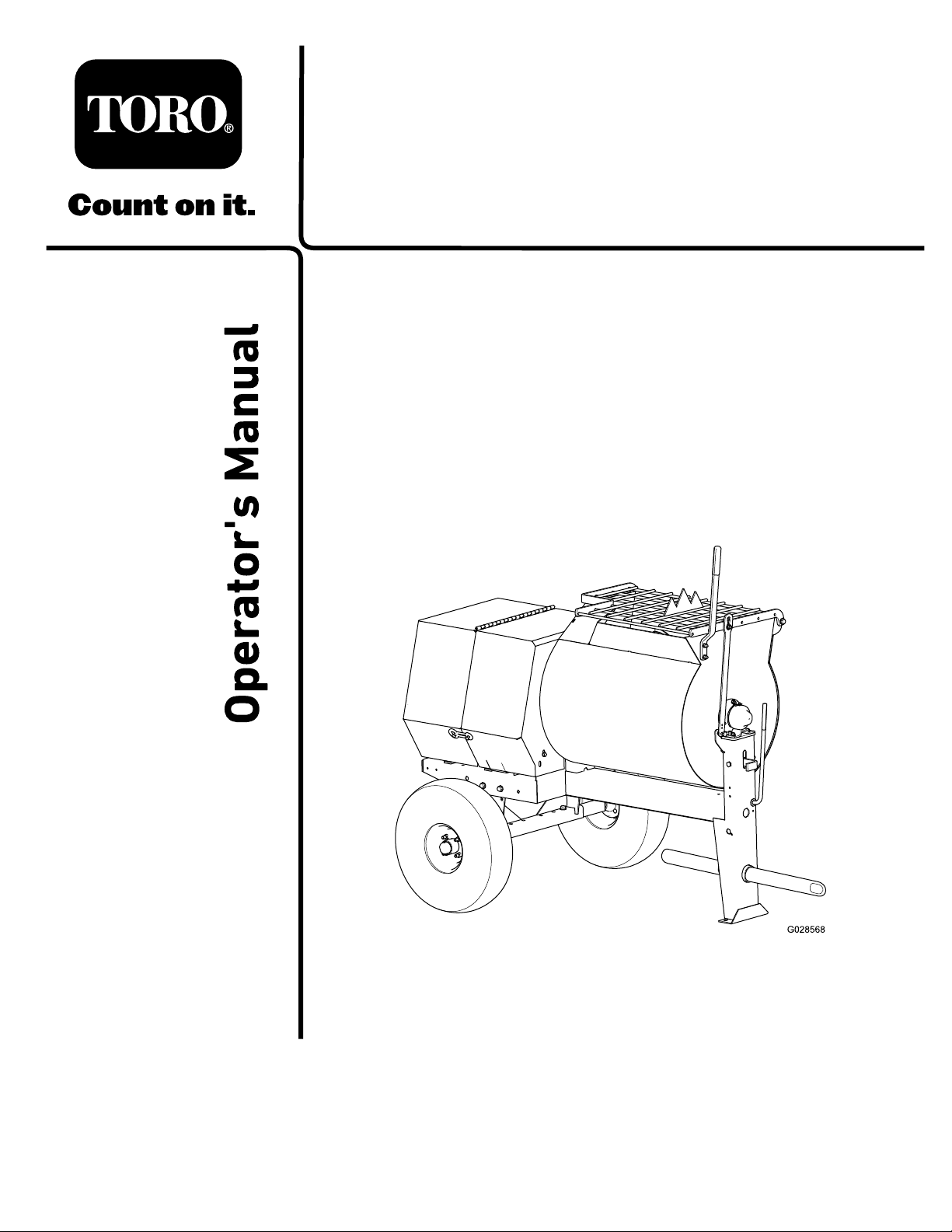

Toro MMX-650E-S User manual

FormNo.3429-703RevA

MMX-650E-SandMMX-850E-S

MortarMixers

ModelNo.60212—SerialNo.404320000andUp

ModelNo.60218—SerialNo.404320000andUp

ModelNo.60219—SerialNo.404320000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3429-703*A

WARNING

CALIFORNIA

Proposition65Warning

Thepowercordonthisproductcontains

lead,achemicalknowntotheState

ofCaliforniatocausebirthdefects

orotherreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisdesignedtomixmortar,plaster,

reproongmaterial,grout,andothersmall-grained

cementproducts.Avehicleequippedwithan

appropriatepintlehitchorballhitchcantowthe

machine..

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Writethe

numbersinthespaceprovided.

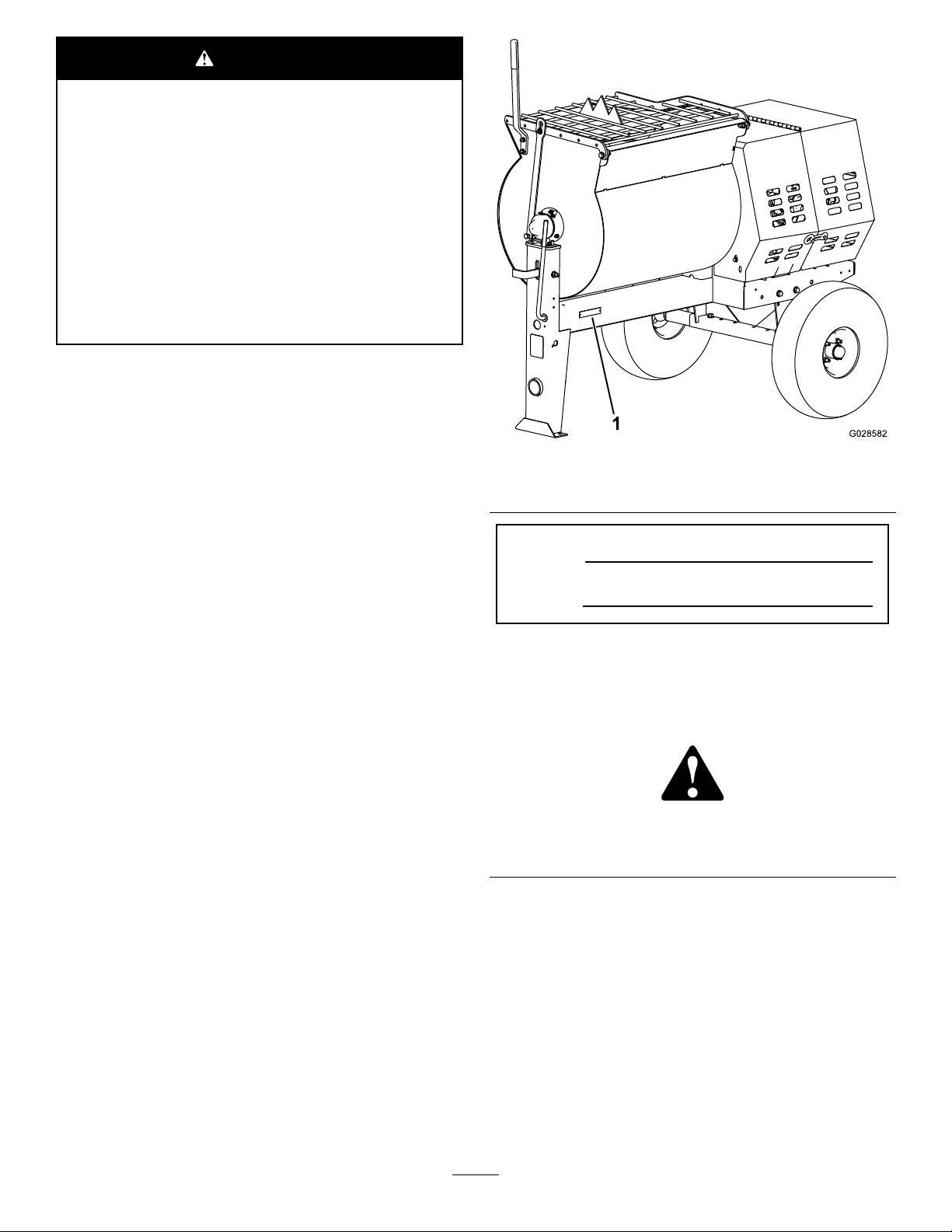

g028582

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesameor

betterratings.

