Tough Jets T-14 EDF User manual

©2011 ToughJets, LLC Kittery, ME Page 1 of 22

Wingspan……………….31in Weight……………..2.5 lb

Length…………………..41.75in Radio………...3 channel

Wing Area………………615 sq in Motor………...Brushless

EDF............70mm 12 Blade Battery…14.8v 2200mah 40c

INSTRUCTION MANUAL

Specifications

T

M

T-14 EDF

©2011 ToughJets, LLC Kittery, ME Page 2 of 22

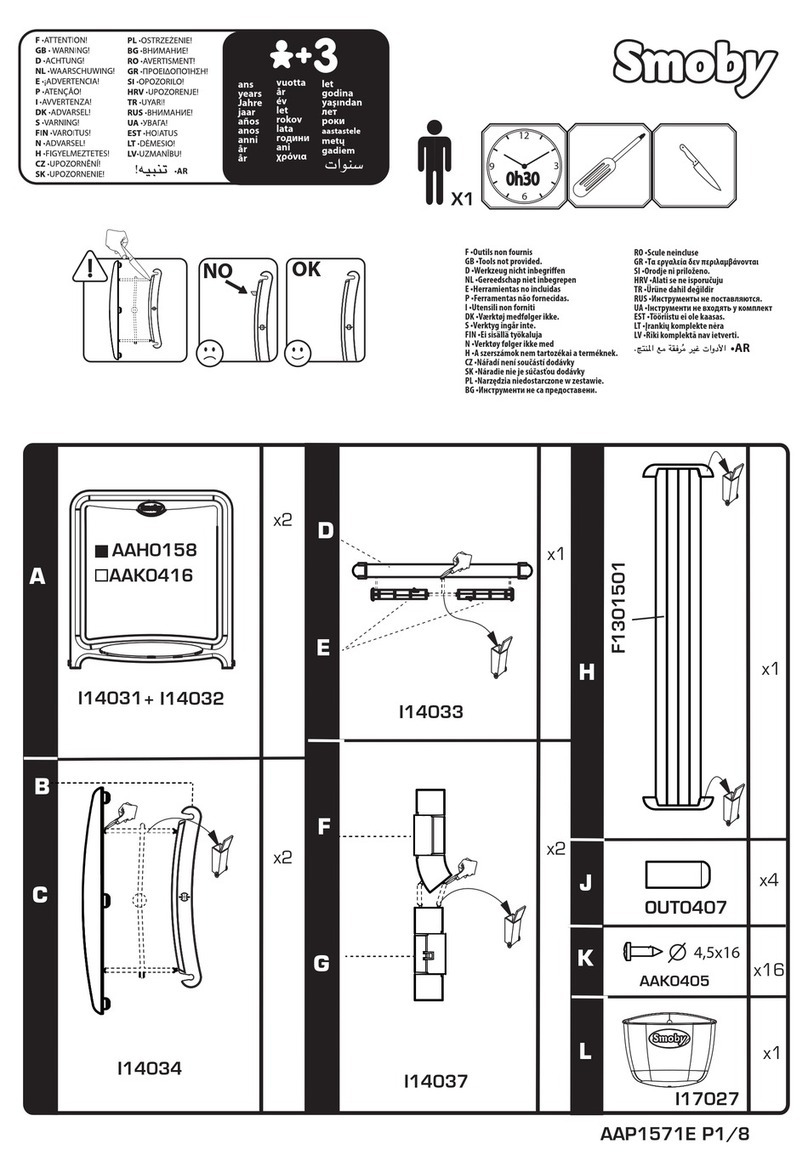

KIT CONTENTS

(1) Wing

(1) Fuselage

(2) Nacelles

(1) Battery box spacer

(2) Vertical stabilizers

(1) Canopy

(1) Canopy hinge

(1) Rare Earth magnets

(4) 3mm X 12mm Bolts

(4) 3mm X 14mm Bolts

(8) 3mm Lock Nuts

(4) Flat washers

(4)Control horns

(4)Clevis

(4)Push rods

(4)Push rod keepers

(1) Coroplast® motor mount stiffener

(4) Wood dowels

(2) 14 Gauge wire

(1) Carbon Fiber Shaft 30 inch

©2011 ToughJets, LLC Kittery, ME Page 3 of 22

BEFORE YOU BUILD

WARNING!!

