MBS (Wallmount) Installation - 64523-009 3

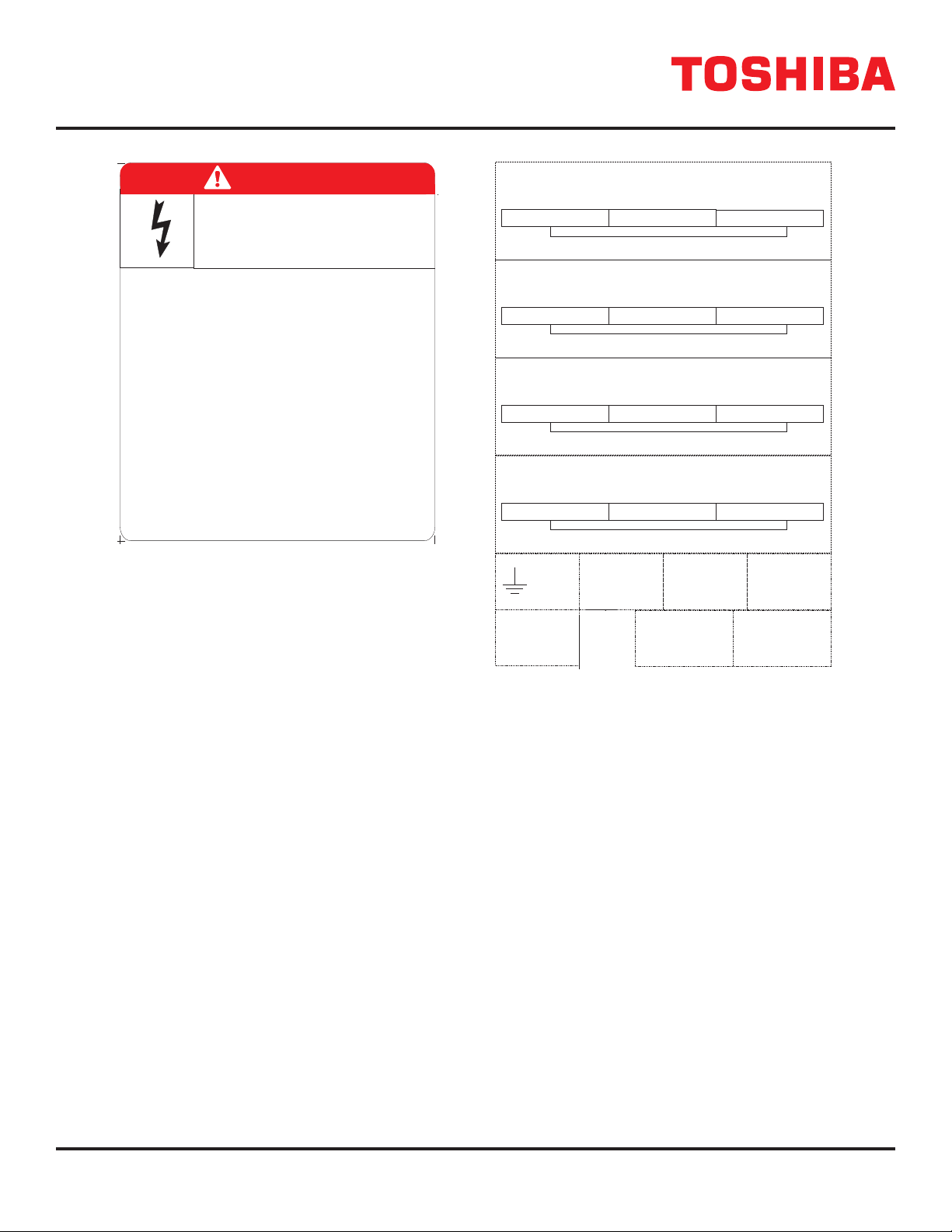

DANGER

Hazardous voltages are used in the operation

of this equipment and could cause severe personal

injury or loss of life.

The following precautions should be observed to

reduce the risk of injury or death.

HAZARDOUS VOLTAGES

Only qualified technicians familiar with this equipment and the

information supplied with it should be permitted to install and

operate this equipment.

Installation of electrical equipment must be done in

accordance with National Electrical Code and any other state

or local codes. Proper grounding and conductor sizing must

be installed for safe operation.

During operation, keep all covers in place and cabinet

doors shut.

When performing visual inspections and maintenance, if

possible, be sure the MBS is turned off and the incoming

AC feed is turned off and locked out.

