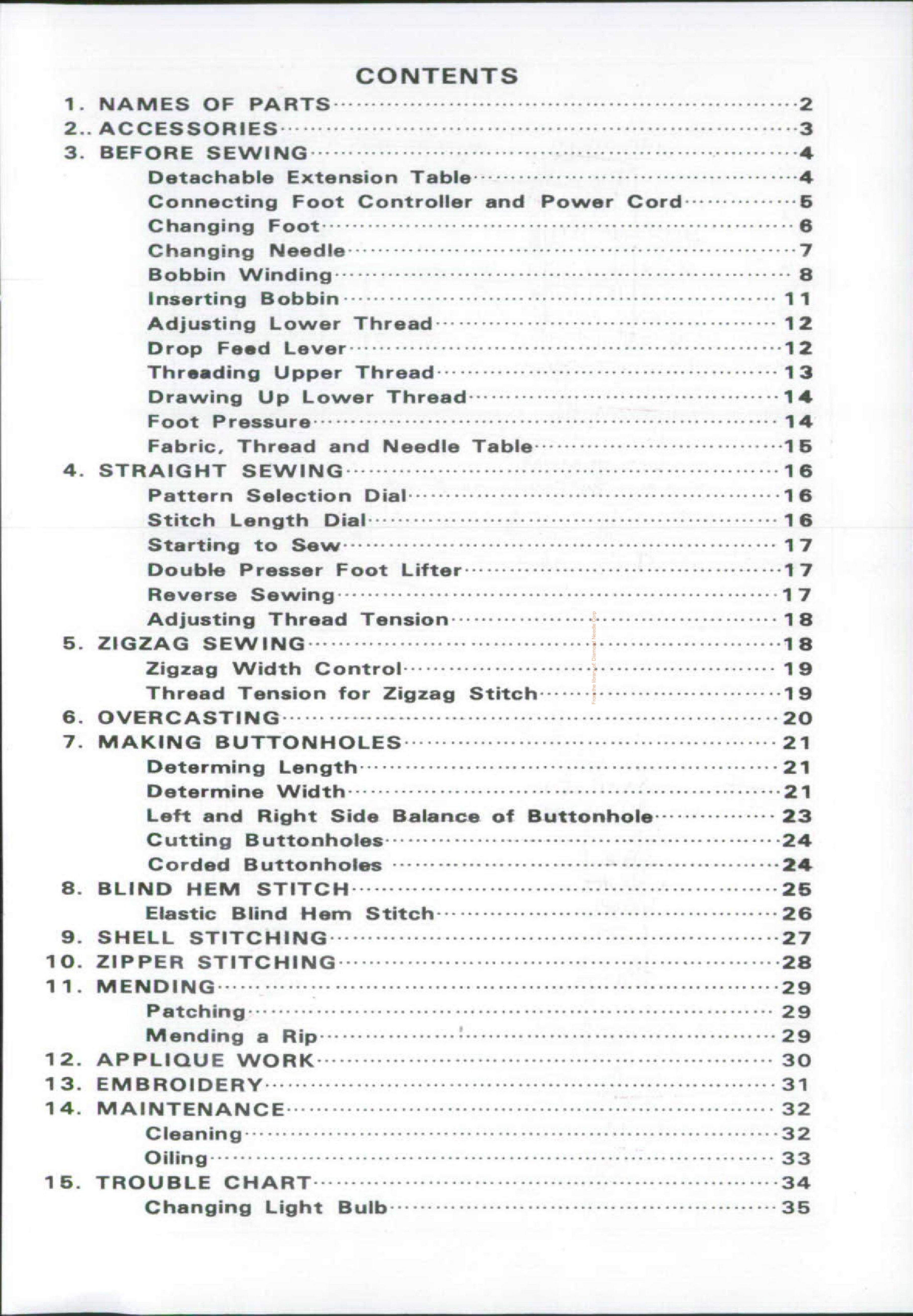

CONTENTS

1_

NAMES

0F

PARTS...........................................................

ZACCESSORIES

Detachable

Extension

Table

------------------------------------------

Connecting

Foot

Controller

and

Power

Cord-~----~~--~

changing

Foot

..............................................................

changing

Hood's............

Bobbin

Winding

............................................................

Inserting

Bobbitt"-

...................................

.

.................

11

Adjusting

Lower

Thread........

12

Drop

Feed

Lever

.........................................................

12

Threading

Upper

Thread

---------------------------------------------

13

Drawing

up

Lower

Thread

.........................................

1‘

F001:

pressure

.............................................................

14

Fabric.

Thread

and

Needle

Table

---------------------------------

15

4.

STRAIGHT

SEWING‘IB

Pattern

Selection

Dial

------------------------------------------------

16

Stitch

Length

Dlal16

Double

Presser

Foot

Lifter

..........................................

17

Reverse

Sewing

..........................................................

17

Adjusting

Thread

Tension

...........................................

13

5_

ZIGZAG

SEWING

..............................................................

1B

Zigzag

Width

Control

.................................................

19

Thread

Tension

for

Zigzag

Stitch

--------------------------------

1B

'

OVERCASTING

.................................................................

2°

_

MAKING

BUTTONHOLESH...............................................21.

Determing

Length

.......................................................

2"

Determine

Width

......................................................

...21

Left

and

Right

Side

Balance

of

Buttonhole

---------------

23

Cutting

Buttonhole:

....................................................

24

Col-dad

But-tanho'“

...................................................

2‘

8.

BLIND

HEM

STITCH

........................................................

25

Elastic

Blind

Hem

Stitch

---------------------------------------------

26

9_

SHELL

STITCHING

...........................................................

27

10‘

ZIPPER

STITCHINGZB

Patching.....................................................................

29

Manding

5

Rip..................:

.........................................

29

12.

APPLIOUE

WORK

............................................................

3°

13_

EMBROIDERY31

14_

MAINTENANCE32

c'eaning

......................................................................

32

15-

TROUBLE

CHART34

Changing

Light

Bulb35

muonapur‘o

N10

From the library of: Diamond Needle Corp