Compact hydraulic power packs type KA and KAW

for short-term and intermittent service

for 3+and 1+phase power supply, as single or dual circuit pumps

D 8010

Compact power pad

KA and KAW

December 2011-00©2006 by HAWE Hydraulik

HAWE HYDRAULIK SE

STREITFELDSTR. 25 • 81673 MÜNCHEN

1.1

Flow Qmax = 19.9 lpm (1450 rpm)

Operating pressure pmax = 700 bar

Additional information:

Compact hydraulic power packs type KA 4 D 8010-4

type HC D 7900

type HCG D 7900 G

type NPC D 7940

type MPN D 7207

type HK D 7600 ++

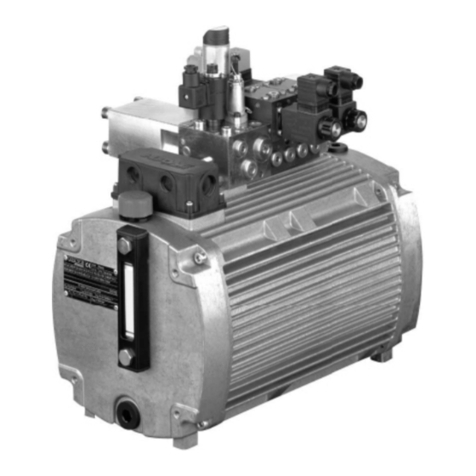

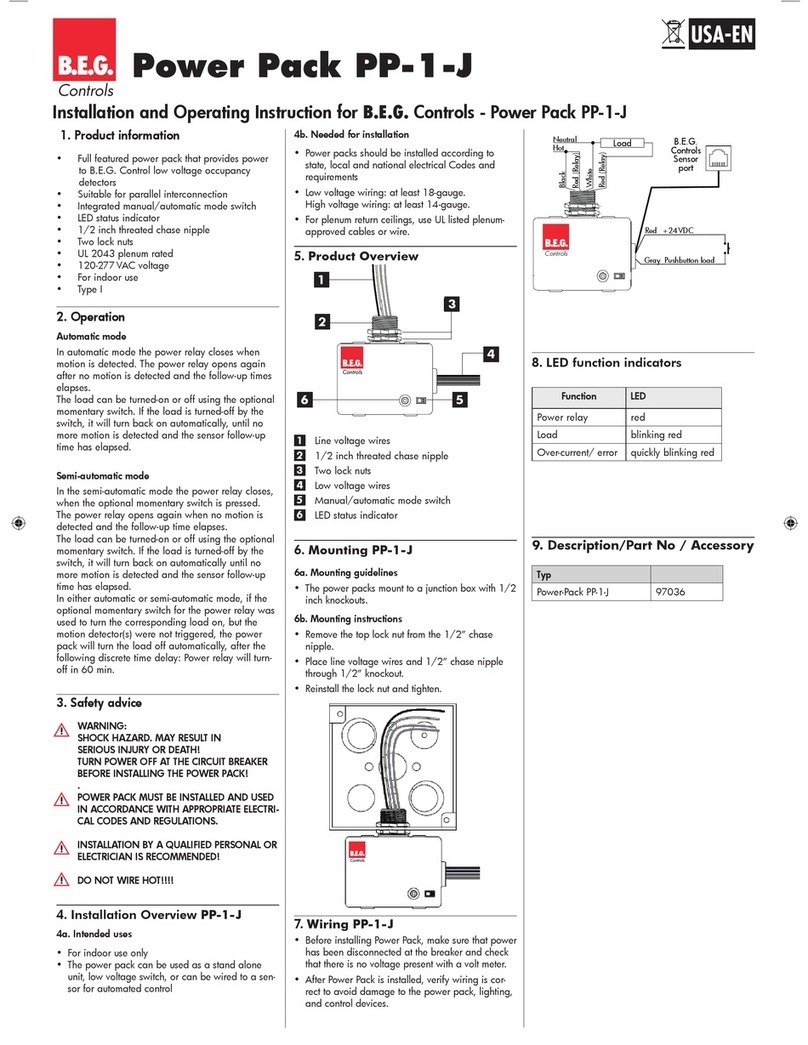

;Tank with pressed in stator

<Fluid filling / breather

= Terminal box or alternatively: Version with plug Co. HARTING

>Connection pedestal with one (single circuit pump) or two

pressure ports (dual circuit pump) and one return port.

Prepared for the mounting of connection blocks for ongoing

pressure and reflow pipes or with directly mounted directional

valve banks (see D 6905 ++).

1. Design and general information

Order example

KA 24 ST/H 0,66

- A 2/650

- VB 11 FM-H 3 N 3-1-N 24-

3x400 V 50 Hz

1.1 Basic design

The compact hydraulic power pack type KA serves to

supply pressurized fluid for intermittently or short-term

operated hydraulic circuits.

The basic hydraulic power pack consists:

o the tank (available in different sizes)

othe drive motor (available for different voltages and power

requirements)

othe radial piston or gear pump directly driven by the

motor shaft

The compact style obtained with this design represents an

essential advantage opposite conventional units.

Complete turn-key solutions can be easily arranged via a

wide range of connection blocks (see D 6905 ++) and

directly mountable valve banks (see photo).

There is a wide field of applications for theses compact

power packs within tool machines, jig assemblies and

general mechanical engineering.

The power pack is suited for operation modes S2 (short

time service) and S3 (intermittent service). The load can be

up to 1.8 of the nom. power rating during these operation

modes.

Table of contents

1. General information ......................................1

1.1 Basic design ..................................................................... 1

2. Available versions ......................................... 2

2.1 Motor and tank section .................................................... 2

2.2 Pump section.................................................................... 4

2.2.1 Single circuit pumps ......................................................... 4

2.2.2 Dual circuit pumps ........................................................10

3. Additional parameters .................................11

3.1 General .............................................................................11

3.2 Hydraulic ........................................................................... 12

3.3 Electrical .......................................................................... 12

4. Dimensions .................................................. 16

4.1 Mounting hole pattern ...................................................... 16

4.2 Basic pump ....................................................................... 17

4.3 Electrical and hydraulic connections ................................ 20

5. Appendix ...................................................... 22

5.1 Notes regarding selection................................................ 22

5.2 Assembly and installation notes ........................................ 26

5.3 Servicing ........................................................................... 28

5.4 Declaration of conformity ................................................. 28

;

<

=

>