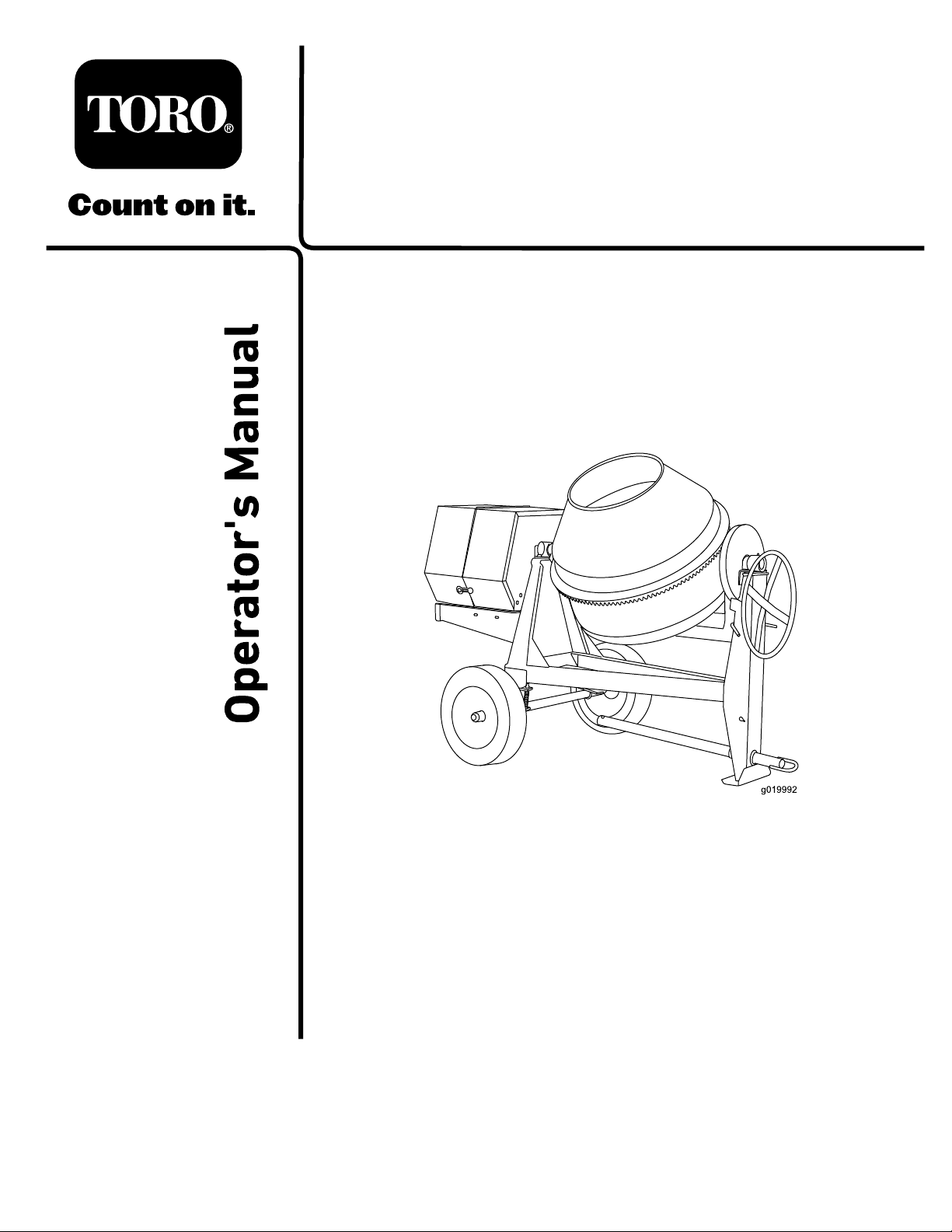

Toro CM-1258Y-SD User manual

FormNo.3398-640RevA

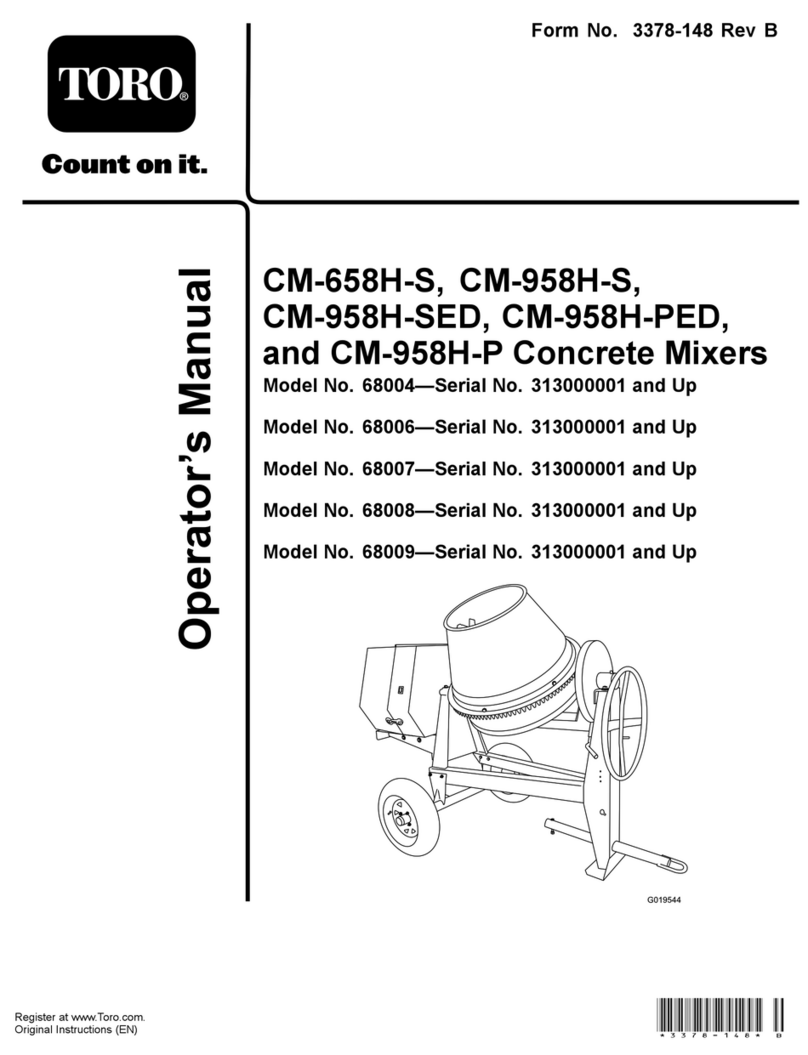

CM-1258Y-SDConcreteMixer

ModelNo.68011—SerialNo.316000001andUp

g019992

Registeratwww.Toro.com.

OriginalInstructions(EN)*3398-640*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442or4443touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredlandunlesstheengineisequippedwith

asparkarrester,asdenedinSection4442,maintained

ineffectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisdesignedtomixconcrete,plaster,reproong

material,grout,andothersmall-grainedconcreteproducts.

Themachinecanbetowedbehindavehicleequippedwith

ahitchappropriateforthetypeoftowpoleyourmachine

has(ballorpintlehitch).

