TORSIONX XP-115 User manual

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 2

Safety Guide

To use the XP-115 Multi-Port Power Pack safely you must follow correct operation guidelines

and inspect the equipment regularly. Read and follow all instructions and put on proper

personal protective equipment (PPE) prior to use.

UPON RECEIPT OF THIS TOOL, INSPECT THE PACKAGE FOR DAMAGE.

Carefully inspect all components for damage incurred during shipping. If any shipping damage is

found, notify the carrier at once. Shipping damage is NOT covered by warranty. The carrier is

responsible for all repair or replacement costs resulting from damage in shipment.

Neither TorsionX, nor its distributors are responsible for damage caused by unsafe and/or faulty

operations. If a problem arises during use, shut off the power immediately and consult your

TorsionX distributor.

ALL OF OUR PRODUCTS MAY HAVE UPGRADES AND MODIFICATIONS WITHOUT NOTICE.

Table of Contents

Warnings ......................................................................................................................................... 3

XP-115 Multi-Port Power Pack ........................................................................................................ 3

Hydraulic Couplers .......................................................................................................................... 4

Set Up .............................................................................................................................................. 5

Operation ........................................................................................................................................ 7

Features: ......................................................................................................................................... 7

Warranties ...................................................................................................................................... 8

Trouble Shooting Guide .................................................................................................................. 9

Appendix ....................................................................................................................................... 10

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 3

Warnings

Hydraulic Hose:

Inspect hose for wear and damage prior to every use.

Only use twin line high pressure hydraulic hoses rated for 10,000 PSI with at

least a 3:1 safety factor.

The maximum operating pressure is 10,000 PSI - Do not exceed 10,000 PSI.

Do not let the hose kink, twist, curl or bend so tightly that oil flow within the hose is

blocked or reduced.

The minimum bending radius: R>5 inch.

Too small of a bending radius will kink and destroy the high pressure hydraulic

hose.

Before operating the hydraulic power pack, tighten all hydraulic hose connections with

the proper tools.

Do not overtighten.

Connections should be tightened securely and leak-free.

Over tightening can cause premature coupler thread failure.

Shut off the electric motor before breaking any hydraulic connections in the system.

Should a hydraulic hose ever rupture, burst, or need to be disconnected,

immediately shut off the hydraulic power pack.

Never attempt to grasp a leaking pressurized hose with your hands. The force of

the escaping hydraulic fluid could cause serious injury.

Do not subject the hose to potential hazards such as:

Fire

Sharp surfaces

Extreme heat or cold

Heavy impact

Hose material and coupler seals must be compatible with the hydraulic fluid.

Keep hoses away from contact with corrosive materials such as creosote-

impregnated objects and some paints and solvents.

Never paint a hydraulic hose.

Never paint hydraulic couplers.

Hose deterioration due to corrosive materials can result in premature failure and

serious personal injury.

XP-115 Multi-Port Power Pack

Do not exceed the maximum hydraulic pressure rating of 10,000 PSI.

Do not tamper with the internal high pressure relief valve.

Creating pressure beyond rated capacities can result in serious personal injury.

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 4

Before replenishing the hydraulic oil, retract the system to prevent overfilling the pump

reservoir.

Overfilling can cause personal injury due to excess reservoir pressure created

when the wrenches are retracted.

Power Supply:

Disconnect the hydraulic power pack from the power supply when performing

maintenance or repairs.

If the power supply is damaged or the inner wiring is exposed in any way, replace

immediately.

If the power cord is damaged or wiring is exposed, replace or repair immediately.

Check the total amperage draw for the electrical circuit you will be using.

Low amperage can cause the power pack to generate excessive heat and may

cause the electric circuit breakers to trip.

Hydraulic Couplers

Never overtighten the

hydraulic coupler.

Overtightening

can cause

premature thread

failure.

Check for gaps in the hydraulic coupler.

Gaps can cause a disruption in the flow of hydraulic

fluid.

Gaps will cause the hydraulic torque wrench to not

operate.

Immediately replace any worn or damaged hydraulic couplers.

Do not use the hose to move the attached equipment.

IMPORTANT

WHEN ONLY USING ONE HYDRAULIC TORQUE WRENCH, COVER THE EMPTY

HYDRAULIC COUPLINGS WITH DUST CAPS.

USE A STABLE ELECTRIC SOURCE. IF POWER SUPPLY IS UNSTEADY IT MAY AFFECT THE

PERFORMANCE AND MAY DAMAGE THE HYDRAULIC POWER PACK.

IF YOU ARE USING AN EXTENSION CORD TO POWER THE HYDRAULIC PUMP, USE A HEAVY

GAUGE CORD (12 GAUGE OR BETTER).

Figure 1

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 5

Operation Warnings:

Do not permit anyone to stand in front of open hydraulic couplers during operation.

