Fastech Ezi-Step Mini User manual

Operating Manual

www.fastech-motions.com

www.fastech-motions.com - 2

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

3

6

7

7

7

8

8

9

9

10

11

11

12

12

12

13

13

13

13

13

14

14

15

16

17

18

Table of Contents

1. Precautions

2. Main characteristics

3. Ezi-STEP MINI Part Numbering

4. Standard Combination

5. Combination with Brake

6. Specifications of Drive

7. Dimensions of Drive [mm]

8. Specifications of Motor

9. Torque Characteristics of Motor

10. Dimensions of Motor [mm]

11. Notes on Installation

12. Settings and Operation

12.1 Drive Status LED

12.2 Stop Current Setting Switch(SW1.1~1.4)

12.3 Resolution Setting Switch(SW1.5~1.8)

12.4 Rotational Direction Setting Switch(SW2.5)

12.5 Pulse Input Setting Switch(SW2.6)

12.6 Signal Connector(CN1)

12.7 Motor Connector(CN3)

12.8 Power Connector(CN4)

13. System Configuration

13.1 Options

13.2 Connector Specifications

14. External Wiring Diagram

15. Control Signal Input/Output Description

Appendix

www.fastech-motions.com - 3

※ Before operation ※

·Thank you for your purchasing Ezi-STEP MINI.

·Ezi-STEP MINI is an all-in-one Unit. For high-speed and high-precision drive of a stepping motor,

Ezi-STEP MINI is an unique drive that adopts a new control scheme owing to an on-board high-

performance 32bit digital signal processor.

·This manual describes handling, maintenance, repair, diagnosis and troubleshooting of Ezi-STEP MINI.

·Before operating Ezi-STEP MINI, thoroughly read this manual.

·After reading the manual, keep the manual near the Ezi-STEP MINI so that any user can read the

manual whenever needed.

1. Precautions

◆ General Precautions

·Contents of this manual are subject to change without prior notice for functional im provement, change of

specifications or

user's better understanding. Thoroughly read the manual provided with the purchased

Ezi-STEP MINI.

·When the manual is damaged or lost, please contact with Fastech's agents or our company at the address

on the last page of the manual.

·Our company is not responsible for a product breakdown due to user's dismantling for the product, and such

a breakdown is not guaranteed by the warranty.

◆ Put the Safety First

·Before installation, operation and repairing the Ezi-STEP MINI, thoroughly read the manual and fully understand

the contents. Before operating the Ezi-STEP MINI please, understand the mechanical characteristics of the Ezi-

STEP MINI and related safety information and precautions.

·This manual divides safety precautions into Attention and Warning.

·Although precaution is only a Attention, a serious result could be caused depending on the situation.

Follow safety precautions.

Attention : If user does not properly handle the product, the user may seriously or slightly injured

and damages may occur in the machine.

Warning : If user does not properly handle the product, a dangerous situation (such as an electric

shock) may occur resulting in deaths or serious injuries.

www.fastech-motions.com - 4

◆ Check the Product

Check the Product is damaged or parts are missing.

Otherwise, the machine may get damaged or the user may get injured.

Attention

◆ Installation

Carefully move the Ezi-STEP MINI.

Otherwise the Product may get damaged or User's foot may get injured by dropping the

product.

Use non-flammable materials such as metal in the place where the Ezi-STEP MINI is to

be installed.

Otherwise, a fire may occur.

When installing several Ezi-STEP MINI in a sealed place, install a cooling fan to keep the

ambient temperature of the Ezi-STEP MINI as 50℃ or lower.

Otherwise, a fire or other kinds of accidents may occur due to overheating.

The process of Installation, Connection, Operation, Checking and Repairing should be

done with qualified person.

Otherwise, a fire or other kinds of accidents may occur.

Attention

Warning

◆ Connect Cables

Keep the rated range of lnput Voltage for Ezi-STEP MINI.

Otherwise, a fire or other kinds of accidents may occur.

Cable connection should follow the wiring diagram.

Otherwise, a fire or other kinds of accidents may occur.

Before connecting cables, check if input power is off.

Otherwise, an electric shock or a fire may occur.

The case of the Ezi-STEP MINI is insulated from the ground of the internal circuit by the

condenser. Ground the Ezi-STEP MINI.

Otherwise, an electric shock or a fire may occur.

Attention

Warning

www.fastech-motions.com - 5

◆ Operation

◆ Check and Repair

If a protection function(alarm) occurs, firstly remove its cause and then release(alarm reset)

the protection function.

If you operate continuously without removing its cause, the machine may get damaged or

the user may get injured.

Do not make Motor Free and make input signal to ON during operation.

Motor will stop and stop current will become zero. The machine may get damaged or the

user may get injured.

Make all input signals to OFF before supply input voltage to Ezi-STEP MINI.

The machine may get damaged or the user may get injured by motor operation.

All parameter values are set by default factory setting value. Change this value after

reading this manual throughly.

Otherwise, the machine may get damaged or other kinds of accidents may occur.

Stop to supply power to the main circuit and wait for a while before checking or

repairing the Ezi-STEP MINI.

Electricity remaining in the capacitor may cause danger.

Do not change cabling while power is being supplied.

Otherwise, the user may get injured or the product may get damaged.

Do not reconstruct the Ezi-STEP MINI.

Otherwise, an electric shock may occur or the reconstructed product can not get

After-Service.

Attention

Attention

www.fastech-motions.com - 6

2. Main characteristics

3

Drive Output Signal Monitoring

Ezi-STEP MINI provides loss of step, run/stop, over-

current, over-heat, over-voltage, power and motor

connection alarms that can be monitored by the

controller and visible by a motor-mounted flashing LED

indicator.

1

Microstep and Filtering

The high-performance MCU operates at step resolutions

of 1.8 ° up to maximum 0.0072 ° (1/250 steps) and Ezi-

STEP adjusts PWM control signal in every 25 μsec,

which makes it possible for more precise current control,

resulting in high-precision Microstep operation.

High precision Microstep function and Filtering

2

Software Damping

Vibration suppression and High-speed operation (Patent

pending) Motor vibration is created by magnetic flux

variations of the motor, lower current from the drive

due to back-emf from the motor at high speeds and

lowering of phase voltages from the drive.