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Writethenumbersinthespaceprovided.

g019994

1

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:RefertoSpecications(page12)andensurethatall

replacementtiresmeetorexceedtheratingsforthismachine.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................6

Setup............................................................................8

1InstallingtheTowPole..........................................8

2InstallingtheSafetyChain......................................9

ProductOverview..........................................................9

Controls................................................................9

Specications........................................................12

Operation....................................................................12

PreparingtoTowtheMachine..................................12

TowingtheMachine...............................................16

PreparingtoUsetheMachine...................................17

OpeningandClosingtheCowl.................................17

AddingFuel...........................................................18

CheckingtheEngine-OilLevel.................................19

StartingandStoppingtheEngine..............................20

UsingtheMachine..................................................22

MixingtheMaterial.................................................22

UsingtheDrum.....................................................22

Maintenance.................................................................24

RecommendedMaintenanceSchedule(s)......................24

PremaintenanceProcedures........................................24

PreparingtheMachineforMaintenance.....................24

RemovingandInstallingtheDividerPlate..................24

Lubrication...............................................................25

LubricatingtheMachine..........................................25

LubricatingtheDriveChain.....................................26

EngineMaintenance..................................................26

ServicingtheAirCleaner.........................................26

ChangingtheEngineOil.........................................27

ServicingtheEngine-OilFilter.................................28

RemovingandInstallingtheEngine..........................29

FuelSystemMaintenance...........................................29

ServicingtheFuelSystem........................................29

DriveSystemMaintenance.........................................31

ServicingtheReductionCase...................................31

ServicingtheDriveChain........................................31

Cleaning...................................................................32

CleaningtheMachine..............................................32

Storage........................................................................33

StoringtheMachine................................................33

Troubleshooting...........................................................34

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans:

Caution

,

W ar ning

,

or

Danger

—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonalinjury

ordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Alwaysfollow

allsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Usewaterfordustsuppression

whenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenyoucannoteliminatethehazardsfrom

inhalation,youandanybystandersshouldwear

arespiratorapprovedbyOSHAforthematerial

beinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

3

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

Towing

Checkwithyourlocalcountyorstatetowingsafetyregulations

beforetowingthemachine.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesurethat

thetowingvehicleismechanicallysoundandingood

operatingcondition.

•Shutdowntheenginebeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheballhitch

youareusingisthepropersizeforthehitchcoupleron

themachine.

•Whentowingwithapintlehitch,ensurethattheeyeof

thetowpoleisthecorrectdimensionforthepintlehook.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdamagedordefectivehitches,couplings,

chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicleandthe

machine.

•Checkthetiretreadandsidewallfordamageandwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthedirectionalandbrakelightsareworking

properly(ifthemachineisequippedwiththelightkit).

•Ensurethatthedirectional,backup,andbrakelightsof

thetowvehicleareworkingproperly(ifthemachineis

equippedwiththelightkit).

•Beforetowing,checktomakecertainyourmachineis

correctlyandsecurelyattachedtothetowingvehicle.

•Ensurethatthesafetychainsareproperlysecuredtothe

vehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhentowing.

•Avoidsuddenstopsandstarts.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.Towonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

•Donottowthemachinefasterthan88km/h(55mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehiclebefore

usingit.

•Placechockblocksunderneaththetirestopreventthem

fromrollingwhilethemachineisparked.

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonalprotectiveequipmentandappropriate

clothing,includingthefollowing:

–Hardhat

–Respiratorordustmask

–Faceshield

–Safetyglasses

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesthataretightatthewrists

–Tight-ttinggloveswithoutdrawstringsorloosecuffs

•Securelonghair,looseclothing,orjewelrythatmayget

tangledinmovingparts.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Installthefuelcapandtightenitsecurely.

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Chockthetiresofthemachinetopreventunintended

movement.

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly(ifthe

machineisequippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

4

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachineforany

reason.

Neverleavearunningmachineunattended.Alwaysstop

theengineandverifythatallmovingpartshavestopped.

•Chockthetiresofthemachineorkeepitattachedtothe

towingvehiclewhenitisnotinuse,topreventitfrom

rolling.

•Avoidprolongedbreathingofexhaustfumes.Engine

exhaustfumescancausesicknessordeath.

•Keephandsawayfromanymovingparts.Keepfeetaway

fromthetiresandthefrontpost.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverplaceyourhandsoranysolidobjectintothedrum

whenthemachineisinoperation.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhiletheengineisrunning.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,stoptheengineandemptythedrum.Waitfor

allmovingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Inspectfor

cloggingordamage.Cleanandrepairand/orreplace

damagedparts.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

–Stoptheengine.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

–Lettheenginecoolbeforeperformingmaintenance

orstoring.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Stopandinspectthemachineifaforeignobjectentersthe

drumorcausesanotherobstruction.Makeanynecessary

repairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Chockthetireswhenstoringthemachine.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

5

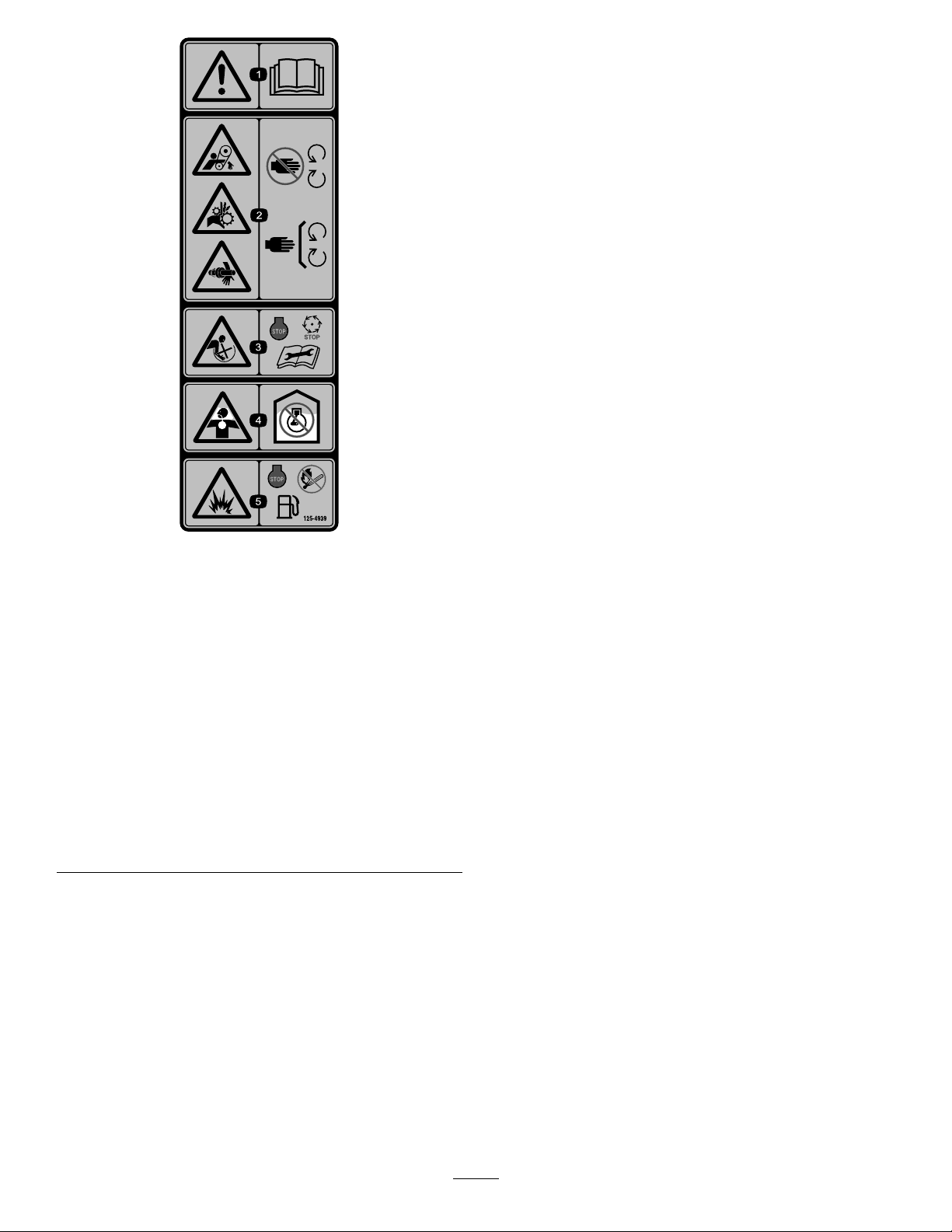

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125–8216

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

2.Warning—limittowing

speedtolessthan88km/h

(55mph)

117–2718

125–8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

132–7176

1.Pulluptostarttheengine.2.Pushdowntostopthe

engine.

