TPG CA Series User manual

VARIABLE FREQUENCY

DRIVE

Operation Manual

CA Series

1

PREFACE

Thank you for using TPG CA series drive. For proper operations and safety

purposes, please do read and follow specific instructions contained in this manual

before using the product.

SAFETY PRECAUTION

Please read this manual thoroughly and pay attention to the safety precautions

marked with “ DANGER ” or “ CAUTION ” before the installation, wiring,

maintenance, or troubleshooting.

Only the qualified personnel may proceed with the installation, wiring, testing,

troubleshooting, or other tasks.

※Qualified Personnel: Must be familiar with the fundamentals, structures,

characteristics, operating procedures, and installation, and this personnel must

read the manual in details and follow the steps of security measures to prevent

possible dangers.

DANGER

User may cause the casualty or serious damages if user

does not abide by the instructions of the manual to execute

the tasks.

CAUTION

User may cause injuries to the people or damage the

equipment if user does not abide by the instructions of the

manual to execute the tasks.

※Although the “ ” mark may indicate minor damages, serious damages or

injuries may be possibly incurred if the caution is not under user’s attention.

Installation

CAUTION

a. The installation shall take place only on top of the metal surface or any material

with the fire resistant. Any place or location of high temperature, moist, oil and

gas, cotton fiber, metal powder and erosive gas shall be avoided.

b. If the product specification indicates IP00 (the protective level of the equipment

structure), any human contact is forbidden at the installation location to avoid the

electric shock. The option of installing AC reactor(ACL) shall be very cautious.

c. Please note the surrounding temperature shall not exceed 50°C when the

installation needs to be placed inside the control panel.

d. For the environment of storage and installation, please follow the instructions of

the environmental conditions illustrated in the sections of the common

specification of CA.

2

Wiring

DANGER

a. Do Not conduct any wiring during the system power ON to avoid the electric shock.

b. R/L1,S/L2,T/L3 are power inputs (electric source terminals) and U/T1,V/T2,W/T3

are drive’s outputs to a motor. Please Do Not connect these input and output

terminals to terminals P♁, N○

-, and PR.

c. Once the wiring is complete, the cover of the drive must be put back and must

seal the drive to avoid other’s accidental contact.

d. The drives have three specifications base on the input power source 100V / 200V

/ 400V, Do Not input the voltage exceed the specifications.

e. The grounding terminal( ) must be exactly grounded. Ground the drive in

compliance with the NEC standard or local electrical code.

f. Please refer to the manual page for the screwing torque of the wiring terminal.

g. Please refer to the national or local electric code for the appropriate spec of the

cords and wires.

h. Please install an appropriate Molded Case Circuit Breaker (MCCB) or Fuse at

each path of power lines to a drive.

i. Please install the thermal relay between the individual motor and the drive when

using one drive to propel several motors.

j. Do Not connect power factor leading capacitor, surge absorber, or

non-three-phase motor to the drive’s U/T1, V/T2, or W/T3 side.

k. AC reactor(ACL) installation is required when the power capacity exceeds

500kVA or 10 times or more than the drive rated capacity.

l. Do Not touch the drive or performing any unwiring actions before drive indicator

light turns off after the power off. Use a multi-meter with the DC voltage stage to

measure the cross voltage between P♁and N○

-terminals (The voltage must

be less than 25V).

m. When the motor do the voltage-proof, insulation testing, unwiring the

U/T1,V/T2,W/T3 terminal of drive at first.

CAUTION

a. The CA series outputs are designed to drive a three-phase induction motor. Do

Not use for single-phase motor or using for other purposes.

b. The main circuit and control circuit must be wired separately; control circuit must

use a shielded or twisted-pair shielded wires to avoid possible interferences.

3

Operation

DANGER

a. Do Not open or remove the cover while power is on or during the drive operation.

Do close up the cover before powering on the drive. Do Not remove the cover

except for wiring or periodic inspection when power off.

b. At the function F3.30= 1 or 3, the drive will automatically restart when the power

is restored. Stay away from the motor and machine.

c. At the function F1.05=0 and F1.00=0 or 1 or 10, the key on the operation

panel is ineffective. Please use an emergency stop switch separately for safe

operations.

d. The drive can produce high frequency outputs. Before adjusting the frequency,

please check the specs of motor carefully to prevent the motor from unexpected

damages.

e. If any of the protective functions have been activated, and the start command is

set to terminal control(F1.00=0 or 1 or 10), first remove the case and check the

all run commands set to OFF. Then press the key to release the alarm.

