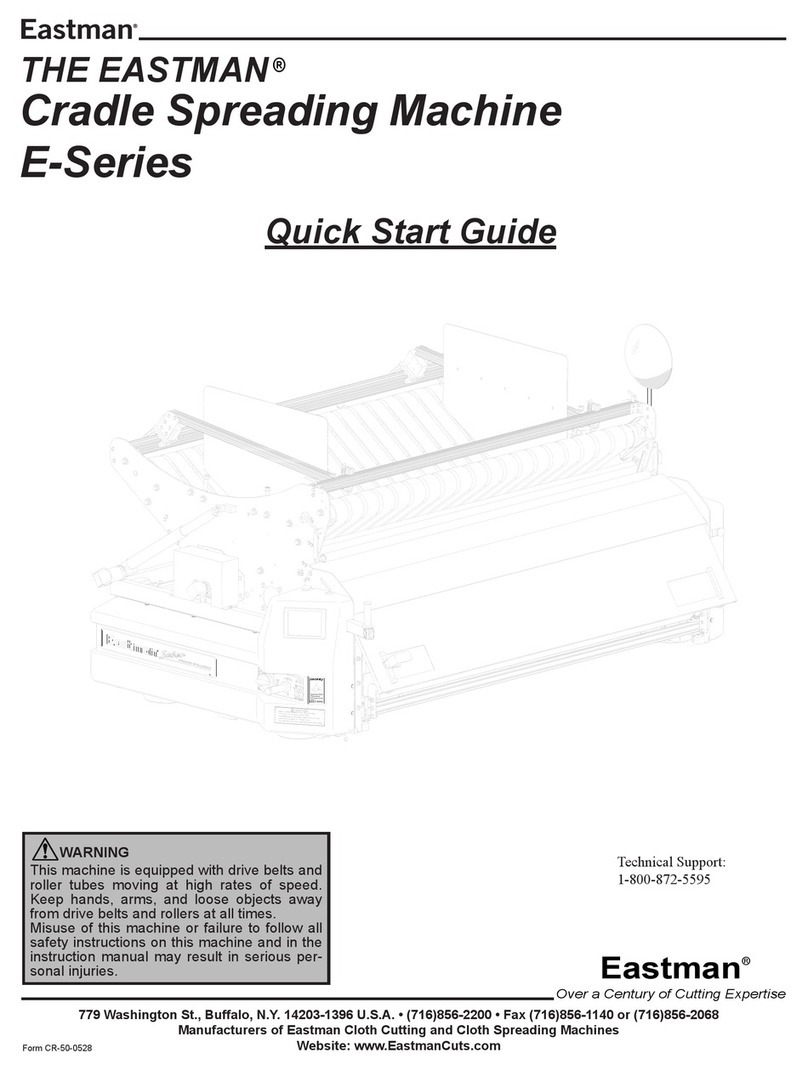

TPI Fostoria CH Series Use and care manual

Flat Panel Emitter Replacement Element Guide

For CH, MR and FHK Series

The at panel emitter is a total element replacement for metal sheath elements.

• All metal sheath elements and reectors are replaced by one complete unit including:

• The at panel emitter.

• All mounting hardware to convert the metal sheath elements to the at panel emitter.

• All hardware and components for power connection requirements.

• A heavy-duty wire guard for units that do not have one as standard equipment.

All at panel emitter replacement elements except (CH-4 and MR-4) come fully assembled and wired

for ease of eld conversion.

METAL SHEATH REPRESENTATION FLAT PANEL EMITTER REPRESENTATION

TPI Corporation

P.O. BOX 4973

JOHNSON CITY, TN 37602

www.tpicorp.com

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 1 OF 9

Preparation of Existing CH or MR series For

installing Flat Panel Emitter

This procedure applies to all CH and MR series

metal sheath heaters.

1. Remove existing u-shaped or straight metal

sheath elements and element retaining clips

from heater assembly. See Detail ‘A’.