6

125–4939

1.Warning—readthe

Operator’sManual.

4.Toxicgasinhalation

hazard—Donotrunthe

engineinanenclosed

space.

2.Handandarm

entanglementatthechain

drive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandshieldsin

place.

5.Explosionhazard—stop

theengineandkeep

awayfromameswhen

refueling.

3.Entanglementhazardat

paddles—stoptheengine

andwaitforallmoving

partstostopbefore

performingmaintenance.

7

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Towpolekit(soldseparately)1Installthetowpole.

Safetychain1

2Connectinglink2Installthesafetychain.

1

InstallingtheTowPole

Partsneededforthisprocedure:

1Towpolekit(soldseparately)

InstallingtheTowPoletotheMachine

Note:Thetowpoleispurchasedseparatelyandincludesthe

nutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

HitchTypeLength

50mm(2inch)ball—stamped127cm(50inches)

50mm(2inch)ball—forged127cm(50inches)

Pintle127cm(50inches)

1.Removetheboltandnutfromthetowpole(Figure3).

5

12

4

6

3

G019804

Figure3

1.Towpole4.Bolthole

2.Frontpost5.Frametting

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholeinthe

polewiththeholeintheframetting(Figure3).

3.Inserttheboltthroughtheholesinthettingandthe

pole(Figure3).

4.Threadthenutontotheboltandtightenthemuntil

theyaretightagainsttheframetting(Figure3).

Note:Iftheself-lockingnyloninsertinthelocknut

wearswithuse,replacethenutwithanewGrade5or

Grade8locknut.

8

2

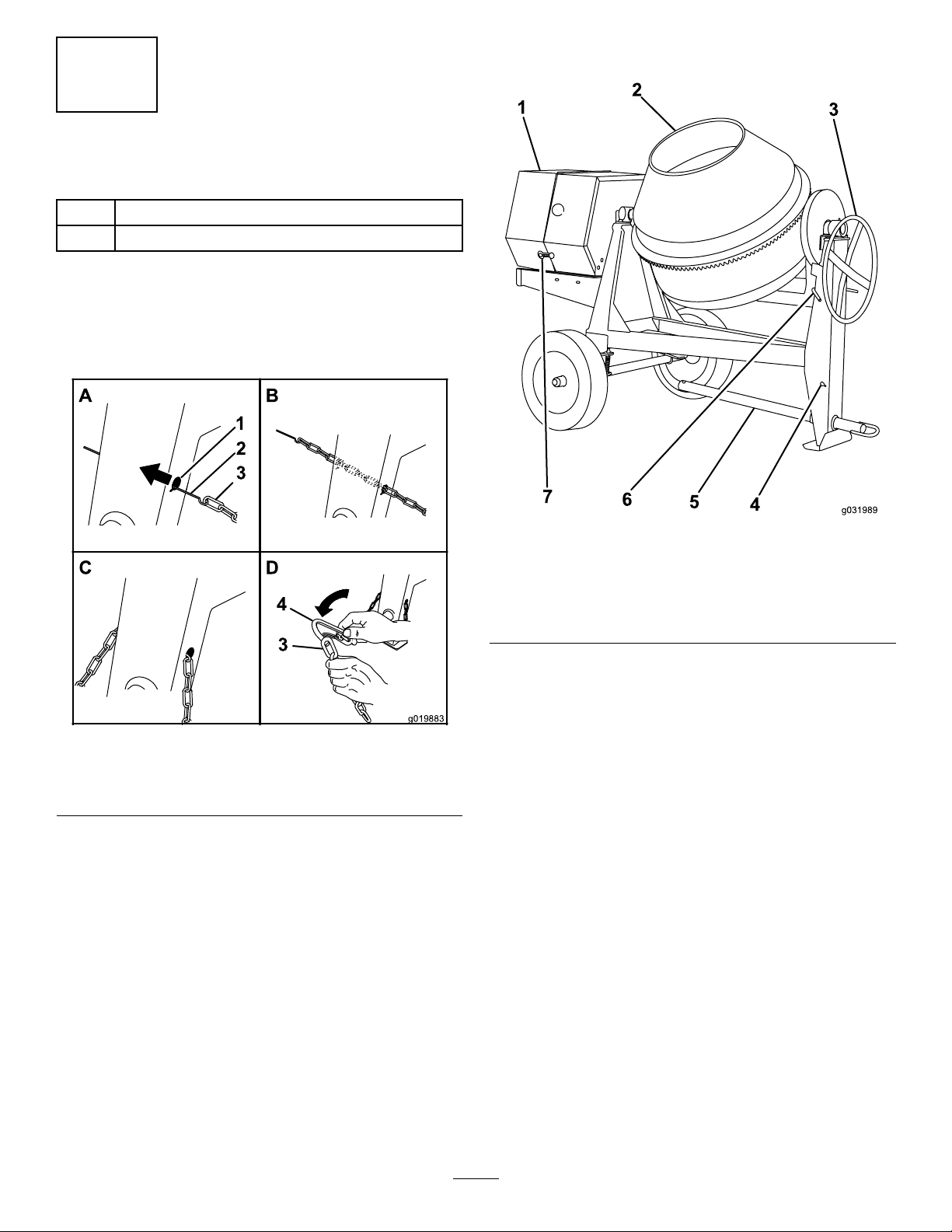

InstallingtheSafetyChain

Partsneededforthisprocedure:

1Safetychain

2Connectinglink

InstallingtheSafetyChain

1.Formahookontheendofabendablepieceofrod

orstiffwire(notincluded),andinsertitthroughboth

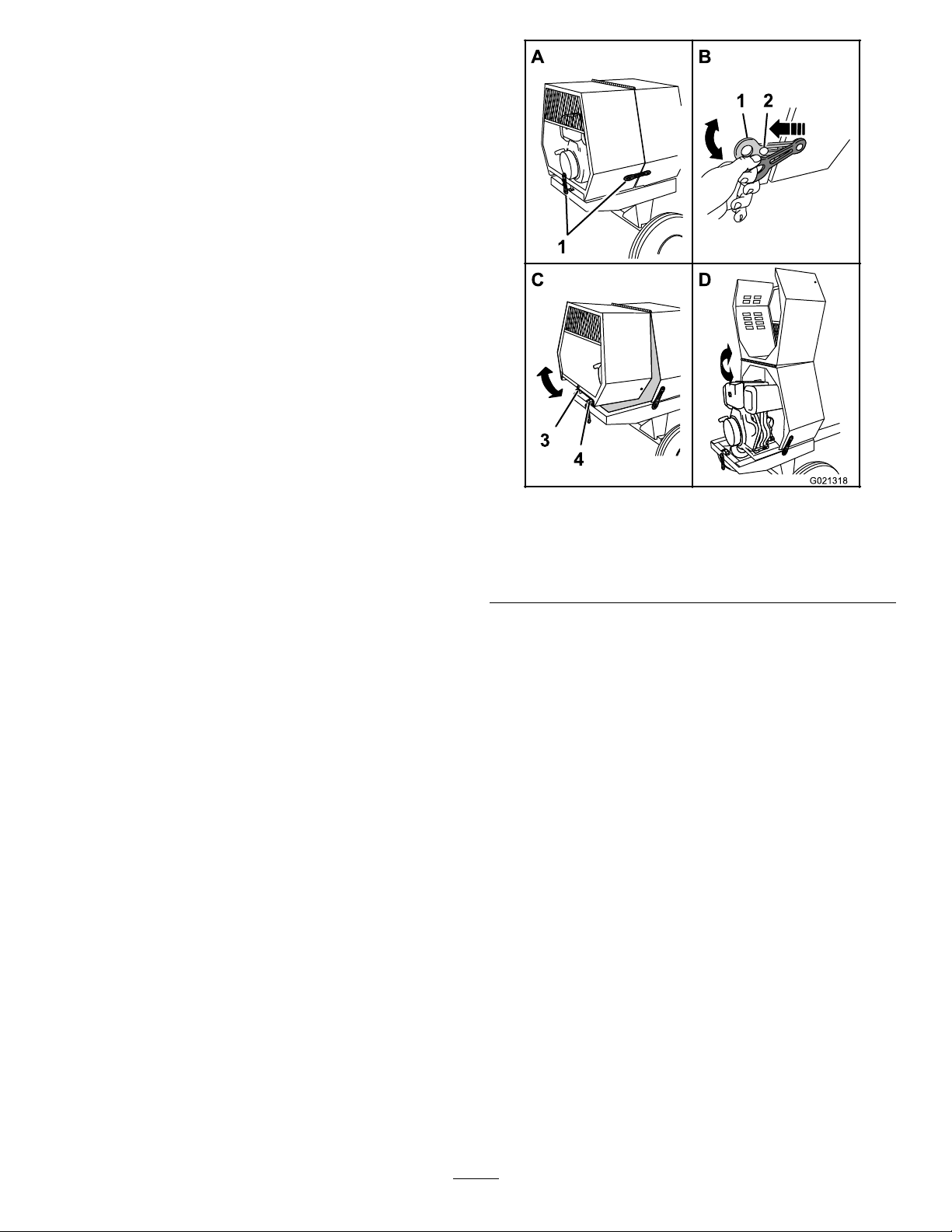

keyholesinthefrontpostofthemachine(Figure4A).

A

B

C

D

g019883

2

3

4

3

1

Figure4

1.Keyhole3.Safetychain

2.Rodorwire(notincluded)4.Connectinglink

2.Attachthesafetychaintothelengthofrodorwire

(Figure4A).

3.Pulltherod,orwire,andthesafetychainthroughboth

keyholes(Figure4B).

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

InstallingtheConnectingLinks

1.Aligntheconnectinglinktothelastlinkinoneendof

thesafetychain(Figure4D).

2.Inserttheconnectinglinkthroughthechainlinkuntil

theconnectinglinksnapsclosed.

3.Repeatsteps1and2toinstalltheotherconnectinglink

intheotherendofthesafetychain.

ProductOverview

Figure5

1.Enginecowl5.Towpole

2.Drum6.Drum-tiltbrake

3.Handwheel7.Rubberlatch

4.Safety-chainkeyholes

Controls

Becomefamiliarwithallofthecontrolsbeforeyoustartthe

engineandoperatethemachine.

Handwheel

Thehandwheelcontrolsthetiltofthedrum.

Drum-TiltBrake

Thedrum-tiltbrakelocksthedrumintoposition.

9

EngineControls

g020004

891

7

6

5

4

3

2

13

10

12

11

Figure6

1.Fueldrainplug8.Fueltank

2.Aircleaner9.Fuelcap

3.Recoil-starthandle10.Decompressionlever

4.Oilcap/dipstick11.Oillter

5.Engine-speed-control

knob

12.Oil-drainplug

6.Fuel-injectionpump13.Oilcap/dipstick

7.Fuel-shutofflever

EngineSpeedControlHandle

Theengine-speed-controlhandle(Figure7)allowsthe

operatortostartandstoptheengine.Itislocatedonthe

enginecowl,andisconnectedtotheengine-speed-control

knob,whichislocatedontheengine(Figure8).Tocontrol

theengine-speed-controlhandle:

1.Rotatetheengine-speed-controlhandle

counterclockwisetounlockit.

2.Pullitallthewayoutandlockitbyrotatingitclockwise.

3.Rotateitcounterclockwiseandpushitintostopthe

engine.

Note:Thespeed-controlknobontheenginemustbe

loose(rotatedcounterclockwise)forthecowl-mounted

speed-controlhandletowork.

Figure7

1.Engine-speed-controlhandle

10

g020001

1

Figure8

1.Engine-speed-controlknob

Fuel-ShutoffLever

Thefuel-shutoffleverislocatedunderneaththefueltank.

Movethefuel-shutofflevertotheONpositionbefore

attemptingtostarttheengine.Onceyouhavenishedusing

themachineandyouhaveshutofftheengine,movethe

fuel-shutofflevertotheOFFposition.

g020002

1

Figure9

1.Fuel-shutoffleverinOnposition

Recoil-StartHandle

Tostarttheengine,pulltherecoil-starthandle(Figure6)

quicklytoturntheengineover.Theenginecontrolsdescribed

abovemustallbesetcorrectlyfortheenginetostart.

11

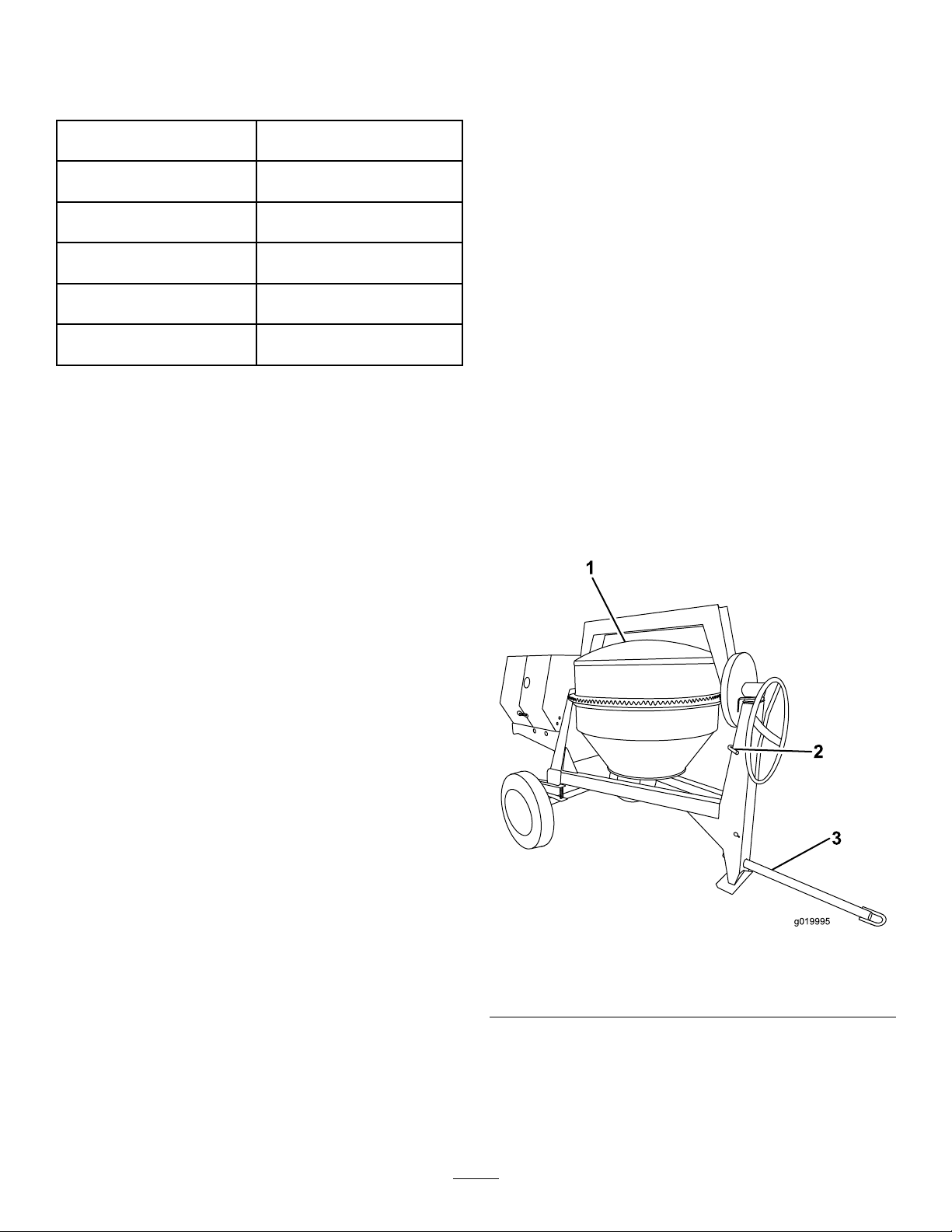

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

BatchCapacity0.34m3

(12ft3)

TotalVolume0.56m3

(19.8ft3)

Length241cm

(95inches)

Width142cm

(56inches)

Height178cm

(70inches)

Weight407kg

(897lb)

Operation

Important:Beforeoperatingthemachine,checkthe

fuelandoillevelsandremovedebrisfromthemachine.

