TouchTronics PowerTouch 914 User manual

NST13308-P914_A 2020-06-10 Page 1

57315 Nagy Dr

Elkhart, IN 46517

800-294-2570

574-294-2570

www.touchtronics.com

By TouchTronics, Inc.

Power

All four outputs are 5 amp, switched relays.

Flexibility

Installer can select polarity of voltage outputs on all channels.

Optional Transmitters

Large, oval transmitters with large buttons can be ordered.

Standard 4 Channels

Two and four channel transmitters are interchangeable.

Special Features and Applications

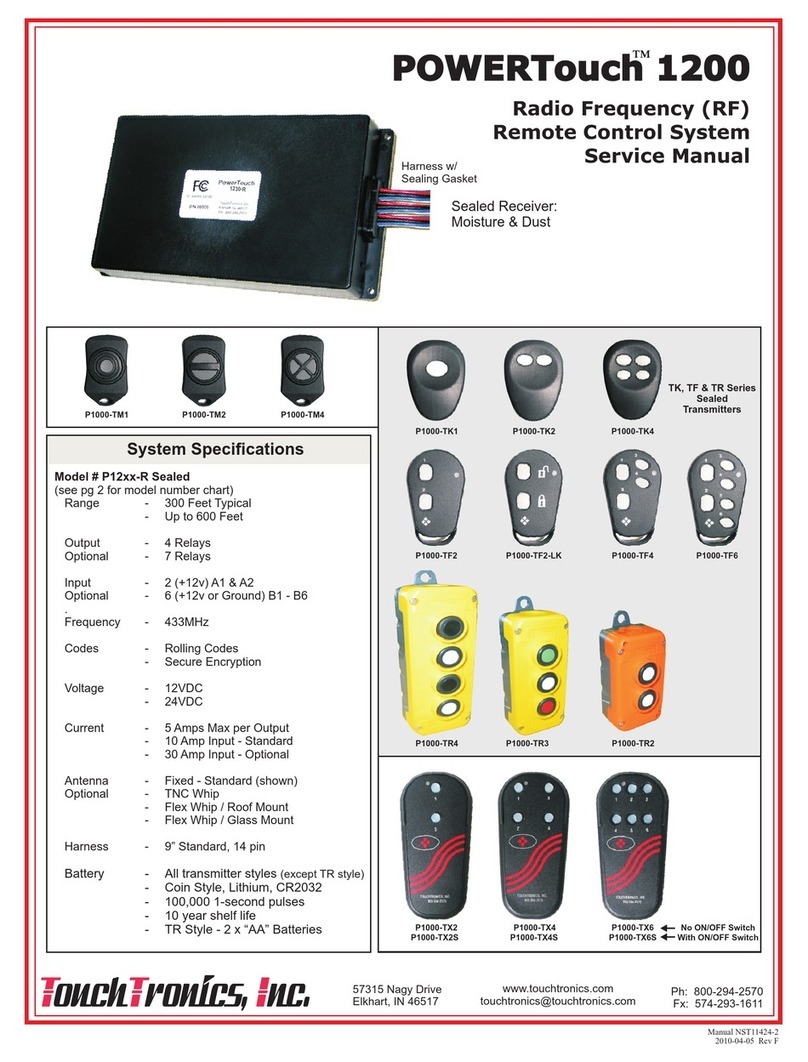

914 PowerTouch Remote Control Receiver

With Two (4 button) Key Chain Transmitters

Also showing optional:

Two (two button) Key Chain Transmitters

And Oval Transmitter

co mi l

Eno ca

nd

a

Ver t esa il

Please read entire instruction manual prior to starting the

PowerTouch Remote Contr ol System Installation.

PowerTouch 914

Range

Typical antenna range is 60-feet.

Compact

Receiver is small and easy to install.