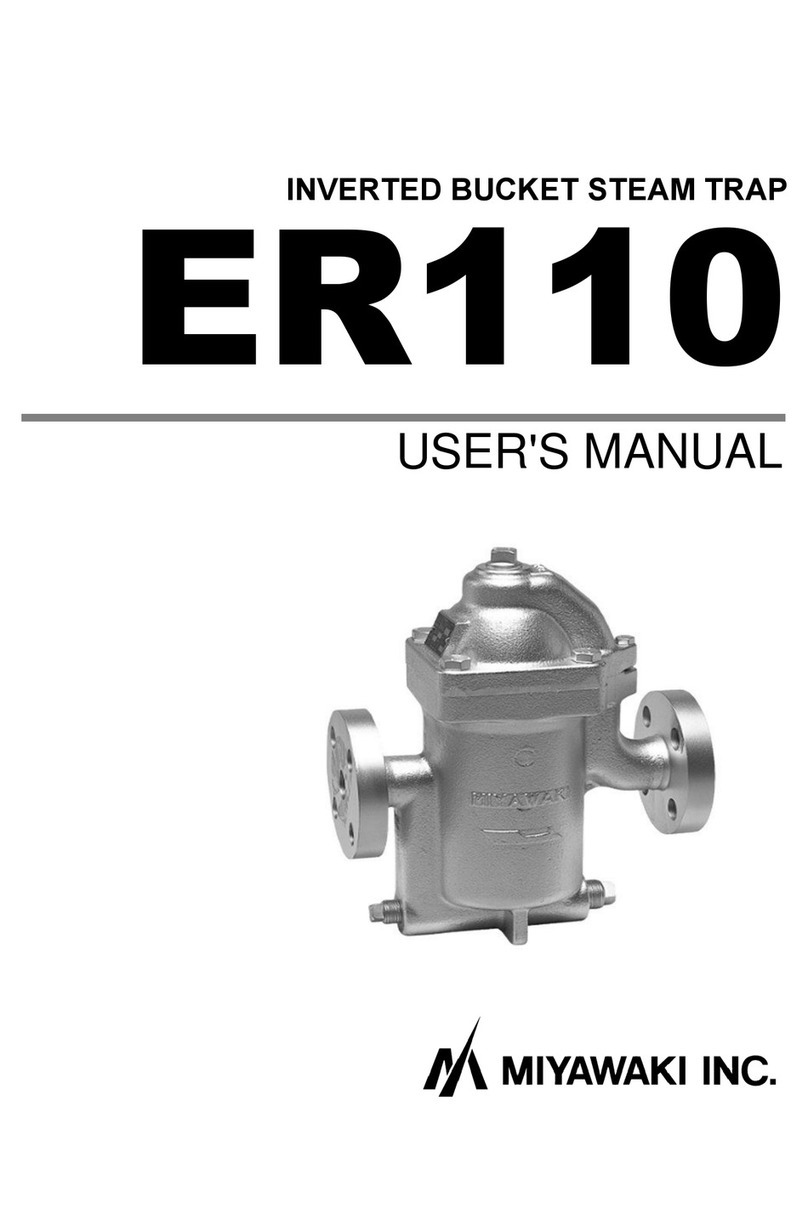

2. Remove reector/extrusion assembly by

removing the 3/8” nuts on the back of the

mounting channel. See Detail ‘B’.

