The Draco BG is a model boost glider (BG) based on the

real-life Boeing GBU-39 SDB (Small Diameter Bomb) which

originally was an air-drop ordinance and was later modied

for launching from ground vehicles. This modied version is

known as the GLSDB (Ground-Launched Small Diameter

Bomb) and is a precision weapon system that allows delivering

a payload of 93kg (205 lbs) to a location within a range of 150

km (93 mi) from the mobile launch platform. Development of

the GLSDB was a joint project of Boeing and the Saab Group.

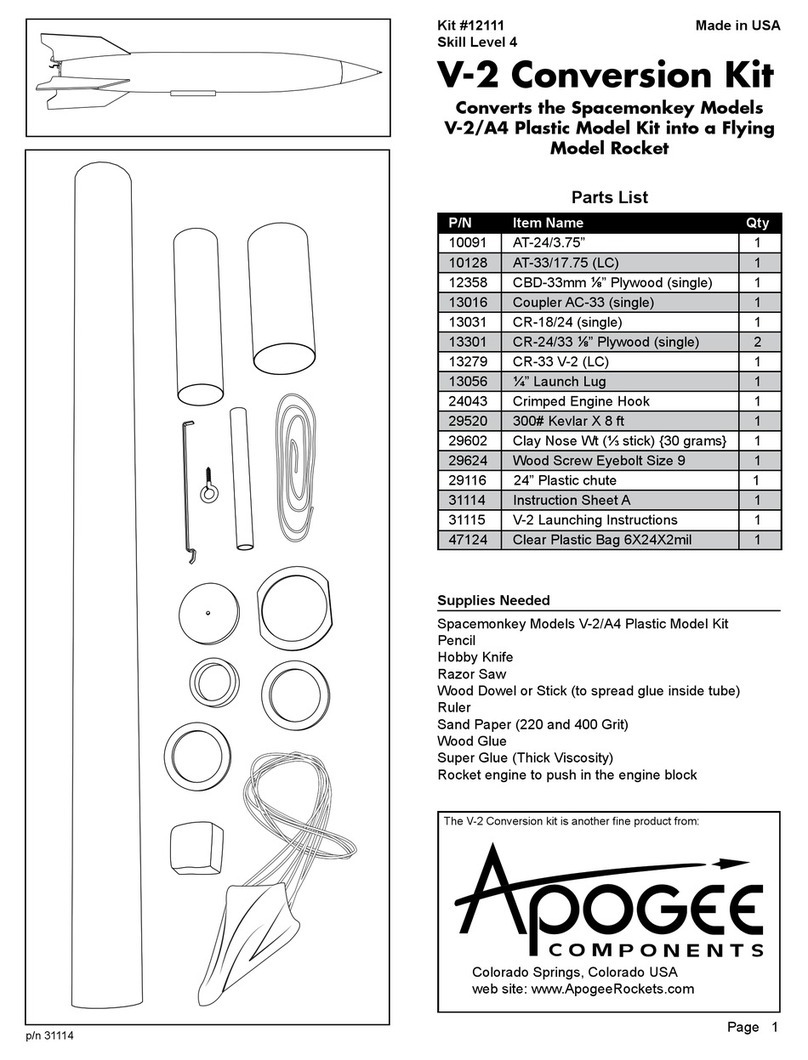

The Draco BG copies the overall conguration of the GLSDB

and the unique folding wing arrangement.

