9

JES

WPT

SensorforAirCylinder

High-Power

PullStudClamp

modelWPTHigh-PowerPullStudClamp Cautions

Performance

Curve

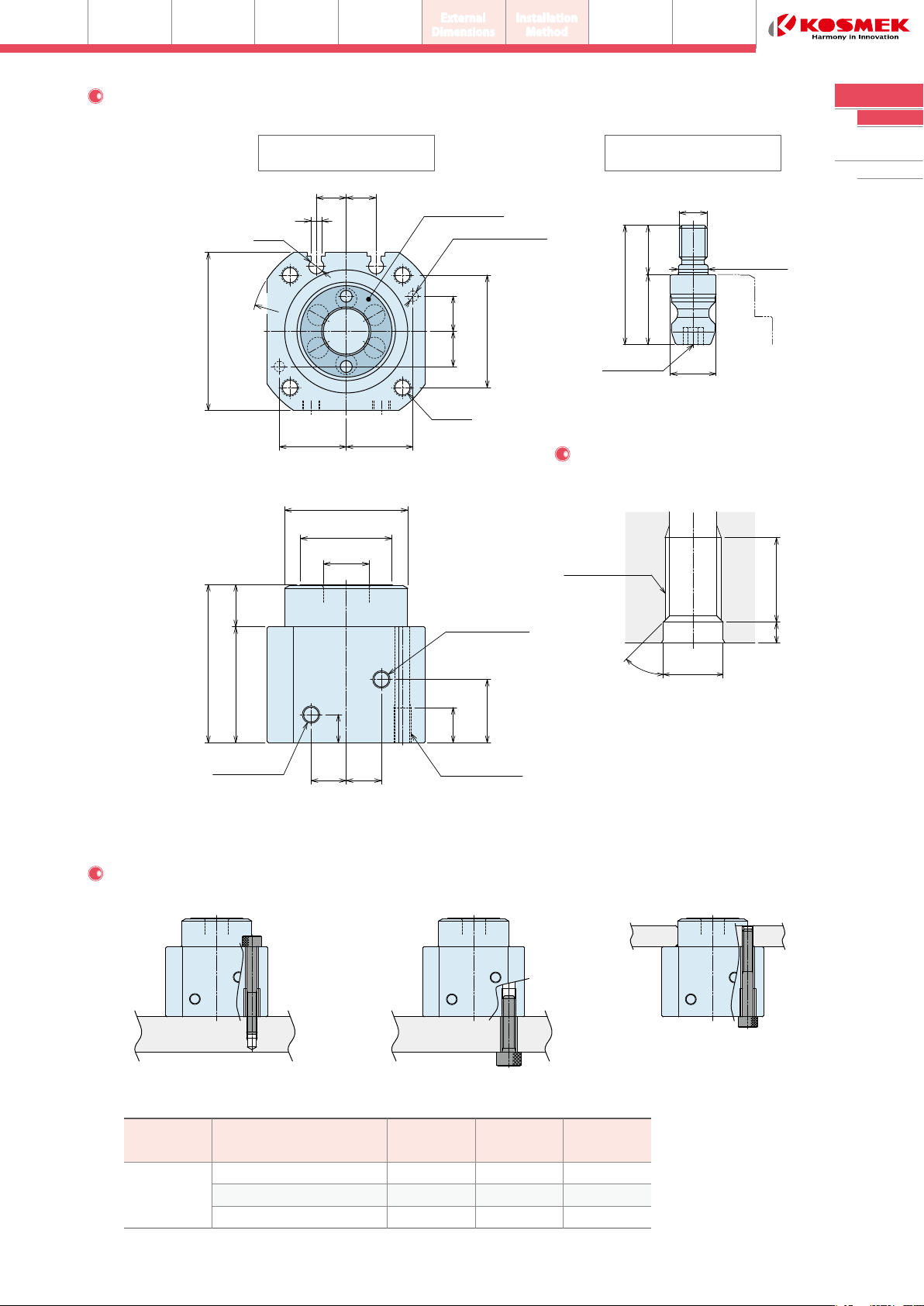

External

Dimensions

Installation

Method

Accessory

SensorforAirCylinder

Cautions

ModelNo.

Indication

Specifications

FeaturesFeatures

●NotesforDesign

1) CheckSpecifications

●ModelWPT:Maximumoperatingairpressureis0.5MPa.