Ensurethattheareaisclearofpeople.

PreparingtoTowtheMachine

Important:Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Note:Ensurethatyourtowvehiclehastheappropriatehitch

totowthemachine;optionsincludea50mm(2inch)ball

hitchorapintlehitch.

Note:Ifthemachineisequippedwithatrailer-lightkit,

ensurethattheelectricalconnectorofthetowvehicleis

compatiblewiththeelectricalconnectorofthemachine.

Ifyourtowvehiclehasadifferenttypeofplug,obtainan

adapterfromanautomotivepartsstore.

1.Ensurethattheengineisstopped,thefuel-shutoff

leverisoff,andthedrumisempty.

2.Usingthehandwheel,positionthedrumsothatitis

pointingdowntowardtheground(Figure10).

g019995

1

2

3

Figure10

1.Drumpointingdown3.Towpoleboltedinplace

2.Drum-tiltbrakeengaged

3.Lockthedrumintopositionbypushingdownonthe

drum-tiltbrakehandle(Figure11).

12

1

2

G019733

Figure11

Drum-TiltBrake

1.Unlockedposition2.Lockedposition

4.Ensurethattheenginecowlisclosedandlatched;refer

toClosingtheCowl(page17).

5.Inspectthetiresandwheels;refertoCheckingthe

TiresandWheels(page13).

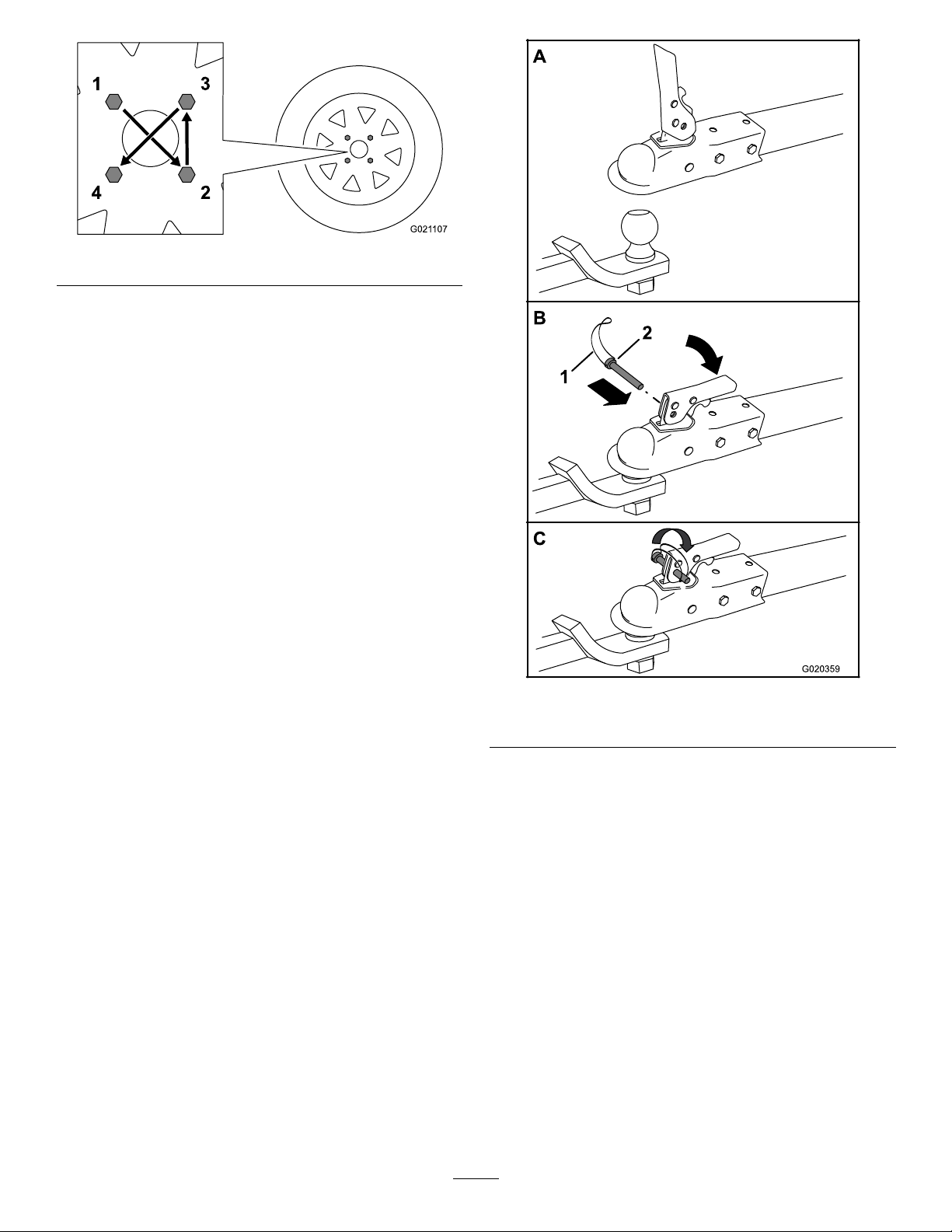

CheckingtheTiresandWheels

ServiceInterval:Beforeeachuseordaily—Inspectthetires

andwheels.

Aftereachuse—Torquethelugnutsto108to122

N-m(80to90ft-lb)aftertowing.

WARNING

Failuretomaintaincorrecttirepressuremayresult

intirefailureandlossofcontrol,resultingin

propertydamageandseriousinjuryordeath.

•Checkthetirepressurefrequentlytoensure

properination.Ifthetiresarenotinatedto

thecorrectpressure,theywillwearprematurely.

•Inspectthetireconditionbeforetowingand

afteranyoperatingaccident.

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:RefertoSpecications(page12)andensurethatall

replacementtiresmeetorexceedtheratingsforthismachine.

1.Visuallyinspectthetiresfordamageandwear(Figure

12andFigure13).

G020836

Figure12

1.Exampleoftirewearcausedbyunderination

Figure13

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtothecorrect

air-pressure.Thefollowingratingindicatesthe

appropriateairpressureforthetiresasinstalledatthe

factory.

Important:Alwayschecktheinformation

ontheactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunderination.Maintainfullair

pressure.

AirPressure:Max241kPa(35psi)

3.Ensurethatthewheellugnutsaretorquedto108to

122N-m(80to90ft-lb).

Note:Checkthetorqueofthewheellugnutsinitially

andaftertowing.

Note:Torquethelugnutsinthesequenceshownin

Figure14.

13

1

2

3

4

G021 107

Figure14

HitchingaMachinewithaStampedBall

Coupler

1.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

2.Oilthepivotpointsandslidingsurfacesofthecoupler

withSAE30motoroil.

3.Openthecouplerlatch(Figure15).

