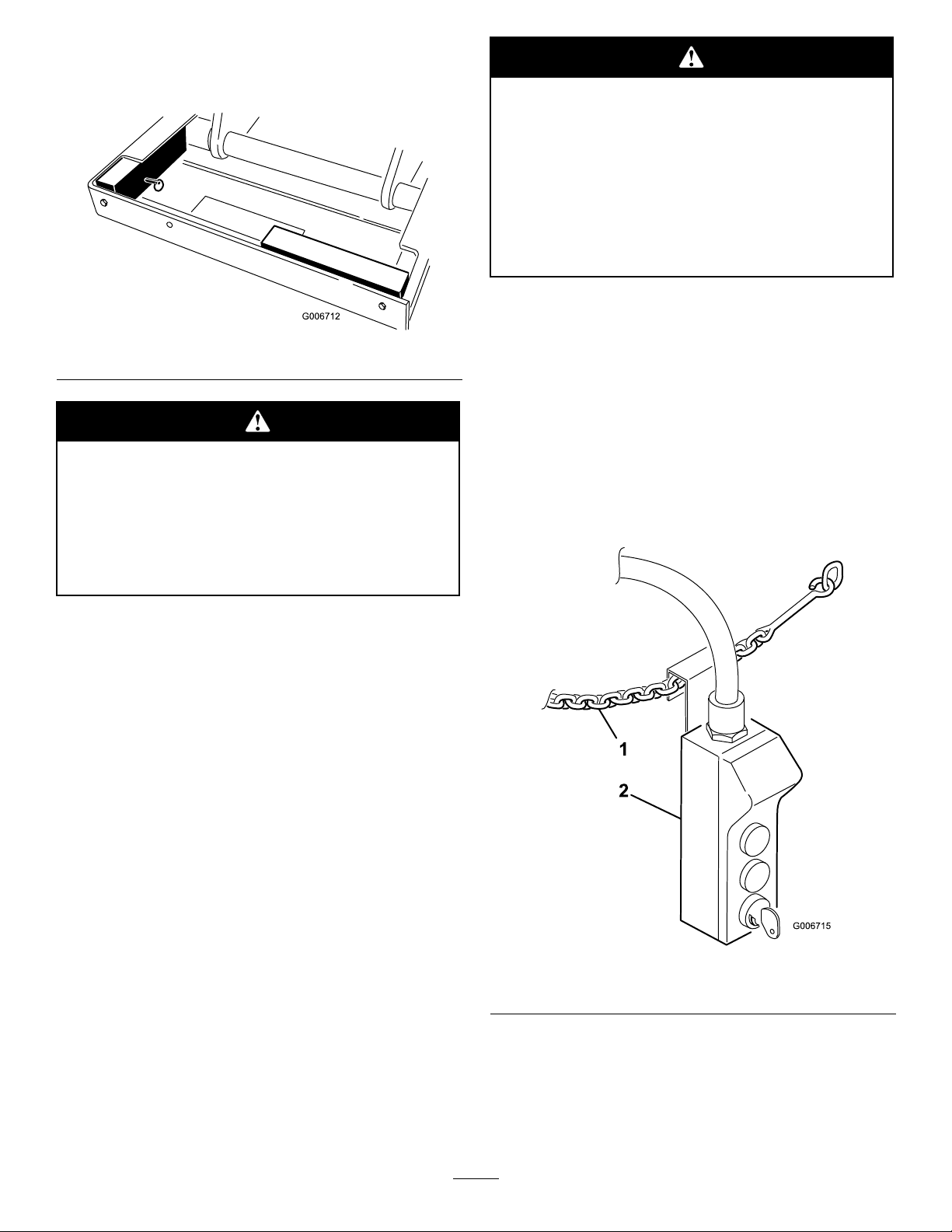

6.Removeretainingpinssecuringsafetyblockstoside

ofliftframe(Figure21).

Figure21

1.Safetyblock2.Retainingpin

15

7.Rotatesafetyblocks90degreesinchanneland

securetoendsofliftframewithretainingpins

(Figure22).

Figure22

Platformliftcancrushandcausepersonal

injury.

•Neverworkunderraisedplatformwithout

liftsafetyblocksinstalled.

•Neverusesafetyblockstosupportaload

onlift.

8.Press"DOWN"buttononpendantcontroland

lowerliftuntilrollersgentlycontactsafetyblocks.

9.Toremovesafetyblocks:

•Raiseliftslightly.

•Removeretainingpins.

•Returnsafetyblockstostorageposition.

•Securewithretainingpins.

OperatingtheLift

The1/3platformliftisdesignedtobeusedonlywith

aWorkmanVehicleandmustbemountedwiththe

wiringharness,level,decals,switchesandallinterlock

switchesinstalled.