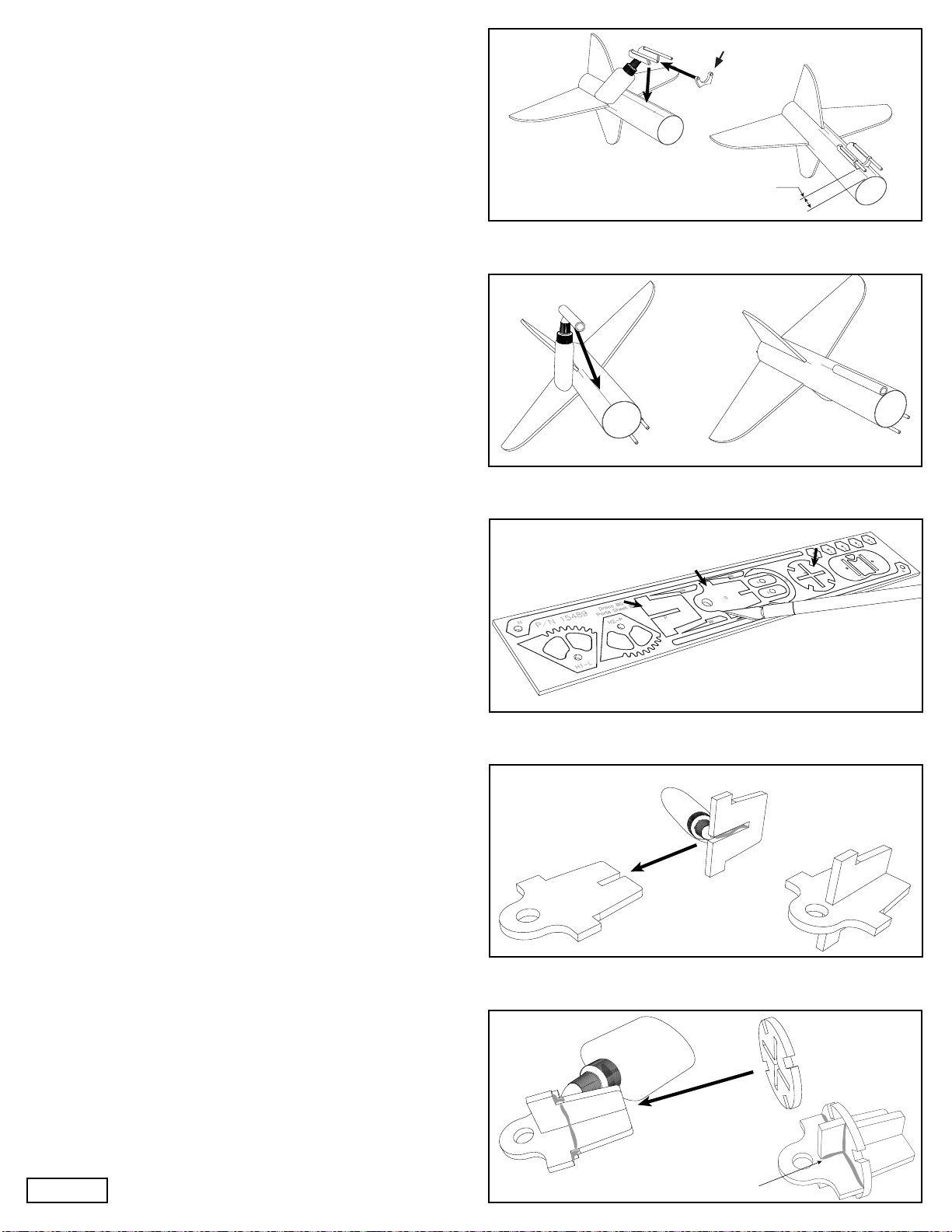

Despite the fancy wing mechanism, ights of the Draco

BG model are simple. It launches upward on 24mm diam-

eter rocket motors. The simple interstage/wing-lock system

ensures reliable transition of the upper stage to glide congu-

ration while the booster recovers under a parachute. While a

challenging build, the Draco BG is a fantastic rocket for those

interested in mechanical design, gliders, and military history.