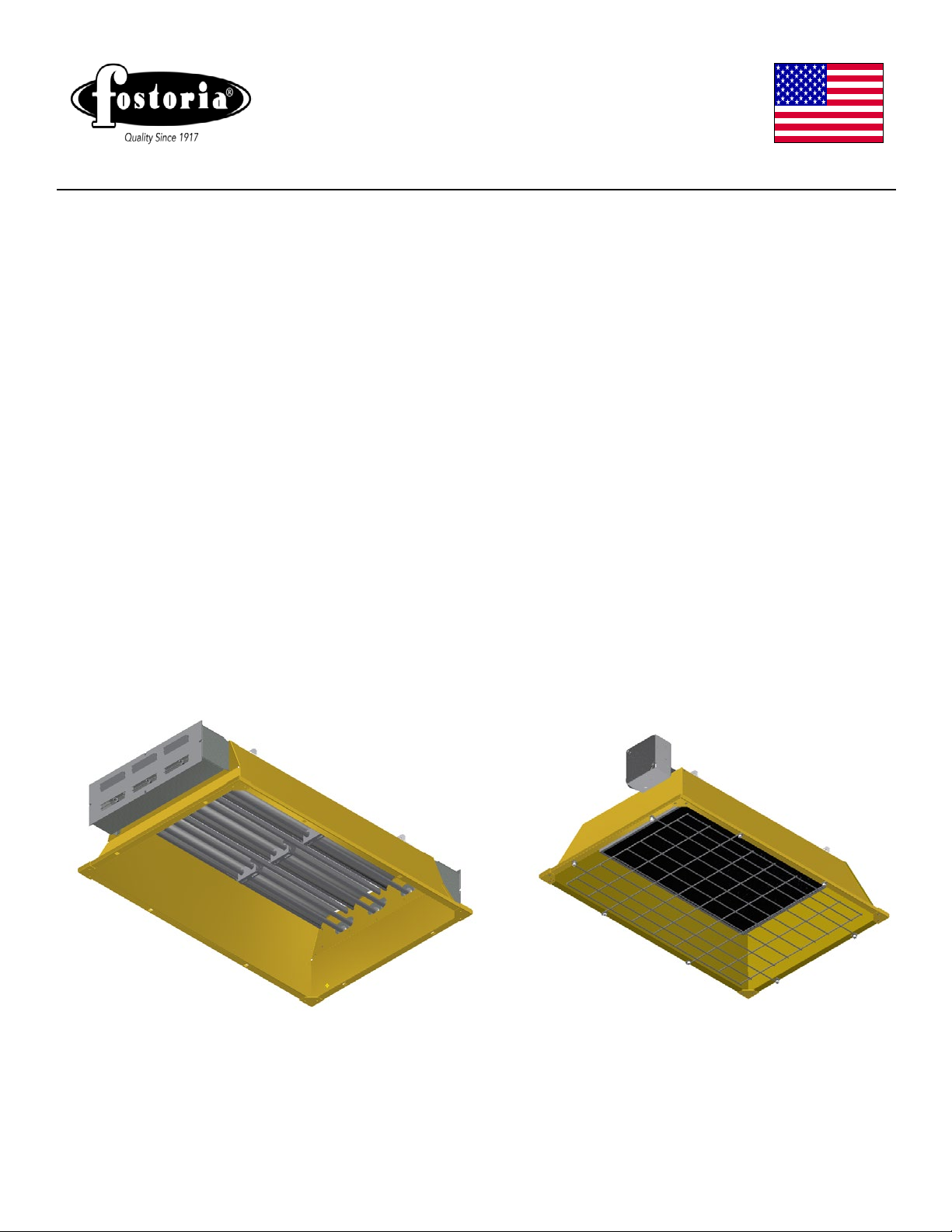

3. Remove the terminal box or boxes (2 on MR

series) by removing the sheet metal screws on

the inside of the housing. See Detail ‘C’.

ELEMENT

RETAINER

ELEMENT

DETAIL ‘A’

ELECTRICAL SHOCK HAZARD

• Serious injury or death may

occur.

• Disconnect heaters from

electrical supply before

replacing parts.