Improperoperationofplatformliftmaycause

seriouspersonalinjuryordeath.Toreducerisk

tooperatorandbystanders:

•Readandunderstandallsafetyinstructions

inWorkmanandPlatformLiftOperator’s

Manualsandwarninglabels.

•Neveruseaplatformliftwithoutproper

trainingandauthorization.

Theelectricalcontrolsystemoftheliftrequiresthe

vehicletobeparkedonaslopeoflessthana5degree

angle,parkingbrakeengagedandthevehiclekeyinthe

“Off”positioninordertoactivatetheliftcircuit.

Operating

1.Setparkingbrakeandchockwheels.

2.Rotatevehiclekeyswitchto"Off"position.

3.Climbintoplatformandsecuresafetychainsacross

entry(Figure23).

Figure23

1.Safetychain2.Pendantcontrol

4.Grasppendantcontrolandrotateliftkeyswitchto

"On"position.

5.Press"UP"buttontoraiselift;"DOWN"button

tolowerlift.

16

Operationofplatformliftwithoutparkingbrake

engagedcanresultintip-overandpersonal

injury.

•Alwaysapplyparkingbrakebeforeoperating

platformlift.Theuseofwheelchocksis

recommended.

•Donotreleaseparkingbrakewhileplatform

liftisraised.

•Donotraisetheplatformliftifthebubbleis

outsideoftheoperatingregiononthelevel

indicator.

Lossofcontrolortip-overwillresultifvehicle

ismovedwithplatforminraisedpositionand

maycauseseriouspersonalinjurytooperator

orbystanders.

•Nevermovevehiclewhileplatformisraised.

•Alwaysapplyparkingbrakebeforeraising

platform.Wheelchockuseisrecommended.

•Neverreleaseparkingbrakewhileplatform

israised.

•Checksafetyinterlocksbeforeeachuseof

platform.Seeoperator’smanualforsafety

interlockcheckinstructions.

•Neverbypasssafetyinterlocks.

•Neverallowridersonplatforminany

position.

Ifliftdoesnotoperate:

•Makesurevehiclekeyandliftkeyarein"Off"

position.

•Makesurevehicleisparkedonlessthana5

degreeangleslope.

•Makesurevehicleparkingbrakeis"On".

6.Whennishedwithworkoperation,lowerliftallthe

waydowntostopsandremovekeyfromliftpendant

controltopreventoperationwhenunattended.

Important:Ifenginekillswhenreleasing

parkingbrake,itmayindicatethatliftisnot

completelylowered.Vehiclecannotbedriven

withliftraisedatanyheight.

Contactbetweennon-insulatedplatformlift

andpowerlineswillcauseelectrocution.

•Electrocutionwillcauseseriouspersonal

injuryordeath.

•Neveruseplatformliftnearpowerlines.

•Neverallowplatformlifttotouchpower

lines.

•Ifpowerlinecontactoccurs:

–Lowerunitawayfromcontactifpossible.

–Donottouchpowerline.

–Nevertouchgroundwhiletouching

platformliftorpowerline.

–Jumpclearifnecessary,withouttouching

platformliftorpowerline.

•Ifoperatingplatformliftnearelectrical,high

pressureoranytypeofrotatingequipment:

–Alwaysdisconnectpowertothat

equipment.

–AlwaysuseOSHAapprovedlock-out

devices.

•Neverusetheplatformliftduringathunder

orlightningstorm.

Lowertheplatformliftandavoidopenareas

intheeventofthreateningweather.

EmergencyLowering

1.Reachintoaccessopeningonlytoactivate

emergencyloweringvalve.

2.Pushinredknobonsolenoidvalve(Figure24)and

rotate180degreescounter-clockwisetoactivate

emergencyloweringvalve.

17

Contactwithmovingscissorarmscancause

personalinjury.

•Standclearofscissorarmswhileplatform

ismoving.

•Makesureareaisclearofbystandersbefore

loweringplatform.

•Neverworkunderraisedplatformwithout

liftsafetyblocksinstalled.

•Alwaysremovekeyfromliftcontrolbox

whenplatformisnotinuse.

Figure24

1.Emergencyloweringvalveknob

3.Tostopliftandreturntonormaloperation,push

buttonin,rotate180degreesclockwiseandrelease.

Fallingorjumpingfromraisedplatformwill

causepersonalinjury.

•Securebothhandrailsnapchainsacross

openingbeforeraisingplatform.

•Neverpullonobjectswhilereachingfrom

raisedplatform.

•Neverreachoverhandrailsunlessbothfeet

areonplatformdeck.

•Neverstepabovelevelofplatformdeckor

useladders,steprisersorplatformrailsto

extendworkingheightofplatform.

