Totai TOTG4502CB User manual

Issue 1-2019

Safe Appliance

LP Gas Safety Association

Distributed by: D.K.Gas Appliances (Pty) Ltd

email: [email protected]. Website: www.totai.co.za

PO Box 34191 Erasmia 0023

Safe Appliance

LP Gas Safety Association

This appliance complies with the requirements of SANS 1539.

LPGSASA Permit number: 1051-203/1-RSA-17-A

Distributed by: D.K.Gas Appliances (Pty) Ltd

PO Box 34191 Erasmia 0023

email: [email protected]. Website: www.totai.co.za

Read these instructions carefully before installing and using

the appliance, and retain them for future reference

TOTAI 4 Burner Gas Hob

Model TOTG4502CB

Instructions for installation and use

Important information for the user

Read these instructions carefully before using the appliance and retain them for future

reference. This appliance consumes oxygen when in use and it is important that it is only used in

a well ventilated area for the efficient performance of the appliance and for the safety of the

occupants of the area.

This appliance may only be installed by a registered LP Gas installer. All registered

installers are issued with a card carrying their registration number. Ask to be shown the card

before allowing the installation work to commence and make a note of the Installer registration

number. Upon completion of the installation, the installer is required to explain the operational

details of the appliance together with the safety instructions. You will be asked to sign

acceptance of the installation and be provided with a completion certificate. You should only

sign for acceptance of the installation when the installation is completed to your satisfaction.

Note that your invoice is required in the event that you wish to make a guarantee claim.

The appliance has been designed specifically for use with LPG and may not be used with Towns

Gas or Natural Gas.

Read these instructions carefully before commencing the installation.

Important information for the installer.

This appliance may only be installed by a LP Gas installer registered by SAQCC Gas, the

government appointed registering body for all gas installers. The appliance must be installed in

accordance with the requirements of SANS 10087-1 and any fire department regulations and/or

local bylaws applicable to the area. If in doubt, check with the relevant authority before

undertaking the installation. Upon completion of the installation you are required to fully explain

and demonstrate to the user the operational details and safety practices applicable to the

appliance and the installation.

For detailed installation instructions refer to section 8 & 9 of this manual.

Model Number

TOTG4502CB

Gas Type: LP Gas

Operating pressure

2,8 kPa

Total gas consumption: 545 g/h

Small Burners (1)

Jet size:0,50mm

Gas consumption: 73g/h

Medium Burner (2)

Jet sizs:0.65mm

Gas consumption: 127 g/h per burner

Large Burner (1)

Jet size 0,85mm

Gas consumption: 218 g/h

Technical data

Thank you for purchasing your new Totai Gas Hob manufactured to the highest standards

and fully tested in South Africa to ensure compliance with the South African Standard. This

appliance is designed to give the user years of trouble free and efficient service. Please read

the following instructions carefully. It is important to note that this appliance must be installed

by a registered LP gas installer as indicated below. The manufacturer and /or its agents and

distributors will not be held responsible for injuries or damages caused by faulty or incorrect

installation or use of the appliance.

2 7

Burner cap

Burner head

Jet

Grid

Ignitor location

Thermocouple Sensor

Ignitor

Fig 1

Clamp Worktop

Hob

Retaining Screw

Fig 3

Fig 1 is a typical Burner assembly showing how a burner has is located over the jet assembly

and next to the insulated ignitor post and thermocouple sensor (Flame Failure device). When

removing and replacing the burner heads take care not to knock or damage the ignitor or

thermocouple. When removing and replacing the burner heads note the original positions to

make sure they that correctly placed. Care must also be taken during cleaning of the hob.

The hob is fitted with a Flame Failure device. This is a safety feature such that in the event of a

loss of flame on any burner the gas supply will shut down

1

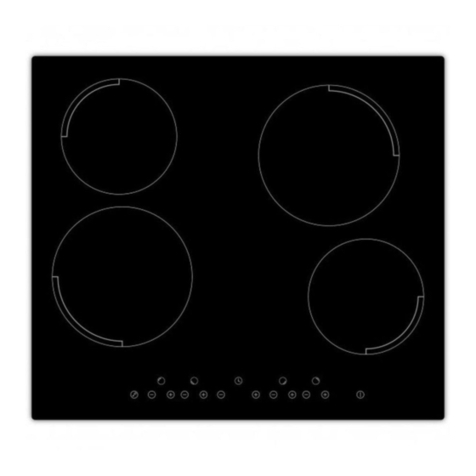

2

4

3

1

2

3

4

Fig 4

Identification of the burner

control knob to each burner

Fig.2

Battery Box

Positive

Terminal Negative

Terminal

6 3

·This model requires a low pressure 2,8 kPa LPG Regulator that complies with the requirements of

SANS 1237 to be fitted to the gas cylinder. Ensure that you obtain the correct regulator for the type of

cylinder used with the appliance. Cylinders suitable for use with the appliance are 9kg or greater. Do

not connect the appliance directly to a cylinder with a hose. It is dangerous to do so

·These appliances are fitted with a flame failure device on the cooker burners and therefore may be

connected to a fixed pipework system.