Pr ogram Options

Two channels can be programmed as latching,

On - Of

f

Channel 2 can be programmed with a 2-second courtesy light delay

NST13308-P914_A 2020-06-10 Page 2

Contents

Special Features and Applications Page 1

Contents, Specications, InstallationTools, Technical Support Page 2

Component Parts List Page 3

Operation: Remote Control Page 3

Installation: Planning Page 4

Installation: Receiver Page 4

Installation: Electrical Connections Page 5

Installation: Application Schematics Page 6

Installation: Motors Using Relays, Safety Disable Switch Page 7

Trouble Shooting Guide Page 8, 9, 10

Limited One (1) Year Warranty Page 11

Blank Page (Installation Notes or Diagrams) Page 12

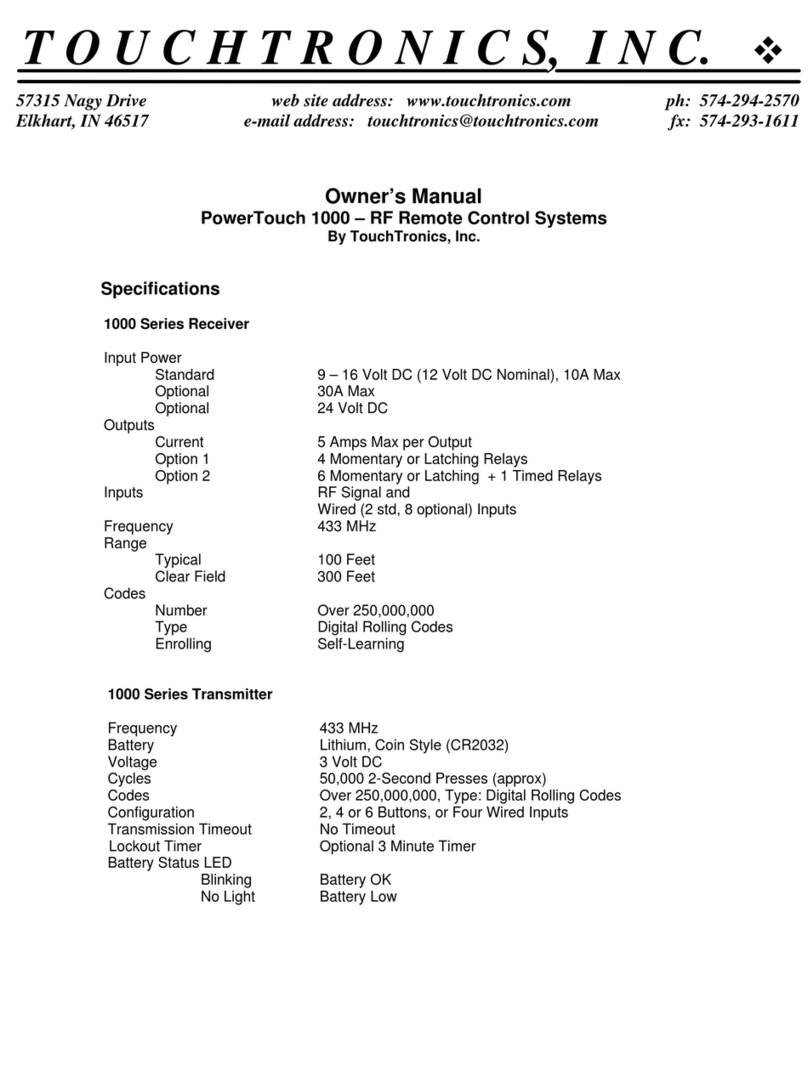

Specications

914 Receiver: FCC Approved

RF System 19,000 Digital Codes

Voltage 12 Volt DC (available in 24 Volt DC)

Output 5 Amp

Frequency 300 MHz

Range 60 Feet (typical - using standard 9” wire style, antenna)

Note: Range may be extended with an externally mounted antenna

914 Transmitter: FCC Approved

RF System 19,000 Digital Codes

Battery 12 Volt DC

Cycles 7,300 One Second Pulses

Frequency 300 MHz

Note: Key chain style transmitters are water resistant, NOTwater proof

Oval style transmitters are water and dust resistant

Physical:

Receiver: 4.5” x 2.5” x 1” (width, height, depth)

Transmitter: 1” x 2” (width, length) key chain style

2” x 4 ½” (width, length) oval(hand held) style

Installation Tools

Voltmeter, analog or digital

Phillips Screw Driver

Adjustable Wrench

Screw Driver

Wire Cutter

Wire Stripper

To Clean Grounding Pad: Scraper, Sand Paper, Alcohol Based Cleaner

Technical Support

Visit the factory website to download a copy of these instructions, e-mail technical questions and see other

TouchTronics, Inc. products.