Note:Thevariousmachinesinthismanualhave

differentweights;refertoSpecications(page12)to

ensurethatthetiresonyourmachinemeetorexceed

theweightrequirementsofyourmachine.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

SafeOperatingPractices....................................3

SafetyandInstructionalDecals..........................7

Setup........................................................................8

1InstallingtheDumpHandle..............................8

2InstallingtheT owPole.....................................8

3InstallingtheSafetyChain...............................9

4AdjustingtheMixingPaddles.........................10

ProductOverview...................................................10

Controls............................................................11

Specications..................................................12

Operation................................................................14

PreparingtoT owtheMachine...........................14

ExtendingtheAxle............................................17

TowingtheMachine..........................................18

PreparingtoUsetheMachine...........................18

OpeningandClosingtheCowl..........................19

PoweringtheMachine......................................20

StartingandStoppingtheMotor........................21

ControllingthePaddles.....................................21

MixingtheMaterial...........................................22

UsingtheDrum.................................................24

Maintenance...........................................................25

RecommendedMaintenanceSchedule(s)...........25

Pre-MaintenanceProcedures..............................25

PreparingtheMachineforMaintenance............25

RemovingandInstallingtheDivider

Plate..............................................................25

Lubrication..........................................................26

LubricatingtheBearingsandSeals...................26

LubricatingtheMotorBearings.........................27

LubricatingtheDriveChain...............................28

BeltMaintenance................................................28

ServicingtheBelts............................................28

ReplacingtheBelts...........................................29

AligningthePulleys..........................................31

DriveChainMaintenance.....................................32

CheckingandAdjustingtheDrive

Chain............................................................32

PaddleMaintenance............................................33

AdjustingthePaddles.......................................33

Cleaning..............................................................35

CleaningtheMachine.......................................35

Storage...................................................................35

StoringtheMachine..........................................35

Troubleshooting......................................................36

Schematics.............................................................37

Safety

Improperlyusingormaintainingthemachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

means:Caution,Warning,orDanger—personal

safetyinstruction.Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Always

followallsafetyinstructionstoavoidseriousinjuryor

death.

WARNING

Machiningorhandlingstone,masonry,

concrete,metal,andothermaterialscan

generatedust,mists,andfumescontaining

chemicals,suchassilica,knowntocause

seriousorfatalinjuryorillness,suchas

respiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Watershouldbeusedfor

dustsuppressionwhenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupational

andtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannot

beeliminated,theoperatorandany

bystandersshouldweararespirator

approvedbyOSHAforthematerialbeing

handled.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readorunderstandtheinformation,itisthe

owner'sresponsibilitytoexplainthismaterialto

them.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

3

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmay

restricttheageoftheoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriestopeopleordamageto

property.

Towing

Checkwithyourlocalcountyorstatetowingsafety

regulationsbeforetowingthemachine.

•Inordertoreducethepossibilityofanaccident

whiletransportingthemachineonpublicroads,

makesurethetowingvehicleismechanically

soundandingoodoperatingcondition.

•Turnoffthemotorbeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheball

hitchyouareusingisthepropersizeforthehitch

coupleronthemachine.

•Whentowingwithapintlehitch,ensurethatthe

eyeofthetowpoleisthecorrectdimensionfor

thepintlehook.

•Inspectthehitchandcouplingforwear.Nevertow

themachinewithdamagedordefectivehitches,

couplings,chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicle

andthemachine.

•Checkthetiretreadandsidewallfordamageand

wear.

•Properlyattachthesafetychainstothetowing

vehicle.

•Ensurethatthedirectionalandbrakelightsare

workingproperly(ifthemachineisequippedwith

thelightkit).

•Ensurethatthedirectional,backup,andbrake

lightsofthetowvehicleareworkingproperly.

•Beforetowing,checktomakecertainyour

machineiscorrectlyandsecurelyattachedtothe

towingvehicle.

•Ensurethatthesafetychainsareproperlysecured

tothevehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhen

towing.

•Avoidsuddenstopsandstarts.Thiscancause

skidding,orjackkning.Smooth,gradualstarts

andstopswillimprovetowing.

•Avoidsharpturnstopreventrolling.Towonlywith

avehiclethathasahitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitch

point.

•Donottowthemachinefasterthan88km/h(55

mph).

•Usecautionwhenbackingup;useaspotter

outsidethevehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

Preparation

Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

4

•Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearpersonalprotectiveequipmentand

appropriateclothingincluding:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesthataretightatthe

wrists

–Tight-ttinggloveswithoutdrawstringsorloose

cuffs

•Securelonghair,looseclothing,orjewelrythat

maygettangledinmovingparts.

•Operatingtheequipmentsafelyrequiresthefull

attentionoftheoperator.Donotwearradioor

musicheadphoneswhileoperatingthemachine.

•Ensurethatthemachineisonalevelsurface

beforeoperatingthemachine.

•Chockthetiresofthemachinetoprevent

unintendedmovement.

•Beforeeveryuse:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly(if

themachineisequippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

Operation

•Neverrunthemachineinapoorlyventilated

orenclosedareawithoutproperrespiratory

protection.Dustfrommaterialsbeingmixedcan

beveryharmfultooperatorsandbystanders.

•Onlyoperatethemachineingoodlighting

conditions.

•Beforestartingthemachine,makesurethatthere

arenopersonsorobstaclesnearorunderthe

machine.

•Neverleavearunningmachineunattended.

Alwaysstopthemotorandverifythatallmoving

partshavestopped.

•Chockthetireswhenusingthemachine.

•Whennotusingthemachine,chockthetiresor

keepitattachedtothetowvehicle.

•Keephandsawayfromanymovingparts.Keep

feetawayfromthetiresandthefrontpost.

•Donotoperatethemachineoutdoorsintherain.

•Donotoperatethemachineundertheinuence

ofalcoholordrugs.

•Ensurethattheareaisclearofotherpeopleor

petsbeforeoperatingthemachine.Stopthe

machineifanyoneentersthearea.

•Neverplaceyourhandsoranysolidobjectintothe

drumwhenthemachineisinoperation.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservicethemachine.

•Nevermovethemachinewhilethemotoris

running.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurely

inplacebeforeoperatingthemachine.

•EnsurethattheON/OFFswitchisintheOFF

positionbeforeconnectingthemachinetothe

electricalsource.

•Ifthemixingpaddlesstrikeaforeignobjectorif

themachineshouldstartmakinganunusualnoise

orvibration,stopthemotorandemptythedrum.

Waitforallmovingpartstocometoacomplete

stopandcool.Vibrationisgenerallyawarningof

trouble.Inspectforcloggingordamage.Clean

andrepairand/orreplacedamagedparts.

•Lightningcancausesevereinjuryordeath.Ifyou

seelightningorhearthunderinthearea,donot

operatethemachine;seekshelter.

5

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

–Stopthemotor.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

–Letthemotorcoolbeforeperforming

maintenanceorstoringthemachine.

–Unplugthemachinebeforemakinganyrepairs.

•Neverlubricate,service,repair,oradjustthe

machinewhileitisrunning.

•Keepequipmentmaterialsclearfromthemotor.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Keephands,feet,andclothingawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

themotorrunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Removeanybuildupofgrease,oil,ordebrisfrom

themachine.

•Donotmodifytheelectricalconnectorsorwiring.

•Donotconnectthegroundcircuitofthemachine

totheenergizedcircuitoftheelectricalsource.

•Donottamperwithsafetydevices.

•Chockthetireswhenstoringthemachine.

•Keepallnuts,bolts,screws,andhoseclamps

securelytightened.Keepequipmentingood

condition.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty..

6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedorlost.

decal125-8175

125–8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

decal125-8216

125–8216

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

2.Warning—limittowing

speedtolessthan55mph

/88km/h.

decal133-8062

133-8062

decal127-1652

127–1652

1.Warning—readthe

Operator’sManual.

3.Entanglementhazardat

paddles—stopthemotor

andwaitforallmoving

partstostopbefore

servicingthemachine.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandsafetiesin

place.

4.Shockhazard—makesure

themachineisgrounded

beforeoperation.