•Ifyoumustexitraisedplatform,slowlyand

carefullyclimbdownoutsideofscissorarm

frame.

OperatingTips

Theelectricalsystem,batteryandhydraulicliftcylinder

arenotdesignedforcontinuoususe.Allowsome

time,approximately1-1/2to2minutes,betweenlift

operationstomaintainoperatingtemperatures.

Frequentusewithouttheenginerunningoridling,

betweenliftuse,maydischargethebattery.Ifengine

operationisnotpossibletokeepbatterycharged,it

maybenecessarytosupplementoperationwithanover

nightbatterycharger.

Checkthespecicgravityoftheuidinthebatteryto

assureitisfullycharged.RefertoBatteryCaresection.

18

Tip-overofWorkmanVehiclewhileplatformis

raisedwillresultinpersonalinjurytooperator

and/orbystanders.

•Alwaysparkvehicleonrm,levelsurface

beforeraisingplatform.

•Neverexceed5degreemaximumangleof

operation.

•Neverraiseplatformifbubblelevelindicator

isoutsiderecommendedoperatingrange.

•Neverraiseplatformifoneormorevehicle

tiresunderinated;checktirepressuredaily.

•Neverpullonobjectswhilereachingfrom

raisedplatform.

•Neveruseplatformforcarryingorlowering

treelimbs,branchesorheavyoruneven

loads.

•Neverexceedcapacityofplatformlift(one

personwithequipmentnottoexceed600

lbs.)

•Neverraiseplatformduringhighwindsor

threateningweather.

•Neverby-passsafetyinterlocks.

•Neverallowridersonplatforminany

position.

Note:Toprailofplatformliftishigherthanvehicle

ROPSsobealerttolowoverheadareaswhen

transporting(driving)vehicle.

Fallingobjectsandoverheadobstructionscan

causepersonalinjury.

•Alwayswearhardhatandeyeprotection

whileoperatingplatformorwhileinarea

belowplatform.

•Neverdroporthrowarticlesfromraised

platform.

•Whenraisingplatformbealertforoverhead

obstructionswhichcouldcauseeye,head

orcrushinginjuries.

19

Maintenance

CheckSafetyCircuits

Theelectricalsafetycircuitsoftheliftrequirethevehicle

tobeparkedonaslopeoflessthan5degrees,parking

braketobeengagedandtheignitionkeyoffinorder

toactivatetheliftcircuit.

Toverifyparkingbrakeswitch

operation:

1.Positionthevehicleonalevelsurface,setparking

brakeandchockwheels.

2.Rotatevehiclekeyswitchto"Off"position.While

standingnexttomachine,grasppendantcontroland

rotateliftkeyswitchto"On"position.Press"UP"

buttonandraiseliftafewinches.Releasebutton.

3.Releaseparkingbrakeandtrytoraiseliftagain.Lift

mustnotrise.Ifliftdoesnotraise,safetycircuitis

operatingcorrectlyandproceedtonextstep.Iflift

risesthereisamalfunctionintheelectricalcircuit

thatmustberepairedbeforeoperatinglift.

4.Withtheplatformpartiallyraisedandparkingbrake

released,trytostartengine.Ifenginedoesnot

startandremainrunning,safetycircuitisoperating

correctly.Lowerliftallthewayandproceedtonext

step.Ifenginestartsandremainsrunningthereis

amalfunctionintheelectricalcircuitthatmustbe

repairedbeforeoperatinglift.

Toverifyrearaxlelevelswitch

operation:

1.Positiononesideofvehicle(rearaxle)onaslope

greaterthan5degrees(oorjack,moundofmaterial

orsmallhill).

2.Setparkingbrakeandchockwheels.

3.Rotatevehiclekeyswitchto"Off"position.While

standingnexttomachine,grasppendantcontroland

rotateliftkeyswitchto"On"position.Press"UP"

buttonandtrytoraiselift.Ifliftdoesnotraise,

safetycircuitisoperatingcorrectly.Raiseopposite

sideofmachineandrepeatprocedure.Ifliftrises,

witheithersideofmachineinraisedposition,there

isamalfunctionintheelectricalcircuitthatmustbe

repairedbeforeoperatinglift.Lowerliftimmediately.

BatteryCare

1.Batteryelectrolytelevelmustbeproperlymaintained

andthetopofthebatterykeptclean.Ifthemachine

isstoredinalocationwheretemperaturesare

extremelyhigh,thebatterywillrundownmore

rapidlythanifthemachineisstoredinalocation

wheretemperaturesarecool.