Minimumoperatingairpressureis0.3MPa.

ApplyingexcessiveloadonthePullStudClampleadsto

deformation,gallingandairleakage.

2) Donotapplyimpactonaworkpiece,etc.connectedtoPullBolt.

●Otherwise,itmayresultinbreakageoftheproduct.

3) NotesforCircuitDesign

●Pleasedesigntheaircircuitproperlyandreviewthecircuit

designinadvanceinordertoavoidmalfunctionorbreakage

ofthedevice.

4) Pleasesupplyfilteredcleandryair.

●Oilsupplywithalubricatoretc.isunnecessary.

5) OperatingEnvironment

●WPThasnofunctionthatpreventscontaminants.

Donotuseunderenvironmentwithcoolantandcuttingchips.

6) InsertionofPullBolt

●PleaseinsertthePullBolttotheendbeforeprovidinglockair

pressure.(PreventionofclampingfailureanddamageofPullBolt.)

7) ProtectiveCoverInstallation

●Ifthemovingpartsoftherobotorrobotichandmayendanger

operator,pleaseinstalltheprotectioncover.

8) FallPreventionMeasures

●Incaseofaccidentsuchasdetachmentofaworkpiece,

pleasepreparefallpreventionmeasuresforsafety.

1) UsableFluid

●Pleasesupplyfilteredcleandryair.(Installadrainremovingdevice.)

●Oilsupplywithalubricatoretc.isunnecessary.Oilsupplywith

alubricatormaycauselossoftheinitiallubricant.Theoperation

underlowpressureandlowspeedmaybeunstable.(Whenusing

lubricant,pleasesupplylubricantoilcontinuously.Otherwise,

theinitialgreaseappliedbyKOSMEKwillberemoved.)

2) ProcedurebeforePiping

●Thepipeline,pipingconnectorandfixturecircuitsshouldbe

cleanedandflushedthoroughly.

Thedustandcuttingchipsinthecircuitmayleadtoairleakage

andmalfunction.

●Thereisnofilterprovidedwiththisproductforpreventionof

contaminantsintheaircircuit.

3) ApplyingSealingTape

●Whenusingsealingtape,wrapwithit1to2timesfollowing

thescrewingdirection.Whenpiping,becarefulthatcontaminant

suchassealingtapedoesnotenterinproducts.

Piecesofthesealingtapecancauseairleakageandmalfunction.

4) InstallationoftheMainBodyandthePullBolt

●Pleaseusehexagonsocketbolts(withtensilestrengthofA2-70

orgreater),andtightentheproductwiththetighteningtorque

listedonP.5~P.8.

●Thetighteningtorqueforpullboltisshownbelow.

●Installationfailurecausesairleakage,deformationanddamage

ofthePullStudClampandthePullBolt.

5) DoNotUseDeformedPullBolts

●IfaPullBoltisdeformedasshownbelow,PullStudClampand

PullBoltwillbebroken,and/orwillnotbeabletoreleaseproperly.

●InstallationNotes

Cautions

6) AllowableOffsetwhileClamping

●Whileclamping,thegapbetweentheseatingsurfacesofthe

PullStudClampandaworkpiece,etc.shouldbe0.2mmorless.

Atthistime,insertthePullStudClampverticaltothePullBolt.

Afterclamping,thePullBoltispulledinandtheseatingsurfaces

andworkpiececomeincontact.

●AllowablepositionoffsetofPullStudClampandPullBoltwhile

teachingmustbewithintheallowablepositionoffsetrange.

Atthistime,thechangingworkpieceshouldnʼtbecompletely

fixedandshouldhavespacewithintherangeofallowableoffset.

AllowablePositionOffsetinHorizontalDirection

ModelNo.

WPWZ500-P1

WPWZ600-P1

WPWZ800-P1

WPWZ1000-P1

BoltSize

M4×0.7

M5×0.8

M6×1

M8×1.25

TighteningTorque(N・m)

2.3

4.0

9.0

18

ModelNo.

WPT0500

WPT0600

WPT0800

WPT1000

AllowableOffsetAmm

A=±0.5mm

A=±0.7mm

A=±0.8mm

A=±0.9mm

0.2mmorless

NoGap

Workpiece

SeatingSurface

PullStudClamp

SeatingSurface

InsertVertically BeforeClamping AfterClamping

A

PullStud

Clamp

PullBolt