7

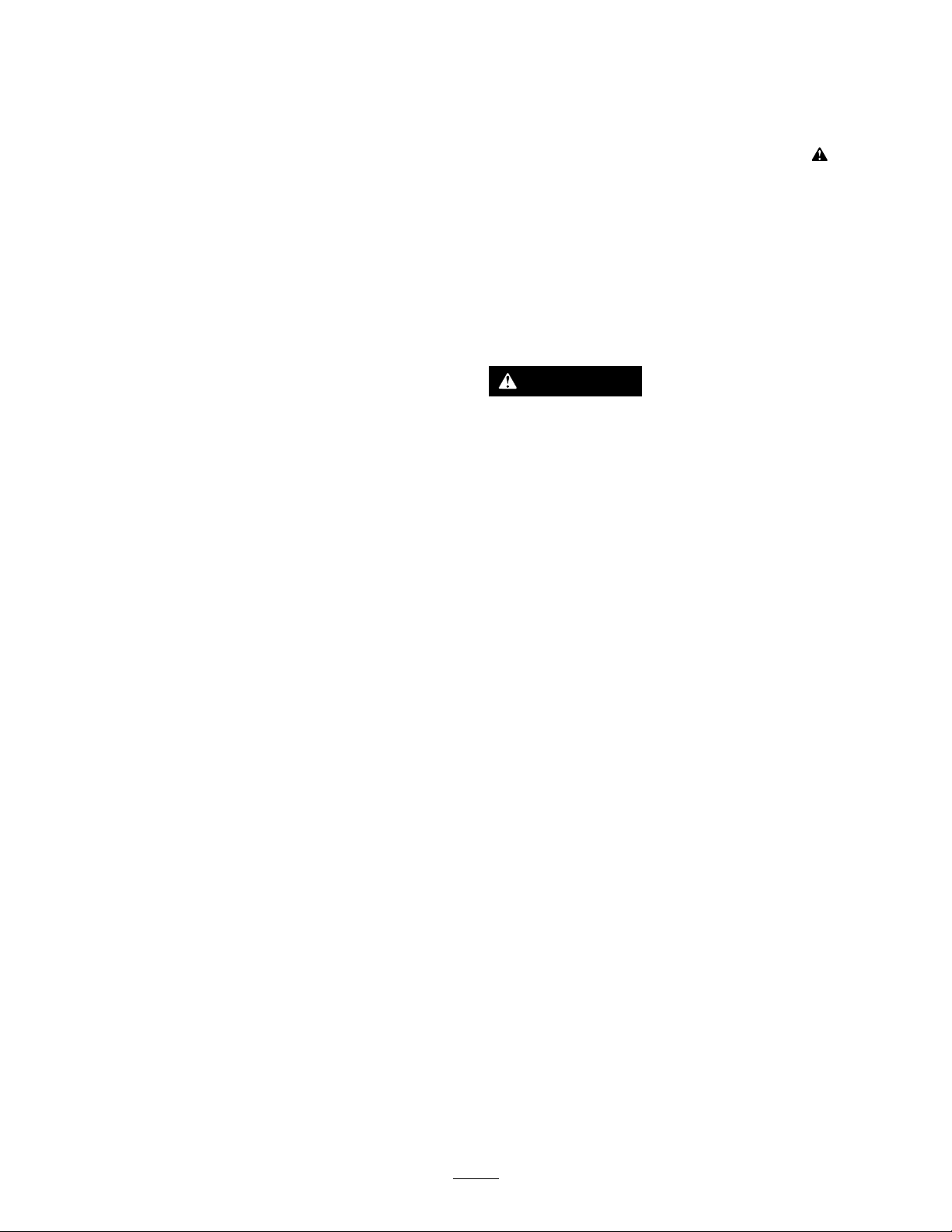

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

Dumphandle1

Bolt2

1Nut2

Installthedumphandle.

2Towpolekit(soldseparately)1Installthetowpole.

Safetychain(soldwithoptionaltowpole

kit)1

3Connectinglink(soldwithoptionaltow

polekit)2

Installthesafetychain.

4Nopartsrequired–Adjustingthemixingpaddles.

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2Bolt

2Nut

InstallingtheDumpHandletothe

Drum

1.Cutthecabletiestoremovethedumphandle

fromtheundersideofthegrate.

2.Positionthedumphandlesothattheboltholes

alignwiththeboltholesinthedrum(Figure3).

g028569

Figure3

3.Insert1carriageboltintothesquarebolthole

andslidethecorrespondingholeofthedrum

handleoverit(Figure3).

4.Installanutontothebolt,andtightenit.

5.Repeatthepreviousstepsfortheremaining

carriagebolt.

8

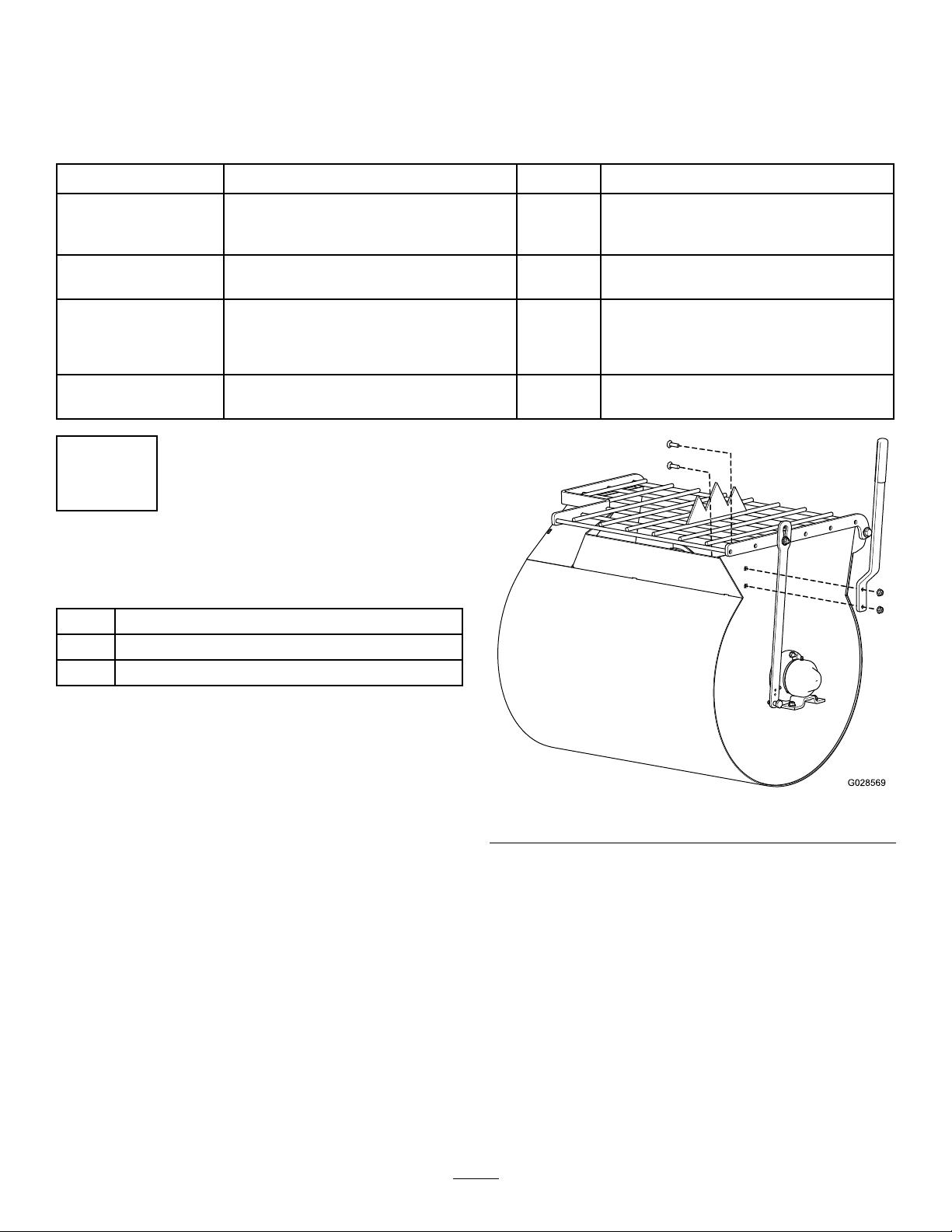

2

InstallingtheTowPole

Partsneededforthisprocedure:

1Towpolekit(soldseparately)

InstallingtheTowPoletothe

Machine

Note:Thetowpoleispurchasedseparatelyand

includesthenutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

HitchTypeLength

50mm(2inch)ball—stamped78.7cm(31inches)

50mm(2inch)ball—forged78.7cm(31inches)

Pintle78.7cm(31inches)

1.Removetheboltandnutfromthetowpole

(Figure4).

g019804

Figure4

1.Towpole4.Bolthole

2.Frontpost5.Frametting

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholein

thepolewiththeholeintheframetting(Figure

4).

3.Inserttheboltthroughtheholesinthettingand

thepole(Figure4).

4.Threadthenutontotheboltandtightenthem

untiltheyaretightagainsttheframetting

(Figure4).

Note:Iftheself-lockingnyloninsertinthe

locknutwearswithuse,replacethenutwitha

newGrade5orGrade8locknut.