Phone / Fax Numbers

Indiana Local 1-574-294-2570

Toll Free 1-800-294-2570

Fax 1-574-293-1611

Web Site

www.touchtronics.com

E-Mail

‘Contact Request’link on the web page

X

NST13308-P914_A 2020-06-10 Page 3

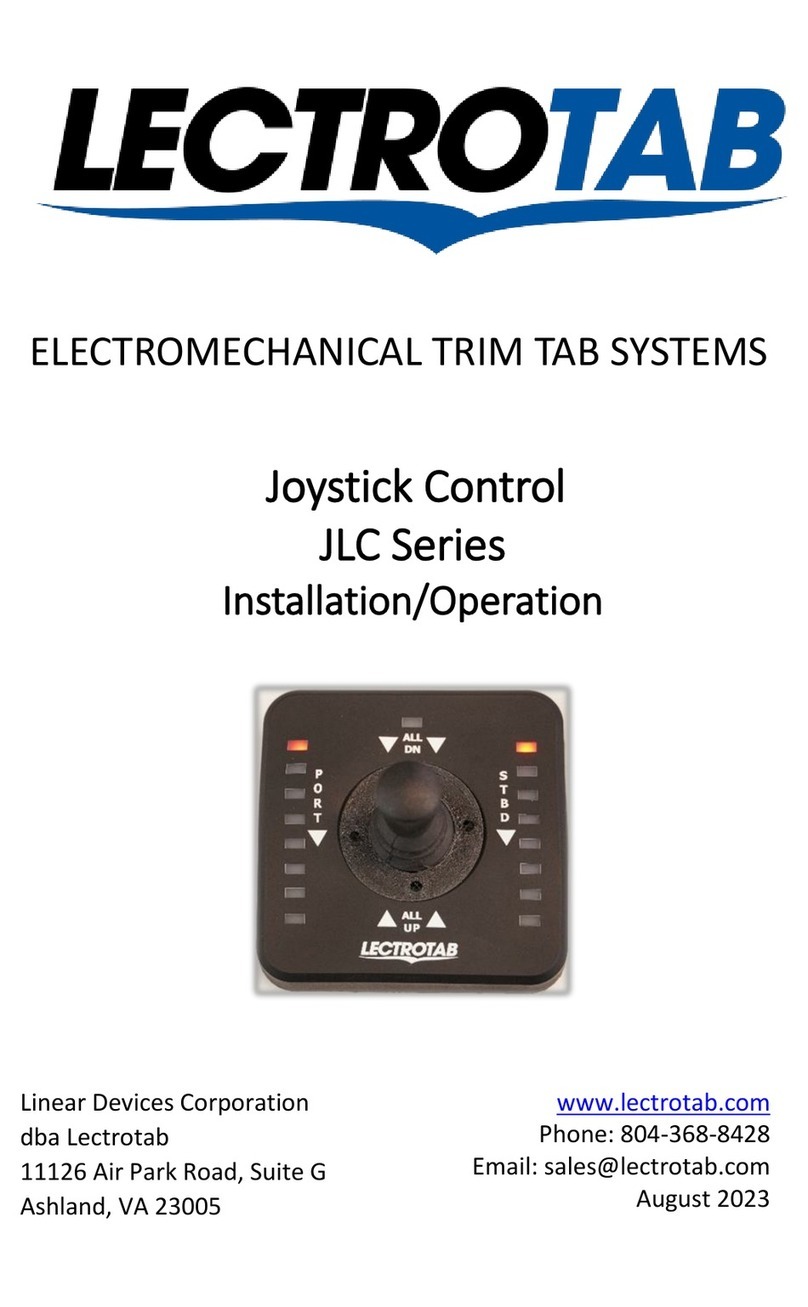

1) 1 pc 914rRF Receiver , 4 Channel

w/9” antenna wire

2) 1 set 914hHarness - 10 wire, 9”

3) 2 pcs 914T4 Transmitter,

4 button key chain style

Optional 914T2 Transmitter,

2 button key chain style

Optional 914T4XS Transmitter,

4 button oval (hand held) style

Component Parts List

Operation: Remote Control

Transmitters:

1) Press and releasebutton

Or

2) Press and hold button

3) Red Status LED

Signal is sent to receiver - 1 second pulse

Signal is sent to receiver as long as button

is held. Signal will stop when button is

released.

A) LED On red indicates signal is being

sent

B) LED On bright and solid indicates

battery voltage is ok.

2 Button

1

1 & 2

2

N/a

Channel

1

2

3

4

Function

Motor or Lamp

Motor or Lamp

Motor or Lamp

Motor or Lamp

Power Output

+12v or Ground(-)

+12v or Ground(-)

+12v or Ground (-)

+12v or Ground (-)

Signal T ype

Momentary

Momentary

22 sec delay (ch 4)

Momentary

Or Latching

Momentary

Or Latching

Transmitter Operation Receiver Operation

Output

5 Amps Max

5 Amps Max

5 Amps Max

5 Amps Max

*Example - Courtesy light turns on for 22 seconds when button 2 is pressed,

and the channel 4 output is connected to the courtesy lights.

All outputs must be same polarity

*See example below

4 Button

1

2

3

4

Transmitter Transmitter

Pr essed at the

same time

NST13308-P914_A 2020-06-10 Page 4

1) Receiver Output Voltages

A) The receiver has four output voltage (channels) which will operate four separate circuits. The

output voltage is 12 volts direct current (vdc).The maximum drive current for each of the four

output channels is 5 Amps (maximum) . The four outputs can turn On (drive) bulbs, relay coils or

small motors.

B) Check the power requirement for the bulb or motor before connecting to the receiver.

Maximum 5 amps @ 12vdc or 60 watts @ 12vdc

2) Determine where the receiver and antenna will be located.

Typically the RF receiver is located under the dash or behind a wall panel in the back. If the receiver

is to be mounted outside the cab area then you must protect the receiver. The receiver is NOT

waterproof or moisture resistant*.

DO NOT mount the receiver and antenna:

A) Within 6 feet of a motor

B) Near lar ge bundles of wires

C) Near other antennas or RF devices

D) The antenna should not be touching any metal as this grounds the RF (radio

frequency) signal

*T ouchTronics offers weather resistant housings for many different types of applications. Call the

factory @ 1-800-294-2570 for information on yourparticular application needs.