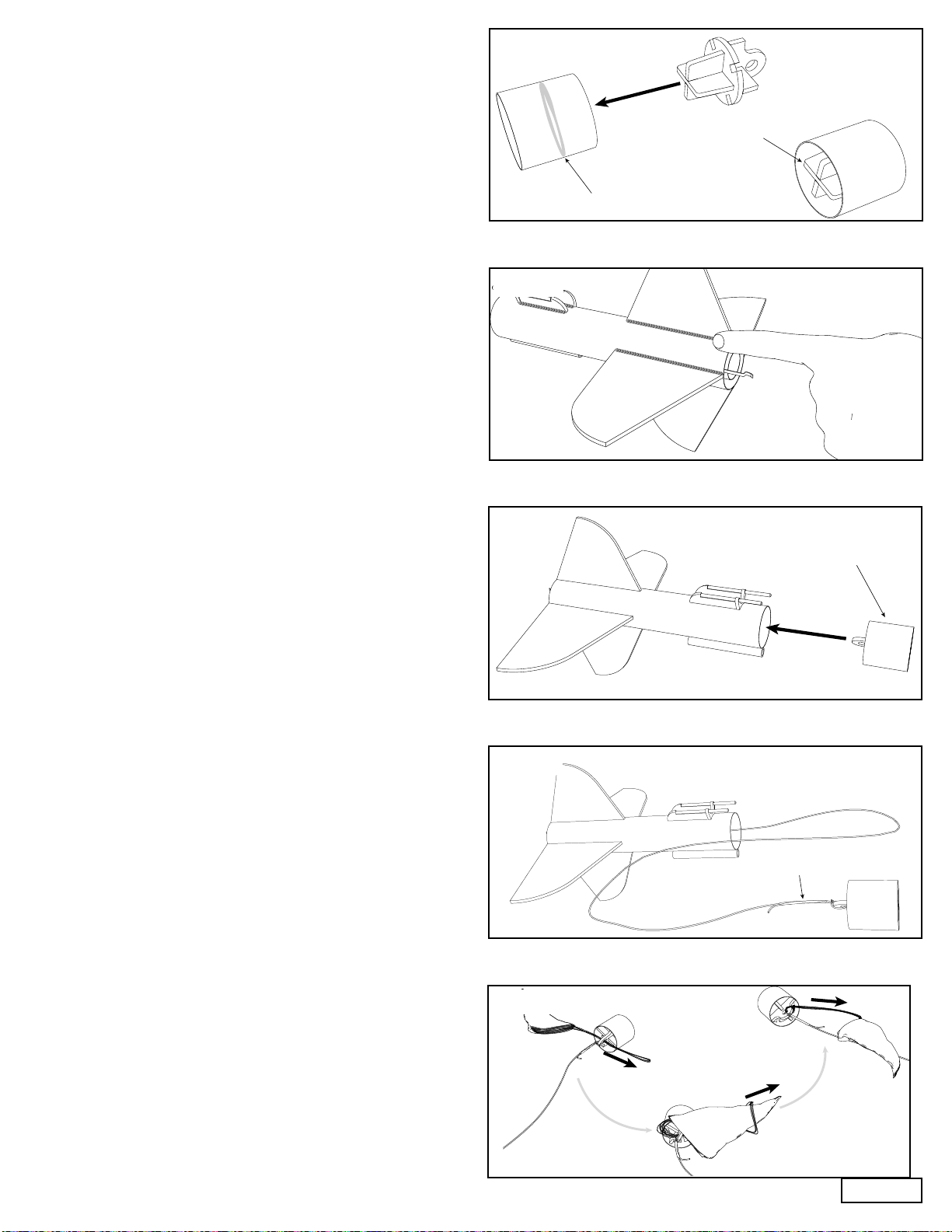

Item # Item Name Qty

10091 AT-24/3.75” (Motor Tube) 1

10151 AT-41.6/9” (Booster Tube) 1

10154 AT-41.6/18” LC (Fuselage Tube) 1

12976 #4 Flat Washer 4

12977 #4 3/16”x1/4” Unthreaded Off-White Nylon

Standoff 5

12978 #4 3/16”x5/32” Unthreaded Off-White Nylon

Standoff 2

12979 4-40 x 1/2 Black Nylon Panhead Screw 7

13031 CR-18/24 1

13035 CR-24/29 1

13123 AC-41.6/1.5” LC 1

13051 1/8" Launch Lug 1" Long 2

13056 1/4" Launch Lug 3" Long 2

14263 1/8" x 2.5" Wood Dowel 2