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 2 OF 9

EXTRUSION

DETAIL 'B'

DETAIL 'C'

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 3 OF 9

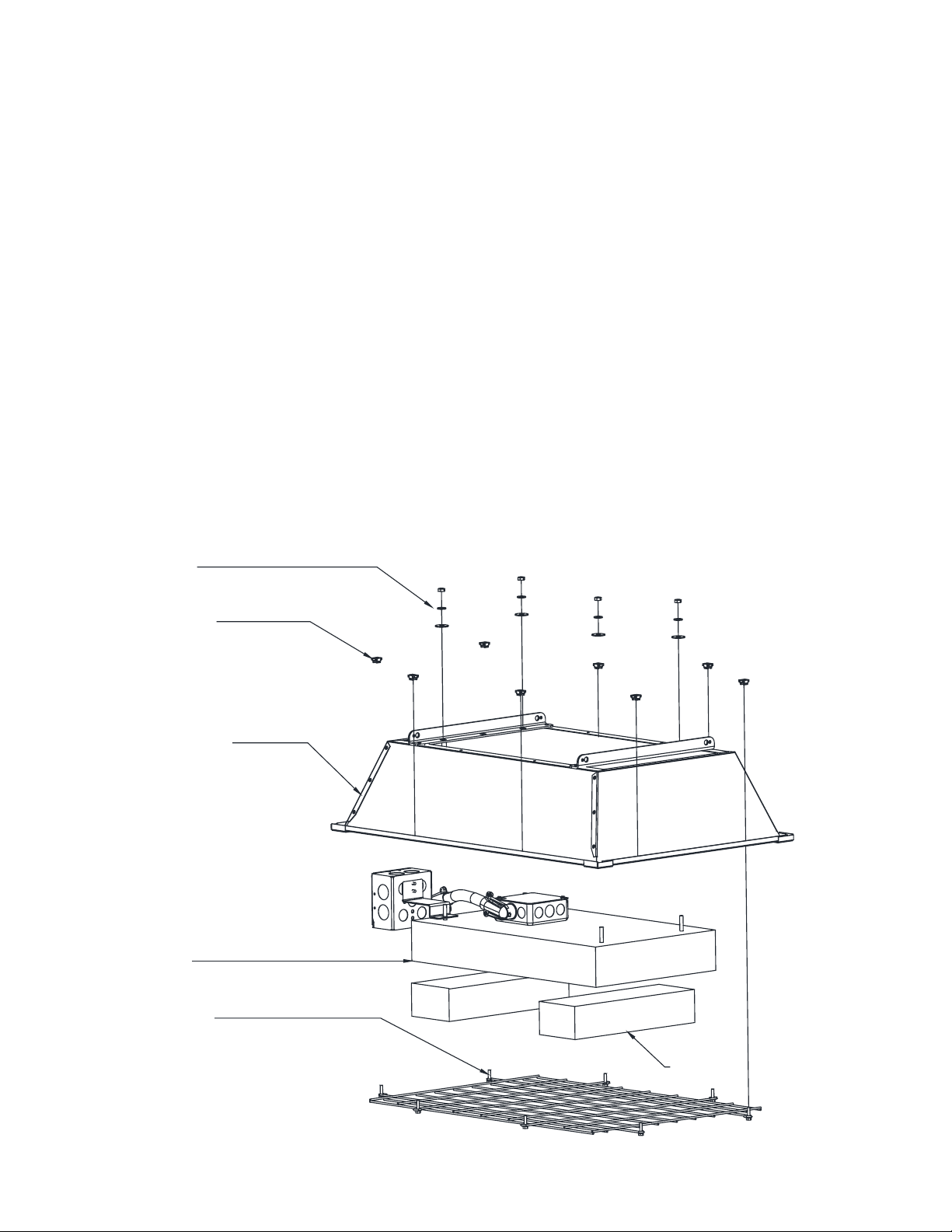

Installing the Flat Panel Emitter CH & MR-6,-13 AND 27

1. Install cage nuts into housing for grille attachment.

2. For ease of assembly, rest the element assembly on blocks high enough to allow the housing to set

down over the element assembly and not rest on the work surface. Be careful to not damage the

front of the Flat Panel Emitter.

3. Place the housing over the element assembly while feeding the conduit and connection box through

the housing.

4. Once the housing is in place, secure the housing and connection box bracket to the element

assembly with the hardware provided. Be sure to use a at washer and split washer on each

stud.