CAUTION

a. Do Not touch the heat sink or brake resistors due to the high heat.

4

INTRODUCTIONS

Features

a. Special function key(SPEC):

Programmable function key for forward/reverse running, jog speed,

selection of primary/secondary frequency command…etc.

b. Allow RS-485 communication interface control (Modbus RTU

communication protocol).

c. 6 sets of fault records:

Record 4 types of information under fault condition, respectively. (fault

code, output current, DC bus voltage, output frequency)

d. Running hours and supply power time of drive can be saved and

displayed.

e. Group design for the functions ease the function setting and

management.

f. Sequential operation control and PID control function.

g. Provide 8 sets of monitor displays(three of displays can be defined as

another extra displays).

h. Provide PTC sensor setting functions for preventing the motor from

overheating.

i. Energy-saving selection for light-duty load.

j. Auto-torque boost function.

k. Provide 8 preset speeds control.

l. The analog input signal of filter can be adjusted.

m. The response time of digital input signal is adjustable(adjustable dead

band detection).

n. Independent adjustment selection of V, F for analog input signal.

o. Two sets of analog input signals can do addition, subtraction and gain

control.

p. The switching frequency can be adjust between 800Hz ~ 16kHz.

5

Chapter 1 Cautions Before Installation

1-1 Product Verification

The product has passed the strictest quality test before shipped out from the

factory. However, the product might possibly sustain minor damages due to the

impact, shaking, vibration, and other factors during the transportation. Please

make sure to verify the following items after receiving this product. If the

product verification finds anything abnormal, please contact the agent

immediately for the further assistance.

1-1-1 Confirmation of Appearance

1.Check up the drive’s model number is identical with the shipping label on

the carton.

2.Check up the appearance of the drive for any paint chipped off,

smearing, deformation of shape, etc.

3.Check up the nameplate (as below figure) of the drive to verify the

product descriptions with the order specification.

XXXXXXXX

0201-1

3PH AC200-240V1.5A 0.1-400Hz

1PH AC200-240V 3A 50/60Hz

CA-202A

SERIAL NO.

PGM NO.

OUTPUT

INPUT

TYPE Model Number

Input Power Specs

Output Current & Capacity

Sofware Number

Product Serial Number

ISO 9001 IP20

XXXXXXXXX

1-2 Standard Specifications

Model name CA CA-201A CA-202A

Maximum applicable motor (W) 125 200

Rated output capability (VA) 400 600

Rated output current (A) 0.9 1.5

Rated output voltage (V) Three-phase 200~240V

Range of output frequency (Hz) 0.1~400Hz

Power source (ψ, V, Hz) 1Ø, 200~240V , 50 / 60Hz

Input current (A) 1.7 3

Permissible AC power source

fluctuation 176V~264V 50/60Hz /±5%

Overload protection 150% of drive rated output current for 1 min.

Cooling method Nature cooling

Protective structure IP20

Weight / Mass(kg) 384g

6

1-3 Common Specifications

1-3-1 The Features of Control and Operation

Control method ․Voltage vector sinusoidal PWM control(V/F control);

․Switching frequency: 800Hz~16kHz

Range of

frequency setting 0.1~400.00Hz

Resolution

of frequency

setting

․Operation panel: 0.01Hz

․Analog signal: 0.06Hz / 60Hz

Resolution

of output

frequency

0.01Hz

Overload

protection 150% of drive rated output current for 1 minute

DC braking

․Start/stop braking time: 0~60.0sec

․Stop braking frequency: 0.1~60Hz

․Braking ability: 0~150% of rated current

Braking torque Approximately 20%(with the external braking resistor

connected, braking torque is approximately 100%)

V/F pattern

․V/F pattern (2 V/F points)

․Square curve, 1.7th power curve, 1.5th power curve.

․Output voltage adjustment of V/F pattern(Variable voltage

(V) adjustment of V/F pattern for acceleration /

deceleration).

Acceleration/

deceleration time

․0sec(coast to stop), 0.0~3200.0sec(Independent setting of

the acceleration / deceleration).

․The time setting range of the speed acceleration from 0 to

60Hz is 0.015sec ~ 19200000sec(222 days).