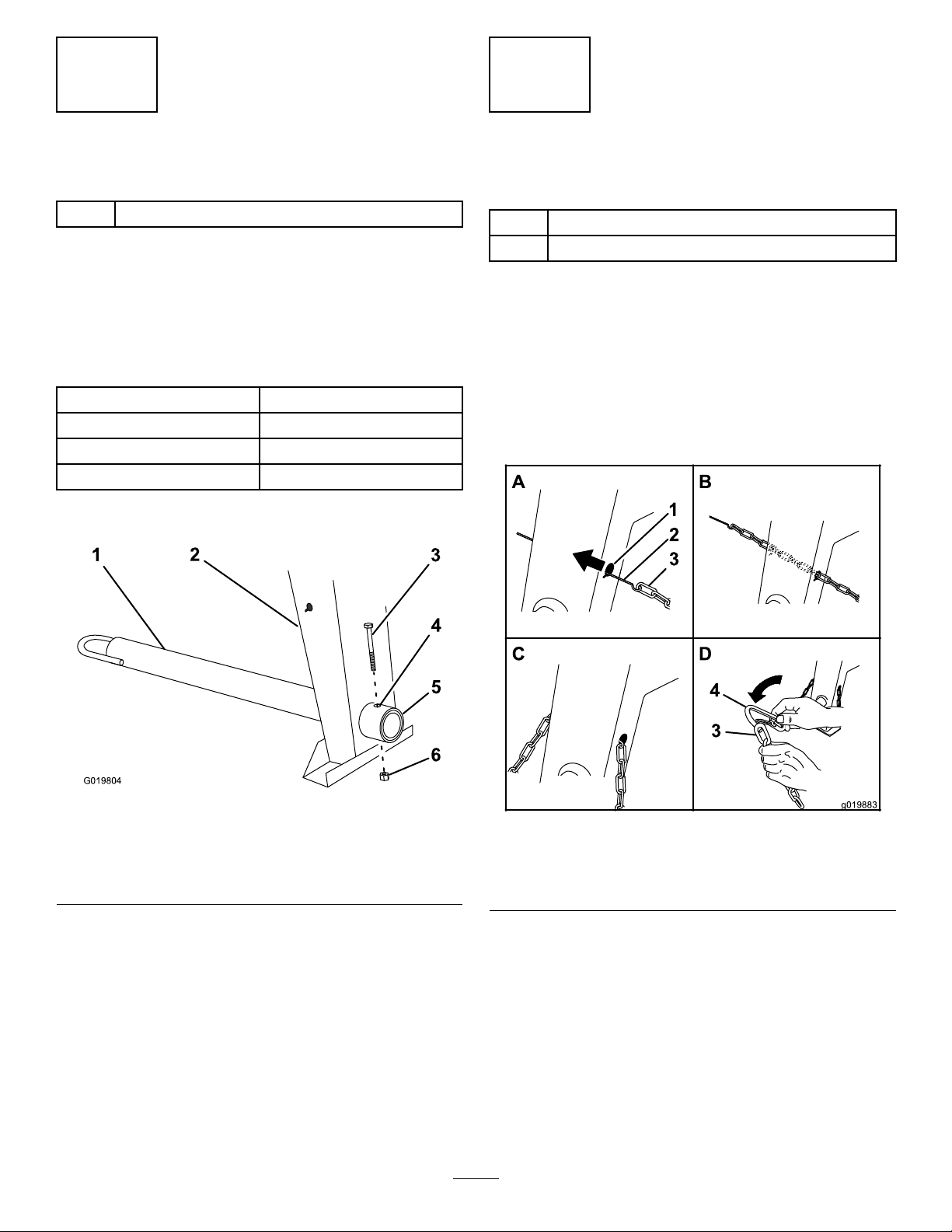

3

InstallingtheSafetyChain

Partsneededforthisprocedure:

1Safetychain(soldwithoptionaltowpolekit)

2Connectinglink(soldwithoptionaltowpolekit)

InstallingtheSafetyChain

Note:Thesafetychainispartoftheoptionaltow

polekit.

1.Formahookontheendofabendablepiece

ofrodorstiffwire(notincluded),andinsertit

throughbothkeyholesinthefrontpostofthe

machine(Figure5A).

g019883

Figure5

1.Keyhole3.Safetychain

2.Rodorwire(notincluded)4.Connectinglink

2.Attachthesafetychaintothelengthofrodor

wire(Figure5A).

3.Pulltherod,orwire,andthesafetychain

throughbothkeyholes(Figure5B).

Note:Ensurethatapproximatelyequallengths

ofsafetychainextendfromeithersideofthe

frontpost.

9

InstallingtheConnectingLinks

Note:Theconnectinglinksarepartoftheoptional

towpolekit.

1.Aligntheconnectinglinktothelastlinkinone

endofthesafetychain(Figure5D).

2.Inserttheconnectinglinkthroughthechainlink

untiltheconnectinglinksnapsclosed.

3.Repeatsteps1and2toinstalltheother

connectinglinkintheotherendofthesafety

chain.

4

AdjustingtheMixing

Paddles

NoPartsRequired

Procedure

Ifthemixingpaddlesandwipersneedadjustment,

adjustthepaddlesandwipers;refertoAdjustingthe

Paddles(page33).

ProductOverview

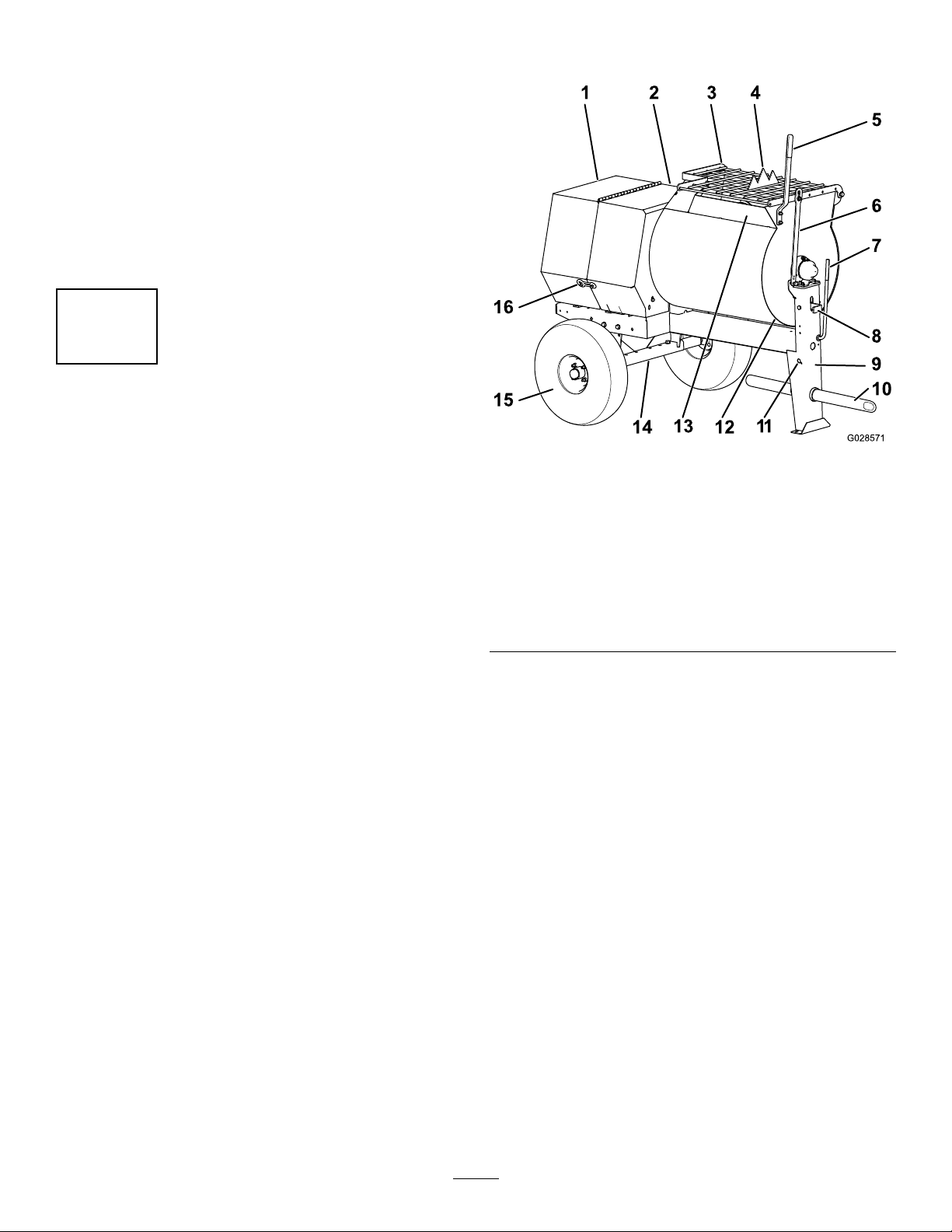

g028571

Figure6

1.Rearcowl7.Clutchlever13.Chute

2.Frontcowl8.Dumplatch14.Axle

3.Grate9.Frontpost15.Wheel

assembly

4.Bagsplitter10.Towpole16.Cowllatch

5.Dumphandle11.Safety-chain

keyhole

6.Grateliftarm12.Drum

10

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

themotorandoperatethemachine.

ClutchLever

Theclutchleverisusedtoengageanddisengage

motorpowertothepaddles.

g019875

Figure7

1.Clutchlever

DrumLatch

Thedrumlatchsecuresthedrumtothemixposition

(upright)formixingoperationsandwhentransporting

themachine.

g019877

Figure8

1.Drumlatch

DumpHandle

Usethedumphandletorotatethedrumtothedump

positionandtorotatethedrumtothemixposition

(upright).

g028572

Figure9

1.Dumphandle

VoltageBlock

Usethevoltageblocktosettheoperatingvoltagefor

themachine(Figure10).

11

g029823

Figure10

1.Voltageblock

MotorControls

Thefollowingmotorcontrolsarefoundonallmodels:

g022280

Figure11

1.Thermal-overload

protectorresetbutton

3.Powercord

2.ON/OFFswitch

MotorON/OFFSwitch

TheON/OFFswitch(Figure12)allowstheoperatorof

themachinetostartandstopthemotor.Thisswitchis

locatedonthefrontofthemotor.Itismarked(ON)and

(OFF).RotatetheON/OFFswitchtotheONpositionto

startandrunthemotor.RotatetheON/OFFswitchto

theOFFpositiontostopthemotor.

g020669

Figure12

1.MotorON/OFFswitch

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

MachineSpecications

12

MachineSpecications(cont'd.)