This kit is not a toy.

This model is intended for the competent builder and RC pilot aged 14

years and older. It is the responsibility of the modeler to ensure the

model is airworthy before attempting to fly it.

Always ensure that any glue, paint or solvents used to build this kit are compatible with the

materials contained in this kit. Some glues and paint can melt Styrofoam and plastic that is

contained in this kit.

Before gluing any parts together, we strongly suggest trial fitting the parts without glue first;

to ensure that all the parts align and fit properly. This will ensure the airplane is built straight

and square.

ABOUT THE TOUGHJETS T-14 EDF

The ToughJets T-14 EDF was designed by life-long RC modeler Wayne Roberts to be the

highest performing fun scale RC propjet on the market. You’ll find the T-14 has an enormous

flight envelope. It’s capable of 65+mph, it’s highly aerobatic, yet it lands at near zero ground

speed in the slightest of headwinds.

TOOLS AND SUPPLIES REQUIRED

5 Minute Epoxy Hobby knife

CA glue Wire Cutters

Electric Drill Scissors

Assorted Drill Bits Clear Packaging Tape

Needle nose pliers Pencil

Small screw drivers Rubbing Alcohol

Allen wrench 2.5mm 3M Type 77 Spray Adhesive

©2011 ToughJets, LLC Kittery, ME Page 4 of 22

ADDITIONAL EQUIPMENT REQUIRED

3, channel radio with mixing (Minimum)

4, sub micro 9 gram servos (Tower Pro or equivalent)

2, Y servo cords.

70mm 12 blade Ducted Fan (FMS 70mm Ducted Fan or equivalent)

70 amp electronic speed control

4 cell lipo battery 14.8 volt 2200 mAh 40 c or 2600mAh 40 c

EXPLODED VIEW

Use this exploded view to help guide you through the assembly of the major components of

your ToughJets T-14

©2011 ToughJets, LLC Kittery, ME Page 5 of 22

LET’S BEGIN BUILDING

It is strongly suggested you review the drawings, photos and captions to familiarize yourself

with the design and construction of the model.