Stall prevention

Stall prevention at acceleration / constant speed(the current

level of stall prevention is 30~200%), Stall prevention at

deceleration

Control Characteristics

Other functions

Slip compensation, auto-torque compensation,

auto-adjustment for output voltage stability, auto-operation for

energy-saving, auto-adjustment of switching frequency,

restart after instantaneous power failure, speed tracing,

over-torque detection, DC braking, dynamic braking duty

control, sequential operation control, counter function, PID

control, Modbus communication, jump frequency, holding

frequency, upper/lower limits of output frequency, 16-preset

speeds, acceleration/deceleration switch, S-curve

acceleration/deceleration, fan control, parameters

duplication, overload detection

7

Start method

Command the drive via 3 programmable multi-function input

terminals(X1~X3): Forward command / Reverse command,

3-wire start/stop control, 8 sets preset speed control.

4 programmable input terminals: X1~X3

Response time (1~255, unit: 1ms)

Multi-function

inputs Refer to the chapter of function setting description for

F5.19~F5.21.

1 set of analog inputs: AI(DC 0~10V / 2~10V or DC 0~20mA /

4~20mA)

Analog filter (0~255, unit: 5ms), the dead band of

Analog frequency, gain and bias are adjustable.

Input

Analog inputs

Refer to the chapter of function setting description for F5.01,

F5.02.

1-set programmable output terminal: Ta / TcMulti-function

outputs Refer to chapter of function setting description for F5.26.

1 set of analog output: FM(DC 0~10V / 2~10V or DC 0~20mA

/ 4~20mA)

The gain and bias are adjustable.

Operation Characteristics

Output

Analog

outputs Refer to the chapter of function setting description for

F5.12~F5.15.

Atmosphere Non-corrosive or non-conductive, or non-explosive gas or

liquid, and non-dusty

Surrounding

temperature

-10°C (14°F) ~ +50°C (122°F) (Non-freezing and

non-condensing)

Storage

temperature -20°C (-4°F) ~ +60°C (149°F)

Relative humidity 90% RH or less (No-condensing atmosphere)

Vibration Less than 5.9m/sec² (0.6G)

Altitude Less than 1000m (3280 ft.)

E

n

v

i

r

o

n

m

e

n

t

8

Chapter 2 Installation and Confirmation

2-1 Basic Equipment

The drive needs the several components for the conjunctive operation. These

components are called “basic equipment”, listed in the following:

2-1-1 Power Source: The voltage with three-phase or single-phase of

the power source must meet the drive specifications.

2-1-2 MCCB or NFB: MCCB (Molded Case Circuit Breaker) or NFB (No Fuse

Breaker) can withstand the inrush current at instant power-on and

providing the overload and over-current protection to the drive.

2-1-3 Drive: The rated current of motors are different for the different pole or

rated voltage. Please base on the rated voltage and rated current of

motor to select drive. Do not select the drive only base on the horse

power specification of motor. (please refer to the lists of standard

specifications of drives)

2-1-4 Motor: The specifications of motor are determined from the

requirement. Please be cautious to the motor rated current that must

not exceed the drive current.

Note: CA is only used for three-phase induction motor control, and must not be used

for single-phase motor.

2-2 Environmental Conditions

For the safe operation of the drive, please be cautious to the environmental

conditions where the drive is going to be installed.

2-2-1 AC Power: AC power input must be complied with the AC power input

specification of the drive.(see CA standard specifications)

2-2-2 Location: Due to the heat dissipating requirement during the drive

operation, the drive must keep enough space for heat dissipation. Please

keep the least clearance space when installation. (shown as below

figure):

10cm

5cm

10cm

5cm

9

2-2-3 Specifications of Associated Accessories: The specifications of the

accessories must be according to the specifications of the drive.

Otherwise, the drive will be damaged and the lifetime of the drive will be

shorten.

Do Not add any power factor leading capacitor(RC, LC or other capacitance

component) between the drive and motor to avoid any accidents.

2-2-4 Cleaning of Environment: The installed location of drive must consider

the ventilation, cleanliness and moisture.

2-2-5 Operator: Only the qualified personnel can perform the operation and

troubleshooting.