Model602126021860219

BatchCapacity0.17cubicm(6.0cubicft)0.23cubicm(8.0cubicft)0.23cubicm(8.0cubicft)

TotalVolume0.20cubicm(7.1cubicft)0.25cubicm(9.0cubicft)0.25cubicm(9.0cubicft)

Length

(withouttowpole)

150cm(59inches)168cm(66inches)168cm(66inches)

Width86cm(34inches)86cm(34inches)86cm(34inches)

Height142cm(56inches)142cm(56inches)142cm(56inches)

Weight250kg(550lb)275kg(605lb)275kg(605lb)

Axle86to117cm(34to46inches)

extendable

86to117cm(34to46inches)

extendable

86to117cm(34to46inches)

extendable

Motor1.5hpBaldorElectric1.5hpBaldorElectric2hpBaldorElectric

13

Operation

Important:Beforeoperating,removeanydebris

fromthemachine.Ensurethattheareaisclear

ofpeople.

PreparingtoTowthe

Machine

Important:Ensurethatyourtowvehiclehas

towingcapacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Note:Ensurethatyourtowvehiclehasthe

appropriatehitchtotowthemachine;optionsinclude

a50mm(2inch)ballhitchorapintlehitch.

Note:Ifthemachineisequippedwithatrailer-light

kit,ensurethattheelectricalconnectorofthetow

vehicleiscompatiblewiththeelectricalconnectorof

themachine.Themachineusesastandard4-at

plug.Ifyourtowvehiclehasadifferenttypeofplug,

obtainanadapterfromanautomotivepartsstore.

1.Stopthemotor,unplugthemachine,andempty

thedrum.

2.Ifthedrumhasaccumulatedanywater,dump

thedrum;refertoDumpingtheDrum(page24),

steps1,3,4,and5.

3.Usingthedumplever,positionthedrumsothat

itisinthemixposition(upright)andlocked.

4.Closethecowlandsecurethecowllatches

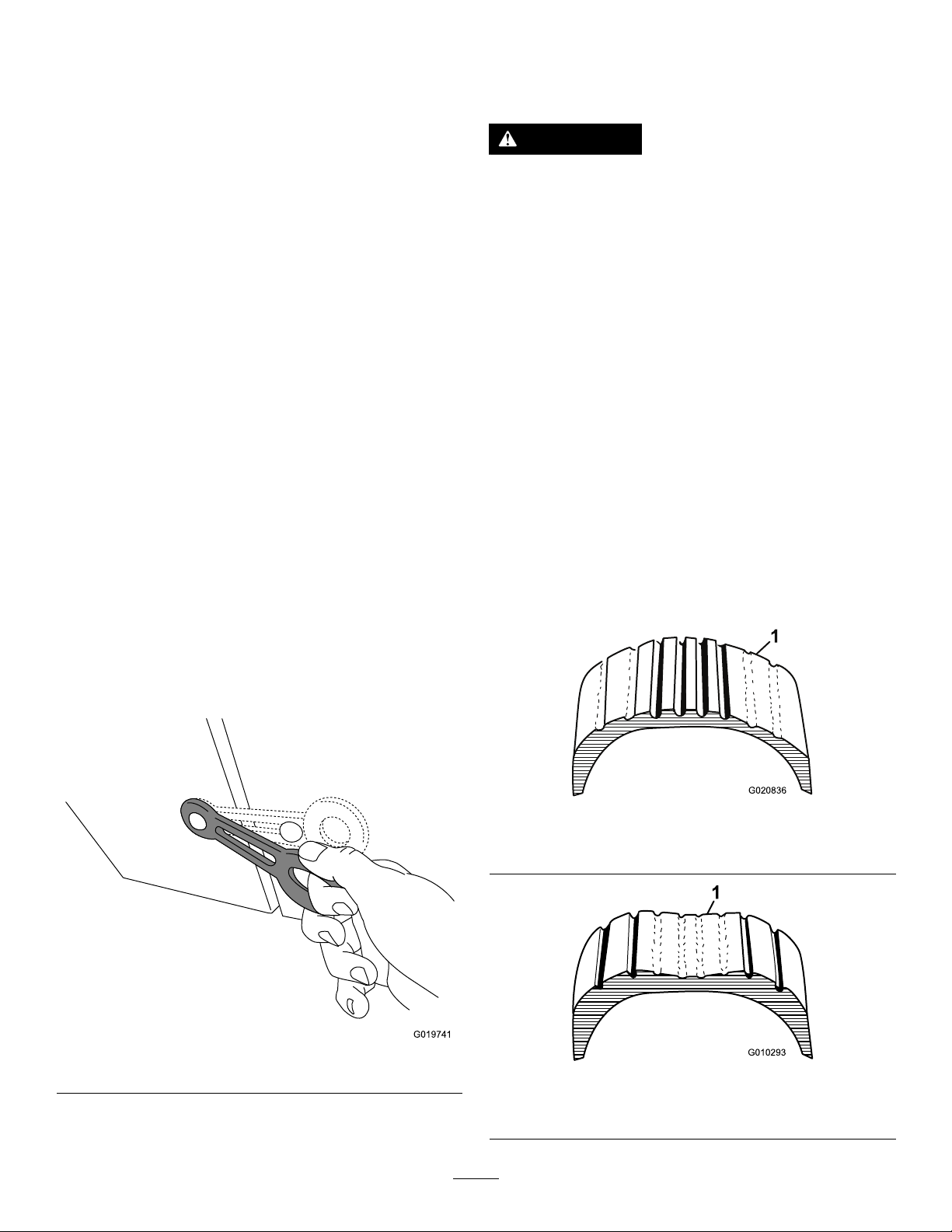

(Figure13).

g019741

Figure13

5.Extendtheaxle;refertoExtendingtheAxle

(page17).

CheckingtheTiresandWheels

ServiceInterval:Beforeeachuseordaily—Inspect

thetiresandwheels.

WARNING

Failuretomaintaincorrecttirepressure

mayresultintirefailureandlossofcontrol,

resultinginpropertydamageandserious

injuryordeath.

•Checkthetirepressurefrequentlyto

ensureproperination.Ifthetiresarenot

inatedtothecorrectpressure,theywill

wearprematurely.

•Inspectthetireconditionbeforetowing

andafteranyoperatingaccident.

TheDOTtireinformationislocatedonthesideof

eachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:Thevariousmachinesinthismanualhave

differentweights;refertoSpecications(page12)to

ensurethatthetiresonyourmachinemeetorexceed

theweightrequirementsofyourmachine.

1.Visuallyinspectthetiresfordamageandwear

(Figure14andFigure15).

g020836

Figure14

1.Exampleoftirewearcausedbyunderination

g010293

Figure15

1.Exampleoftirewearcausedbyoverination

14

2.Ensurethatthetiresareinatedtothecorrect

airpressure.ThefollowingTireAirPressure

tableshowstheappropriateairpressureforthe

tiresasinstalledatthefactory.

Important:Alwayschecktheinformationon

theactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunder-ination.Maintainfullair

pressure.

TireAirPressure

ModelTirepressure

68012Max414kPa(60psi)

68018,68019Max241kPa(35psi)

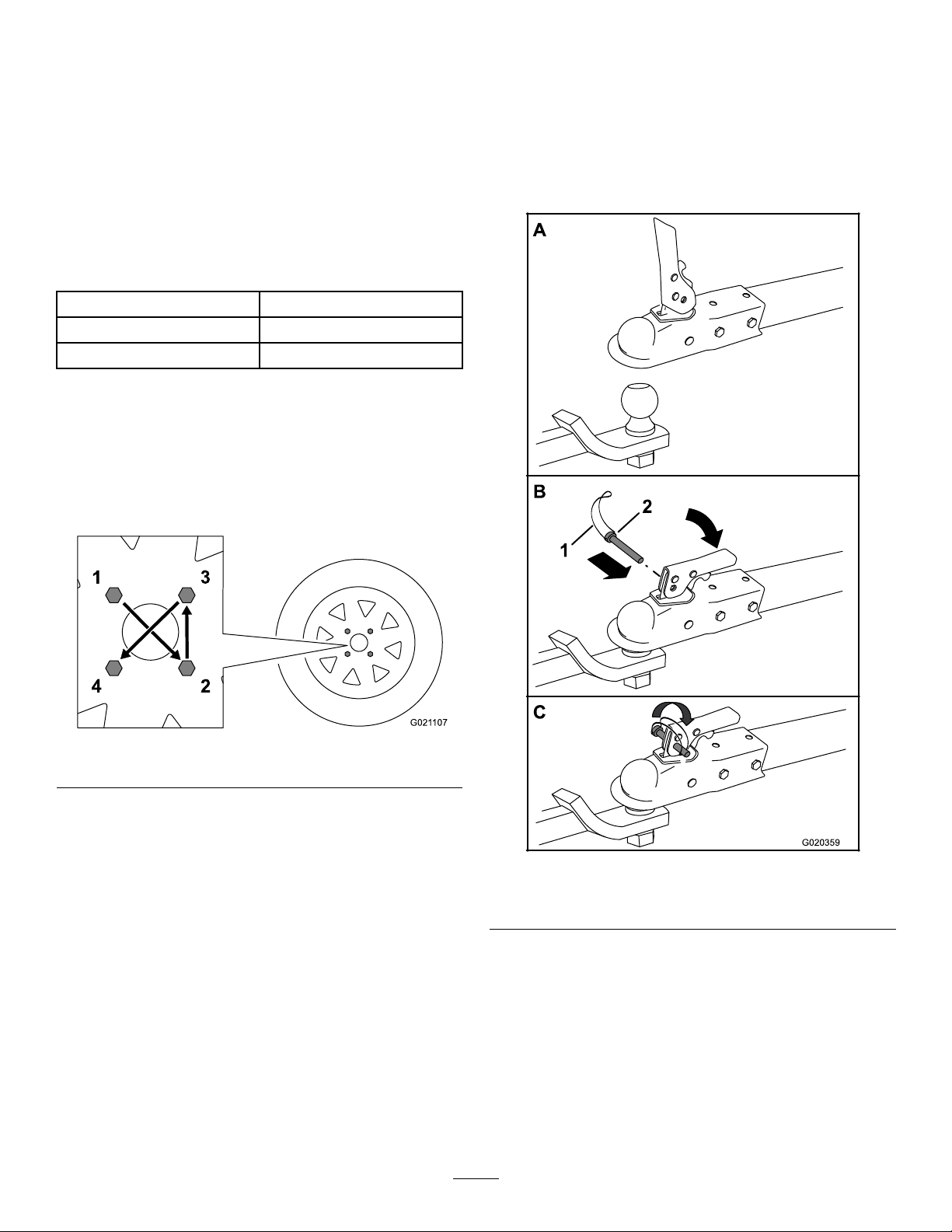

3.Ensurethatthewheellugnutsaretorquedto

108to122N-m(80to90ft-lb).