5. Mount the heavy duty wire guard to the front of the housing using the screws provided.

6. Hang the heater in the same manner as originally installed.

7. Wire heater as need referring to the wiring diagram on the front of the wiring box.

8. Restore power.

ELEMENT ASSEMBLY

HOUSING

GRILLE AND SCREWS

CAGE NUTS

MOUNTING HARDWARE

BLOCKING

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 4 OF 9

Installing the Flat Panel Emitter CH & MR-4

1. Remove extension ring from element assembly. This must be done to allow insertion between side

bafes.

2. For ease of assembly, rest the element assembly on blocks high enough to allow the housing to set

down over the element assembly and not rest on the work surface. Be careful to not damage the

front of the Flat Panel Emitter.

3. Place housing over the element assembly, mount the 2 x 4 outlet box and bracket over the mounting

stud and secure all to the housing with the hardware provided.

4. Attach lead wires to element termination with supplied hardware, making certain connections are

tight.

5. Replace extension ring on element assembly.

6. Connect conduit and connector to extension ring.

7. Feed lead wires through conduit and secure conduit to 2 x 4 outlet box.

8. Install cage nuts into housing for grille attachment.

9. Mount the heavy duty wire guard to the front of the housing using the screws provided.

10. Hang the heater in the same manner as originally installed.

11. Restore power.

Typical CH or MR-4 with Flat Panel Emitter

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 5 OF 9

Preparation of Existing FHK-6 AND FHK-13

series For installing Flat Panel Emitter

1. DISCONNECT POWER FROM THE

ELECTRICAL SUPPLY CABLE OF

THE PORTABLE HEATER BEING

REPAIRED.

2. Position heater with reector opening pointing

U P.

3. Remove the wire guard from the heater to

access the fasteners that attach the terminal

box. Remove and save the (12) screws shown

in Illustration 1 with a 5/16” nut driver.

4. Remove and discard the (4) screws that

attach the terminal box to the heater,

with a 1/4” nut driver. See Illustration 2.

5. Grasp terminal box assembly and rmly pull

in the direction shown in Illustration 3.

The

elements have been fed through some

support clips inside the heater housing

.

These clips will cause some drag or resistance

to removal.

There will be some unpleasant

noise as the elements slide through the clips.

6. Discard all.

ELECTRICAL SHOCK HAZARD

• Serious injury or death may

occur.

• Disconnect heaters from electrical

supply before replacing parts.