10

2-3 Descriptions of Terminal and Wiring Diagram

2-3-1 Wiring Diagram

2-3-2 Wiring Diagram

a. Main Circuit Connection

Type Symbol Function Description

Power

Source L1,L2

AC power

source input

terminals

Single-phase; sinusoidal power

source input terminal.(200~240V)

Motor U,V,W

Drive outputs to

motor terminals

The terminals output three phase

variable frequency and voltage to

motor.

Grounding

Grounding

terminal

Ground the drive in compliance

with the NEC standard or local

electrical code.

b. Control Terminals

Type Symbol Function Description

X1 Multi-function

input terminal 1

X2 Multi-function

input terminal 2

Input

terminals

X3 Multi-function

input terminal 3

Short the terminal with COM and

set the function F5.19~F5.21.

Y1 Multi-function

output terminal 1

Short the terminal with COM and

set the function F5.26

Output

terminals COM Input/output

common terminal

The common terminal of input

control signal.

V+

Power terminal for

analog input

control

12V position: Maximum supplied

current is 20mA.

Control power

VI Analog signal

input terminal DC 0~10V

11

GND

Common terminal

for analog input

control

Common terminal for control

power (12V/24V) and analog input

terminal (AI)

c. Modbus Port (RJ-45)

Type Pin Function Description

1 Communication transmission

terminal (DX+)

2 Communication transmission

terminal (DX-)

Differential input of

RS-485

*Note 1

Modbus (RS-485)

communication only uses

pin1, 2.

Modbus

(RS-485)

3-8 Reserved Reserved

Note 1: The terminal resistor(100Ω) selection is set by DSW1(default: ON)

8-pin telephone cable: The cable length must be within 5 meters.

Network cable(AMP): The cable length can be over 5 meters (the longest length

is 100 meters)

12

Chapter 3 The Setting of Operation Panel & Remote Controller

3-1 The Operation of the Operation Panel and Monitor Mode

3-1-1 The Operation of Operation Panel

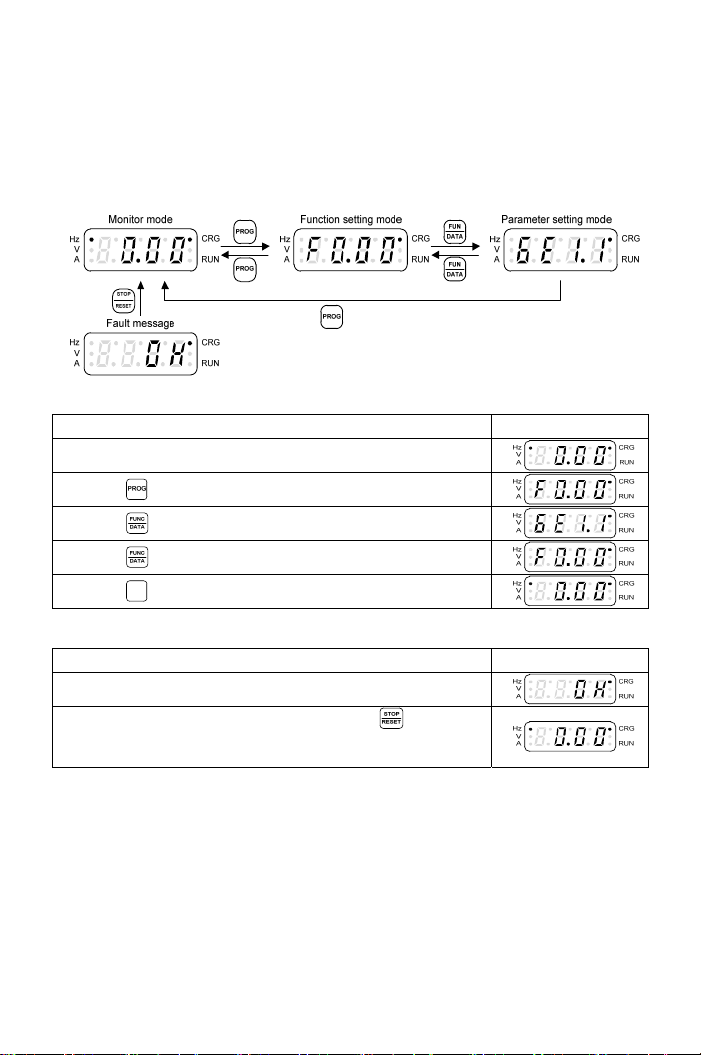

The operation of the operation panel includes fault messages and three

modes. The switching methods are shown as below figure:

The operation steps are shown in the below table (by default setting)

Operation Steps Display

1.Start the drive and enter the main display.