·Ensure that the gas cylinder is fitted or changed in a well-ventilated location, away from any sources of

ignition, such as naked flames and away from other people.

·In the event of a burnback, where the flame burns back and ignites at the jet, immediately turn off the

gas supply by firstly closing the control valve on the gas cylinder or ,where the cylinder is outside , the

isolation valve and then the appliance burner valve. Wait 1 to 2 minutes and light the affected burner in

the normal manner. If the burnback re-occurs call a service technician to examine the appliance and

do not use it until it has been certified as safe to do so.

1. General

·Where a flexible hose is used it hose must comply with the requirements of SANS 1156-2. The hose

must be clamped with a suitable hose clamp at both ends. Note: The hose and regulator are not

supplied with the Totai Hobs. Contact your local gas dealer to purchase the correct hose and regulator.

2. Safety Information

·The hose and the seal on the regulator must be checked for wear or damage before every use and

before connecting to the gas cylinder .

·Ensure the appliance is used away from flammable materials. Minimum safe distances are: above the

appliance 600 mm, at the rear and sides 500 mm.

·Do not place the appliance near doors and windows in order to avoid the possibility of draughts

affecting the burners

·Do not use an appliance that is leaking, damaged or which does not operate properly.

·Keep gas cylinders away from heat and flame.

·If there is a leak on your appliance (smell of gas), check for a gas leak as indicated below.

·Before testing for a leak firstly check that the regulator seal is in place and in good condition. Replace if

in doubt. Also check that the hose clamps on the regulator and the appliance are in place and properly

tightened. Examine the hose for signs of splitting or any other type of damage or wear. Replace if in

doubt.

·When satisfied that the above points are all in order then follow the steps below to check for a leak. Do

not try to detect leaks using a flame, use soapy water.

·Connect the cylinder to the appliance, open the cylinder valve and with the appliance valves in the

closed position, check for a gas leak as indicated below.

·If a gas leak persists return the product to your gas dealer for inspection and/or repair.

·In the event of a gas leak or smell of gas in the house or room in which the appliance is installed, close

the isolation or emergency shut off valve and open all the door and windows to ventilate the area. Do

not use any device with a flame, or turn any electrical switch on or off until the area is clear of gas and

the leak has been fixed by a qualified technician.

·Do not modify the appliance. Do not use it as a heater.

·During use, parts of the appliance will become hot. Avoid touching hot parts with bare hands. The use

of oven type gloves is recommended.

·Keep young children away from the appliance at all times.

·Hot oil and fats are flammable, use them very carefully. In the event of a fire involving hot oil or fats, turn

all the control knobs to the off position and extinguish the flames by smothering them with a pot lid or a

wet towel. Never throw water onto the flames as this will not extinguish them and may even

cause the flames to spread.

·To check for a gas leak, brush all the connection joints with soapy water. If bubbles form then there is a

gas leak. Immediately turn off the gas supply firstly by closing the control valve on the gas cylinder and

then the appliance valve, check that all the connections are properly tightened. Re-check with soapy

water.

Minimum clearance

each side 300 mm

View from front of hob

indicating the minimum

side clearances

View from side of hob in-

dicating the minimum front

and rear clearances

Minimum clearance

front and rear 50 mm

Fig 9

·Fig 9 shows the minimum

clearances for the sides, front and

rear of the appliance. It is important

for the safe operation of the

appliance that these minimum

clearances are observed.

·Now turn the hob up the correct

way and place it in the pre cut

opening in the work top ensuring

that it is centrally placed and that

the sealing strip is still in position

and is not pinched or trapped (see

Fig. 6)

·Now mount the four clamps (see

Fig 3) and tighten using the screws

provided. Do not over tighten.

·The unit is now ready to connect to

the gas supply

·To mount the hob in position, first

remove the grids , burner caps and

burner bodies from the hob. Turn

the hob upside down and rest it on

a firm flat surface. Apply the sealing

strip provided (see Fig 6) and fix

into position.

·The connection between a rigid metal gas supply pipe and the flexible hose must be made using a

proper gas fitting. The side of the fitting that connects to the metal pipe should preferably be a

compression fitting and the side that connects to the flexible hose should have a hosetail of the

form shown in Fig 7.

9. Gas connection information

·It the hob is installed over an oven fitted in the space below the worktop then a rigid pipe shall be

used to supply the gas. A flexible hose is not permitted under these circumstances.

·A mechanical fitting using a flared fitting using a rigid pipe

·A rigid metal gas supply pipe is the preferred method. If the circumstances of installation make the

use of a rigid pipe difficult then the maximum length of flexible hose allowed is 1,5 metres. When

using flexible hose ensure that it cannot come into contact with hot surfaces

·A mechanical compression gas fitting using a rigid pipe. Note that water fittings are not

allowed.

·This appliance requires a gas supply pressure of 2,8 kPa. A regulator that complies with SANS

1237 must be installed.

·The gas connection may be one of the following types:

·A hose connection using a flexible hose clamped to the hosetail (provided with the hob).See

Fig 7.