Ezi-STEP drive detects these problems and the MCU

adjusts the phase of the current according to the pole

position of the motor, drastically suppressing vibration.

This allows the smooth operation of the motor at high

speeds.

Vibration suppression and high-speed

operation

Software Damping OFF

※ This is real measured speed that using 100,000 [pulse/rev] encoder.

Software Damping ON

www.fastech-motions.com - 7

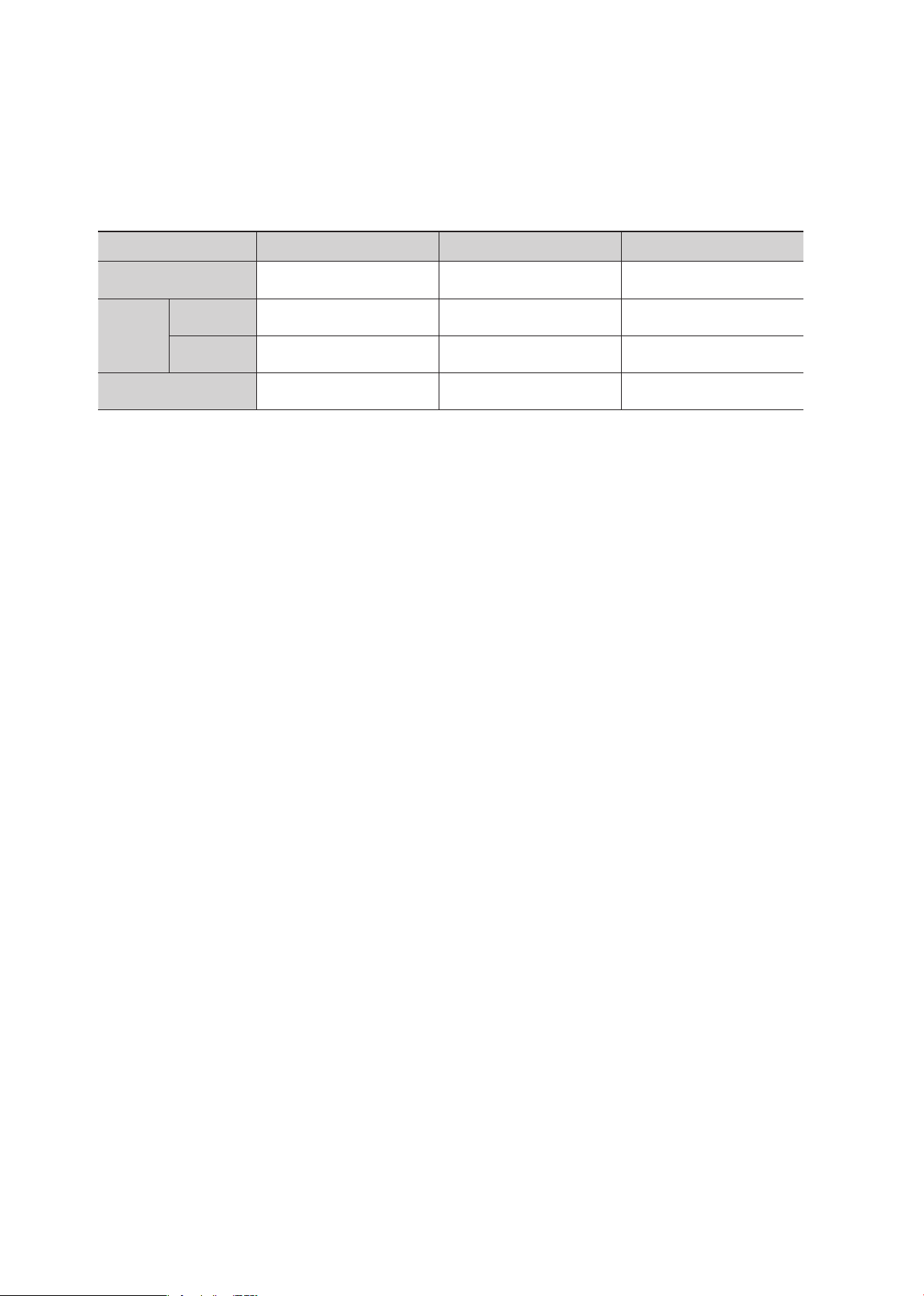

3. Ezi-STEP MINI Part Numbering 4. Standard Combination

5. Combination with Brake

Unit Part

Number

Motor Model

Number

Drive Model

Number

Ezi-STEP-MI-20M BM-20M EzStep-MI-20M

Ezi-STEP-MI-20L BM-20L EzStep-MI-20L

Ezi-STEP-MI-28S BM-28S EzStep-MI-28S

Ezi-STEP-MI-28M BM-28M EzStep-MI-28M

Ezi-STEP-MI-28L BM-28L EzStep-MI-28L

Ezi-STEP-MI-42S BM-42S EzStep-MI-42S

Ezi-STEP-MI-42M BM-42M EzStep-MI-42M

Ezi-STEP-MI-42L BM-42L EzStep-MI-42L

Ezi-STEP-MI-42XL BM-42XL EzStep-MI-42XL

Ezi-STEP-MI-42M-BK-□

Product Name

User Code

20

:

20mm

28

:

28mm

42

:

42mm

S

: Small

M

: Medium

L

: Large

XL

:

Extra Large

Motor Flange Size

Motor Length

Brake

Blank : Without Brake

BK : Brake

MI : Mini Type

Drive Series Type

Unit Part

Number

Motor Model

Number

Drive Model

Number

Ezi-STEP-MI-42S-BK BM-42S-BK EzStep-MI-42S

Ezi-STEP-MI-42M-BK BM-42M-BK EzStep-MI-42M

Ezi-STEP-MI-42L-BK BM-42L-BK EzStep-MI-42L

Ezi-STEP-MI-42XL-BK BM-42XL-BK EzStep-MI-42XL

www.fastech-motions.com - 8

82.8

2.9

53.9

21.5

9

2-3.5

69.8

77

Motor Model BM-20

series BM-28

series BM-42

series

Driver Model EzStep-MI-20

series EzStep-MI-28

series EzStep-MI-42

series

Input Voltage 24VDC ±10%

Control Method Bipolar PWM drive with 32bit MCU

Current Consumption Max 500mA (Except motor current)