Installation: Planning

Installation: Receiver

(-)

Battery

(+)

12

11

10

09

08

07

06

05

04

03

02

01

PowerT ouch Remote Contr ol System

Series 914 RF Receiver

This device complies with FCC rules part 15.

Operation is subject to the following 2 conditions:

1) This device may not cause harmful interference

2) This device must accept any interference received

including that causing undesired operation

9” Antenna Wire

*Maximum output current 5 Amps. Overcurr ent will damage outputs.

1a Maximum

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red

Ch 4 - Output, 5 amp

Power +12v - 5 amp

Ch 3 - Output, 5 amp

Ch 1 - Input for rr@g circuit (-)*

Ch 2 - Input for rr@g circuit (-)*

Ch 1 - Output, +12v, 5 amp

Ch 2 - Output, +12v, 5 amp

Empty

Do Not Use

Chassis Ground

Empty

Logic +12v

*RR@G - Reversal Rest @ Gr ound

Notes:

1) Channels 1 and 2 are momentary outputs as long as the button is pressed.

2) Channels 3 and 4 are factory set as momentary outputs as long as the button is pressed. These outputs can be

programmed as latching (push on - push off). Call the factory for program information at 1-800-294-2570

10a Maximum

Range of your Remote

Control is affected by

the installation location

of the receiver antenna

Warning!

Use only a voltmeter to check voltage during installation and testing.

*Using a test light WILL damage the outputs!

*See Note Below

Scrape paint and clean area before installing ground screw

#10 x 3/4” Screw

#10 3/16” Star Washer

#10 3/16” Ring Terminal

Vehicle Frame

CHASSIS GROUND

NST13308-P914_A 2020-06-10 Page 5

1) Install Power

Connect the Red wire to a constant +12v battery power source. Note: For best performance, run a

clean +12v (15A) directly from the battery or a fuse that is NOTsupplying any power to motors,

lights or any other type of high current device.

2) Install Gr ound

Connect the Black wire to chassis ground

A) Scrape all paint and grease away from the body frame.

A loose chassis ground connectionWILL cause intermittent operation of r eceiver.

B) Clean the area using an alcohol based cleaner to remove paint chips and grease.

C) Crimp a #10, 3/16” ring terminal onto the black ground wire.

D) Insert the ring terminal and a #10, 3/16” star washer over a 10x3/4” hex head,

self-tapping ground screw.

E) Tighten ground screw securely into clean frame area.

3) Install Outputs - Maximum output is 5Amps per channel

A) Connect only One Channel output wire at a time to a relay or function which uses 5 Amps

B) Solder connections and protect with shrink tube or use an 18g insulated butt terminal.

Installation: Electrical Connections

Channel

Channel 1

Channel 2

Channel 3

Channel 4

Output

RR@G

(+) positive

RR@G

(+) Positive

(+) Positive

(+) Positive

Wi re

Color

Green / Black

Green / Red

Yellow / Black

Yellow / Red

Tan

White / Tan

Max

Output

5 Amp

5 Amp

5 Amp

5 Amp

5 Amp

5 Amp

Pin

Position

09

07

08

06

10

12

4) W iring Inspection

A) Check all wiring

connections visually

B) Check the polarity

of all wires

C) Tape off or remove

all unused wires.

See Diagram on Page 4 - ‘Installation: Receiver ’

Input

+

+

-

W ir e Color

Red

Purple

Black

Max Input

1 Amp

10 Amp

1 Amp

Pin Position

01

11

03

Logic Power

Relay Power

Ground

See Diagram

on Page 4

Orange - Pin 4 - Not Used

30

87a

85

86

87

N.C . N.O.

R elay 4

87a

85

86

87

N.C . N.O.

30

87a

85

86

87

N.C . N.O.

R elay 3 30

87a

85

86

87

N.C . N.O.

30

87a

85

86

87

N.C . N.O.

R elay 2 30

87a

85

86

87

N.C . N.O.

30

87a

85

86

87

N.C . N.O.

R elay 1 30

87a

85

86

87

N.C . N.O.

Channel 4

Channel 3

Channel 2

Channel 1

Pin 7 - Green / R ed

Ground

Pin 4 - Orange Do Not Use

Pin 3 - B lack C hassis Ground

Pin 1 - R ed +12v Power

Pin 9 - Green / B lack

Pin 6 - Y ellow / R ed

Pin 8 - Y ellow / B lack

Pin 12 - White / Tan

Pin 11 - Purple Power

Pin 10 - Tan

B oard Jumper

Power Touch R eceiver / R elay Schematic

+1

+2

+3

+1

+2

+3

+1

+4

+2

+5

+3

+6

+12v

Fused

Ground

M

A pplication for Door s and W indows

Master

Relay

System

Switch 1 Switch 2

Door

Lock

or

Window

Switches

Master

Relay

DPDT(DM)

Door Lock or

Window Motor

+12v

Fused

914 PowerTouch

Green/Red Wire 914 PowerTouch

Yellow/Red Wire

Relays may dier

from manufacturer

to manufacturer.