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 6 OF 9

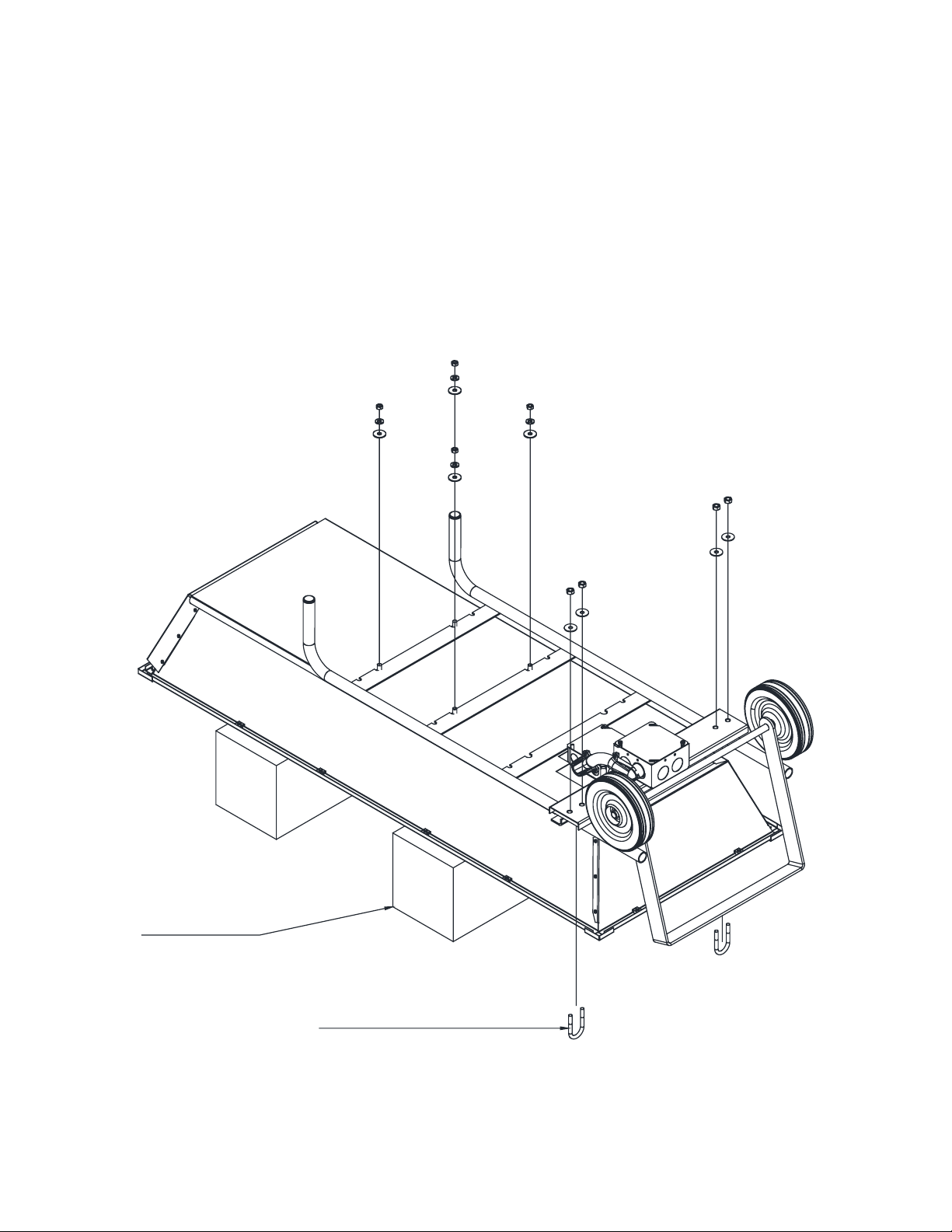

REMOVING REFLECTORS AND EXTRUSION

To remove the reector and extrusion :

1. Lay heater face down and remove the cart

from the heater by taking off the (4) jam nuts

as shown in Illustration 4.

2. Lift the back shield and (4) washers off the

heater.

3. Remove the (2) support clips from the front

of the reector.

4. Remove (4) jam nuts that secure the

extrusion to the housing. The extrusion

and reector will now come out of the

housing.

5. Discard all.

6. The housing is now ready for installation of

the Flat Panel Emitter.

INSTALLING THE FLAT PANEL EMITTER

1. For ease of assembly, rest the element assembly on blocks high enough to allow the housing to

set down over the element assembly and not rest on the work surface. Be careful to not damage

the front of the Flat Panel Emitter.

2. Place the housing over the element assembly while feeding the conduit , connection box and

mounting bracket through the housing.

3. Install the (4) washers and back shield as shown in Illustration 5.

BLOCKING

HOUSING

WASHERS

BACK

SHIELD

ILLUSTRATION 5

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 7 OF 9

BLOCKING

U-BOLT

ILLUSTRATION 6

4. Re-install cart assembly as shown in Illustration 6. Be sure that the connection box and mounting

bracket are on the back side of the cart. Secure the cart to the housing using the 1/4” hardware provided.

Secure the mounting bracket to the cart frame using the u-bolts and 5/16” nuts and washers.

