CONTENTS

1. PREFACE.................................................................................................... 1

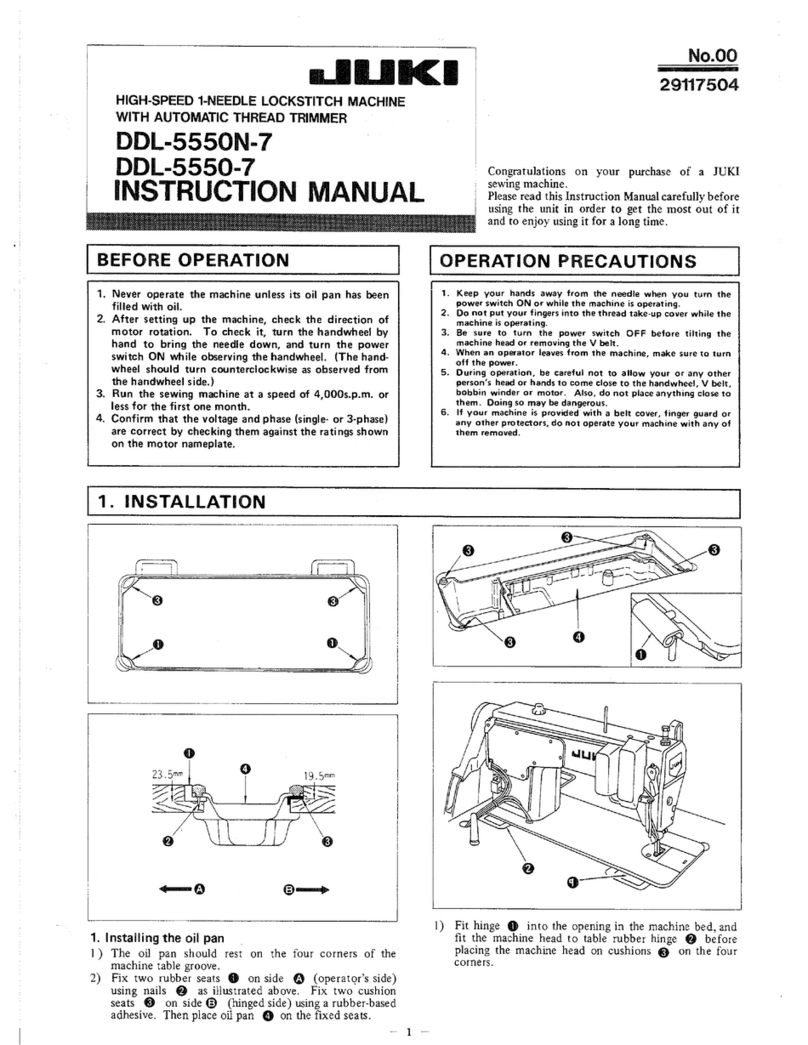

2. SET-UP........................................................................................................ 1

(1) Installing M-91 small sized motor unit ................................................................................................1

(2) Installing to the table ............................................................................................................................2

(3) Adjusting the belt (when M-91 is used)............................................................................................... 2

(4) Adjusting the belt cover (when M-91 is used) .................................................................................... 3

(5) Connecting the cords ...........................................................................................................................4

(6) Attaching the circuit board ..................................................................................................................5

(7) Connecting for IP-110 panel.................................................................................................................7

(8) Installing the operation display panel...............................................................................................10

(9) How to use the operation display panel ...........................................................................................10

(10) Adjusting the bottom feed pitch display......................................................................................... 11

3. INSTALLING THE OPERATION PANEL.................................................. 12

4. CONNECTING THE CORD....................................................................... 13

5. HOW TO USE THE OPERATION PANEL ................................................ 14

(1) Names and functions of each components......................................................................................14

(2) Adjusting the contrast of the operation panel display .................................................................... 16

(3) Production control switch connecting connector ...........................................................................16

6. SCREEN LIST........................................................................................... 17

(1) Fundamental screen list.....................................................................................................................17

(2) Pop-up list ...........................................................................................................................................18

(3) Other screens......................................................................................................................................19

7. OPERATING PROCEDURE OF THE SEWING PATTERN ...................... 20

(1) Selecting procedure of the sewing pattern ......................................................................................20

(2) Editing procedure of the sewing pattern ..........................................................................................20

(3) Teaching mode....................................................................................................................................23

(4) Selecting the sleeve to be sewn ........................................................................................................23

(5) Selection of the alternate sewing ......................................................................................................24

(6) Insertion and deletion of the step .....................................................................................................25

(7) Operating procedure of the number of stitches of the reverse stitching...................................... 26

8. PATTERN OPERATION............................................................................ 27

(1) Sewing pattern register ......................................................................................................................27

(2) Copy of the sewing pattern ...............................................................................................................29

(3) Deletion of the sewing pattern...........................................................................................................30

9. HOW TO USE THE BOBBIN THREAD COUNTER ................................. 31

10. NO. OF PCS. COUNTER........................................................................ 32

11. BOTTOM FEED AMOUNT DISPLAY...................................................... 32

12. RE-SEWING SWITCH............................................................................. 33

13. NEEDLE UP/DOWN COMPENSATION SWITCH .................................. 33

14. ON/OFF SWITCH OF THE MATERIAL EDGE SENSOR .................. 33

15. AUTOMATIC THREAD TRIMMING SWITCH .................................... 33

16. ONE-SHOT AUTOMATIC STITCHING SWITCH ............................... 33

17. THREAD TRIMMING PROHIBITION SWITCH .................................. 33

18. INFORMATION ....................................................................................... 34

(1) Information operator level..................................................................................................................34

(2) Setting for functions...........................................................................................................................37

(3) External interface................................................................................................................................41

19. ERROR DISPLAY ................................................................................... 42

(1) Error code list (Error display in panel) .............................................................................................43