-2

+1

+3 -4

+5

M

Slave Switch

Door Lock or

Window Motor

914 PowerTouch

Green/Red Wire

914 PowerTouch

Yellow/Red Wire

R eversal Rest@ G round Switch System

-2

+1

+3 -4

+5

Master Switch

914 PowerTouch

Green/Black Wire

914 PowerTouch

Yellow/Black W ire

Cut

Door Lock or W indow Switches

NST13308-P914_A 2020-06-10 Page 6

Installation: Suggested Application Schematics

The following schematics are for reference only. The installer must verify that the circuit is properly wired

with the correct gauge of wire, and properly fused with the correct fuse size and type for the circuit.

Vehicle window switches and door lock switches can be designed as a positive pulse, a negative pulse or

a reversal rest @ ground circuit.

To determine which type is used in your vehicle, take a voltmeter and probe one of the output wires at the

switch. Check the polarity with the switch pressed and without the switch pressed. Compare results with

the chart below.

Window or Door Lock Switch

Positive Pulse

Negative Pulse

Reversal Rest@Ground

Switch NOT Pressed

No Voltage / Floats

No Voltage / Floats

Ground

Switch Pressed

+12 Volts

Ground

+12 Volts

Typical # of Wires

3 Wires

3 Wires

5 Wires

**Please Note:

Due to continually changing wire colors through-out the automotive industry, TouchTronics can

NOT provide accurate wire color information on a consistent basis.Therefore, if the wire colors

needed for installation are not known, please contact a local dealer and they should be able to

provide any necessary information.

Vehicle Door

Lock R elays

To Door

Lo ck M otors

Pass Door

Lock Switch

Positive Pulse System

Button ‘1’

Door Unlatch

Lock Unlock Lock Unlock

+12V DC +12V DC

Drive Door

Lock Switch

(+)

(+)

(+)

Vehicle Door

Lock R elays

To Door

Lo ck M otors

Pass Door

Lock Switch

Negative Pulse System

Button ‘1’

Door Unlatch

Lock Unlock Lock Unlock

Ground Ground

Drive Door

Lock Switch

(-)

(-)

(-)

Diagram 6b

Diagram 6a

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Pur ple - *+12V DC

Tan

Green/B lack

Y el low/B lack

G r een/R ed

Yellow/R ed

Empty

Orange

B lack

Empty

R ed

PowerTouch

914 R eceiver

(+)

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Pur ple - * G r ound

Tan

Green/B lack

Y el low/B lack

G r een/R ed

Yellow/R ed

Empty

Orange

B lack

Empty

R ed

PowerTouch

914 R eceiver

(-)

Unlock

Lock

Unlock

Lock

Driver Door

Lock Switch

Pass Door

Lock Switch

R eversal Rest@ Ground System

30

87a

85

86

87

30

87a

85

86

87

Lock Relay Unlock Relay

To Door

Lock Motors

+12v Fused

@ 10 Amps

5

Unlock

Typical Switch

Electrical Diagram

Reversal Rest @ Ground

1

Lock

GND

2

+12v

3

GND

4

CUT

(+)

(+)

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple- *+12V DC

Tan

Green/Black

Yellow/Black

Gr een/Red

Yellow/Red

Empty

Orange

Black

Empty

Red

Po uchwerTo

9 ec v r14 R ei e

(+)

(+)

*C onnect P ur ple

wire t o G R OUND

*C onnect P ur ple

wire to +12V D C

Diagram 6c Diagram 6d

Ground

*C onnect P ur ple

wire to +12V D C

NST13308-P914_A 2020-06-10 Page 7

Installation: Motors Using Relays, Safety Disable Switch

WARNING! If using any type of motor, such as a window motor, a ramp motor, a door motor

,

or a winch motor - add a Disable switch to prevent the door or window circuit from operating when

vehicle is in motion.

A disable switch should be installed in many applications to deny operation of the motor when a

vehicle is in motion. However, due to changes in automotive electrical design and the addition of

computer controlled circuits, it is no longer advisable or safe to tap into or cut wires to disable automotive

factory circuits. To overcome this problem, you must install an electro-mechanical switch which will

determine gear position, thus safely disabling the circuit while the vehicle is in motion. Below are three

options for installing a Safety Disable Switch.

Unlock

Lock

Unlock

Lock

Driver Door

Lock Switch

Pass Door

Lock Switch

R eve rsal Rest@ G round System

30

85

86

30

85

86

Driver Door

Lock Relay

Pass Door

Lock Relay

Door

Lock

Motors

CUT

M M

Typical Current

Draw is 100mA

Positive Switch System

30

87a

N.C.

85

86

87

N.O.