Note:Checkthetorqueofthewheellugnuts

initiallyandaftertowing.

Note:T orquethelugnutsinthesequence

showninFigure16.

g021107

Figure16

HitchingaMachinewithaStamped

BallCoupler

1.Applychassisgreasetothesocketofthe

couplerandtheareaoftheclampthatcontacts

theball.Oilthepivotpointsandslidingsurfaces

ofthecouplerwithSAE30motoroil.

2.Openthecouplerlatch(Figure17).

g020359

Figure17

1.Bail2.Safetypin

3.Positionthecouplerontopofthehitchball

(Figure17).

4.Closethecouplerlatch(Figure17).

5.Openthebailonthesafetypinandinsertthepin

throughtheholeinthelatch(Figure17).

6.Rotatethefreeendofthebailovertheendof

thesafetypinthatisprotrudingthroughthelatch

(Figure17).

15

7.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothe

wireplugofthemachine.

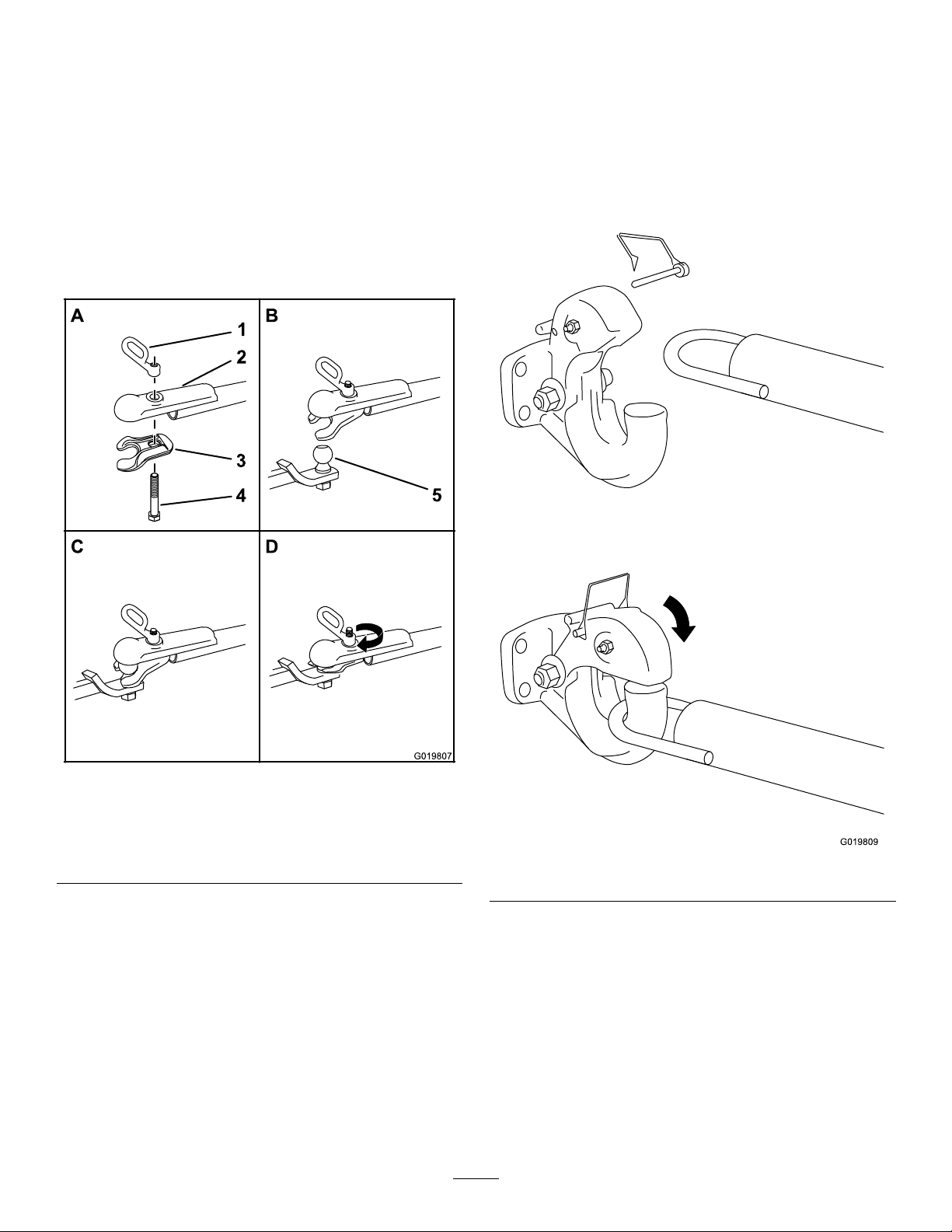

HitchingaMachinewithaForged

BallCoupler

1.Applyremovablethread-lockingcompoundto

thethreadsofthecouplerbolttopreventthe

couplerhandlefromcomingloose(Figure18).

Important:Applythread-lockingcompound

asneededinthefuture.

g019807

Figure18

1.Couplerhandle4.Bolt

2.Coupler5.Hitchball

3.Clamp

2.Applychassisgreasetothesocketofthecoupler

andtheareaoftheclampthatcontactstheball.

3.Pushthecouplerboltupthroughthecoupler

clampandthecouplertop,andconnectthe

couplerhandletothebolt(Figure18).

4.Positionthecouplersothesocketisontopof

thehitchballandtheclampisundertheball.

5.Turnthecouplerhandleclockwisetothreadit

ontotheboltuntilitissecure(Figure18).

Note:Useawrenchtokeeptheboltfrom

spinning.

6.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothe

wireplugofthemachine.