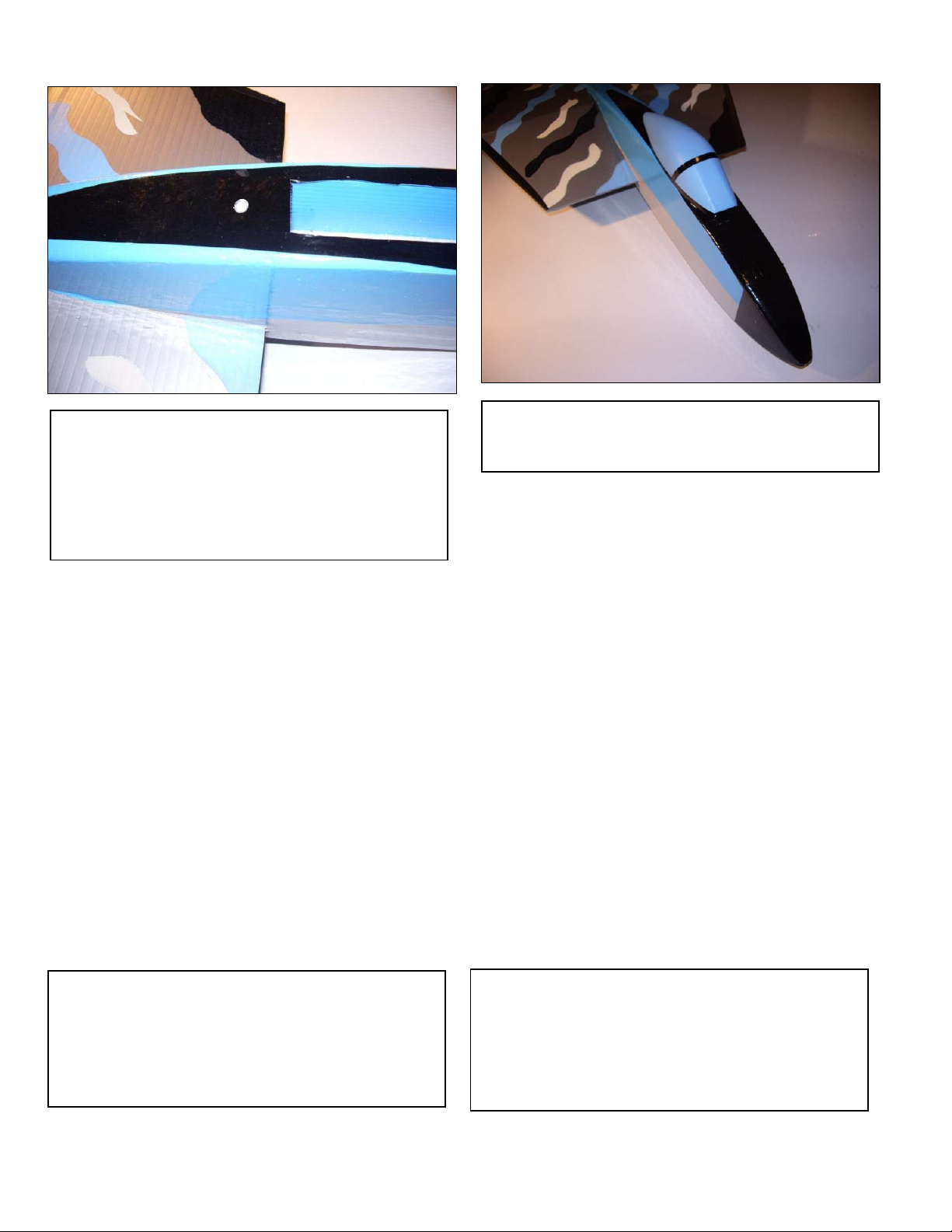

Before beginning construction, you will want to decide whether to paint or cover the foam

parts with heat shrink film such as EconoKote, or packaging tape. You may also choose to

leave these parts uncovered. If you choose EconoKote, or packaging tape, spray the surfaces

to be covered with 3M Type 77 spray adhesive prior to covering. Allow the adhesive to set for

5 minutes prior to applying the covering, this will improve the overall adhesion of the covering

to the foam. When covering the nacelles, do not apply covering material or paint to the

surfaces to be epoxied to the wing.

It is highly recommended to apply the covering material or paintprior to assembling the

model. Do NOT apply covering to the top edge and slant of the nacelle (see insert)