If it is necessary to make measurements with the power

on, do not touch any electrical connection points. Remove

all jewelry from wrists and fingers. Make sure test equipment

is in good, safe operating condition.

While servicing, stand on some type of insulation, and be

sure not to be grounded.

Follow the safety instructions given in the equipment manual

carefully and observe all danger, warning and caution notices.

64818

MATERIAL - VINYL OR POLYESTER

TEMPERATURE - MINUS 20 TO 100 deg. C

ADHESIVE - V23 OR EQUIV.

MUST RESIST OIL SOLVENTS

ALL MATERIALS USED MUST

BE UL RECOGNIZED

WARNING AREA BACKGROUND COLOR: ANSI DANGER RED

WARNING AREA TEXT COLOR: ANSI WHITE

TEXT AREA BACKGROUND COLOR: ANSI WHITE

TEXT AREA TEXT COLOR: ANSI BLACK

CORNER RADIUS: VENDOR STANDARD

0.00

0.00

3.75

4.50

The UPS and Battery Cabinet will have hazardous

voltages present even after the AC feed is turned off.

THIS MATERIAL IS THE EXCLUSIVE PROPERTY OF TOSHIBA INTERNATIONAL

CORPORATION AND SHALL NOT BE REPRODUCED, USED, OR DISCLOSED

TO OTHERS UNLESS PRIOR WRITTEN AUTHORIZATION IS OBTAINED.

TITLE: SCALE:

DRAWING NO.:

ECN DATE BY

DRAWN: CHECKED: APPROVED:

DANGER LABEL

GENERAL - MBS

64818

FULL

WLM 3-9-11

REV:

0

13131 WEST LITTLE YORK ROAD, HOUSTON, TX 77041 U.S.A.

WLM 3-10-11

ZIR 3-10-11

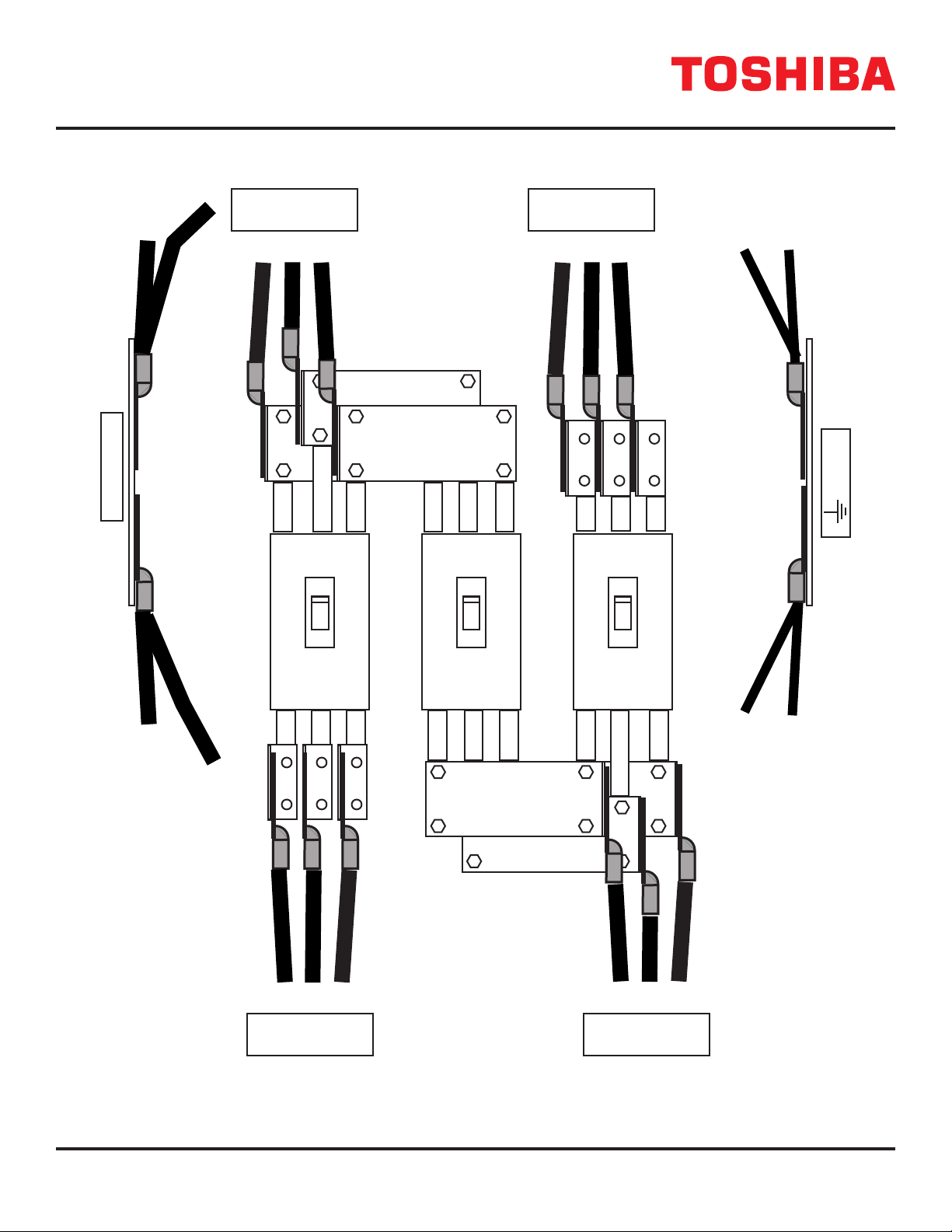

UNLESS PRIOR WRITTEN AUTHORIZATION IS OBTAINED.

THIS MATERIAL IS THE EXCLUSIVE PROPERTY OF

BE REPRODUCED, USED OR DISCLOSED TO OTHERS

TOSHIBA INTERNATIONAL CORPORATION AND SHALL NOT

APPROVED BY DATE

CHECKED BY

DRAWN BY DATE

DATE

DRAWING NO.

13131 WEST LITTLE YORK ROAD, HOUSTON, TX, 77041 U.S.A.

TITLE SCALE

OFSH.

ORDER NO.

64820

WALL MOUNT MBS CONNECTION

LABEL SHEET

1=1

11

DISK: PRT

REV: 1

AB C

1/2” BOLT-SAE GRADE 8

TORQUE SPEC: 119 FT LB

ENSURE PROPER PHASING

LINE IN

USE COPPER CONDUCTORS ONLY!

REFER TO INSTRUCTION MANUAL FOR WIRE SIZE

AB C

1/2” BOLT-SAE GRADE 8

TORQUE SPEC: 119 FT LB

ENSURE PROPER PHASING

LOAD IN

USE COPPER CONDUCTORS ONLY!

REFER TO INSTRUCTION MANUAL FOR WIRE SIZE

AB C

1/2” BOLT-SAE GRADE 8

TORQUE SPEC: 119 FT LB

ENSURE PROPER PHASING

UPS IN

USE COPPER CONDUCTORS ONLY!

REFER TO INSTRUCTION MANUAL FOR WIRE SIZE

AB C

1/2” BOLT-SAE GRADE 8

TORQUE SPEC: 119 FT LB

ENSURE PROPER PHASING

UPS OUT

USE COPPER CONDUCTORS ONLY!

REFER TO INSTRUCTION MANUAL FOR WIRE SIZE

B1 CB2

NEUTRAL

SKRU

B1

1

2

T

C

4.50"

3.50"

1.75"

MATERIAL - POLYESTER

TEMPERATURE - MINUS 20 TO 100 deg. C

ADHESIVE - V23 OR EQUIV.

MUST RESIST OIL SOLVENTS

ALL MATERIALS USED MUST BE UL & RoHS RECOGNIZED

TEXT BACKGROUND: ANSI WHITE OR SILVER

TEXT COLOR: ANSI BLACK

KISS CUT TO BORDER LINES

6.00"

9.00"

1.75"

CB3

GND

INITIAL RELEASE 04-11

ZIR

1.00"

1.50"

1.00"