2.Press key and enter the function setting mode.

3.Press key and enter the parameter setting mode.

4.Press key and return to the function setting mode.

5.Press PROG key and return to the monitor mode.

Fault message display:

Operation Steps Display

The fault message displayed during the drive operation

1.After the error is troubleshooted, pressing key to

clear the fault message and then return to the monitor

mode.

13

3-1-2 Monitor Mode

There are eight monitor modes can be selected in the monitor mode. User

can determine one of eight monitor modes as the main display on the

operation panel. And the monitor mode can be switched as shown in below

figure:

Hz

V

A

CRG

RUN

Hz

V

A

CRG

RUN

Hz

V

A

CRG

RUN

Hz

V

A

CRG

RUN

Display 1

(Output Frequency)

Display 2

(Frequency Command)

Display 3

(Output Voltage)

Display 8

(Default:Motor Speed(RPM))

Hz

V

A

CRG

RUN

Display 4

(DC bus Voltage)

Hz

V

A

CRG

RUN

Hz

V

A

CRG

RUN

Hz

V

A

CRG

RUN

Display 7

(Default:Temperature of Heat Sink)

Display 6

(Default:Terminal Status)

Display 5

(Output Current)

Enter monitor mode

FUN C

DATA

FUNC

DATA

FUN C

DATA

FUN C

DATA

FUN C

DATA

FUN C

DATA

FUN C

DATA

FUNC

DATA

The descriptions of monitor modes are shown in the below table(example by default

setting)

Display Descriptions Display

Display 1 Output frequency (Hz, CRG: ON)

Display 2 Frequency command (Hz, CRG: ON)

Display 3 Output voltage (V, CRG: ON)

Display 4 DC bus voltage (V, CRG: ON)

Display 5 Output current (A, CRG: ON)

Display 6 Terminal status (Hz, V, CRG, RUN: ON)

Display 7 Heat sink temperature (V, A, CRG: ON)

Display 8 Motor speed(RPM) (Hz, A, CRG: ON)

a. User can select the main display from eight monitor displays and switch to another

monitor displays by FUNC

DATA key under monitor mode. The selection of monitor

displays can be set from F1.08.

b. User can determine one of the displays to be the main display according to the

demand. If the user does not change the display back the main display after the

setting is completed, the drive will automatically switch back to the main display

after the operation panel is idle over 3 min.

