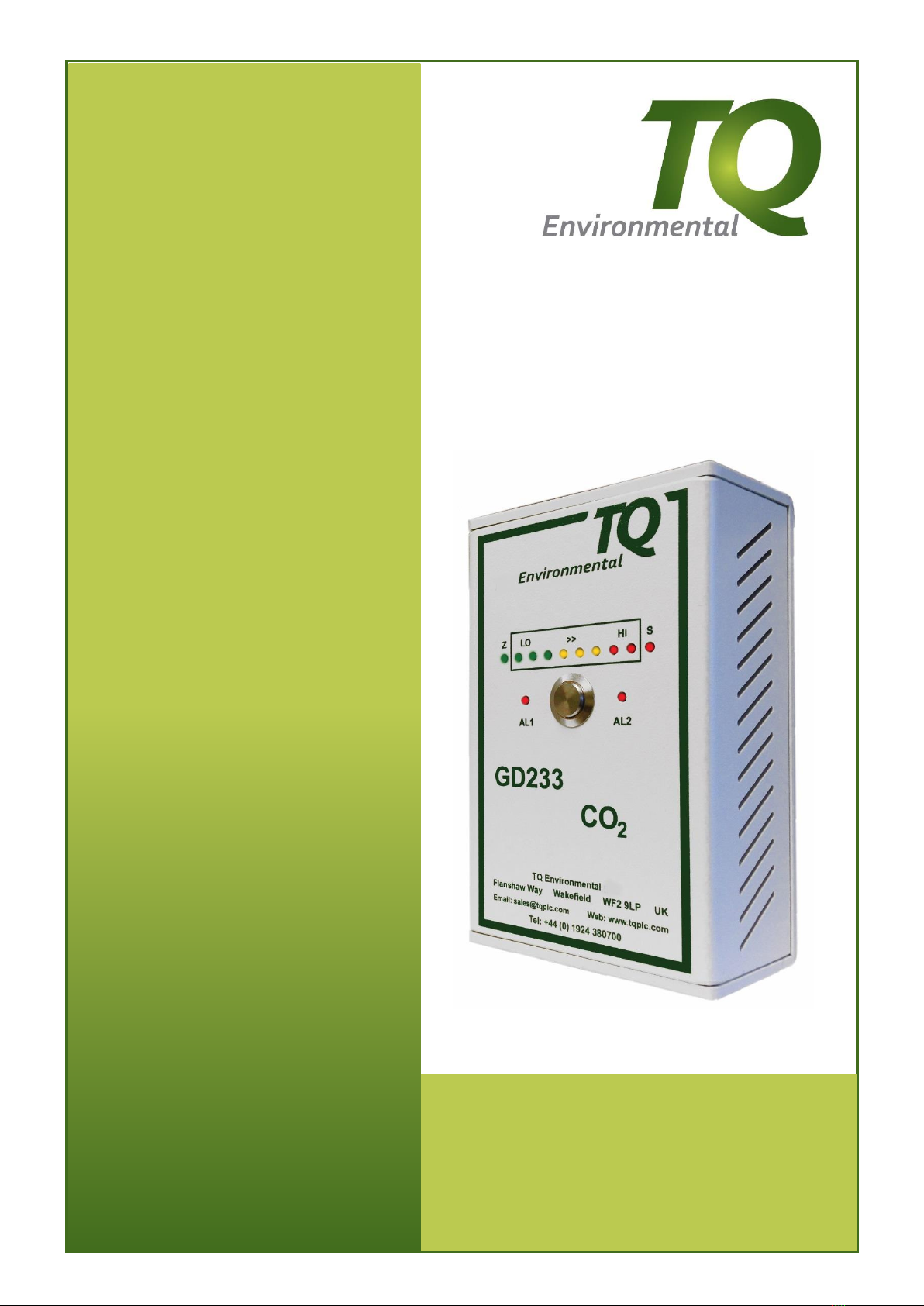

TQ Environmental GD233 User manual

CO2SENSOR

DIFFUSION GAS MONITOR

OPERATING

MANUAL

TQ Environmental Limited

Silkwood Court

Wakefield

WF5 9TP

United Kingdom

Tel: +44 (0) 1924 271013

Fax: +44 (0) 1924 264420

Email: sales@tqenv.com

Web: www.tqenv.com

GD233

TQ Environmental Limited

Issue 6: 01 June 2017

Page 2 of 12 8764UM6

CONTENTS

PAGE

Proprietary

3

Copyright

3

Warning, Cautions and Notes

3

Safety Warnings

4

Section 1

Description

1.1

General description

5

1.2

Sensor unit

5

1.3

Gases monitored

5

1.4

Performance specifications

6

1.5

Storage

6

Section 2

Installation Guidelines

2.1

Mechanical installation

8

2.2

Electrical installation

9

Section 3

Operation

3.1

General

11

3.2

Start up

12

3.3

General Operation

12

3.31

Internal and External Control Buttons

12

3.32

Auto Zero

13

3.33

Auto Span

13

3.34

Gassing

Section 4

Maintenance

4.1

Routine maintenance

14

4.2

Warranty

14

Section 5

Spares

15

TQ Environmental Limited

Issue 6: 01 June 2017

8764UM6 Page 3 of 12

PROPRIETARY

No part of the hardware or documentation may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any language or computer language, in any form or by any means,

without prior written permission of TQ Environmental Limitrd.

While great efforts have been made to assure the accuracy and clarity of this document,

TQ Environmental Limited assumes no liability resulting from any omissions in this document, or from

misuse of the information obtained herein. The information in this document has been carefully

checked and is believed to be entirely reliable with all of the necessary information included.

TQ Environmental Limited reserves the right to make changes to any products described herein to

improve reliability, function, or design, and reserves the right to revise this document and make

changes from time to time in content hereof with no obligation to notify any persons of revisions or

changes. TQ Environmental Limited does not assume any liability arising out of the application or

any use of any product or circuit described herein; neither does it convey license under its patent

rights or the rights of others.