Operating

Condition

Ambient

Temperature

·In Use: 0~50℃

·In Storage: -20~70℃

Humidity ·In Use: 35~85% RH (Non-Condensing)

·In Storage: 10~90% RH (Non-Condensing)

Vib. Resist. 0.5g

Function

Rotation Speed 0~3,000 [rpm] *1

Resolution [ppr]

500 1,000 1,600 2,000 3,200 3,600 4,000 5,000 6,400 8,000 10,000 20,000 25,000 36,000 40,000 50,000

* Default: 10,000

Maximum Frequency 500kHz (Duty 50%)

Protection Functions Over Current Error, Over Speed Error, Step Out Error, Over Temperature Error, Over Regenerated

Voltage Error, Motor Connect Error, Motor Voltage Error, System Error, ROM Error

LED Display Power Status(Green), Alarm Status(Red), CW Rotation(Yellow), CCW Rotation(Orange)

STOP Current 10%~100% (Selectable with DIP Switch) Be setted to set value of STOP Current after 0.1 second after

motor stop. * Default: 50%

Pulse Input Method 1 Pulse / 2 Pulse (Selectable with DIP Switch) * Default: 2 Pulse

Rotational Direction CW/CCW (Selectable with DIP Switch) * Default: CW

Speed/Position

Control Command Pulse Train Input (Photocoupler Input)

I/O

Signal

Input Signals Alarm Reset / Motor Free (Photocoupler Input)

Output Signals Alarm, Run/Stop (Photocoupler Output)

*1 : Up to the resolution of 10,000[ppr], maximum speed can be reached by 3,000[rpm] and with the resolution more than 10,000[ppr], maximum speed

shall be reduced accordingly.

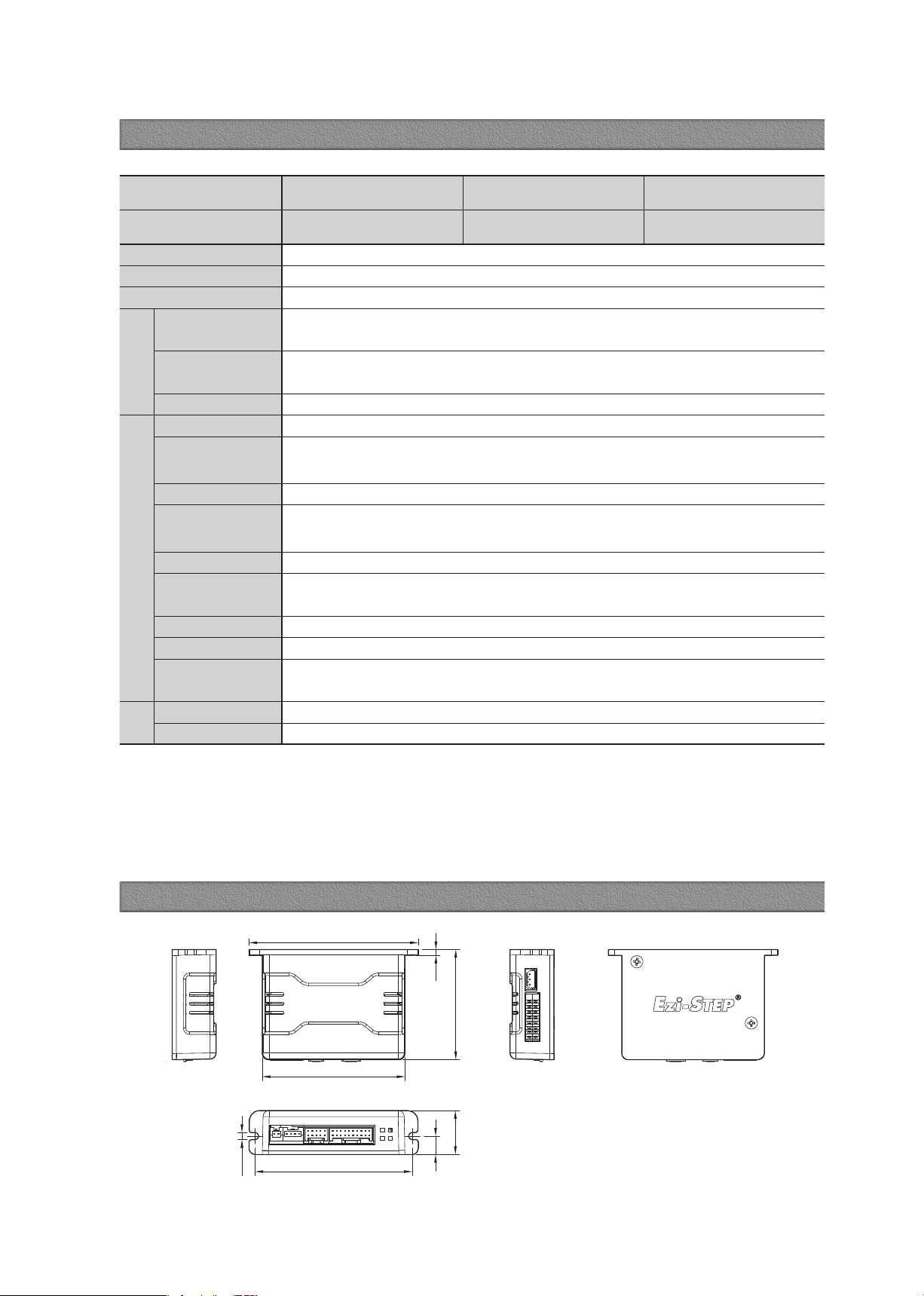

6. Specifications of Drive

7. Dimensions of Drive [mm]

www.fastech-motions.com - 9

MODEL

BM-20

series

BM-28

series

BM-42

series

UNIT 20M 20L 28S 28M 28L 42S 42M 42L 42XL

DRIVE METHOD -BI-POLAR

NUMBER OF PHASES -2 2 2 2 2 2 2 2 2

VOLTAGE VDC 2.75 3.0 3.0 3.0 3.0 3.36 4.32 4.56 7.2

CURRENT per PHASE A0.5 0.5 0.95 0.95 0.95 1.2 1.2 1.2 1.2

RESISTANCE per PHASE Ohm 5.5 6.0 3.2 3.2 3.2 2.8 3.6 3.8 6.0

INDUCTANCE per PHASE mH 2.0 2.6 2.0 2.7 3.2 5.4 7.2 8.0 15.6

HOLDING TORQUE N·m 0.016 0.025 0.069 0.098 0.118 0.32 0.44 0.5 0.65

ROTOR INERTIA g·c m

2

2.5 3.3 9.0 13 18 35 54 77 114

WEIGHTS g50 80 110 140 200 250 280 350 500

LENGTH(L) mm 28 38 32 45 50 34 40 48 60

PERMISSIBLE

OVERHUNG LOAD

(DISTANCE FROM

END OF SHAFT)