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 8 OF 9

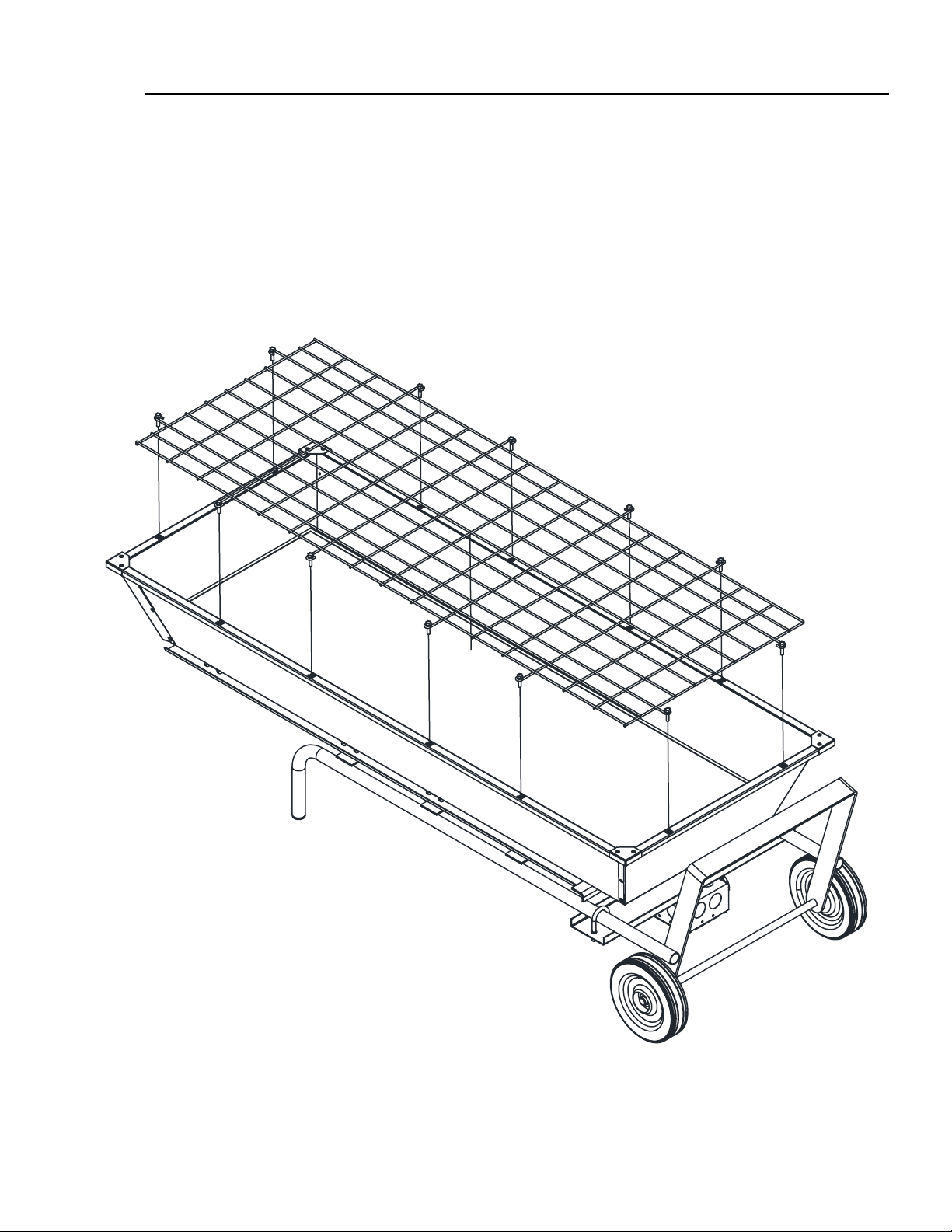

5.

After installing the cart, turn the complete assembly over and install the wire guard using the original

screws.

DO NOT OPERATE ANY FSP-SERIES WITHOUT THE WIRE GUARD INSTALLED.

6.

Install cable or conduit as previously used on the heater. For additional wiring space, an

extension ring may be used on the connection box.

7. Restore power.

ISSUE DATE 7/2015 REV. DATE- REV. LEVEL: - ECO 1-7065 OIPM P/N 8422 PG 9 OF 9

This manual suits for next models

12

Table of contents