Never exceed the maximum operating pressure of 10,000 PSI.

Before performing any maintenance, shut off power.

Do not operate without oil.

Keep the power pack clean.

Do not operate in wet conditions.

Set Up

Filling the Reservoir:

Attention: The power pack has been shipped without oil in the reservoir. Only use a high-grade

(Grade 46 or better), quality non-foaming hydraulic oil.

1. Clean the area around the filler cap.

a. Any dirt or grime in the hydraulic oil can damage the internal workings of the

power pack.

2. Remove the filler cap, and insert a clean funnel.

3. Fill with hydraulic oil to 1” from the top of the filler hole.

4. Replace filler cap.

5. Cycle the power pack (with hydraulic torque wrench attached) several times.

6. Retract the hydraulic torque wrench and check the oil level in the power pack reservoir

again.

a. This will also help eliminate air from the system.

Hydraulic Connections:

1. Inspect all hydraulic twin line hoses, threads and fittings for signs of wear or damage

and replace as needed.

2. Clean all hose ends and hydraulic couplers.

3. Connect the twin line hydraulic hose to the hydraulic torque wrench and the power

pack, making sure all hydraulic couplers are snug.

4. Jog the power pack several times.

a. The power pack is now ready to be put into regular operation.

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 6

Adjusting the Hydraulic Pressure:

NOTE: For easy adjustment of the pressure

regulating valve always adjust the pressure by

increasing to the desired pressure setting.

1. Loosen the locknut on the pressure

regulating valve, and back the adjusting

knob out a few turns.

a. Do so by turning the adjusting

knob in a counterclockwise

direction. (Figure 2)

b. This will decrease the pressure setting to a pressure lower than the desired

pressure.

ATTENTION: THE POWER PACK MUST BE COMPLETELY CONNECTED AND THE HYDRAULIC

TORQUE WRENCH MUST NOT BE ON THE APPLICATION WHEN ADJUSTING THE PRESSURE.

2. Connect the electric power supply and flip the on/off switch to

“On”

a. This switch is located on the back of the electrical

control box.

3. Press the rocker switch on the remote control handle to the

center position to turn the power pack on.

a. The power pack will deliver hydraulic oil to the low

pressure port (Port B).

4. Press the rocker switch on the top position to “Advance”.

a. The power pack will deliver hydraulic oil to the high pressure port (Port A).

5. While holding remote rocker in the “Advance” position, slowly turn the adjusting knob

in a clockwise direction.

a. This will gradually increase the pressure setting.

6. When the desired pressure is reached, lock the adjusting knob in position by tightening

the locknut.

IMPORTANT: NEVER EXCEED 10,000 PSI

Figure 2

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 7

Operation

1. Press the remote rocker switch on the top to advance the hydraulic torque wrench.

2. When you hear an audible “Click” from the hydraulic torque wrench, release the remote

rocker.

a. The hydraulic torque wrench will automatically

retract.

3. When the hydraulic torque wrench is fully retracted, repeat

the process until the desired pressure/torque rating is

reached.

To disconnect tools and hoses from system, you must release

system pressure.

a. To release pressure from system, press the rubber

button on top of the solenoid. (Figure 3)

Attention: When using a hydraulic power pack for the first time, activate the hydraulic torque

wrench prior to putting tool on an application; this will help remove any air from the system.

Features:

XP-115 Multi-Port Power Pack is a three-stage power pack. The pressure relief valve is

assembled in the high pressure port.

Flow rates for the power pack by stage are:

50in /min in high pressure stage

110in /min in mid pressure stage

500in /min in low pressure stage

Maximum operating pressure: 10,000 PSI

The XP-115 Multi-Port Power Pack can simultaneously run two torque wrenches at the

same time.

Electric power options:

115V 60HZ, 1.2 Hp Motor

220V 50HZ, 1.6 Hp Motor

220V 60HZ, 1.6 Hp Motor

Acceptable working temperature: -20 F to 120 F

Overall dimensions: 11.8” x 14.8” x 17.9”

Weight (no oil): 60lbs

Hydraulic oil: ISO VG 46#

Figure 3

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 8

Warranties

1. TorsionX guarantees the XP-115 Multi-Port Power Pack quality for 12 months from the date

of purchase.

2. If any quality issue due to the defects of the materials or workmanship is found within the

guarantee period, TorsionX will repair or replace the defective products at TorsionX’s

discretion.

3. If the equipment is found to be damaged due to negligence, operating the power pack

incorrectly, tampering with, or attempting to repair the power pack in part or whole, the

warranty is invalidated.

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 9

Trouble Shooting Guide

Malfunction

Reason for malfunction

Solution

The power pack does not start.

Un-suitable power source.

Confirm the power supply meets the

pump’s specifications.

The power is not connected.

Check the power connection.

The system has no hydraulic

pressure.