A

B

C

G020359

2

1

Figure15

1.Bail2.Safetypin

4.Positionthecouplerontopofthehitchball(Figure

15A).

5.Closethecouplerlatch(Figure15B).

6.Openthebailonthesafetypinandinsertthepin

throughtheholeinthelatch(Figure15B).

7.Rotatethefreeendofthebailovertheendofthesafety

pinthatisprotrudingthroughthelatch(Figure15C).

8.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

14

HitchingaMachinewithaForgedBall

Coupler

1.Applyremovablethread-lockingcompoundtothe

threadsofthecouplerbolttopreventthecoupler

handlefromcomingloose(Figure16).

Important:Applythread-lockingcompoundas

neededinthefuture.

A

B

C

D

G019807

5

1

2

3

4

Figure16

1.Couplerhandle4.Bolt

2.Coupler5.Hitchball

3.Clamp

2.Applychassisgreasetothesocketofthecouplerand

theareaoftheclampthatcontactstheball.

3.Pushthecouplerboltupthroughthecouplerclamp

andthecouplertop,andconnectthecouplerhandle

tothebolt(Figure16A).

4.Positionthecouplersothatthesocketisontopofthe

hitchballandtheclampisundertheball(Figure16C).

5.Turnthecouplerhandleclockwisetothreaditontothe

boltuntilitissecure(Figure16D).

Note:Useawrenchtokeeptheboltfromspinning.

6.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

HitchingaMachinewithaPintleHitch

TowPole

1.Removethepinfromthepintlehitchandopenit

(Figure17).

G019809

Figure17

2.Positiontheringonthetowpoleontothehookofthe

pintlehitch(Figure17).

3.Closethetopofthepintlehitchandsecureitwiththe

pin(Figure17).

4.Ifthemachineisequippedwithatrailer-lightkit,

connectthewireplugofthetowvehicletothewire

plugofthemachine.

15

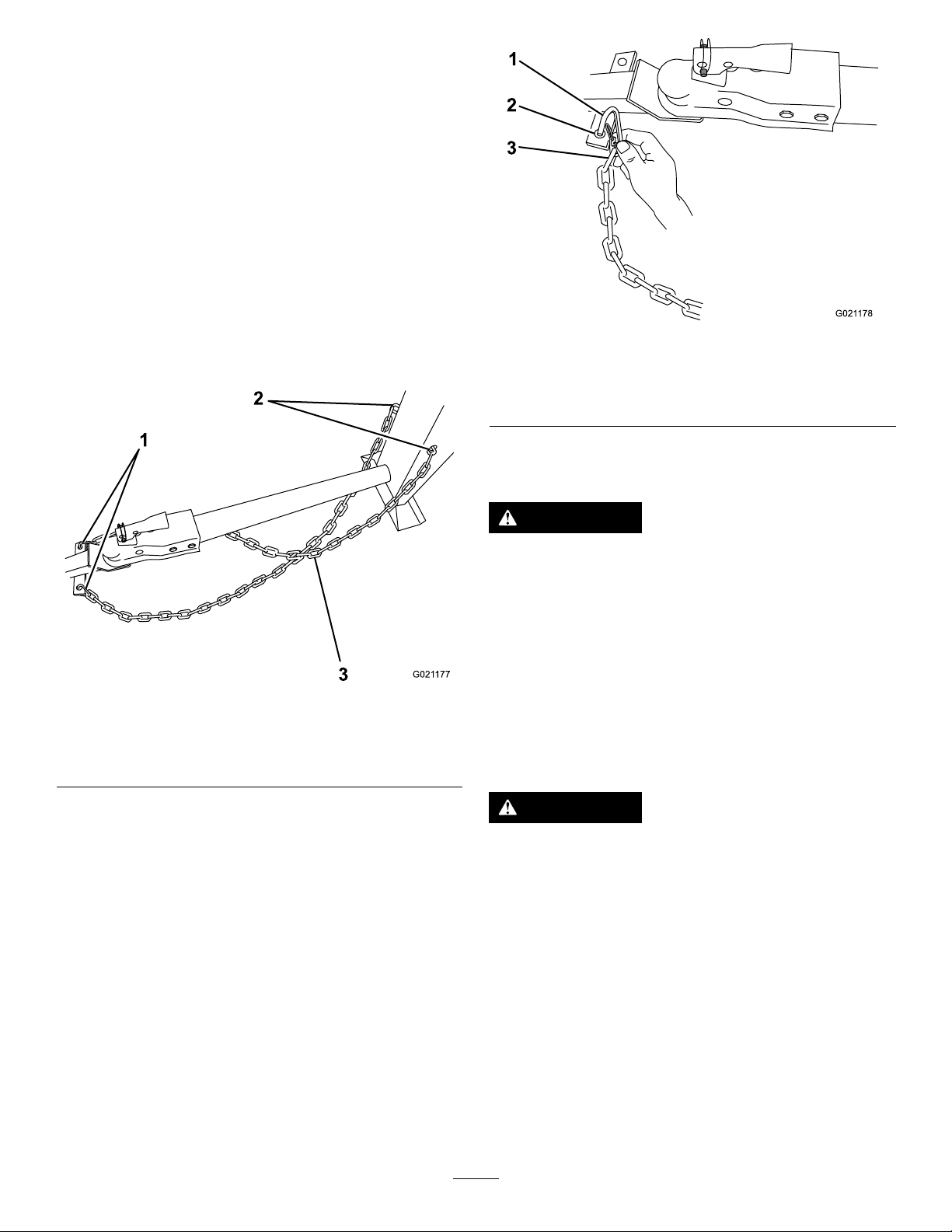

ConnectingtheSafetyChainstothe

TowVehicle

Connectthesafetychaintothemachineandthetowvehicle

asfollows:

1.Pullthesafetychainthroughtheslotsinthekeyholes

locatedinthefrontpostofthemachine,sothatthere

isjustenoughslackoneachsideforturningaround

cornerswhentowingthemachineFigure18).

Note:Stowtheexcesschaininsidethebottomofthe

frontpostbypushingitintothekeyholesandlatching

theappropriatelinksintothekeyholeslots.

2.Crossbothlengthsofchainunderthetowpole.

Note:Crossingthechainsdecreasesthechancesof

thefrontofthemachinedroppingtothegroundifthe

hitchdoesnotholdtheconnection.

1

2

3G021 177

Figure18

1.Connectinglinks3.Chaincrossedundertow

pole

2.Keyholesinfrontpost

3.Connecteachlengthofchaintothesafetychain

mountingpointonthetowvehiclewiththeconnecting

links(Figure19).

G021 178

1

2

3

Figure19

1.Connectinglink3.Chainlink

2.Safetychainmounting

pointontowvehicle

TowingtheMachine

WARNING

Towingthemachineathighspeedincreasesthe

riskofahitchmalfunctionandtirefailure.Higher

speedsalsoincreasethemomentumofthemachine

andbrakingdistance.Ifthemachinebecomes

detachedfromthetowvehicleathighspeed,it

couldcausedamagetoproperty,orinjuryordeath

tobystanders.

Donotexceed88km/h(55mph)whentowingthe

machine.Forpoorroadconditionsorinclement

weather,reducespeedaccordingly.

WARNING

Towingthemachinewithmaterialinthedrum

increasestheriskofahitchmalfunctionandtire

failure.Inaddition,materialcouldbounceoutof

thedrumandhitothervehiclesand/orpeople.

Materialinthedrumincreasestheweight,which

affectsmomentumandbrakingdistance.

Donottowthemachinewithmaterialinthedrum.

•ReviewandunderstandSafeOperatingPractices(page3).

•Testthebrakesofthetowvehiclebeforetowing.

•Avoidsuddenstartsandstopswhiletowingthemachine.