30

85

86

Window Relay

DOWN

Window Relay

UP

+12v Fused

@ 20 amps

Safety Disable

Switch

M

Window Motor

Down

Window Motor

Up

Ground

High

Current

Ground

+12v Fused

Window

Switch

Down (+)

Window

Switch

Up (+)

Negative Switch System

30

85

86

30

85

86

Window Relay

DOWN

Window Relay

UP

M

High

Current

Ground

Ground

Window

Switch

Down (-)

Window

Switch

Up (-)

Safety Disable

Switch

When vehicle is in park, the

safety disable switch is closed

which completes the ground circuit

When vehicle is in park, the

safety disable switch is closed

which completes the power circuit

(-)

Battery

(+)

1a Fuse

Fuse

(-)

Battery

(+)

Fuse

Safety

Disable

Switch

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red

Typical Curr ent

Draw is 100mA

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red

Typical Curr ent

Draw is 100mA

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red

Window Motor

Down

Window Motor

Up

e TouPow r ch

4 R ce91 e iver

e TouPow r ch

4 R ce91 e iver

uPowerTo ch

4 c91 R e eiver

87a

N.C.

87

N.O.

87a

N.C.

87

N.O.

87a

N.C.

87

N.O.

87a

N.C.

87

N.O.

87a

N.C.

87

N.O.

Steering

Column

Magnet

1) Attach magnet to gear shifter.

2) Attach switch to dash so that when

magnets are together the switch is NC

and when magnets are apart the

switch is NO

Swit hc

Option1: Proximity Switch

ea Shif L everG r t

Steering

Column

Option2: Limit Switch

Limit Swi tch

With Lever

ea Shif L everG r t

Steering

Column

Option3: Inductive Proximity

Inductive

Proximity

Sensor

a fGe r Shi t L ever

+12v dc

Ground

+12v dc

Note: input is Positive

pin #11 purple wire

Note: input is Negative

pin #11 purple wire

Note: input is Positive

pin #11 purple wire Schematic: Automotive Relay

30

87a

85

86

87

N.C. N.O.

NST13308-P914_A 2020-06-10 Page 8

Installation: Application Schematics

20 / 30 Amp Motor Application for R eversal Rest@ G round System - C hannels 1 and 2

30

87a

85

86

87

Typical Curr ent

Draw is 100mA

M ultiple M otors

30

87a

85

86

87

30

87a

85

86

87

Window

Relay

DOWN

Window

Relay

UP

M

Window Motor

Down

Window Motor

Up

10 Amp Motor Application ForR eversal Rest @ Ground - C hannels 1 and 2

Primary

Switch

(+)

B attery

(-)

+12v

Switch

SPDT

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red

Typical Current

Draw is 100mA

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red

30

87a

85

86

87

30

87a

85

86

87

Window

Relay

DOWN

Window

Relay

UP

+12v Fused

Safety Disable Switch

M

Window Motor

Down

Window Motor

Up

Ground

High

Current

Ground

+12v L ogic Fused @ 1 amp

(+)

B attery

(-)

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red +12v L ogic Fused @ 1 amp 30

87a

85

86

87 M

+12v

30 Amp

Fused

+12v

30 Amp

Fused

30 Amp

DownUp

Ground

30 Amp

e T uPow r o ch

4 R ce91 e iver

PowerTouch

914 R ecei erv

P werTouo ch

14 R cei e9 e v r

Up

Down

Secondary

Switch

Up

Down

M

Up

Down

Maximum 10 Amps

+12v

Switch

SPDT

+12v L ogic

Fused @ 1 amp

Street Rod A pplication

(+)

B attery

(-)

12

11

10

09

08

07

06

05

04

03

02

01

12

11

10

09

08

07

06

05

04

03

02

01

White/Tan

Purple

Tan

Green/Black

Yellow/Black

Green/Red

Yellow/Red

Empty

Orange

Black

Empty

Red +12v L ogic Fused @ 1 amp

e T uPow r o ch

4 R ce91 e iver

Optional

Magnetic

Switch

30

87a

85

86

87

30

87a

85

86

87 M

+12v

30 Amp

Fused

+12v

30 Amp

Fused

30 Amp

Down

Up

Relay Up

Relay Down

-2

+1

+3 -4

+5

Down Up

+12v

Fused

Window Switch

30

87a

85

86

87

M

Pull Push

+12v

M

Pull Push

+12v

Optional

Magnetic

Switch +12v

Ignition

Switch

**Safety relay circuit when

using door open function

Pass Door

Open Motor

Drive Door

Open Motor

Fuse

Fuse Fuse

Fuse

*Note: All wiring and components must be sized properly for this high current application.

*Note: All wiring and components

must be sized properly for this high

current application.

NST13308-P914_A 2020-06-10 Page 9

Trouble Shooting Guide - 914 Series Remote Contr

1.0 No output from one

or more channels on

remote control receiver

1.1 No signal from

transmitter

1.2 One or all of the

outputs have failed.

1.3 Power wire not

connected

1.4 Receiver outputs ok,

but relays or equipment

does not operate.

1.1a Verify that transmitter is sending a signal and

that transmitter is coded correctly.

1.1b See symptom 3.00

1.2a Press each transmitter button in sequence.