WLM 4-24-13

3/8” BOLT-SAE GRADE 8

TORQUE SPEC: 47 FT LB

3/8” BOLT-SAE GRADE 8

TORQUE SPEC: 47 FT LB

3/8” BOLT-SAE GRADE 8

TORQUE SPEC: 47 FT LB

3/8” BOLT-SAE GRADE 8

TORQUE SPEC: 47 FT LB

ECO 86630 04-13

WLM

WLM 3-9-11

ZIR 4-24-13

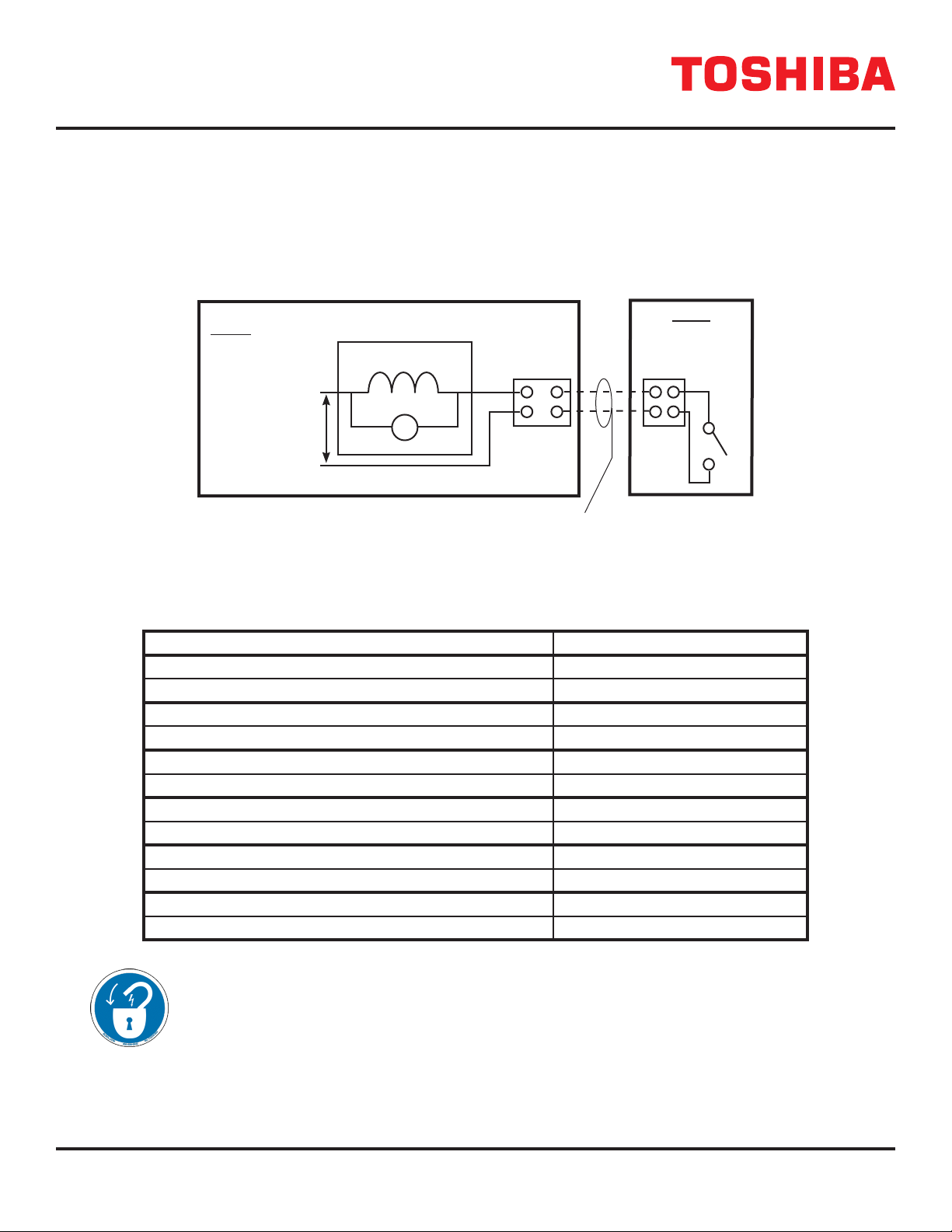

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should be followed during the installation, maintenance, and operation of

the MBS to assure safe and proper operation.

1. Turn o, lockout, and tagout all power sources before connecting the power and SKRU wiring to the equipment or

when performing maintenance.

2. Verify the MBS is de-energized before removing the cabinet dead fronts.

3. Verify cables and terminals are de-energized before installing cable in terminals.

Qualied Personnel ONLY!

Qualied Personnel is one that has the skills and knowledge relating to the construction, installation, operation, and main-

tenance of the electrical equipment and has received safety training on the hazards involved (Refer to the latest edition of

NFPA 70E for additional safety requirements).

Qualied Personnel shall:

1. Have read the entire operation manual.

2. Be trained and authorized to safely energize, de-energize, ground, lockout and tag circuits and equipment, and

clear faults in accordance with established safety practices.

3. Be trained in the proper care and use of protective equipment such as safety shoes, rubber gloves, hard hats,

safety glasses, face shields, ash clothing, etc., in accordance with established safety practices.

4. Be trained in rendering rst aid.

5. Be knowledgeable of batteries and the required handling and maintenance precautions.

For further information on workplace safety visit www.osha.gov.