2.Keeptopofbatterycleanbywashingperiodically

withabrushdippedinammoniaorbicarbonateof

sodasolution.Flushthetopsurfacewithwaterafter

cleaning.Donotremovethellcapwhilecleaning.

3.Batterycablesmustbetightonterminalstoprovide

goodelectricalcontact.

4.Ifcorrosionoccursatterminals,removebattery

cover,disconnectcables,negative(-)cablerstand

scrapeclampsandterminalsseparately.Reconnect

cables,positive(+)cablerstandcoatterminals

withpetroleumjelly.

5.Checktheelectrolytelevelevery50operatinghours

or,ifmachineisinstorage,every30days.

6.Maintaincelllevelwithdistilledordemineralized

water.Donotllcellsabovethebottomofthell

ringinsideeachcell.

7.Ifthemachinewillbestoredformorethan30

days,removethebatteryandchargeitfully.Either

storeitontheshelforonthemachine.Leavethe

cablesdisconnectedifstoredonthemachine.Store

thebatteryinacoolatmospheretoavoidquick

deteriorationofthechargeinthebattery.Toprevent

batteryfromfreezing,makesureitisfullycharged.

Thespecicgravityofafullychargedbatteryis

1.250.

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonanditcausessevereburns.

•Ifyoucarelesslydrinkelectrolyteyoucould

dieorifitgetsontoyourskinyouwillbe

burned.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.

•Wearsafetyglassestoshieldyoureyesand

rubberglovestoprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

•Followallinstructionsandcomplywithall

safetymessagesontheelectrolytecontainer.

20

Table of contents

Popular Lifting System manuals by other brands

R. Beck Maschinenbau

R. Beck Maschinenbau HS 600 operating manual

Ravaglioli

Ravaglioli KP 1396 E manual

Reechcraft

Reechcraft PowerLift PL50 Operators safety manual

AUTEC

AUTEC ALM-6040FL User & installation manual

Braun

Braun Millennium 2 AD NL Series Service manual

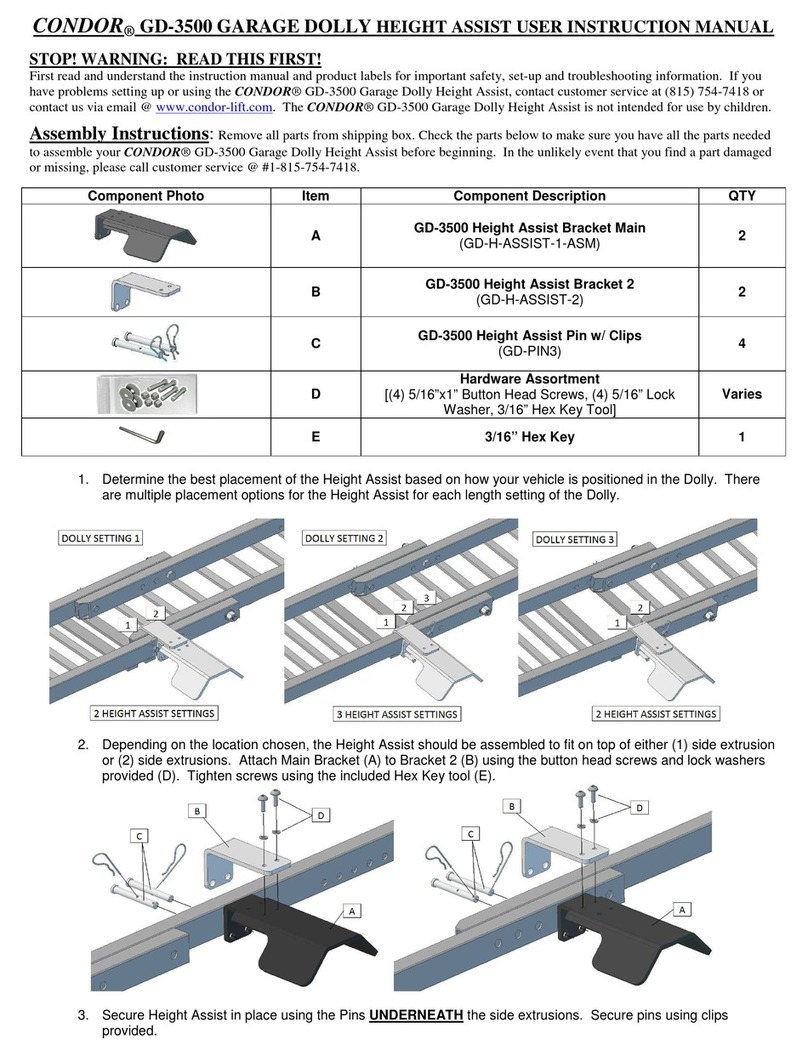

Condor

Condor GD-3500 User instruction manual