15015 CR-24/41.6 Cardstock (Rectangle) 1

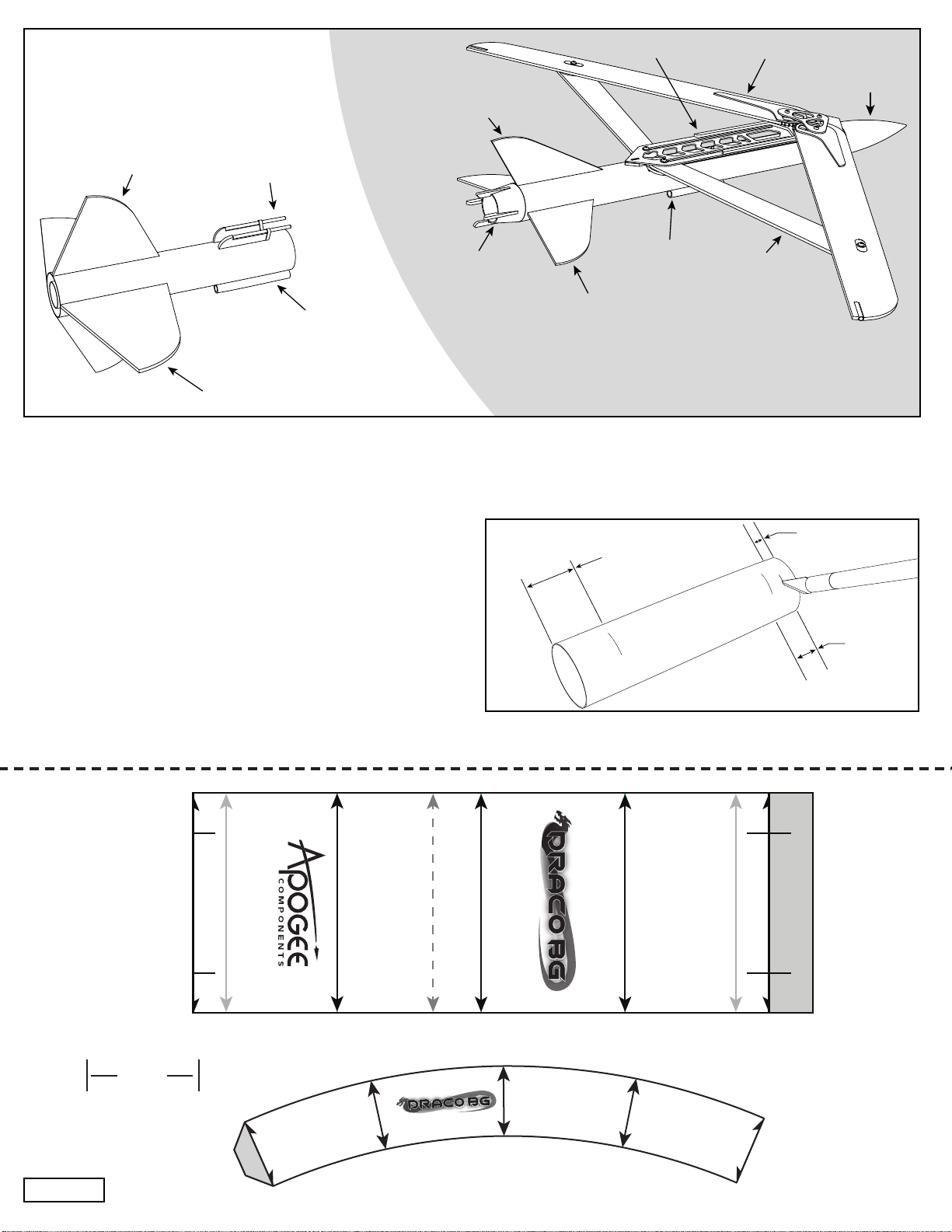

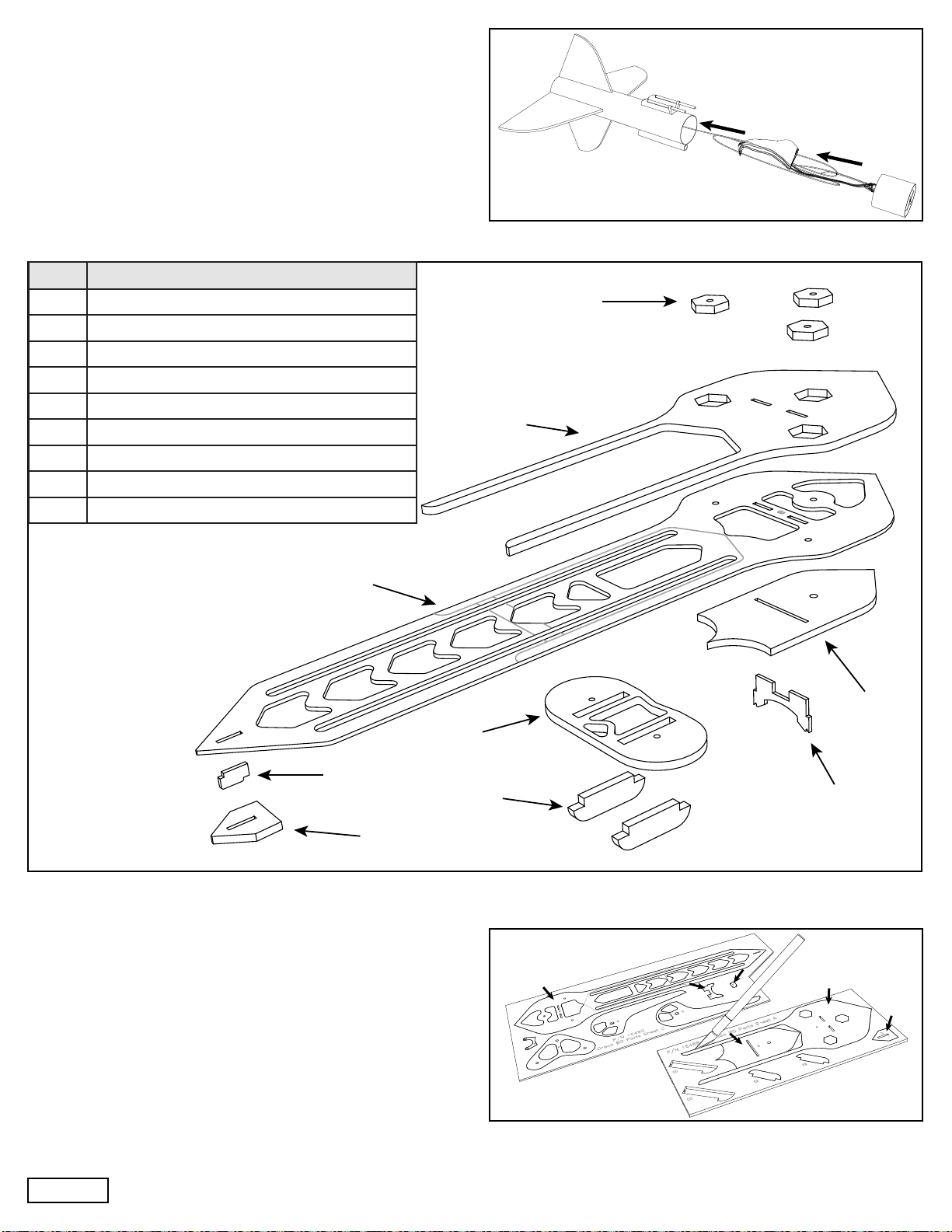

15487 Draco BG Jig Sheet Cardstock 1

15488 Draco BG Parts Sheet A 1/8”x4” Balsa 1

15489 Draco BG Parts Sheet B 1/8” Ply 1

15490 Draco BG Parts Sheet C 1/16” Ply 1

15731 Draco BG Wing Sheet 1/8”x4” Balsa 2

15732 Draco BG Fin Sheet 1/8”x4” Balsa 1

15733 Draco BG Stabilizer Sheet 3/32”x4” Balsa 1

19469 PNC-41mm (BT-60) 1

24003 #117B Rubber Band 1

24044 Crimped "E-size" Engine Hook 1

29090 12" Printed Nylon Parachute 1

29518 100# Kevlar x 5 feet 1

29600 Clay Nose Wt 5g 1

31271 Instructions Sheet A 1

31272 Instructions Sheet B 1

31273 Instructions Sheet C 1

31274 Instructions Sheet D 1

31275 Instructions Sheet E 1

31276 Instructions Sheet F 1

39059 Face Card 1

41116 Decal Sheet 1

Skill Level 5

Extremely Challenging

Draco BG Parts List

Optional Tools / Finishing Supplies

Fin Alignment Guide (P/N 35546)

Flat Needle File

Wood Filler

Sanding Sealer

Extra Fine Sandpaper (600 grit)