3mm

N

18 18 30 30 30 22 22 22 22

8mm 30 30 38 38 38 26 26 26 26

13mm - - 53 53 53 3 3 33 33 33

18mm - - - - - 46 46 46 46

PERMISSIBLE THRUST LOAD NLower than motor weight

INSULATION RESISTANCE Mohm 100 MIN.(at 500VDC)

INSULATION CLASS -CLASS B(130℃)

OPERATING TEMPERATURE ℃0 to 55

Ezi-STEP-MI-20 series Ezi-STEP-MI-28 series

Torque[N.m]

Speed[rpm]

0.012

0.010

0.008

0.006

0.004

0.002

0

10 500 1,000 1,500 2,000 2,500 3,000

20M

20L

24V

Motor Voltage :

Torque[N.m]

Speed[rpm]

0.12

0.10

0.08

0.06

0.04

0.02

0

10 500 1,000 1,500 2,000 2,500 3,000

28S

28M

28L

24V

Motor Voltage :

Ezi-STEP-MI-42 series

0.6

0.5

0.4

0.3

0.2

0.1

0

10 500 1,000 1,500 2,000 2,500 3,000

24V

42S

42M

42L

42XL

Motor Voltage :

Torque[N.m]

Speed[rpm]

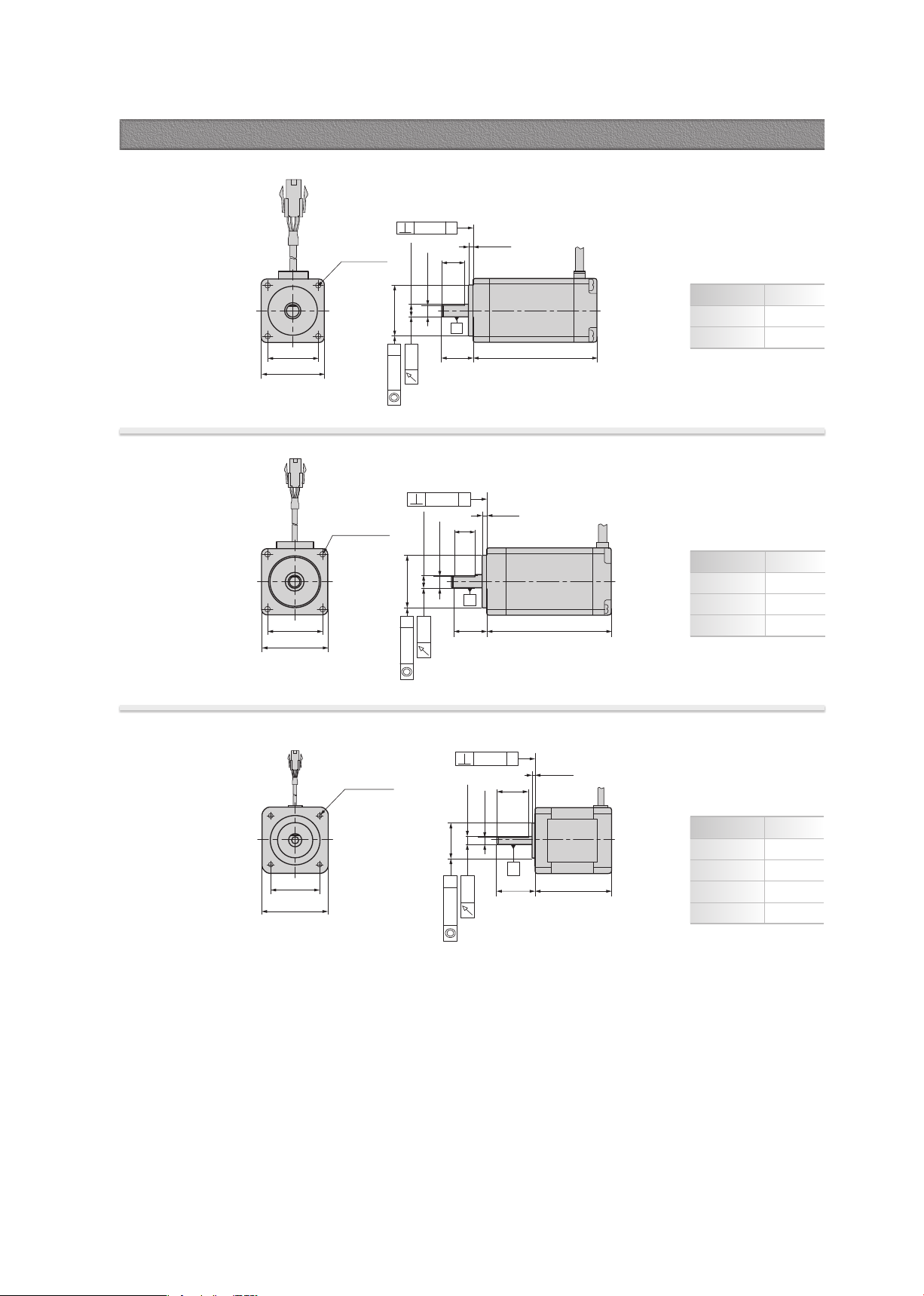

8. Specifications of Motor

9. Torque Characteristics of Motor

www.fastech-motions.com - 10

□

42

0

4-31

±0.2

1.8

±0.2

L

±1

0.075

4-M3 DP4.5

Ø

22.0

-0.05

4.5

±0.1

0

+1

Ø

5

-0.011

0

A

A

20

±0.2

24

±0.5

Ø

0.075

0.025

A

20mm

Model name Length(L)