©2011 ToughJets, LLC Kittery, ME Page 6 of 22

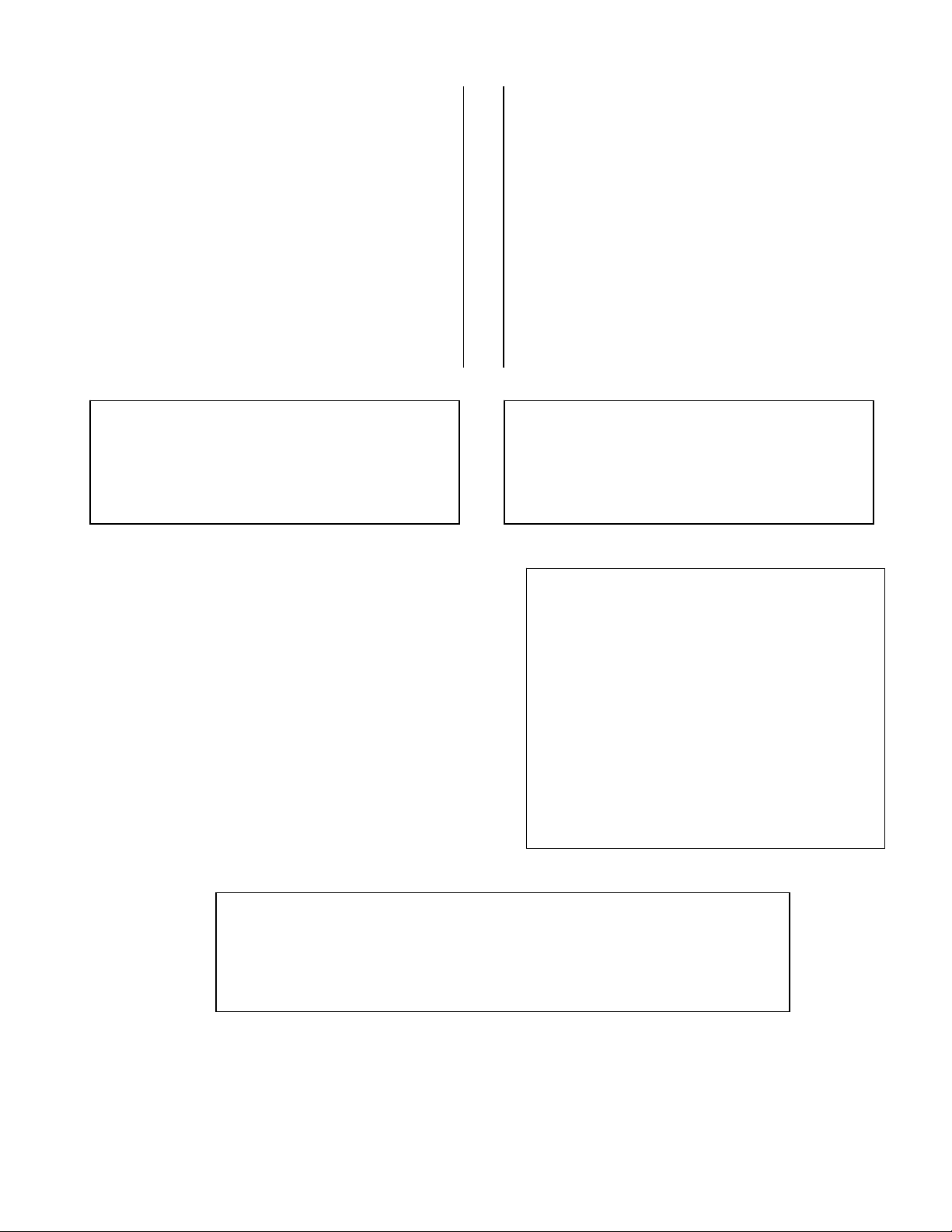

WING / NACELLE / FUSELAGE ASSEMBLY

Lay wing on a flat surface, bottom side up.

This is the side with the hinge slots and

crease.

Clean the bottom of the wing with rubbing

alcohol before gluing

Apply 5 minute epoxy to top of nacelle on

flat section only. Do not apply epoxy

to slanted section at this time. Do not let

epoxy clog vertical stab dowel holes see

insert photo

Carefully align nacelle with leading edge and

crease on the bottom of the wing.

©2011 ToughJets, LLC Kittery, ME Page 7 of 22

Ensure the nacelle is parallel and 90 degrees

to flutes in wing. You have some time to

make slight adjustments before epoxy cures

but move quickly.

Be sure that the nacelle is properly aligned

with crease

Hold the nacelle in place until the five-

minute epoxy cures, check that nacelle is

aligned with leading edge, crease and

centered on Vertical stabilizer dowel holes on

wing.

Repeat the steps to attach the second

nacelle to the wing. Nacelles should be

straight and parallel

©2011 ToughJets, LLC Kittery, ME Page 8 of 22

Now apply 5-minute epoxy to the slanted

sections on both nacelles.

Press both nacelles to leading edge of the

wing applying pressure on a smooth flat

surface for 5 minutes until the e

p

ox

y

cures

Turn the wing over, measure and mark on

the top the center of the wing

Apply 5 minute epoxy to both side of

fuselage wing slot. Slide the fuselage onto

the wing. Be sure that the fuselage is

centered straight and square to wing.