COPYRIGHT

© TQ Environmental Limited 2000-2015

This manual must not be copied or reproduced in part without the express

written permission of TQ Environmental Limited.

All information contained herein is subject to modification

WARNINGS, CAUTIONS AND NOTES

Warnings identify an operating or maintenance procedure, practice,

condition, or statement that, if not strictly followed, could result in death or

injury to personnel.

Cautions, which appear elsewhere in this manual, identify an operating

or maintenance procedure, practice, condition, or statement that if not strictly

followed could result in equipment damage or serious impairment of system

operation.

Notes highlight certain operating or maintenance conditions or statements

that are essential but not of known hazardous nature as indicated by Warnings

and Cautions.

Warnings, Cautions and Notes are included throughout this manual, as

required. Additionally, this section contains important Warnings that may not

be contained elsewhere within this instruction manual.

TQ Environmental Limited

Issue 6: 01 June 2017

Page 4 of 12 8764UM6

SAFETY WARNINGS

THE GD233 CARBON DIOXIDE SENSOR MUST ONLY BE USED IN

AREAS WHERE POTENTIALLY FLAMMABLE GASES ARE NOT

PRESENT.

FOR SAFETY REASONS, THE GD233 SENSOR MUST BE INSTALLED,

OPERATED AND SERVICED BY QUALIFIED PERSONNEL ONLY. READ

AND UNDERSTAND THIS INSTRUCTION MANUAL COMPLETELY

BEFORE OPERATING THE GD233 SENSOR.

TQ Environmental Limited

Issue 6: 01 June 2017

8764UM6 Page 5 of 12

SECTION 1 - DESCRIPTION

1.1 GENERAL DESCRIPTION

The GD233 CO2Sensor is a highly reliable infra-red (IR) absorption type sensor

and may be used to detect the presence of carbon dioxide gas in the presence

other non-combustible gases.

In a typical application, the sensor unit is electrically connected to a system capable

of providing readouts indicating the concentration of the gas detected by the sensor

along with audible and/or visual alarms when the concentration reaches a

predetermined level. Alternatively, the GD233 CO2Sensor may operate as a stand-

alone unit using the LED array to indicate the approximate concentration of gas

present and the internal relays to generate concentration alarms.