BM-20M 28

BM-20L 38

28mm

Model name Length(L)

BM-28S 32

BM-28M 45

BM-28L 50

A

4-16

±0.1

□

20

±0.5

L

±1

1.5

±0.2

7

±0.2

10

±0.5

Ø

0.075

0.025

A

0.075

4-M2 DP2.5

Ø

16

-0.05

3.5

±0.1

0

Ø

4

-0.012

0

A

A

□

28

±0.5

4-23

±0.15

4-M2.5 DP2.5

L

±1

2

±0.2

10

±0.2

15

±0.5

Ø

0.075

0.025

A

0.075

Ø

22

-0.05

4.5

±0.1

0

Ø

5

-0.012

0

A

42mm

Model name Length(L)

BM-42S 34

BM-42M 40

BM-42L 48

BM-42XL 60

10. Dimensions of Motor [mm]

www.fastech-motions.com - 11

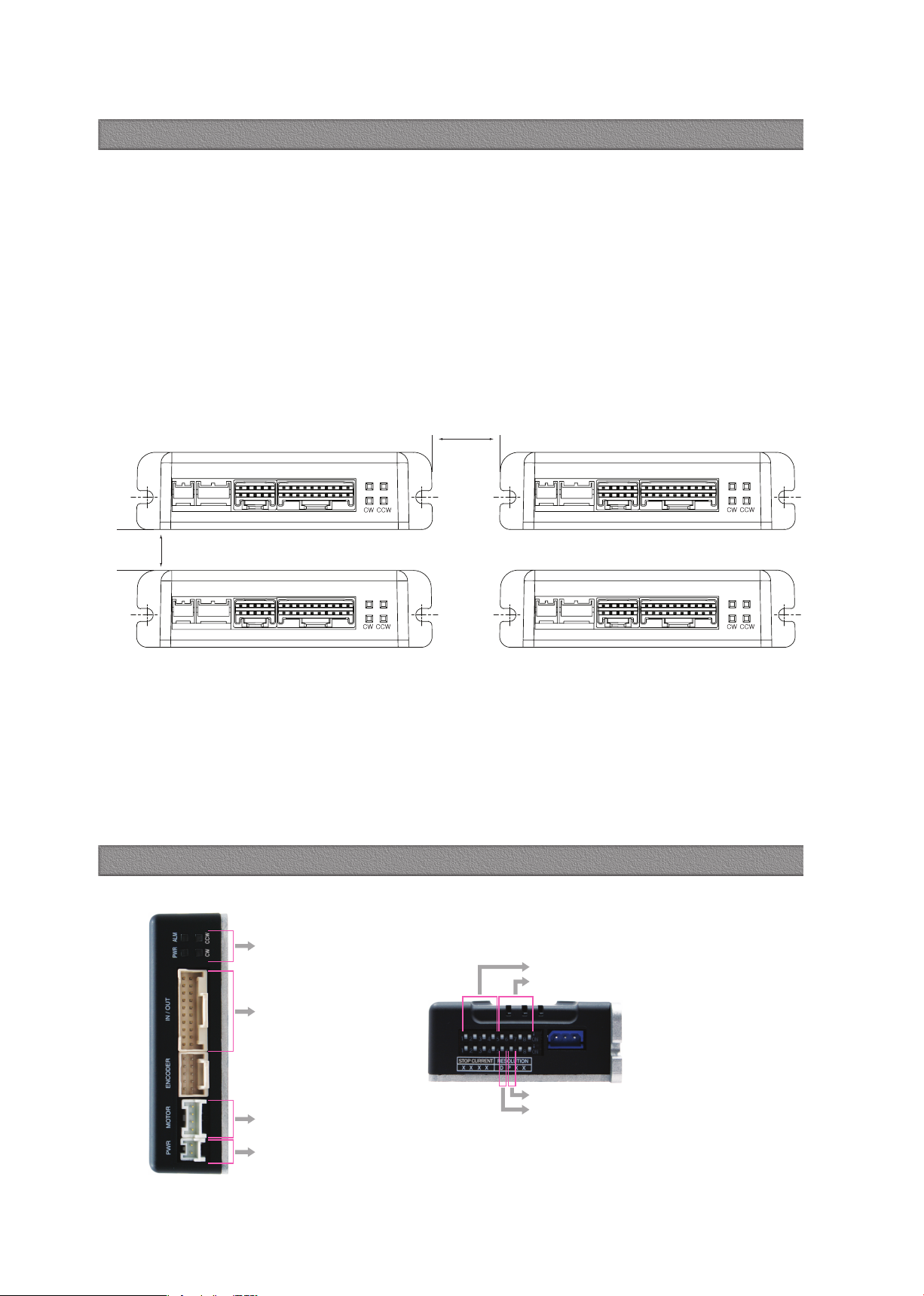

11. Notes on Installation

1) Ezi-STEP MINI is designed for indoor use only.

2) The ambient temperature of the room should be 0℃~50℃.

3) If the temperature of the product case is higher than 50℃, radiate heat of the outside to

cool down.

4) Do not install Ezi-STEP MINI under direct rays, near magnetic or radioactive objects.

5) If you set more than 2 drives, you must set over 20mm horizontally and over 50mm vertically

as shown below.

PWR MOTOR ENCODER IN/OUT PWR ALM PWR MOTOR ENCODER IN/OUT PWR ALM

PWR MOTOR ENCODER IN/OUT PWR ALM PWR MOTOR ENCODER IN/OUT PWR ALM

Drive status LED

Input/Output signal

connection(CN1)

Motor connection(CN3)

Power connection(CN4)

Stop current setting switch(SW1.1~1.4)

Resolution setting switch(SW1.5~1.8)

Pulse input setting switch(SW2.6)

Rotation direction setting switch(SW2.5)