©2011 ToughJets, LLC Kittery, ME Page 9 of 22

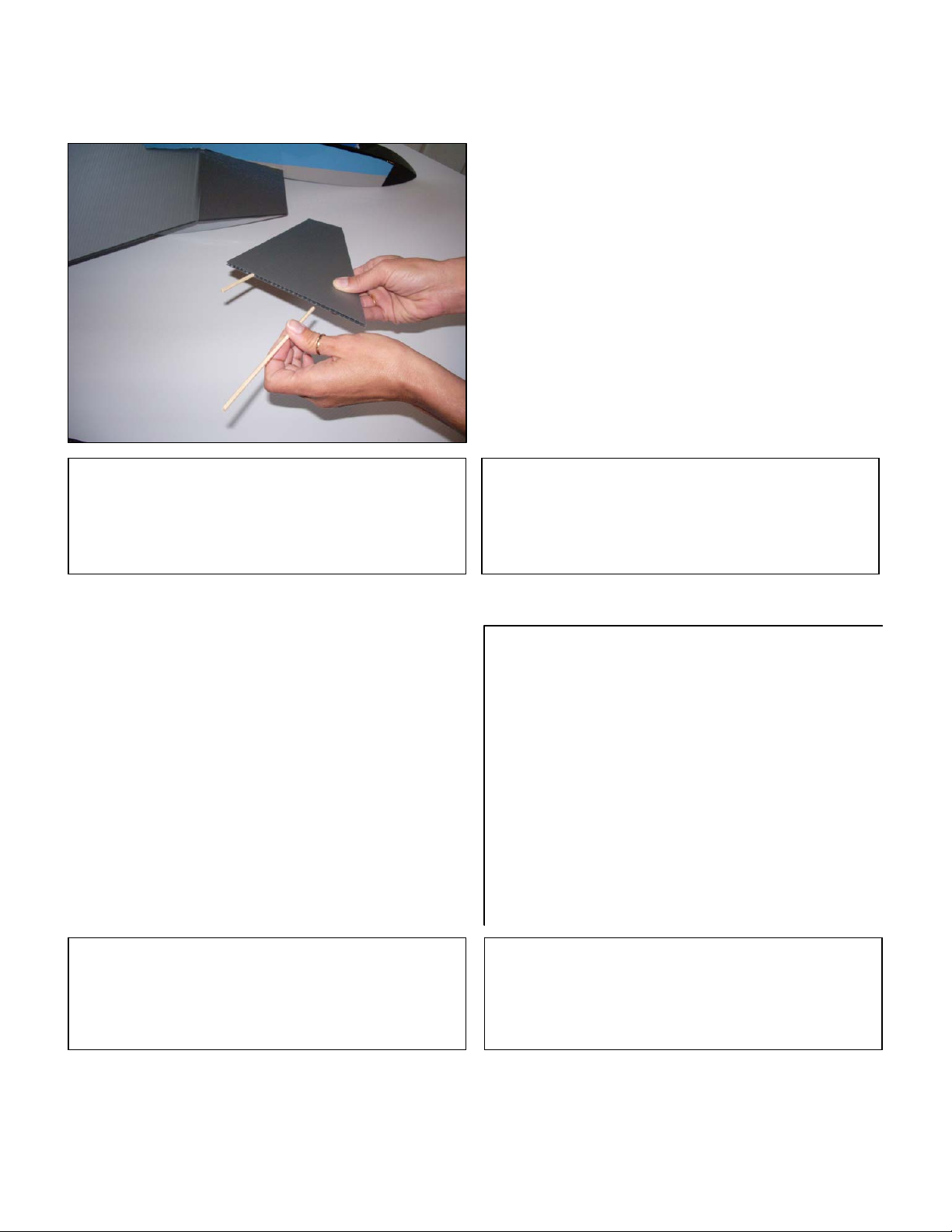

Epoxy 2 dowels into the flutes of each

vertical stabilizers. Position the dowels 1½”

and 4 ½” from the trailing edge. Leave

about 1 ½” of dowel exposed

Peirce foam with sharp dowel by pushing it

down into Vertical stabilizer dowel holes to

clear out foam to for dowels

Repeat steps for other side. It’s starting to

look like a plane now.

Insert stabilizer dowels it should be a

tight fit not needing glue, remaining

removable for transporting.