The hydraulic couplers are not connected

properly.

Tighten or re-install.

No oil in the tank.

Fill oil.

Not enough oil in tank.

Fill oil.

Faulty pressure gauge.

Replace gauge.

The system still has no

hydraulic pressure after

checking the above.

The hydraulic couplers may have a vacuum

lock.

Check hydraulic couplers to hydraulic

torque wrench. Inspect couplers to ensure

they are completely coupled. Occasionally

couplers have to be replaced because the

check ball does not stay open due to wear.

Hydraulic couplers are leaking.

The o-ring, is worn or missing in the female

hydraulic couplers.

Replace the hydraulic couplers.

The desired hydraulic pressure

can not be reached.

The pressure setting for high-pressure

relief valve is adjusted too low.

Replace high pressure relief valve.

Oil is mixed with water.

Replace the oil.

Pressure relief valve broken.

Replace valve.

Air may be in system.

Repeat operating the system with no load

several times to eliminate air.

High-pressure relief valve may be loose.

Tighten valve.

The o-ring for high-pressure relief valve

may be worn or missing.

Replace o-rings.

There is a loud noise when the

power pack is operated.

The bearing(s) may be worn or broken.

Replace bearing(s).

Air may be in system.

Repeat operating the system with no load

several times to eliminate air.

High-pressure flow is reduced.

Piston or spring may be broken.

Replace piston assembly.

Hydraulic couplers may be loose.

Tighten hydraulic couplers.

Oil level may be low.

Fill with oil.

Oil may be too cold.

Change hydraulic oil to a lighter grade.

Dirt in pump or filter is clogged.

Replace filter and clean tank.

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 10

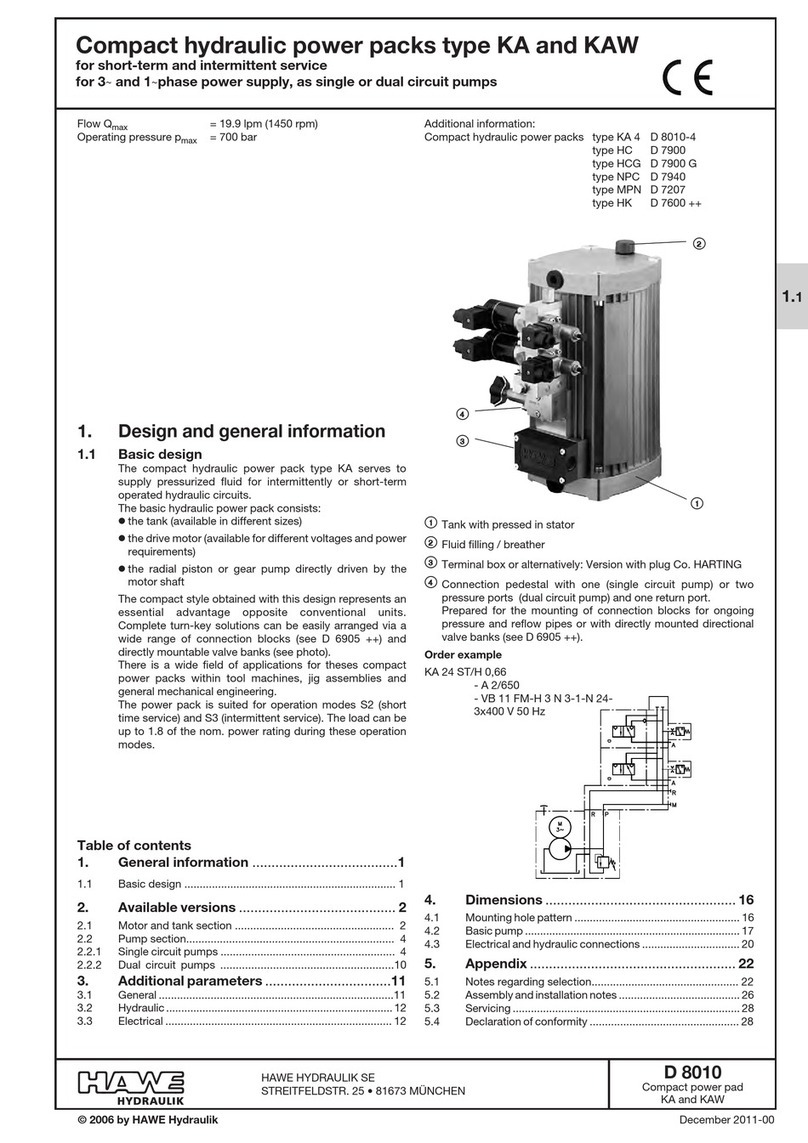

Appendix

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 11

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 12

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 13

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 14

TorsionX XP-115 Multi-Port Power Pack (Updated 1/30/17) 15

Table of contents

Other TORSIONX Power Pack manuals