While pressing button, use only a voltmeter probe

to check each corresponding output

Green / Black Button ‘1’

Yellow / Black Button ‘2’

Tan Button ‘3’

White / Tan Button ‘4’

1.2b If checking voltage, a positive signal is

present when button is pressed and oat when not

pressed if input to purple wire is +12v .

1.2c If outputs read nothing when pressed or not

pressed and you do not hear the relay clicking,

then the power supply is damaged. Send back to

factory for repair or replacement.

1.2d Any of the above problems can be caused by

a defective unit or damage by the customer from

over-voltage, over-current or testing the inputs

and outputs using a test light instead of a

voltmeter.

1.3 Check voltage on purple wire - if +12v not

present, check wire harness for problems.

1.4 Check wire and equipment for problem

Symptom

Trouble Shooting Guide - 914 Series Remote Control

Possible Cause Corrective Action

2.0 Signal transmitted

and relay chatter in

receiver, but no

operation.

2.1 One or both of the

outputs have failed

2.2 Receiver has failed

outputs

2.1a Check wire harness for loose connections or

damaged wires or terminals

2.1b Check equipment for problem in motors or

relays

2.2 Recheck section 1.0

Symptom Possible Cause Corr ective Action

Warning!

Use only a voltmeter to check voltage during installation and testing.

*Using a test light WILL damage the outputs!

NST13308-P914_A 2020-06-10 Page 10

Trouble Shooting Guide - 914 Series Remote Control

3.0 No power to remote

control receiver

3.1 Logic ground or

power connection to

receiver has failed

3.2 Chassis ground

connection has failed

3.1a Check ground (black wire) and power (red

wire). Use a voltmeter probe when checking

voltage.

3.1b If either ground or power is not present, then

locate failure in wire harness and repair.

3.2a Check chassis ground connection, it should

be clean and tight, no paint on metal, an external

tooth star washer should be present, no rust or dirt

in connection.

3.2b Chassis ground should be located on vehicle

frame.

Symptom Possible Cause Corrective Action

4.0 No signal (code)

being transmitted

4.1 Battery voltage low

4.2 Transmitter is not

sending a signal

4.3 Transmitter code is

incorrect

4.4 Not all buttons send

a signal when pressed.

4.1 Check battery voltage. Replace battery if

voltage is 8.5 volts or less. (Signal strength is

dependent upon battery voltage.)

4.2 Place probe from voltmeter on battery (+) and

(-) leads. Press any button, voltage should change

by 0.2 to 0.3 volts if a signal is transmitted. Check

both buttons.

4.3a If transmitter is sending a signal and no

signal is being received, re-code transmitter.

4.3b Send back to factory for re-coding.

4.4 If a signal is not transmitted on all buttons,

send back to factory for repair or replacement.

Symptom Possible Cause Corrective Action

5.0 Poor range 0’to 25’

(pulsating 0’to 25’)

5.1

Antenna damaged or

grounded

5.1a Check antenna placement, it should not be

touching any metal or tinted glass.

5.1b It should not be closer than 6’to any motors

or relays.

5.1c If it is coiled, then stretch it out and place

near a window.

5.1d If antenna is cut or damaged, send back to

factory for repair.

5.1e NOTE: Antenna can NOTbe shortened or

altered in any way

Symptom Possible Cause Corr ective Action

Warning!

Use only a voltmeter to check voltage during installation and testing.

*Using a test light WILL damage the outputs!

NST13308-P914_A 2020-06-10 Page 11

Trouble Shooting Guide - 914 Series Remote Control

Symptom Possible Cause Corr ective Action

5.0 Poor range 0’to 25’

(pulsating 0’to 25’)

5.2 Receiver installed in

poor locations such as

near door or lift motor

5.3 Receiver logic

power input is exposed

to radiated noise from

wire harness or motors

5.4 Receiver logic

ground is exposed to

radiated noise from wire

harness or motors

5.5 Transmitter 9-volt

battery is low

5.6 Out of 25 foot range

5.7 Interference

5.8 Component of

receiver damaged or

defective

5.9 Other equipment

installed in vehicle

causing voltage drop

when initially turning on

5.2a Disconnect door and / or ramp motor and

recheck range.

5.2b If range is ok, then ‘electrical noise’ from

motors is causing interference with RF signal.

5.2c Move receiver and antenna a minimum of 6

feet from the motors.

5.2d If moving receiver 6 feet does not improve,

an external antenna may be required to boost

signal.

5.3a Disconnect receiver logic power input from

main wire harness

5.3b Run new wire from vehicle battery to red

wire.

5.4a Disconnect receiver logic ground input from

main wire harness

5.4b Remove black wire on receiver from wire

harness and install on the vehicle frame fora new

chassis ground or vehicle battery.

5.4c Remove any paint or residue from metal, use

an external tooth star washer and tighten new

chassis ground terminal securely to vehicle frame.