·The gas supply pipeline must be accessible over its complete length. This is particularly important

where a flexible hose is used.

·All joints must be checked for leaks after installation and before use. To check for leaks, apply a

soapy water solution with a brush or spry to all the joints in the system with the gas supply turned

on. Make sure the burner control valves are in the off position when doing this.

45

·Use only genuine Totai spares. These are available from your local gas supplier or directly from

the distributor. The contact details for the distributor are on the back page of this booklet.

9.Spares

3. Ventilation requirements.

·The gas hob is an unflued appliance and as such it is important from a safety perspective to

supply fresh air into the room in which the appliance is used. It is recommended that this is

achieved by means of a permanent opening such as an air brick, or a opening window that is kept

in an open position whilst the appliance is being used.

·Make sure that the area behind the hob is kept clear and that there are no flammable materials above

the hob.

5. Lighting the Burners

Large burner: 240mm-260 mm dia

·This will ensure that you will achieve the best cooking efficiency. If the flame appears to extend up

the sides of the pot either place the pot on a larger burner or reduce the flame height by adjusting

the required burner control knob. The small burner is ideal for simmering.

7. Cleaning the gas hob

4. Preparing the appliance for use

·Indirect ventilation is also allowed by taking air from rooms adjacent to the one to be ventilated.

·Remove all packing materials and protective film, where used

·Ensure that the burners and burner caps are correctly fitted into their specific locations

·Repeat the above process to ignite the other burners as required.

·Turning the control knob in a clockwise direction from the mid position will again reduce the flame level

and if the knob is turned fully in a clockwise direction to the Off position it will shut down the burner.

6. Using the gas hob

·Do not use any abrasive cleaning products on the hob as this will scratch the surface finish. It is normal

practice to remove the Pot grids for cleaning and to use a hot soapy water solution to remove any

spillage residues.

8.Servicing and maintenance

·There are no preset service or maintenance intervals for this appliance. If the appliance is cleaned

after every use, it should give years of trouble free service without needing any repairs or

servicing.

·Check that the pot support grids are in place.

·To light the burners push in and turn the control knob of the burner you wish to light in an anti clockwise

direct to the mid position. (see Fig.8) This will generate the automatic ignition spark causing the burner

to ignite.

·To adjust the flame to the required level, turn the burner control knob further in an anti clockwise

direction to reduce the flame. If turned fully in this direction, the flame will continue to burn at the

simmer position. Turning the control knob back to the mid position will give the maximum flame level.

·When cooking always use the burner that suits the pot size. For the most effective use of the burners

use the recommended pot sizes indicated below:

Medium burner; 200mm-240mm dia

·Note that each burner is fitted with a flame failure sensor which will shut off the gas supply if the burner

flame goes out. After lighting the burner hold the control knob in the pressed in position for 5-10

seconds to allow the flame failure sensor to function correctly, If the flame goes out when the knob is

released, repeat the light procedure and hold the control knob in for a few more seconds

·The power for the automatic spark ignition is provided by a Type D 1,5v dry cell battery(see Fig 2). The

battery box is on the underside on the hob situated on the front edge. It has a hinged lid for easy

access. It is recommended to replace the battery every 6 months

Small burner: 100mm-140 mm dia

Fig 6

Sealing strip

Fig 7

LPG Flexible hose

Hose Clamp

Hosetail

Sealing

Washer

10.1 Fitting instructions

·If a shelf is fitted to the space below the hob it

is important that this be placed at least

150mm below the underside of the hob

·This LP Gas hob may only be installed by a

registered gas installer.

·Before installing the appliance, make sure

that the LP Gas supply is capable of

delivering the required quantity of LP Gas at

the operating pressure shown in the table on

page 2.

·The LP Gas hobs covered by this instruction

manual are for domestic use only and may

not be installed or used for commercial

applications.

·It is important to note that the gas hob is an

unflued gas appliance and as such it may

only be installed in a well ventilated area. It

uses oxygen, and lack of ventilation may

cause oxygen depletion which could

endanger the life of the occupants of the area

in which the gas hob is installed.

·The surface in which the gas hob is mounted

and installed shall be not less than 30mm

thick and shall be of a heat resistant non

combustible material.

10.Installer information

·It is essential that the cut out in the mounting

surface is shown in Fig 5 and that a

minimum clearance of 300mm on the left and

right hand sides on the hob be established.

The 300mm clearance requirement also

applies to the walls adjacent to the appliance

(see fig 9). See also the cardboard template

that is supplied with the appliance to aid in

placing the cut out in the correct position in

the mounting surface.

·Note: After installation and before handing

over the appliance to the user. Check the

min. flame setting on all the burners. This can

be individually adjusted by inserting a small

flat blade screwdriver into the hole in the

control valve spindle for each burner and

turning it in a clockwise or anti clockwise

direction to increase or decrease the flame as

required. Once set this does not require

further adjustment by the user.

500 mm

553 mm

600 mm

473 mm

Fig 5

Worktop

Take note of the minimum clearances for the

front, back and sides as shown on Fig 7

Off

Low

flame

Ignite and

high flame

Fig 8

Other Totai Hob manuals