©2011 ToughJets, LLC Kittery, ME Page 10 of 22

Apply a little 5 minute epoxy to the 3mm

carbon fiber shaft, then insert it in the

second wing flute from the hinge

(see photo)

©2011 ToughJets, LLC Kittery, ME Page 11 of 22

INSTALLING MOTOR

Bolt motor to mount with 3mm x 14mm bolts

included.

Set your EDF unit in wing with ESC wires

facing down DO NOT omit intake ring

Line up motor straight and square. Mark

location and drill holes.

©2011 ToughJets, LLC Kittery, ME Page 12 of 22

Bolt mount through wing and Coroplast®

stiffener don’t over tighten bolts. Place washer and nut on bolt do not over

tighten. (BOTTOM VIEW

(BOTTOM VIEW)

(BOTTOM VIEW)

(TOP VIEW)

©2011 ToughJets, LLC Kittery, ME Page 13 of 22

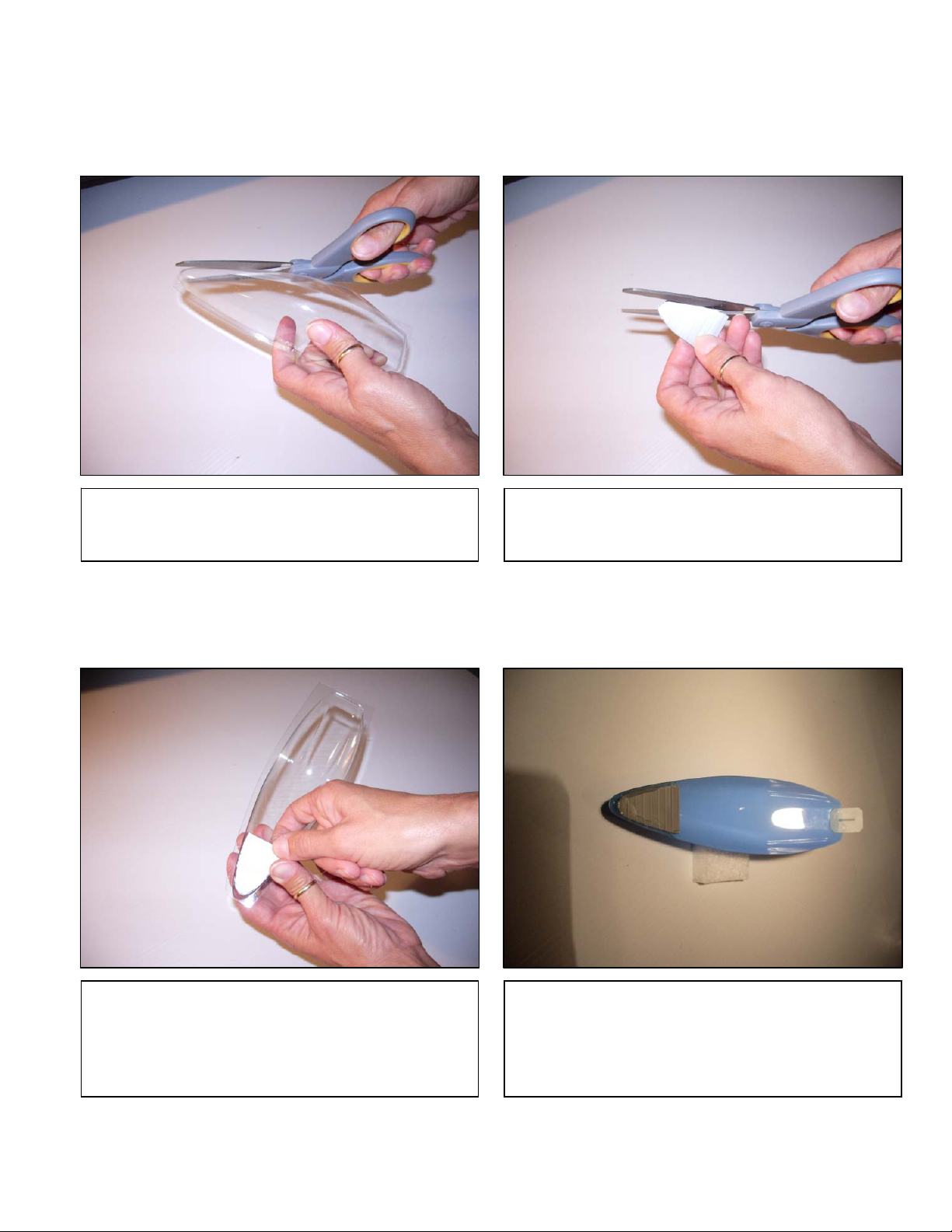

CANOPY / BATTERY BOX ASSEMBLY

Carefully trim the canopy to fit the fusela

g

e. Cut the small piece of Coroplast® to fit the

rear part of the canopy.

Fit the Coroplast® to the canopy. Epoxy the Coroplast® piece and CA glue

canopy hinge into place to the inside of the

canopy, after painting the outside of the

canopy.

©2011 ToughJets, LLC Kittery, ME Page 14 of 22

Cut a slit ½ “ in front of the battery box for

the canopy hinge.

T

est fit the hin

g

e. Then

g

lue into place.

The hinged canopy will cover the battery

box.

Drill a small hole and glue magnet to the

Coroplast at the rear of the canopy.

©2011 ToughJets, LLC Kittery, ME Page 15 of 22

RADIO SYSTEM INSTALLATION

It may be necessary to trim the servo-

mounting hole to accommodate the servos.

Install the outboard servo into the

mounting

hole and glue in place, stacked on top of

inboard servo. We recommend

9 gram sub micro or similar type servo.

T

he canopy is now complete.

Drill a hole the same size as the magnet near

the battery box, position it such that it will

align with the magnet on the canopy. Ensure

the polarity of the magnet is such that they

are attracted when the canopy is closed.

Epoxy the magnet in place

©2011 ToughJets, LLC Kittery, ME Page 16 of 22

Attach the control horn to the right elevon,

don’t over tighten.

Measure and cut the push rod to fit between