c. The display 6~8 are defined by F1.09~F1.11

14

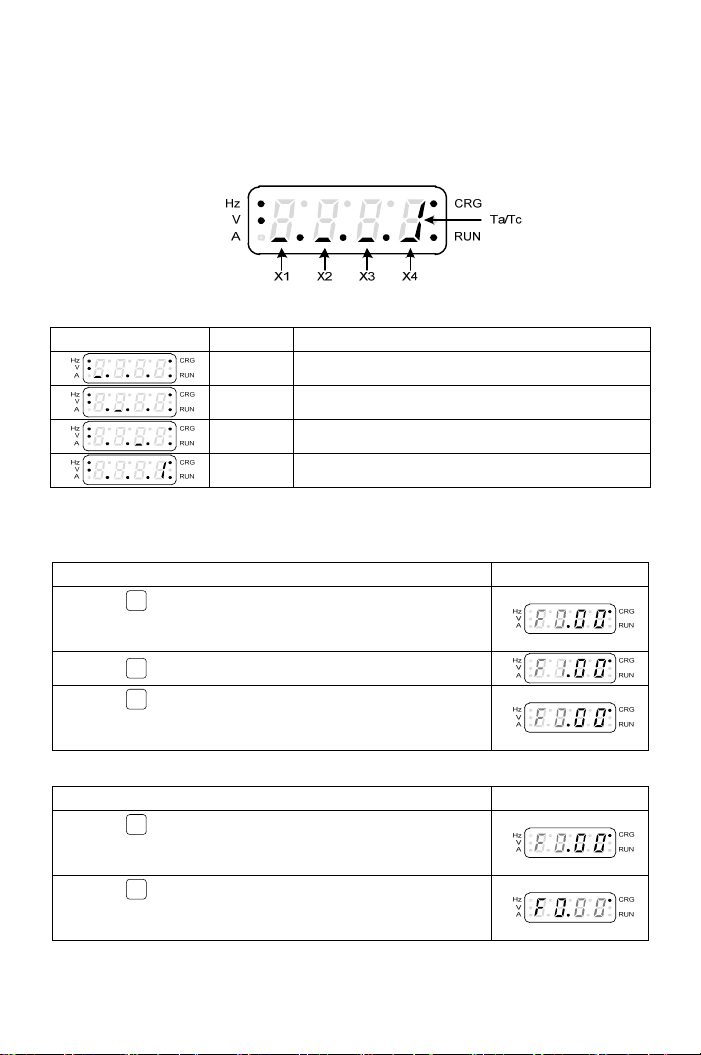

3-1-3 The Status of Multi-function Terminals

The default setting of “Display 6” is the status of multi-function input

terminals and the definition of each segment on the seven-segment display

for 4 digits is shown as below figure:

The definition of display shown in the below table:

Display Terminal Status description

X1 Multi-function input terminal “X1” is active.

X2 Multi-function input terminal “X2” is active.

X3 Multi-function input terminal “X3” is active.

Y1 Multi-function input terminal “Y1” is active.

3-1-4 The Function Setting Mode

a.The selection of function group:

Operation Steps Display

1.Press PROG key to enter function group setting mode

under monitor mode and the function group in the display

will be flashing.

2.Press ▲key to increase the function group number.

3.Press ▼key to decrease the function group number.

See “Chapter 4 Parameter List” for the setting range of

function groups.

b.The switch of function group and function number:

Operation Steps Display

1.Press << key to switch the function number setting

mode to function group setting mode when function group

is flashing.

2.Press << key to switch the function group setting mode

to function number setting mode when function number is

flashing.

15

c.The selection of function number:

Operation Steps Display

1.Press << key to switch to the function number setting

mode after the function group is selected. And the

function number is flashing.

2.Press ▲key to increase the function number.

3.Press ▼key to decrease the function number. See

“Chapter 4 Parameter List” for the setting range of

function numbers.

Note: The grey-color digits in above tables represent the flashing of the digits.

3-1-5 Parameter Setting Mode

The setting range of parameter is according to the function. The operation

steps are shown in the below table:

Operation Steps Display

1.The function setting mode: example F2.17(output

frequency).

2.Press FUNC

DATA key in the function setting mode and enter

parameter setting mode.

3.Press << key to shift the digit; Example: Shift the

number to the last digit after the decimal point.

4.Press ▲key to increase 0.1 to the output frequency.

5.Press ▼key to decrease 0.1 to the output frequency.

6.Press FUNC

DATA key and return to function setting mode.

a.The digit of parameter value is flashing after the parameter value is changed.

(grey-color digits in above table means digit flashing)

b.The setting range of F2.17 is 0.00~400.00Hz

16

3-1-6 The Operation in the Monitor Mode

Frequency command, motor speed(RPM), machine speed(MPM) are

changeable under monitor mode. For example of frequency command

change, the setting steps are shown in the following table.

The operation steps are shown in the below table:

Operation Steps Display

1.In the monitor mode, the display is shown as right.

2.Press << key to shift the digit of frequency command.

3.Press << key to shift the digit of frequency command.

Example: Change the digit of decimal value.

4.Press ▲key to increase 1 to the frequency command.

5.Press ▼key to decrease 1 to the frequency command.

6.Press FUNC

DATA key to save the setting value within 5sec,

when completing setting of the rotation speed.

Note: grey-color digits in above table means digit flashing.

a.Use ▲or ▼key to control the rotation speed in the monitor mode.

b.Press FUNC

DATA key to save the setting value within 5sec(the setting value is

flashing), when the required rotation speed is set. If the setting value is not

saved, the display will return to the monitor mode after 5sec and save the

value automatically after 3 min. If the saving of the setting value is not

completed and drive immediately powers off within 3 min, the setting value will

recover to the original value before setting.(see F1.07 for the setting).

3-1-7 Start/Stop of the Drive

Press RUN and STOP

RESET key to control the output of drive. Shown as below:

3-1-8 SPEC Programmable Special function key(SPEC) for forward/reverse

(grey-color digits in above table means digit flashing)

17

18

3-1-9 Save and Restore the Setting Value.

a.The operation steps of saving drive function setting are shown in the below table:

Operation Steps Display

1.Press PROG key and enter the function setting mode.