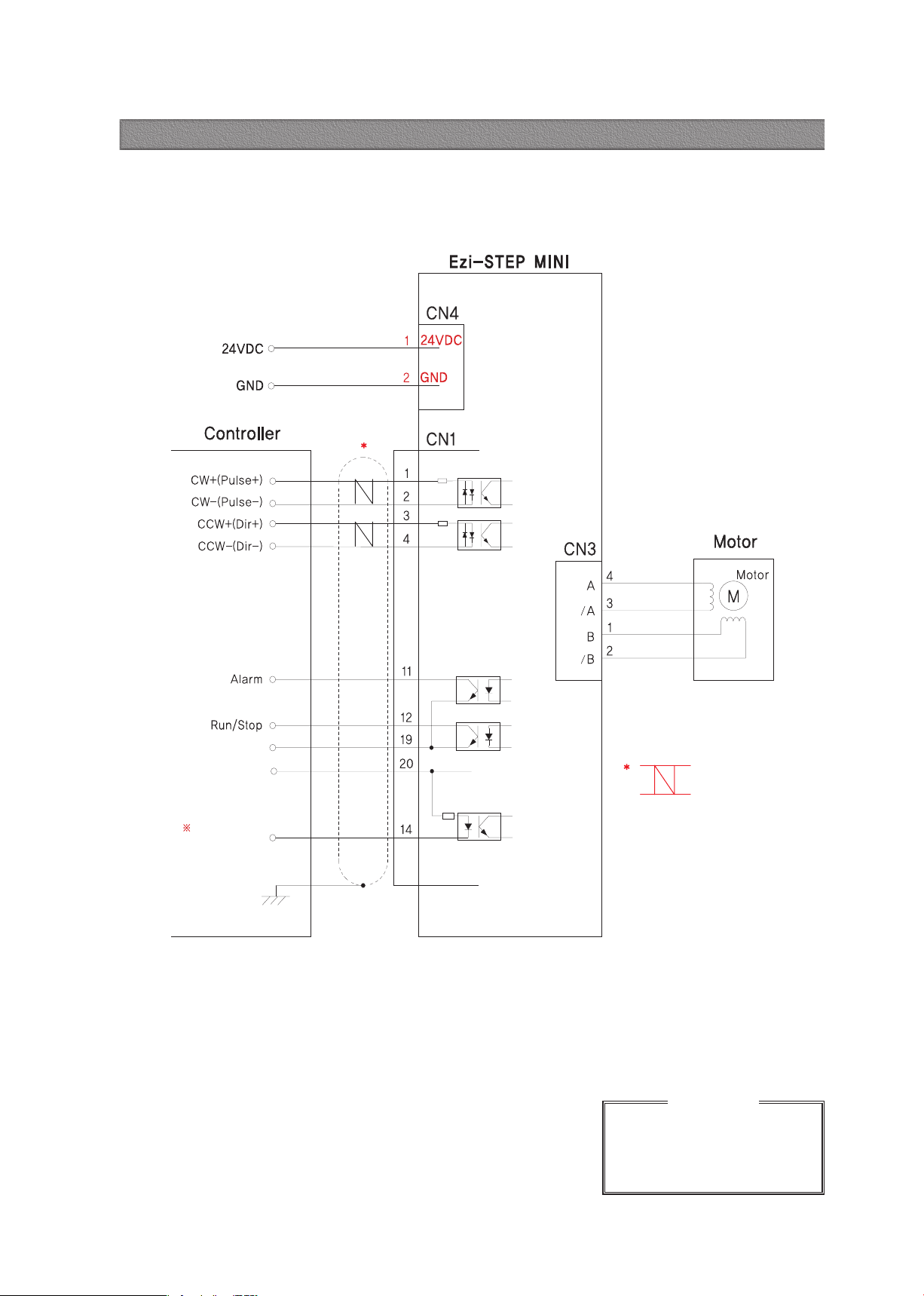

12. Settings and Operation

More 20mm

More 50mm

www.fastech-motions.com - 12

Switch Position

STOP Current (%)

Switch Position

STOP Current (%)

4 3 2 1 4 3 2 1

ON ON ON ON 10 OFF ON ON ON 90

ON ON ON OFF 20 OFF ON ON OFF 100

ON ON OFF ON 30 OFF ON OFF ON 10

ON ON OFF OFF 40 OFF ON OFF OFF 10

ON OFF ON ON 50

*1

OFF OFF ON ON 10

ON OFF ON OFF 60 OFF OFF ON OFF 10

ON OFF OFF ON 70 OFF OFF OFF ON 10

ON OFF OFF OFF 80 OFF OFF OFF OFF 10

12.2 Stop Current Setting Switch(SW1.1~1.4)

Stop Current means the motor current value automatically set in 0.1 sec after motor stops. This is to prevent

the overheat of a motor when the motor is under long time idling. The unit of the selection value is a percentage.

*1 : Default : 50%

12.1 Drive Status LED

Indication Color Function ON/OFF Condition

PWR Green Power Input Indication Lights when power is ON Flashes when motor is

Free status

ALM Red Alarm Indication

Flash when protection function is activated

(Identifiable which protection mode is activated

by counting the flash times)

CW Yellow Motor Rotation Direction Lights when motor rotate CW direction

CCW Orange Motor Rotation Direction Lights when motor rotate CCW direction

◆ Protection functions and LED flash times

Times Protection Conditions

1Over Current Error The current through power devices in drive exceeds the

limit value

*1

2Over Speed Error Motor speed exceeded 3,000 [rpm]

3

Step Out

Error Abnormally motor do not followed pulsed input

5Over Temperature Error Internal temperature of a motor drive exceeded 85℃

6Over Regenerative

Voltage Error Back EMF more than 50V

7Motor Connect Error Power is ON without connection of motor cable to drive

9Motor Voltage Error Motor voltage is below 20V

11 System Error Error occurs in drive system

12 ROM Error Error occurs in Parameter storage Device(ROM)

*1 : Limit value depends on motor model

Alarm LED flash

(Ex, Step Out Error)

2.0s0.5s

12.3 Resolution Setting Switch(SW1.5~1.8)

*1 : Default: 10,000

The Number of pulse per revolution.