the servo arm and control horn.

Connect the push rod to the servo arm 2nd

hole from end and control horn middle hole.

Repeat steps for left side.

NOTE: WHEN SERVO IS IN NEUTRAL

POSITION, THERE SHOULD BE APPROX.

5/8” OF UP DEFLECTON ON THE

OUTBOARD FLIGHT CONTROLS TO

MAINTAIN LEVEL FLIGHT.

Bend the cut end to accommodate the push

rod keeper.

©2011 ToughJets, LLC Kittery, ME Page 17 of 22

Two more servos are placed on the inboard

side of the nacelles opposite and above

outboard servos as seen on page 15 and 16.

The servos are connected with Y cords to

outboard elevon servos.

Thrust Vectoring Flight Center

Elevon Control Surface

Throws

FULL UP: about 1 inch up

NEUTRAL: about 3/32 up

FULL DOWN: about 1/2 inch

down

For Outboard Elevon

(see page 16, 19 and 21)

©2011 ToughJets, LLC Kittery, ME Page 18 of 22

Cut slot in right nacelle for servo wire and

extension, single knife cut is sufficient here.

Embed servo wire and extension. Repeat

steps for left side.

Cut slot for electronic speed control wires, it

may be necessary to extend you electronic

speed control battery wires in order to reach

battery connector exit. Single knife cut is

sufficient here, then use flat tip screw driver

to open slot.

Servo wire exits on inside of nacelle.

©2011 ToughJets, LLC Kittery, ME Page 19 of 22

Embed electronic speed control battery wires

in slot. Use double sided tape to hold speed

control and receiver in place.

you can mount your receiver under

or next to your electronic speed

control as shown in photo

Use servo Y leads to route wires as shown in photo. Once wires

are neatly placed they can be taped in place in the slots and to bottom of

wing with clear packaging tape or vinyl tape to match the color of the

wing. Care must be taken that the wires and receiver antenna are do

become entangle or severed by the fan.

©2011 ToughJets, LLC Kittery, ME Page 20 of 22

Now you have a complete airplane that can be customized with decals tape or

paint to your liking. You may want to cover the exposed flute holes in the leading

edge of the wing and tail surfaces with tape. This does not affect the plane’s

performance.