2.Press << key and switch to the function number setting

mode.

3.Press ▼key to select F0.20.

4.Press FUNC

DATA key and enter the parameter setting mode.

5.Press ▲key and select the “SAv”.

6.Press FUNC

DATA key to save settings. The display of operation

panel will display “End” after 2sec.

7.After the panel displays ”End” for 1 sec, the display

automatically returns to the function setting mode.

8.Press PROG key and return to the monitor mode

(frequency command).

b.The operation steps of resuming drive function setting are shown in the below table:

Operation Display

1.Press PROG key and enter the function setting mode.

2.Press << key and switch to the function number setting

mode.

3.Press ▼key to select F0.20.

4.Press FUNC

DATA key to enter the parameter setting mode.

5.Press ▲key and select the “rES”.

6.Press FUNC

DATA key to save the setting. The panel will display

“End” after 2sec.

7.After the panel displays ”End” for 1 sec, the display

automatically returns to the function setting mode.

8.Press PROG key and return to the monitor mode

(frequency command).

Chapter 4 Parameter List

Group List(Factory Setting: F0.18=0)

brief version function

(F0.18=0)

detail function

(F0.18=1)

Group Function Group Function

F0System

ParametersF0

Systemstatus

Parameterlocking

Passwordprotection

Powersourcevoltagesetting

F1

Startcommandselection

Frequencycommand

selection

Maindisplayselection

SPECkeysetting

Switchingfrequency

Stopmode

F1

Startcommandselection

Frequencycommandselection

Maindisplayselection

SPECkeysetting

Switchingfrequency

Stopmode

F2 Frequency Parameters F2 Frequency

Parameters

Presetspeed

Multi‐acceleration/deceleratio

ntime

V/Fpatternsetting

Upper/lowerlimitsofoutput

frequency

F4 Control

Parameters

F3

Control

Parameters

Holdingfrequencyandtime

Stallpreventionsetting

Motorslipcompensation

Automaticboostvoltagerange

Currentoscillationprevention

Speedtracing

Currentcompensation

F5 Protection

ParametersF4 Protection

Parameters

Groundingfaultprotection

Driveoverloadprotection

Motoroverloadprotection

Driveoverheatprotection

Overload protection setting

F5Multi‐function

parameters

Analoginput

Analogoutput

Multi‐functioninput

Multi‐functionoutput

UP/DOWNsetting

Countingmode

Frequencydetection

F6Special

parameters

Sequentialoperationcontrol

Modbuscommunication

19

F0 System Parameters

Func. Name Descriptions Range of

Setting Unit Factory

Setting Note

F0.00 Drive

Information

0: Software version

1: Drive model number

2: Drive rated current

3: Drive running hours

4: Drive supply power time

5: Software checksum code

── ─

F0.01 Parameter

Lock

0: Parameters are changeable

1: Parameters are locked 0, 1 ─0

F0.02 Reserved Reserved ── ─ *Note 9

F0.03 Reserved Reserved ── ─ *Note 9

F0.04 Reserved Reserved ── ─ *Note 9

100.0~120.0

*Note 3

110.0

*Note 3

190.0~240.0

*Note 4

220.0

*Note 4

F0.05 Power

Source

The value of setting according to

the actual power source

340.0~480.0

*Note 5

0.1V

380.0

*Note 5

*Note 9

F0.08 Fault

Record 1 ── ─ *Note 9

F0.09 Reserved ── ─ *Note 9

F0.10 Reserved ── ─ *Note 9

F0.11 Reserved ── ─ *Note 9

F0.12 Reserved ── ─ *Note 9

F0.13 Reserved

0: Fault code

1: Output current at drive fault

2: DC bus voltage at drive fault

3: Output frequency at drive fault

── ─ *Note 9

F0.18 Function 0:brief 1:detail function 0,1 ─0

F0.19 Reserved

Reserved

*Note 9

0: Disable

CLF: Clear fault records

dF60: Default the factory setting

of 60Hz

dF50: Default the factory setting

of 50Hz

SAv: Store setting

F0.20 Default

Setting

rES: Resume setting

──0

The color as means functions can be set during the operation.

