No. 2D730-148E*O

A

- CAUTION:

2. Be sure to install the system on a level floor and lock the casters. If this is

not done, the system may move, injuring the service personnel.

3. Move the system forward or backward only. If the system is moved to the left

or right, it may fall, causing injury. In addition, be sure to fix the moving

sections such as the operating panel before moving the system. If such

sections move, they may catch the hands or fingers of the persons moving

the system, possibly causing injury.

4. To prevent electric shock, do not connect the peripheral units (video printer,

VCR, etc.) to an external outlet. Peripheral units should be connected to the

service outlet of the system or the optional isolation transformer. For the

connection procedures, contact your TOSHIBA representative.

5. The service outlet of the main unit is intended solely for recommended

peripheral units. Do not connect devices other than recommended

peripheral units to the service outlet. Connecting devices other than those

recommended may cause the consumption current to exceed the power

capacity of the main unit, possibly resulting in malfunction.

6. Do not place any objects on top of the monitor. They may fall, causing

injury.

7. Do not allow fluids such as water to contact the system or peripheral

devices. Electric shock may result.

8. Do not handle the system with wet or moist hands. Electric shock may

result.

9. The monitor is a heavy unit. Two persons are required when mounting or

removing the monitor. If a worker mounts or removes the monitor alone,

he/she may be injured.

10. Be sure to turn OFF the power breaker and disconnect the mains plug from

the outlet before removing the covers of the main unit and performing

internal wiring.

11. When discarding any part of this system, follow all applicable local

regulations.

12. Wear protective gloves to ensure safety and prevent infection when

performing unit replacement, board replacement, internal wiring, or cleaning.

13. Wait at least 30 seconds after turning OFF the power breaker and

disconnecting the mains plug from the outlet before replacing the battery.

Otherwise, an electric shock may result.

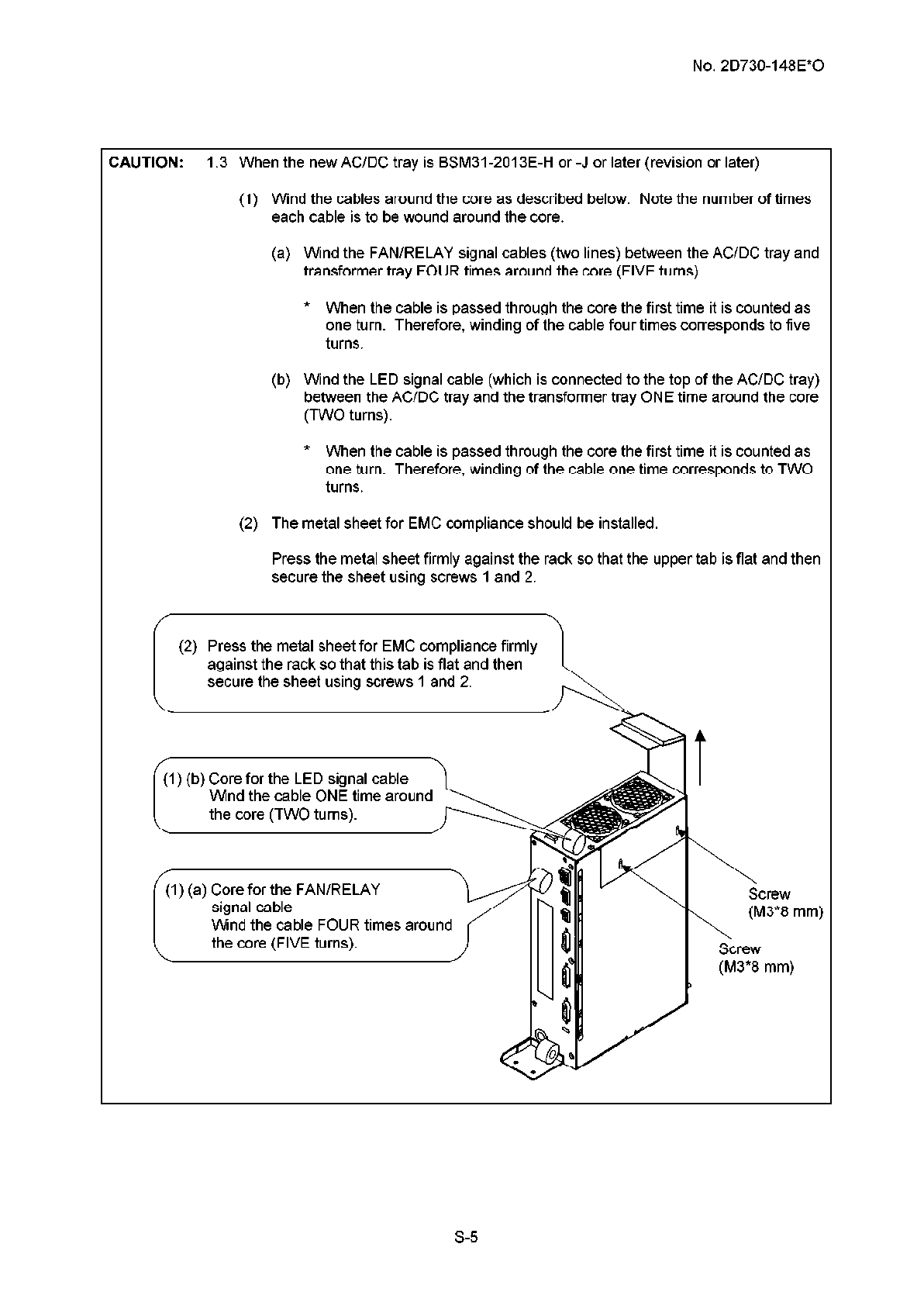

CAUTION: I. When replacing the AC/DC tray of the SSA-770A, check the revision number of the

AC/DC tray supplied for replacement and follow the appropriate procedure according to

the revision number.

1.I When the new AC/DC tray is BSM31-2013E (no revision)

The AC/DC tray is not compatible and must not be used to replace the existing tray.

s-3