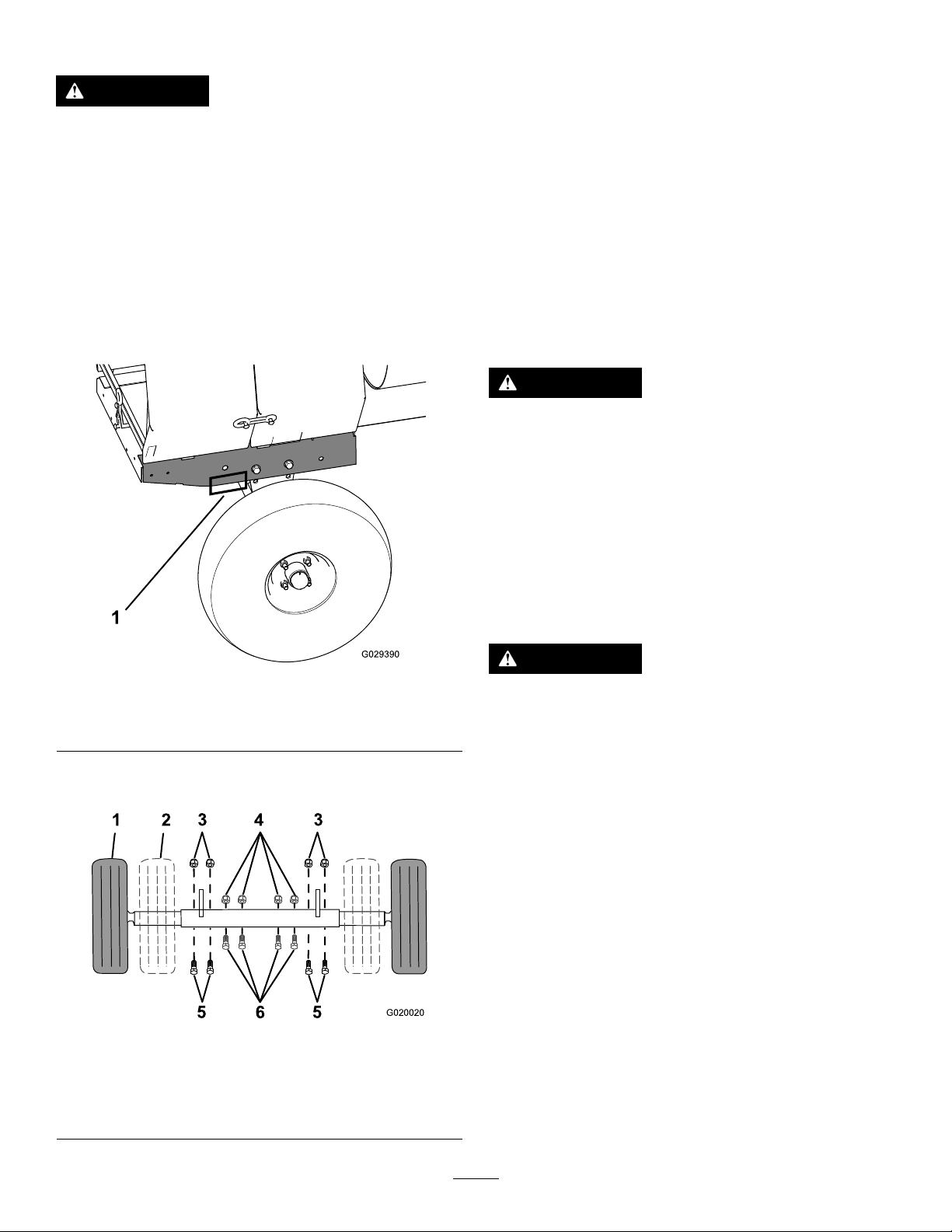

HitchingaMachinewithaPintle

HitchTowPole

1.Removethepinfromthepintlehitchandopen

it(Figure19).

g019809

Figure19

2.Positiontheringonthetowpoleontothehook

ofthepintlehitch(Figure19).

3.Closethetopofthepintlehitchandsecureit

withthepin(Figure19).

4.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothe

wireplugofthemachine.

16

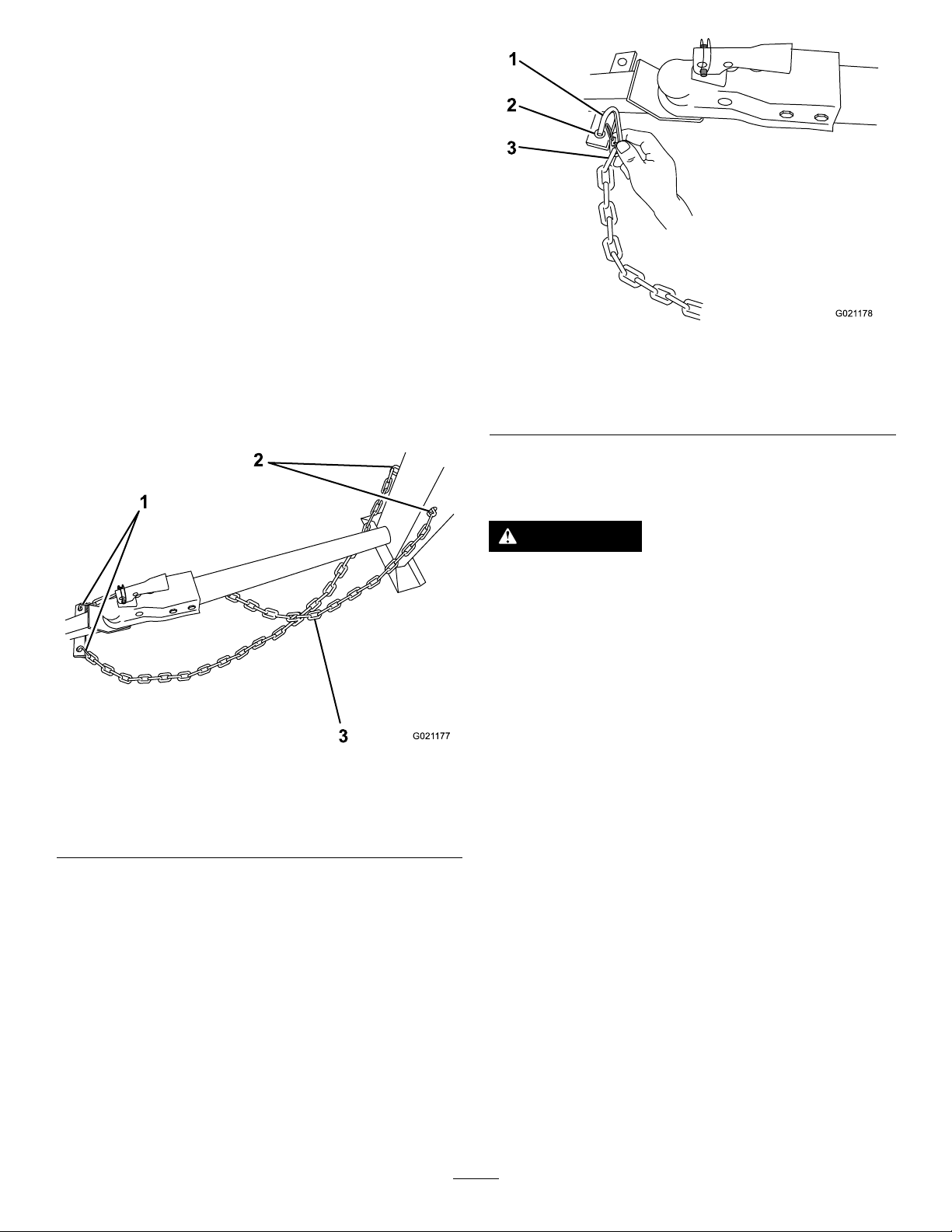

ConnectingtheSafetyChainsto

theTowVehicle

Connectthesafetychaintothemachineandthetow

vehicleasfollows:

1.Pullthesafetychainthroughtheslotsinthe

keyholeslocatedinthefrontpostofthemachine,

sothatthereisjustenoughslackoneachside

forturningaroundcornerswhentowingthe

machine(Figure20).

Note:Stowtheexcesschaininsidethebottom

ofthefrontpostbypushingitintothekeyholes

andlatchingtheappropriatelinksintothe

keyholeslots.

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthe

chancesofthefrontofthemachinedropping

tothegroundifthehitchdoesnotholdthe

connection.

g021177

Figure20

1.Connectinglinks3.Chaincrossedundertow

pole

2.Keyholesinfrontpost

3.Connecteachlengthofchaintothesafety

chainmountingpointonthetowvehiclewiththe

connectinglinks(Figure21).

g021178

Figure21

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

ExtendingtheAxle

WARNING

Themachineisnotstablewhentowingitwith

theaxleinthenarrowposition.

Towthemachinewiththeaxleinthewide

position.

Important:Adjusttheaxletothenarrowposition

onlytomovethemachinethroughanarrow

accesspoint,suchasthegateofafenceorthe

doorwayofabuilding.

PreparingtoChangetheAxle

Width

1.Movethemachinetoaleveljob-sitesurface.

2.Disconnectthemachinefromthetowvehicle.

3.Chockthetires.

4.Ensurethatthedrumisemptyandinthemix

position(upright).

5.Ensurethatthedrumlatchisengagedand

thatthedrumdoesnotrotatetowardthedump

position.