20

This manual suits for next models

2

Table of contents

Popular DC Drive manuals by other brands

Epson

Epson S1F76680 Technical manual

Rhymebus

Rhymebus RM6 Series Operation manual

Exhausto

Exhausto NFO Sinus Optimal Quick installation guide

Danfoss

Danfoss VLT AQUA Drive FC 202 operating guide

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 525 Product information

Festo

Festo CMMT-ST-SW Original instructions

ABB

ABB ACQ580-04 Hardware manual

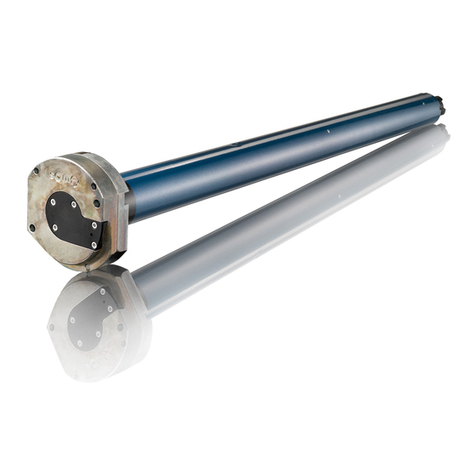

GFA

GFA ELEKTROMAT SI 60.24-55,00 installation instructions

Danfoss

Danfoss vlt aqua operating instructions

TIME LED

TIME LED 781234 Installation and operating instructions

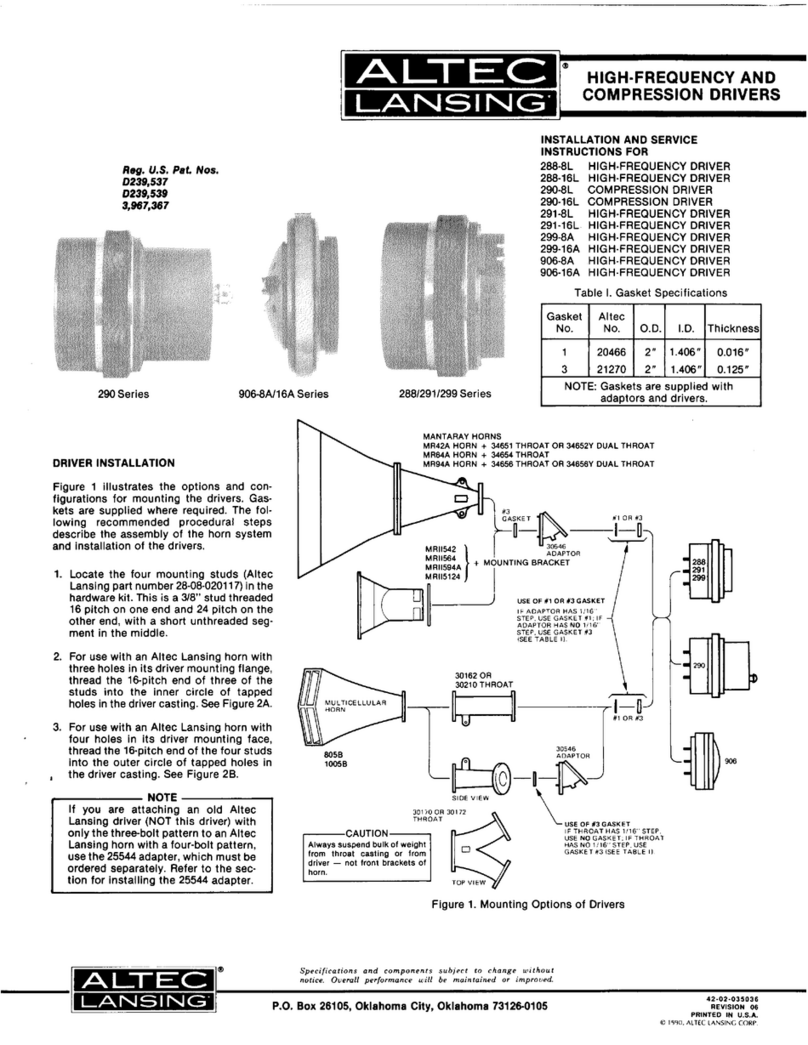

Altec Lansing

Altec Lansing HF DRIVER - REPAIR Repair

Danfoss

Danfoss VLT HVAC Basic Drive FC 101 quick guide