Switch Position Pulse/

Revolution

Switch Position Pulse/

Revolution

8 7 6 5 8 7 6 5

ON ON ON ON 500 OFF ON ON ON 6,400

ON ON ON OFF 1,000 OFF ON ON OFF 8,000

ON ON OFF ON 1,600 OFF ON OFF ON 10,000

*1

ON ON OFF OFF 2,000 OFF ON OFF OFF 20,000

ON OFF ON ON 3,200 OFF OFF ON ON 25,000

ON OFF ON OFF 3,600 OFF OFF ON OFF 36,000

ON OFF OFF ON 4,000 OFF OFF OFF ON 40,000

ON OFF OFF OFF 5,000 OFF OFF OFF OFF 50,000

www.fastech-motions.com - 13

12.7 Motor Connector(CN3)

NO. Function I/O

1B Phase Output

2/B Phase Output

3/A Phase Output

4A Phase Output

12.8 Power Connector(CN4)

NO. Function I/O

124VDC Input

2GND Input

12.6 Signal Connector(CN1)

NO. Function I/O

1CW+(Pulse+) Input

2CW-(Pulse-) Input

3CCW+(Dir+) Input

4CCW-(Dir-) Input

11 Alarm Output

12 Run/Stop Output

14 Alarm Reset Input

19 EXT_GND Input

20 EXT_24VDC Input

Direction setting

switch: ON

Direction setting

switch: OFF

19

1

20

2

1 2 3 4

1 2

12.5 Pulse Input Setting Switch(SW2.6)

12.4 Rotational Direction Setting Switch(SW2.5)

Indication Switch Name Functions

PPulse input mode

Select Switch

Selectable 1-Pulse input mode or 2-Pulse input mode as Pulse input signal.

ON: 1-Pulse mode OFF: 2-Pulse mode ※ Default: 2-Pulse mode

Indication Switch Name Functions

DRotational Direction

Select Switch

Based on CW(+Dir signal) input to driver.

ON: CCW(-Direction) OFF: CW(+Direction) ※ Default: CW mode

CW(Pulse) Pin

CCW(Dir) Pin

Rotational Direction CW CWCCW CCW

2-Pulse Mode 1-Pulse Mode

www.fastech-motions.com - 14

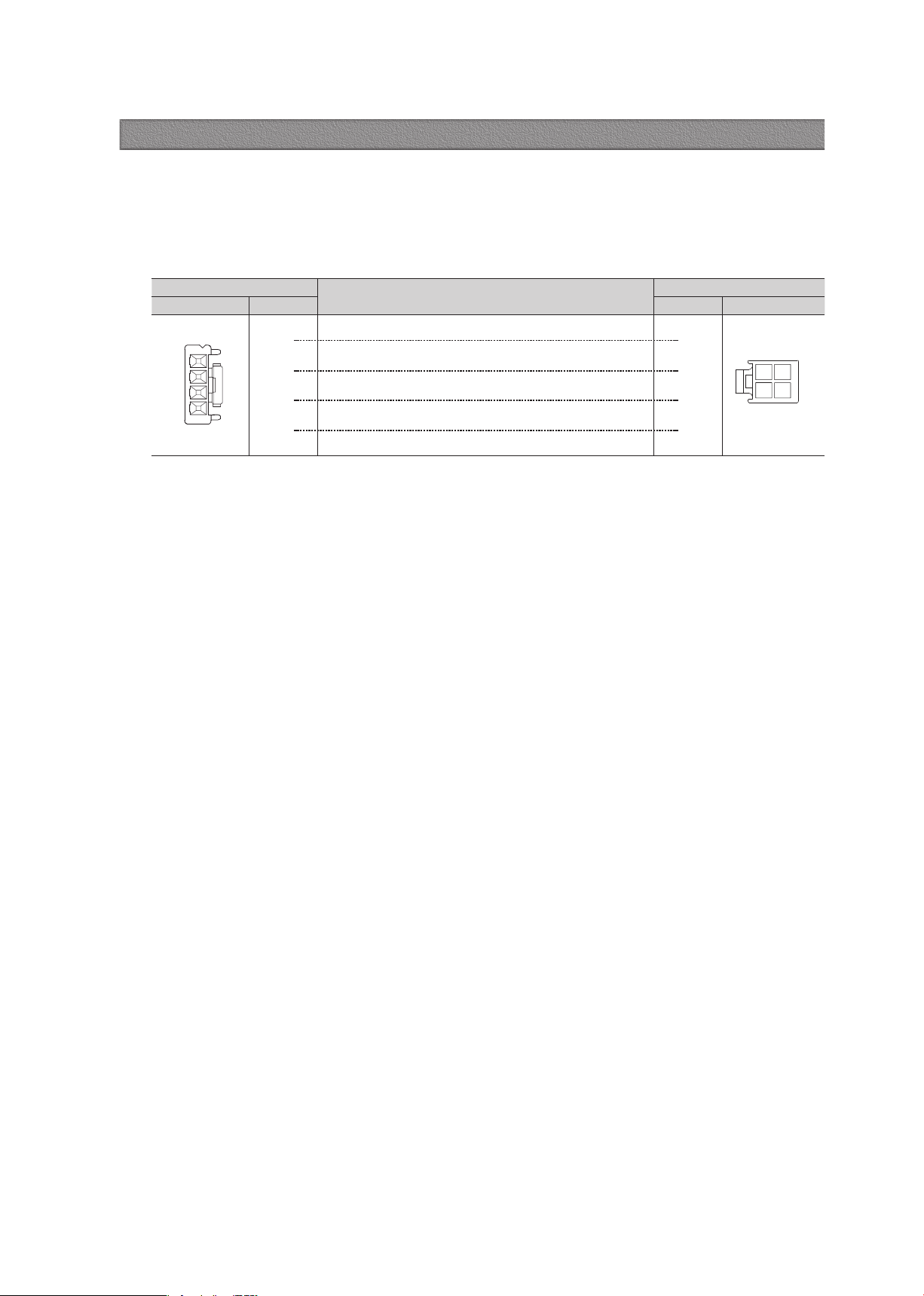

13.1 Options

① Signal Cable

Available to connect between Input/Output Control System

and Ezi-STEP MINI.

Item Length [m] Remark

CSVI-S-□ □ □F

CSVI-S-□ □ □M

□ □ □

□ □ □

Normal Cable

Robot Cable

□ is for Cable Length. The unit is 1m and Max. 20m length.

② Motor Extension Cable

Available to extended connection between motor and

Ezi-STEP MINI.

Item Length [m] Remark

CMNB-M-□ □ □F

CMNB-M-□ □ □M

□ □ □

□ □ □

Normal Cable

Robot Cable

□ is for Cable Length. The unit is 1m and Max. 20m length.