Spray Paint

Wood Dowel

Ruler or Calipers

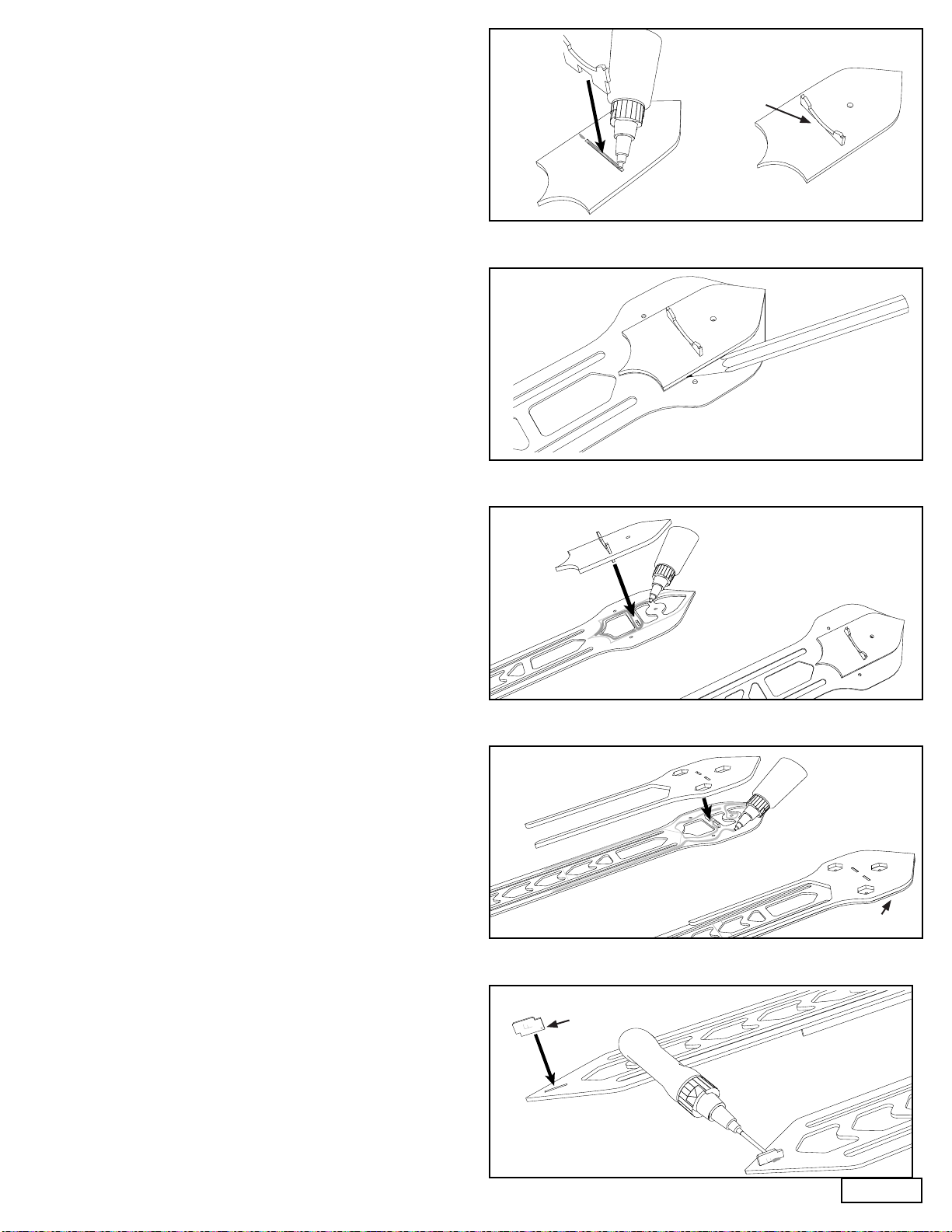

Needed Tools and Materials

Hobby Knife with Sharp Blades

Scissors

Razor Saw

Wood Glue

Thin CyAAdhesive

Medium CyAAdhesive

Masking Tape

Medium and Fine Sandpaper (180, 320 grit)

Aluminum Angle

4-40 Tap Page 1

Assembled In USAKit #05065

Skill Level 5

Manufactured in the USA by:

Apogee Components Inc.

Colorado Springs, Colorado, USA

www.ApogeeRockets.com

Instruction Sheet A: P/N 31271 *Updated 9/1/2023