16

PreparingtoUsetheMachine

•Reviewallofthesafetydecalsonthemachine.

•Useahard-hat,hearingprotection,ashirtwithlong

sleevesthataretightatthewrists,tight-ttinggloves

withoutdrawstringsorloosecuffs,eyeprotection,and

adustmaskorrespirator.Ameshvisoralonedoes

notprovidesufcienteyeprotection;supplementwith

protectiveglasses.

•Ensurethatyouarefamiliarwiththesafetyregulations

andshutdownproceduresdescribedintheOperator’s

ManualandtheEngineOwner’sManual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthepaddlesareinplaceandingood

condition.

•Checkthefuelandoillevelsoftheengine.

•Whenpreparingtomixmaterial:

1.Movethemachinetoaleveljob-sitesurface.

2.Removethemachinefromthetowvehicle.

3.Chockthefrontandbackofthetirestoprevent

themachinefrommoving.

4.Ensurethatthedrumisinthemixposition

(upright).

5.Ensurethatthedrum-tiltbrakeisengagedand

thatthedrumdoesnotrotatetowardthedump

position.

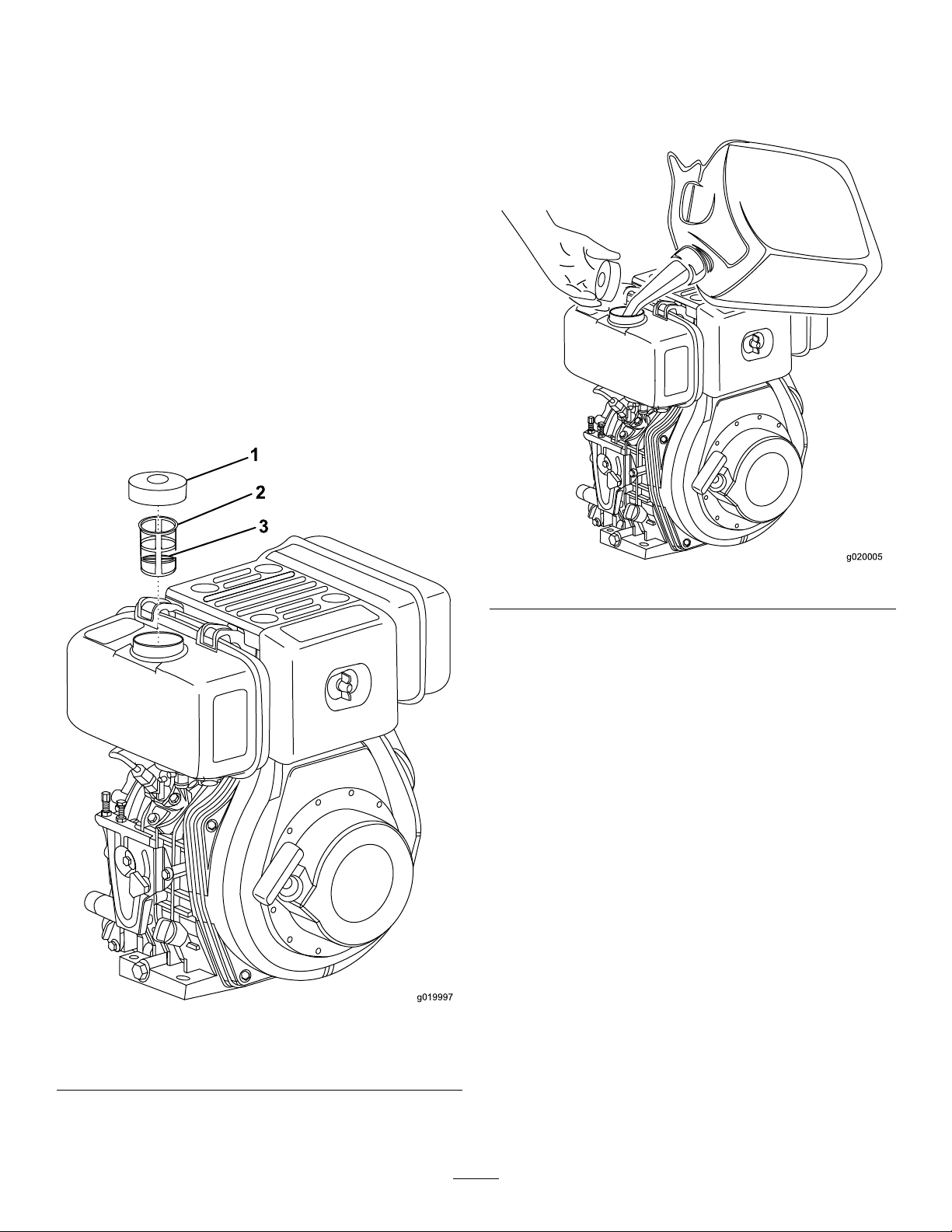

OpeningandClosingtheCowl

OpeningtheCowl

1.Atthesideofthemachinewherethefrontcowland

rearcowlmeet,grasptheringofthelatchandpullit

offfromthelatchanchorontherearcowl(Figure20).

A

B

C

D

1

G021318

2

3

4

1

Figure20

Openingandclosingthecowl

1.Latch3.Receiver

2.Latchanchor4.V-tting

2.Repeat1ontheoppositesideofthemachine.

3.Atthebackofthemachinewheretherearcowlmeets

theframeofthemachine,grasptheringofthelatch

andpullitofffromthelatchanchoronthecowl

(Figure20).

4.Rotatetherearcowlupandforwarduntilitisfully

positionedontopofthefrontcowl(Figure20).

ClosingtheCowl

1.Rotatetherearcowlrearwardanddownuntilthe

receiveratthebottomcenterofthecowlisalignedwith

theV-ttingandushontheframeofthemachine

(Figure20).

2.Atthebackofthemachine,grasptheringofthelatch

andpullitontothelatchanchorontherearcowl.

3.Atthesideofthemachine,grasptheringofthelatch

andpullitontothelatchanchorontherearcowl.

4.Repeatstep3ontheoppositesideofthemachine

(Figure20).

17

AddingFuel

•Useonlyultra-lowsulfur(<15ppm)dieselfuel.

•Purchasefuelinquantitiesthatcanbeusedwithin30days

toensurefuelfreshness.

•Usesummer-gradedieselfuel(Number2-D)at

temperaturesabove-7°C(20°F)andwinter-gradediesel

fuel(Number1-DorNumber1-D/2-Dblend)below

-7°C(20°F).

•Nevermixkerosene,usedengineoil,orresidualfuels

withthedieselfuel.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinter.

•Fueladditivesarenotrecommended.Somefueladditives

maycausepoorengineperformance.

DANGER

Incertainconditions,dieselfuelisextremely

ammableandhighlyexplosive.Areorexplosion

fromdieselcanburnyouandothersandcan

damageproperty.

Useonlydieselfuel.Fillingthefueltankwith

gasolinemayresultinare.

•Fillthefueltankandstorefuelina

well-ventilatedarea.

•Neverrefuelthefueltankwhiletheengineis

running.

•Donotllthefueltankcompletelyfull.Addfuel

untilitisatthesamelevelastheredring.This

emptyspaceinthetankallowsfueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelmaybeignited

byaspark.

•Storedieselinanapprovedcontainerandkeep

itoutofthereachofchildren.Donotbuymore

thana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removefuel-poweredequipment

fromthetruckortrailerandfueltheequipment

withthewheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifyoumustuseafueldispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandthe

fueltankorconditioneropening.

•Keepfuelawayfromyoureyesandskin.

DieselFuelSpecications

Important:Donotmixoilwithdiesel.

Dieselfuelshouldcomplywiththefollowingspecication.

Thetablelists7worldwidespecicationsfordieselfuels.