5.5 Replace battery if voltage is 7.5 volts or below

5.6 Move closer to the vehicle

5.7a Electromagnetic interference (EMI) caused

by any radio frequency (RF) nearby, motors,

welding equipment, relays, etc. May be in close

proximity to receiver / transmitter.

5.7b Move closer to antenna or move vehicle out

of range of EMI caused by radio frequency,

welding equipment, as this is a temporary

problem.

5.7c If EMI is caused by relays, door motors or

lift motors then the receiver must be moved or

shielded or the EMI noise diverted to ground. Call

the factory for details.

5.8 Send back to factory for repair or

replacement.

5.9 Remove all other equipment from logic

ground and power.

NST13308-P914_A 2020-06-10 Page 12

Limited One (1) Year Warranty

Thefollowingrevised warrantyprocedures willbeimplementedand effective March 1, 2002.

1) All products will nowbe shipped withan individual bar codeattached.

2) Thebar code willinclude someor all of thefollowing information.

A) Date of Manufacture

B) Serial Number

C) Private Code

D) Part Number

3) Warranty Cards are no longer required to be eligibleto receivetechnicalsupport and service.

4) Each individual product iswarranted under the TouchTronics Limited Warranty program

for

1 fullyear fromdate ofpurchase or a maximum of 2 years from the date of manufacture.

5) No product will becovered under theTouchTronics Limited Warranty program that has a

manufacture date older than2 years.

6) To receive technicalsupport or warrantyservice,simply call our technicalsupportcenter

during regular business hours.

7) To enable our technicalsupport staff to better serve you, please have the following

information available when you call.

Manufacture

Purchase

Installation

Date Of:

Dealer Name

Dealer Phone

Make / Model

Vehicle Information:

Part Number

Serial Number

Private Code

Product Information:

Please ll in all pertinent information at

the time of purchase or installation

TouchT

ronics, Inc. Warranty Policies and Procedures

SectionOne

Seller will warrant any product originally manufactured or assembled and sold by seller for a period of up to

TWO YEARS (24 months) from the original date of

manufactureor ONEYEAR (12months) from theoriginal retail saleor O.E.M. in-servicedate.

SectionT wo

The following are in lieu of all warranties; expressed; implied; or statutory, including but not limited to, any implied warranty of merchantability of tness for a particular

purpose and of any other warranty obligation on the part of seller. Seller, except as otherwise hereinafter provided, warranty the goods against faulty workmanship or the

use of defective materials for a period of up to TWO YEARS (24 months) from the original date of manufacture or ONE YEAR (12 months) from the original retail or

O.E.M.in-service date.

Sellers sole and exclusive liability shall by (at sellers option) to repair; replace; or credit buyer for such goods which are returned by buyer during the applicable warranty

periodset forth above, provided that(I) seller ispromptly notiedin writing orphone upon discovery by buyerthat such goodsfailed toconform and anexplanation of any

alleged deciencies, (II) such goods are returned to seller , (III) sellers examination of such goods shall disclose that such alleged deciencies actually exist and were not

caused by accident, misuse, neglect, alteration, improper installation, unauthorized repair or improper testing. If seller elects to repair or replace such goods, seller shall

havea reasonable timeto make suchrepairs or replacesuch goods.

Sellers warranties as herein above set forth shall not be enlarged, diminished, or affected by, and no obligation or liability shall arise or grow out of, sellers rendering of

technicaladvice or service.

Damage to products caused by the customer or during installation cannot be claimed under this warranty. All devices returned that are not covered under the sellers

warranty policy, will be charged a minimum of $25.00 for evaluation plus additional charges for components and labor to repair the device not to exceed the original

selling price. Seller considers the following to be typical examples of customer or installation damage: burned or broken traces on the printed circuit board, burned or

damaged components, dirt or water residue on the printed circuit board or inside the case, modications by the customer , broken cases or housings and dead batteries.

SectionThr ee

A return material authorization number (RMA) must be issued by seller before any product is returned for evaluation or repair. Warranty repairs must be completed at

authorizedrepair facilities.

Warrantypolicy1 reva.doc

01.01.03reva

09.30.98revint

Eective January 1, 2003

Other manuals for PowerTouch 914

1

Table of contents

Other TouchTronics Control System manuals

Popular Control System manuals by other brands

GRS

GRS Airtact Operation and maintenance manual

Pure Processing

Pure Processing PureClear Instructions for use

Ingeteam

Ingeteam INGECON EMS Manager Installation and operation manual

NOBOCOOL

NOBOCOOL Ecohub user manual

Rinnai

Rinnai RS100 Operating and installation instructions

SMA

SMA EDML-10 Quick reference guide

MICROPOINT

MICROPOINT mLabs M101-091013 quick start guide

Varifan

Varifan IC-664 installation guide

Autotrol

Autotrol 255 Series Installation, operation and maintenance manual

Ecolab

Ecolab Advanced Laundry Installation & operation manual

SAI HVAC

SAI HVAC Compact Comfort VRF12 Install manual

WEIHONG

WEIHONG NCStudio V12 manual