17

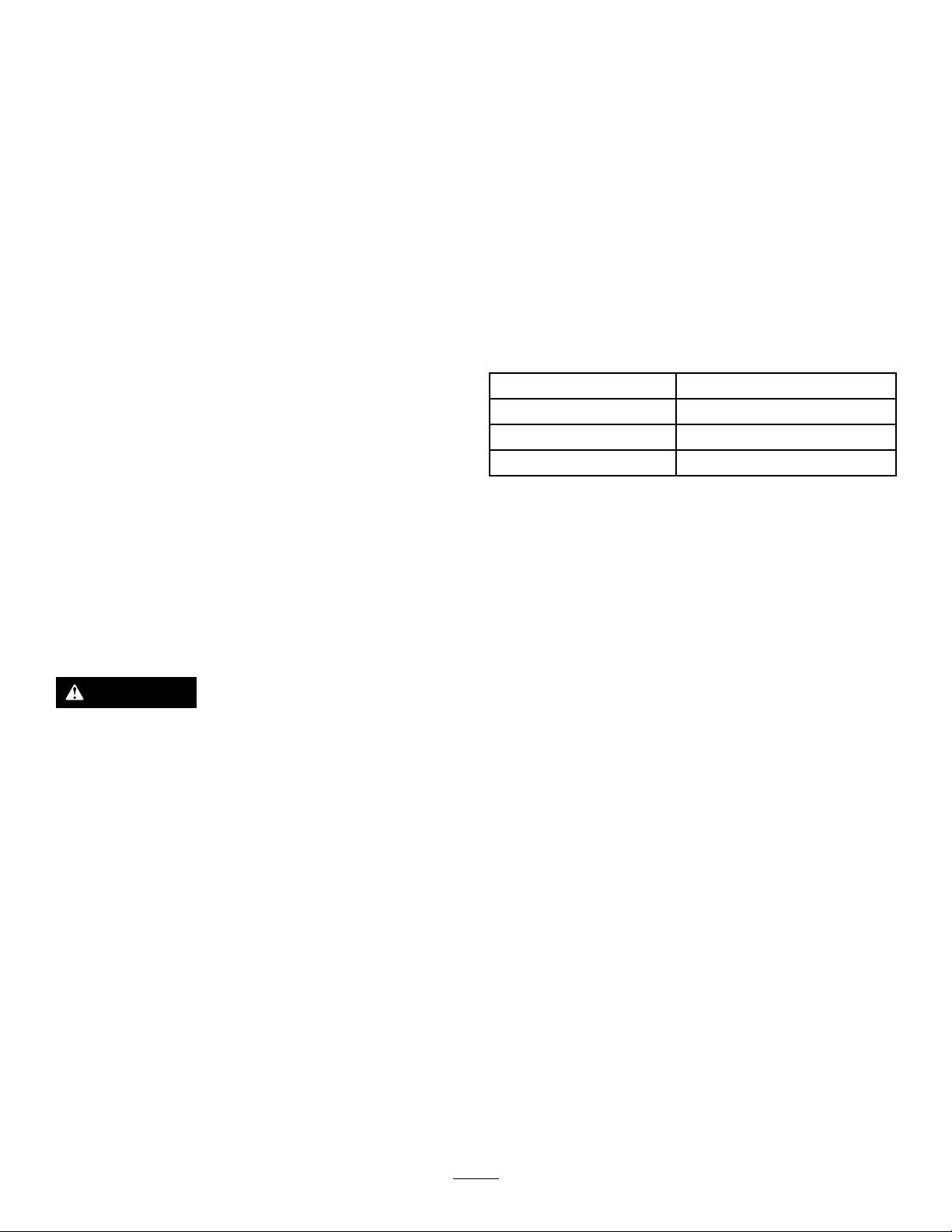

AdjustingtheAxleWidth

WARNING

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseseriousinjury.

Usejackstandswhensupportingthe

machine.

1.Alignajackwithanadequateliftheight

andweightcapacityundertheaxle;referto

Specications(page12).

2.Liftthemachineuntilthetiresareofftheground.

3.Useajackstandateachsupportpointonthe

rearframeextension(Figure22).

g029390

Figure22

1.Supportpoint(2)

4.Removetheboltsandnutsthatsecuretheinner

axletotheouteraxle(Figure23).

g020020

Figure23

1.Wideposition(towing)4.Nut(narrowposition)

2.Narrowposition5.Bolt(wideposition)

3.Nut(wideposition)6.Bolt(narrowposition)

5.Aligntheinneraxletothedesiredpositionas

follows:

•Slideeachsideoftheaxleinwardtothe

narrowposition(Figure23).

•Slideeachsideoftheaxleoutwardtothe

wide(tow)position(Figure23).

6.Aligntheholesoftheinneraxlewiththeholes

oftheouteraxle.

7.Inserttheboltsthroughtheaxleholes(Figure

23).

8.Threadthenutsontothebolts,andtorquethe

nutsto87N-m(64ft-lb).

TowingtheMachine

WARNING

Towingthemachineathighspeedincreases

theriskofahitchmalfunctionandtirefailure.

Higherspeedsalsoincreasethemomentum

ofthemachineandbrakingdistance.Ifthe

machinebecomesdetachedfromthetow

vehicleathighspeed,itcouldcausedamage

toproperty,orinjuryordeathtobystanders.

Donotexceed88km/h(55mph)whentowing

themachine.Forpoorroadconditionsor

inclementweather,reducespeedaccordingly.

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionand

tirefailure.Inaddition,materialcouldbounce

outofthedrumandhitothervehiclesand/or

people.Materialinthedrumincreasesthe

weight,whichaffectsmomentumandbraking

distance.

Donottowthemachinewithmaterialinthe

drum.

•ReviewandunderstandSafeOperatingPractices

(page3).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthe

machine.

PreparingtoUsethe

Machine

•Reviewallofthesafetydecalsonthemachine.

•Useahard-hat,hearingprotection,ashirtwith

longsleevesthataretightatthewrists,tight-tting

18

gloveswithoutdrawstringsorloosecuffs,eye

protection,andadustmaskorrespirator.A

meshvisoralonedoesnotprovidesufcienteye

protection;supplementwithprotectiveglasses.

•Ensurethatyouarefamiliarwiththesafety

regulationsandshutdownproceduresdescribedin

theOperator’sManual.

•Ensurethatallguardsareinplaceandingood

condition.

•Ensurethatthepaddlesareinplaceandingood

condition.

•Checkallthegreasettingstoensurethatthe

machineisproperlylubricated.

•Whenpreparingtomixmaterial:

1.Movethemachinetoaleveljob-sitesurface.

2.Removethemachinefromthetowvehicle.

3.Chockthefrontandbackofthetiresto

preventthemachinefrommoving.

4.Ensurethatthedrumisinthemixposition

(upright).

5.Ensurethatthedrumlatchisengagedand

thatthedrumdoesnotrotatetowardthe

dumpposition.

OpeningandClosingthe

Cowl

OpeningtheCowl

1.Atthesideofthemachinewherethefrontcowl

andrearcowlmeet,graspthelatchandpullitoff

fromthelatchanchorontherearcowl(Figure

24).

g020906

Figure24

1.Latch3.Receiver

2.Latchanchor4.V-tting

2.Repeatstep1ontheoppositesideofthe

machine.

3.Atthebackofthemachinewheretherearcowl

meetstheframeofthemachine,graspthelatch

andpullitofffromthelatchanchoronthecowl

(Figure24).

4.Rotatetherearcowlupandforwarduntilitis

fullypositionedontopofthefrontcowl(Figure

24).

ClosingtheCowl

1.Rotatetherearcowlrearwardanddownuntil

thereceiveratthebottomcenterofthecowlis

alignedwiththeV-ttingandushontheframe

ofthemachine(Figure24).

19

2.Atthebackofthemachine,graspthelatchand

pullitontothelatchanchorontherearcowl.

3.Atthesideofthemachine,graspthelatchand

pullitontothelatchanchorontherearcowl.

4.Repeatstep3attheoppositesideofthe

machine(Figure24).

PoweringtheMachine

SettingtheOperatingVoltage

Themachinecanoperatewitha115Vor230Vsupply

voltage.Thevoltageblockdeterminestheoperating

voltageofthemachine(Figure10).Usethefollowing

stepstochangetheoperatingvoltage:

1.Parkthemachineonlevelground.

2.Stopthemotorandunplugthemachine.

3.Removethe2screwssecuringthevoltageblock

tothemotor.

4.Removethevoltageblockfromthemotor,rotate

thevoltageblock180degreesandplugitback

intothemotor.

5.Securethevoltageplugtothemotorwiththe2

screwsthatyoupreviouslyremoved.

Note:Usetheinstructionsonthevoltageblockto

determinethevoltageblocksetting.

ConnectingtoaPowerSource

DANGER

Contactwithwaterwhileoperatingthe

productcouldcauseelectricshock,causing

injuryordeath.

•Donothandletheplugorthemachinewith

wethandsorwhilestandinginwater.

•Useonlyanextensioncordrecommended

foroutdoorcold-weatheruse.

Important:Checktheextensioncordfrequently

duringuseforholesorcracksintheinsulation.

Donotuseadamagedcord.Donotrunthecord

throughstandingwaterorwetgrass.

Important:Useonlyextensioncordswith

terminalsandsocketsforthelive,neutral,and

groundwires.

Important:Connectthemachinetoonly

areceptaclewithlive,neutral,andground

connections.

Important:Theconnectingwiresorextension

cordshouldbeasshortaspossibleandin1piece.

Toreducetheriskofelectricshock,thismachine

hasapolarizedplug(uniquebladeshapesand

widths).Useonlyapolarizedplugandsocketthatis

compliantwithNEMAspecicationsandanextension

cordthatisUL-listed(CSAcertiedinCanada)and

recommendedforoutdooruse.Apolarizedplugwillt

inapolarizedcordonly1way.Iftheplugdoesnott

fullyintothecord,turnthecord.Ifitstilldoesnott,

purchaseanappropriateextensioncord.Ifyouhavea

polarizedextensioncordandtheextensioncordplug

doesnottfullyintothewallreceptacle,turntheplug.

Ifitstilldoesnott,contactaqualiedelectricianto

installtheproperoutlet.Donotchangethemachine

plugorextension-cordpluginanyway.

Note:Themachineusesatwist-lockingplug.

ExtensionCords

LengthWireGauge

15.2m(50ft)10AWG

22.8m(75ft)10AWG

30.4m(100ft)8AWG

Note:Donotuseanextensioncordover30.4m

(100ft)long.

20

Other manuals for MMX-650E-S

2

This manual suits for next models

4

Table of contents

Other Toro Mixer manuals

Popular Mixer manuals by other brands

Ruhle

Ruhle MPR 1500 Original instructions

Breville

Breville STAND BEM800XL Instruction booklet

Ametek

Ametek Chandler Engineering 3260 instruction manual

Altrad

Altrad Lescha Euro-Mix 125 operating instructions

Sunbeam

Sunbeam MX8800 - MIXMASTER PROFESSIONAL Service manual

VOX electronics

VOX electronics MX-1080 operating instructions