Bobbin Winder ............................................................................................................................ 1

Display Board Box ....................................................................................................................... 2

Needle Bar Height ....................................................................................................................... 3

Hopping Foot Height.................................................................................................................... 4

Hook Holder ............................................................................................................................... 5

Needle Plate ............................................................................................................................... 6

Handle Bars ................................................................................................................................ 6

Timing........................................................................................................................................ 7

Thread Tensioner ........................................................................................................................ 9

Adjusting Thread Tensioner.........................................................................................................10

Extrusions Cover ........................................................................................................................11

Front Cover................................................................................................................................12

Needle Rod Holders....................................................................................................................13

Upper Shaft ...............................................................................................................................14

Pulley and Optical Encoding Wheel ..............................................................................................15

LED Assembly ............................................................................................................................15

Lower Shaft ...............................................................................................................................16

Bushing Block ............................................................................................................................17

Bushing Block ............................................................................................................................18

Main Board ................................................................................................................................19

Power Supply.............................................................................................................................20

Motor Driver Board ....................................................................................................................21

Grounding Wire..........................................................................................................................21

Idler Pulley Tension ....................................................................................................................22

MCU Board Update.....................................................................................................................23

Motor Driver Board.....................................................................................................................26

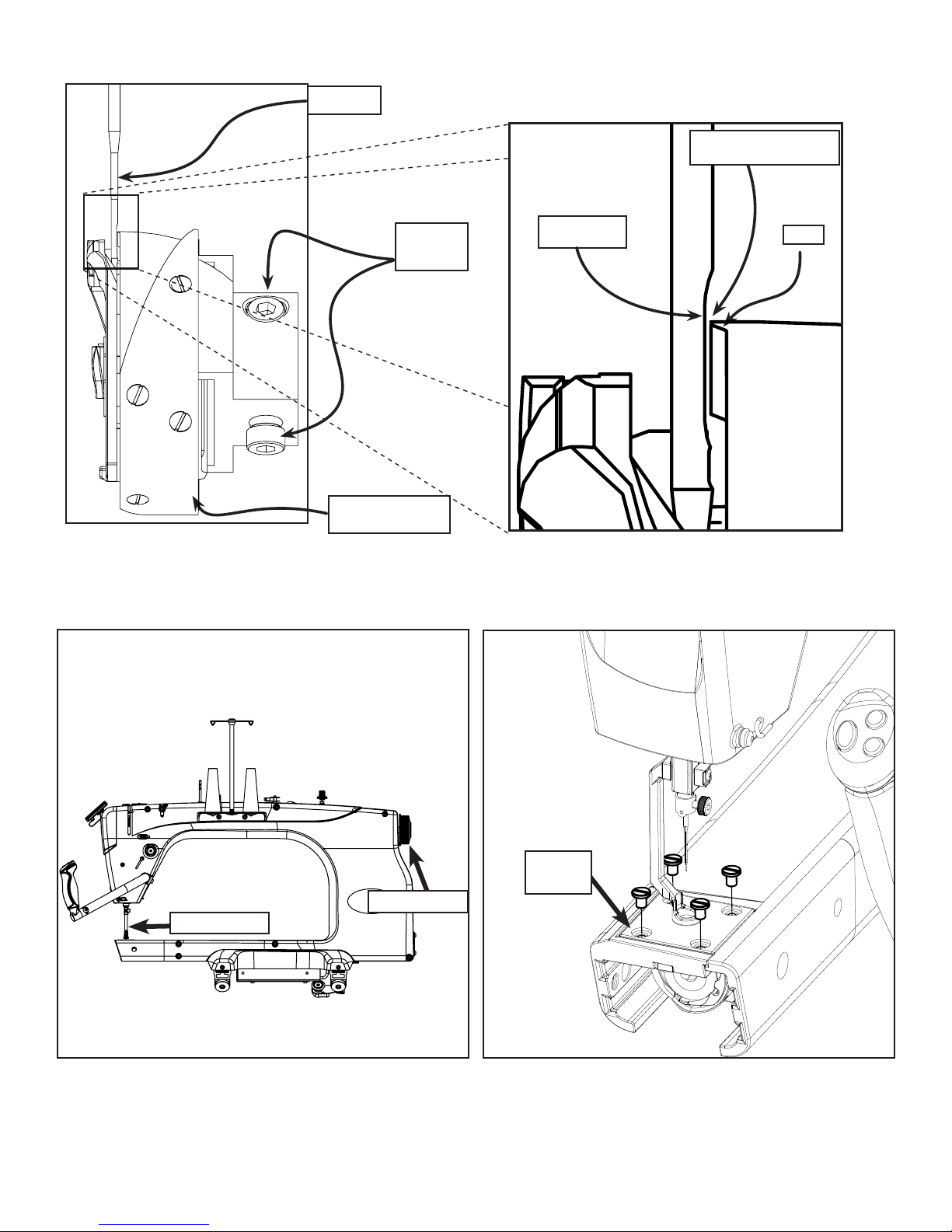

Motor Driver Board Plugs ............................................................................................................26

Self Calibration Instructions ........................................................................................................27

Window Offset Adjustment Instructions .......................................................................................28

Encoder Test..............................................................................................................................29

Button Test ................................................................................................................................29

Sensor Test................................................................................................................................30

i

|Table of Contents Q’nique 21: Service Manual