③ Power Cable

Available to connect between Power and Ezi-STEP MINI.

Item Length [m] Remark

CMNB-P-□ □ □F

CMNB-P-□ □ □M

□ □ □

□ □ □

Normal Cable

Robot Cable

□ is for Cable Length. The unit is 1m and Max. 2m length.

Type Signal Cable Motor Cable Power Cable

Length supplied -30cm -

Max. Length 20m 20m 2m

①

②

③

13. System Configuration

www.fastech-motions.com - 15

Purpose Item Part Number Manufacturer

Power

(CN4)

Housing

Terminal

PAP-02V-S

SPHD-001T-P0.5 JST

Motor

Drive Side

(CN3)

Housing

Terminal

PAP-04V-S

SPHD-001T-P0.5 JST

Motor Side Housing

Terminal

5557-04R

5556T MOLEX

Signal

(CN1)

Housing

Terminal

501646-2000

501648-1000(AWG 26~28) MOLEX

13.2 Connector Specifications

Connector specifications for cabling to drive.

※ Above connector is the most suitable product for the drive applied. Another equivalent connector can be used.

www.fastech-motions.com - 16

Please refer to the Appendix when

connects motor extension cable.

Careful connection will be required to

protect the drive from any damages.

CAUTION

※ Alarm Reset signal line is also used for Motor Free signal.

(For details, please refer to Control Signal Input/Output Description)

※ When connects I/O cable between controller and drive, please turn off the power

of both controller and drive, in order to protect the drive from any damage.

Shielded

Twisted Pair

Cable

14. External Wiring Diagram

www.fastech-motions.com - 17

◆ CW, CCW Input

This signal can be used to receive a positioning pulse

command from a user host motion controller. The user can

select 1-pulse input mode or 2-pulse input mode. The input

schematic of CW, CCW is designed for 5V TTL level. When

using 5V level as an input signal, the resistor Rx is not used

and connect to the driver directly. When the level of input

signal is more than 5V, Rx resistor is required. If the resistor

is absent, the drive will be damaged. If the input signal level

is 12V, Rx value is 680ohm and 24V, Rx value is 1.8Kohm.

◆ Motor Free Input

This input can be used only to adjust the position by manually

moving the motor shaft from the load-side. By setting the

signal [ON], the drive cuts off the power supply to the motor.

Then, one can manually adjust output position. When setting

the signal back to [OFF], the drive resumes the power supply

to the motor and recovers the holding torque. When driving a

motor, one needs to set the signal [OFF]. In normal operations

set the signal [OFF] or disconnect a wire to the signal.

◆ Alarm Reset Input

When a protection mode has been activated, a signal to this

Alarm Reset input cancels the Alarm output. By setting the

alarm reset input signal [ON], cancel Alarm output. Before

cancel the Alarm output, have to remove the source of alarm.

[Caution] If Alarm Reset input signal still remains [ON], motor will be

Free state. Keep in mind to change [ON]→[OFF] state.

1

Input Signal

Input signals of the drive are all photocoupler protected.

The signal shows the status of internal photocouplers

[ON: conduction], [OFF: Non-conduction], not displaying

the voltage levels of the signal.

◆ Alarm Output

The Alarm output indicates [OFF] when the drive is in a

normal operation. If a protection mode has been activated, it

goes [ON]. A host controller meeds to detect this signal and

stop sending a motor driving command.

When the drive detects an abnormal operation such as

overload of overcurrent of a motor, it sets the Alarm output to

[ON], flash the Alarm LED, disconnects the power to a motor

and stops the motor, simultaneously.

2

Output Signal

As the output signal from the drive, there are the

photocoupler outputs (Alarm, Run/Stop). The signal status

operate as [ON : conduction], [OFF : Non-conduction] of

photocoupler not as the voltage level of signal.

◆ Run/Stop Output

Run/Stop Output state is [ON] when motor positioning is

completed. It operates reversely compare to Normal mode,

when you set inverse mode.

Pin No. Function

1 CW+

2 CW-

3 CCW+

4 CCW-

Pin No. Function

14 Alarm Reset/

Motor Free

20 EXT_24VDC

Pin No. Function

11 Alarm

12 Run/Stop

19 EXT_GND

Alarm Reset signal line is also used for Motor Free signal.

15. Control Signal Input/Output Description

www.fastech-motions.com - 18

Connector of Drive wiring Connector of Motor

Pin layout Pin number Pin number Pin layout

1

2

3

4

1

3

4

2

3 1

4 2

1

2

3

4

Appendix

■ Extension Cable for Motor

For cable extension between Motor and Drive.

WIRING DIAGRAM

www.fastech-motions.com - 19

MEMO

'"45&$)$P

-UE

3NEPOH#VDIF

PO5F DIOP1BSL

1Z

FPOHDIFPOSP#VDIFPOTJ(ZFPOHHJEP

3FQVCMJDPG,

PSFB1PTUBM$PEF

5&-

'"9

&NBJMTBMFT!G

BTUFDINPUJPOTDPN

)PNFQBHFXXXGBTUFDINPUJPOTDPN

ś൞ഔ

լ׆ܑవඌవߦ

వഓڋ൞ܛ

5&-'" 9

&NBJMUFBN@TBMFT!GBTUFDINPUJPOTDPN

)PNFQBHFXXXGBTUFDINPUJPOTDPN

www.fastech-motions.com

· It is prohibited to unauthorized or reproduced in whole or in part described in the

User’s Guide

· If you need a user manual to the loss or damage, etc., please contact us or your

nearest distributor.

·

User manual are subject to change without notice to improve the product or

quantitative changes in specifications and user’s manual.

·

Ezi-STEP is registered trademark of FASTECH Co., Ltd in the national registration

ⓒ Copyright 2007 FASTECH Co., Ltd. May 28, 2021 Rev.2

Table of contents

Other Fastech Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Duro Dyne

Duro Dyne GBAC ROTO BONDER owner's manual

OPTIMUM Maschinen

OPTIMUM Maschinen K11-160 operating manual

ABB

ABB XAC20409 Operation manual

Excelitas Technologies

Excelitas Technologies OmniCure S1500 PRO user guide

BIRD

BIRD Termaline 8890 Series Instruction book

SeaSoft

SeaSoft MobilSwitch-Micro-C manual