DieselFuelSpecicationsLocation

Number2-D,Number

1-D,ASTMD975-94

Ultra-lowSulfur(<15ppm)

USA

EN590:96EuropeanUnion

ISO8217DMXInternational

BS2869-A1orA2UnitedKingdom

JISK2204GradeNumber2Japan

KSM-2610Korea

GB252China

18

UsingFuelStabilizer/Conditioner

Useadieselfuelstabilizer/conditionerinthemachineto

keepthefuelfreshduringstorageof90daysorless.Ifyou

arestoringthemachineforlonger,drainthefueltank;refer

to(page).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshfuel.

FillingtheFuelTank

Capacity:4.7L(1.25USgallons)

1.Parkthemachineonalevelsurface,stoptheengine,

andallowtheenginetocool.

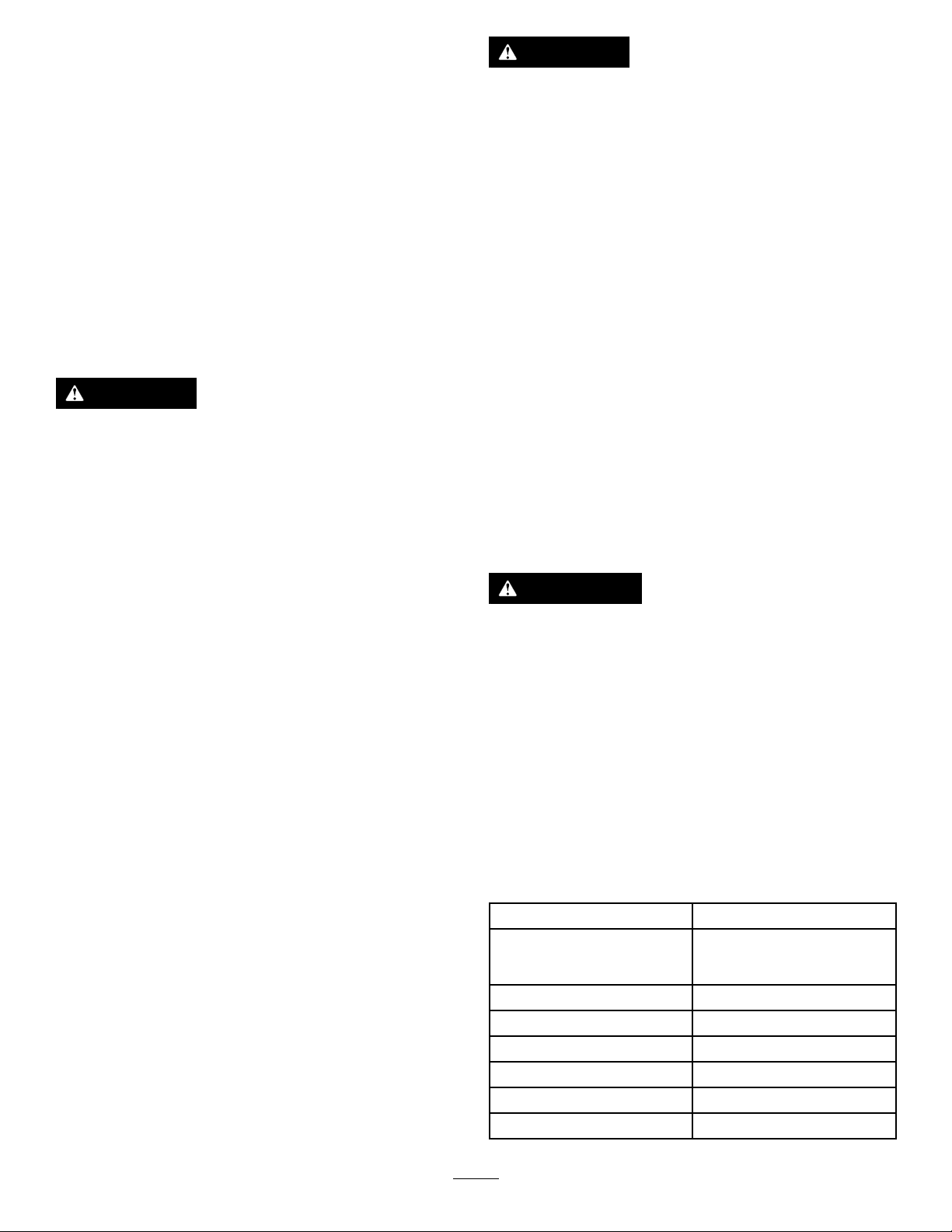

2.Cleanaroundthefuelcapandremoveit(Figure21).

g019997

1

2

3

Figure21

1.Fuelcap3.Redring

2.Inlet-fuelscreen

Important:Keeptheinlet-fuelscreenandthered

ringinthefueltankwhilepouringthefuel.

3.Addfueltothefueltankuntilthelevelisuptothered

ring(Figure22).

Important:Thisspaceinthetankallowsthefuel

toexpand.Donotllthefueltankcompletelyfull.

g020005

Figure22

4.Securelyinstallthefuelcap(Figure21).

5.Wipeupanyfuelthatmayhavespilled.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

Important:Use4-cycleengineoilthatmeetsorexceeds

thefollowingguidelinesandclassications:

•APIServiceCategoriesCH-4,CI-4,CJ-4orhigher

•ACEAServiceCategoriesE-3,E-4,andE-5

•JASOServiceCategoryDH-1

Crankcasecapacity:1.6L(1.7USqt)

Important:Iftheoillevelinthecrankcaseistoolow

ortoohighandyouruntheengine,youmaydamage

theengine.Thistypeofdamageisnotcoveredbythe

warranty.

Viscosity:RefertoFigure23.

19

SAE 10W

SAE 20W

SAE 10W -30

SAE 15W -40

SAE 20

SAE 30

SAE 40

(-4 F)

o(14 F)

o(32oF) (50 oF) (68 oF) (86 oF) (104 oF)

-20oC -10 oC 0oC10 oC

20

o

C

30oC40 oC

g020376

Figure23

Important:Ensurethattheengineoil,engineoil

storagecontainers,andengineoilllingequipmentare

freeofsedimentsandwater.

1.Placethemachineonaat,levelsurface,andstopthe

engine.

2.Allowtheenginetocool.

3.Cleanaroundthedipstick.

4.Removethedipstickandwipetheendclean(Figure24).

g019993

123

Figure24

1.Dipstickupperlimit3.Fillport

2.Dipsticklowerlimit

5.Slidethedipstickfullyintothellportwithout

threadingitintotheport(Figure24).

6.Removethedipstickandlookattheend.Iftheengine

oillevelisbelowthehalfwaypointonthehatchmarks,

slowlypouronlyenoughoilintothellporttoraise

theleveltothehalfwaypointonthedipstick.

7.Installandsecurethedipstick(Figure24).

StartingandStoppingthe

Engine

StartingtheEngine

1.ReadSafeOperatingPractices(page3)andunderstand

theControls(page9)beforeattemptingtostartthe

machine.

2.Makesurethatthefuel-shutoffleverisinthe

ONposition.

g020002

1

Figure25

1.Fuel-shutoffleverintheOnposition

3.Ensurethattheengine-speed-controlknobonthe

engineisloosebyrotatingitcounterclockwise(Figure

26).

20

Other manuals for CM-1258Y-SD

1

This manual suits for next models

1

Table of contents

Other Toro Mixer manuals

Popular Mixer manuals by other brands

Monacor

Monacor IMG STAGELINE MMX-4 instructions

TREVIDEA

TREVIDEA G3 Ferrari PASTAIO 10&LODE G20120 user manual

Häfele

Häfele KYOTO installation manual

KitchenAid

KitchenAid Professional 600 Series Instructions and recipes

Edirol

Edirol V-8 Brochure & specs

Linear Technology

Linear Technology LTC5549 Demo Manual