NOTE: WHEN ELEVATOR STICK IS IN THE NEUTRAL POSITION THERE

SHOULD BE APPROX. 5/8” OF UP DEFLECTON (OR REFLEX) ON BOTH

OUTBOARD FLIGHT CONTROL SURFACES BOTH INBOARD SURFACES

SHOULD BE 3/16" UP TO MAINTAIN LEVEL FLIGHT.

Table of contents

Other Tough Jets Toy manuals

Popular Toy manuals by other brands

Huffy

Huffy Battery Ride-On Trike owner's manual

Eduard

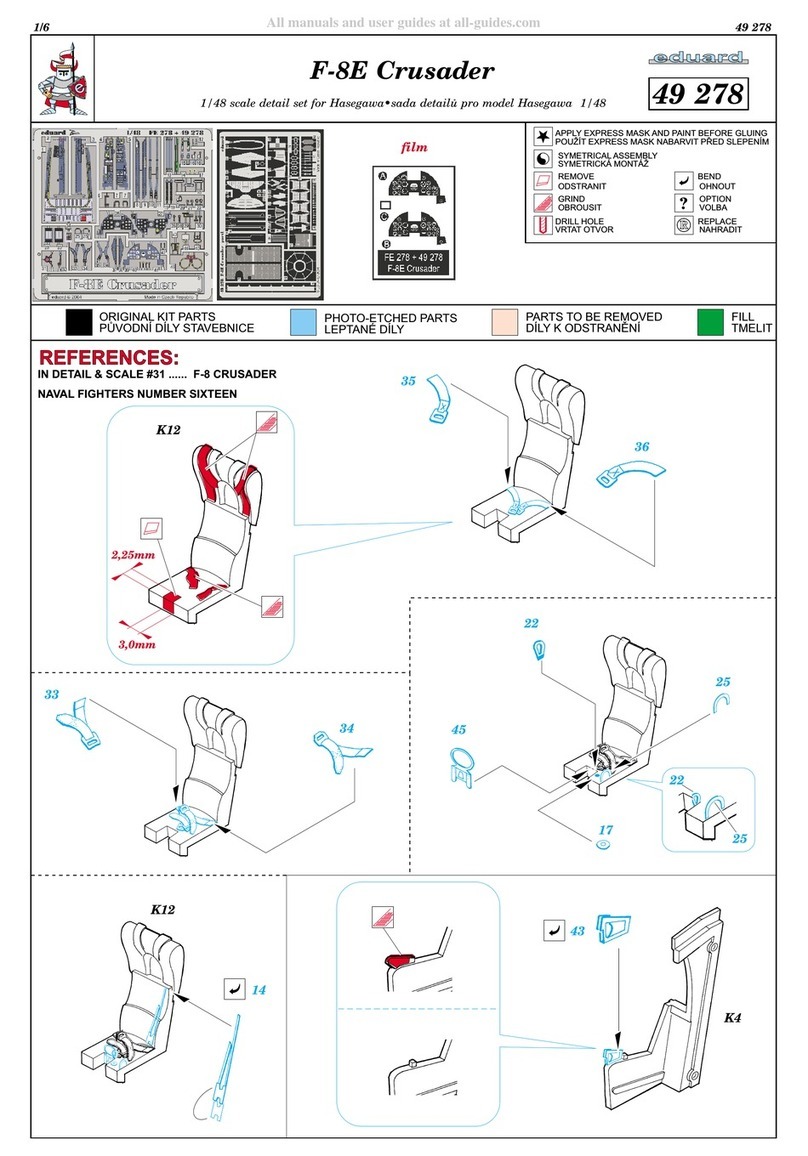

Eduard F-8E Crusader Assembly instructions

Viessmann

Viessmann 4264 Operation manual

Lionel

Lionel Pioneer Zephyr owner's manual

Fisher-Price

Fisher-Price THOMAS & FRIENDS Mad Dash On Sodor Assembly instructions

PILOTAGE

PILOTAGE Stinger 3D 250 user manual