The GD233 CO2Sensor is used for diffusion sensing applications. These are

applications in which the sensor continuously monitors that part of the environment

with which it is in contact and the gas diffuses through the sensor’s optical path.

This technical manual covers the use of the GD233 CO2Sensor as a diffusion type

sensor.

1.2 SENSOR UNIT DESCRIPTION. Refer to Figure 1.

The fully assembled GD233 CO2Sensor has dimensions of:-

158mm (Height) X 97mm (Width) X 57mm (Depth).

The main components of the GD233 CO2Sensor unit are:-

•Flame retardant ABS enclosure which may be mounted onto a wall into which

fits

•The Sensor Assembly mounted onto the hinged lid of the enclosure.

1.3 GASES MONITORED

The GD233 CO2Sensor is designed only to sense and monitor carbon dioxide

and in normal applications is not expected to monitor any other gas or vapour.

TQ Environmental Limited

Issue 6: 01 June 2017

Page 6 of 12 8764UM6

Table 1. Performance Specifications.

1.4 PERFORMANCE SPECIFICATIONS.

FACTOR

SPECIFICATION

Detection Method:

IR Absorption

Sampling Method:

Continuous Diffusion

Measuring Range:

0 –5000ppm, 0 –1% or 0 –2% CO2, set at the factory

Accuracy:

+ 2% Full Scale (FS) Linearised using 4-20mA

Repeatability:

+ 1% FS

Operating Pressure

Atmospheric pressure only

Response Time:

The response time is limited by the movement of gas within

the area being monitored. For a rapid change in gas

concentration an alarm at 50% of the range will occur within

30s.

Flow Rate:

Not applicable to a diffusion type sensor

Temperature Range:

-20C to +50C

Humidity Range:

0 - 99% Relative Humidity (Non-condensing)

Mean Time Between Failures:

Electronics: 10 Years, IR Source: 7 Years

Warranty:

12 Months

Operating Voltage:

9 to 24V dc

Operating Current:

135mA at 12V dc/75mA at 24V dc

Weight:

0.35kg

Electrical Hazardous Area

Certifications:

None

Output

2 concentration alarms (indicated by red LEDs) each being

set independent of the other, and normally open relay

contacts rated at 2A at 12 or 24V DC.

Also a 4-20mA output, and if factory set, a RS485 output

TQ Part No.

340-262

1.5 STORAGE

The GD233 CO2Sensor is a sensitive instrument and as such should be stored

properly when not in use. The GD233 CO2Sensor contains static sensitive devices and

should not be stored in an area of high static electrical charge. The environment it is

stored in should not involve direct sunlight and be dust free. The temperature should be

between 0-50 degrees Celsius.

The unit should not be stored more than 2 years under these conditions.

TQ Environmental Limited

Issue 6: 01 June 2017

8764UM6 Page 7 of 12

SECTION 2 - INSTALLATION

INSTALLATION GUIDELINES

The GD233 CO2Sensor is designed to be installed in a vertical position.

The sensor should be sited in a position out of direct sunlight and in an area not

subject to washing with jets of water.

To ensure continued reliable operation of the GD233 CO2Sensor, the following

installation guidelines should be observed:

CAUTION

The calibration of the sensor may be affected by excessive direct sunlight.

If it is necessary to install the sensor unit in a sunlit area, provide an adequate

sunshade for the sensor unit.

•For the monitoring of heavier-than-air gases, mount the sensor unit as close as

practical to the floor or ground. For monitoring of lighter than air gases, install

the sensor unit as high as practical.

Carbon Dioxide is heavier than air.

•The sensor unit should be installed in a location where it is easily accessible for

repairs.

•Mount the sensor unit in a position that minimises the risk of mechanical

damage.

•For the best performance the sensor should be mounted where there is

movement of air.

•PLEASE NOTE

2 CORE SCREENED CABLE SHOULD BE USED ON ALL APPLICATIONS

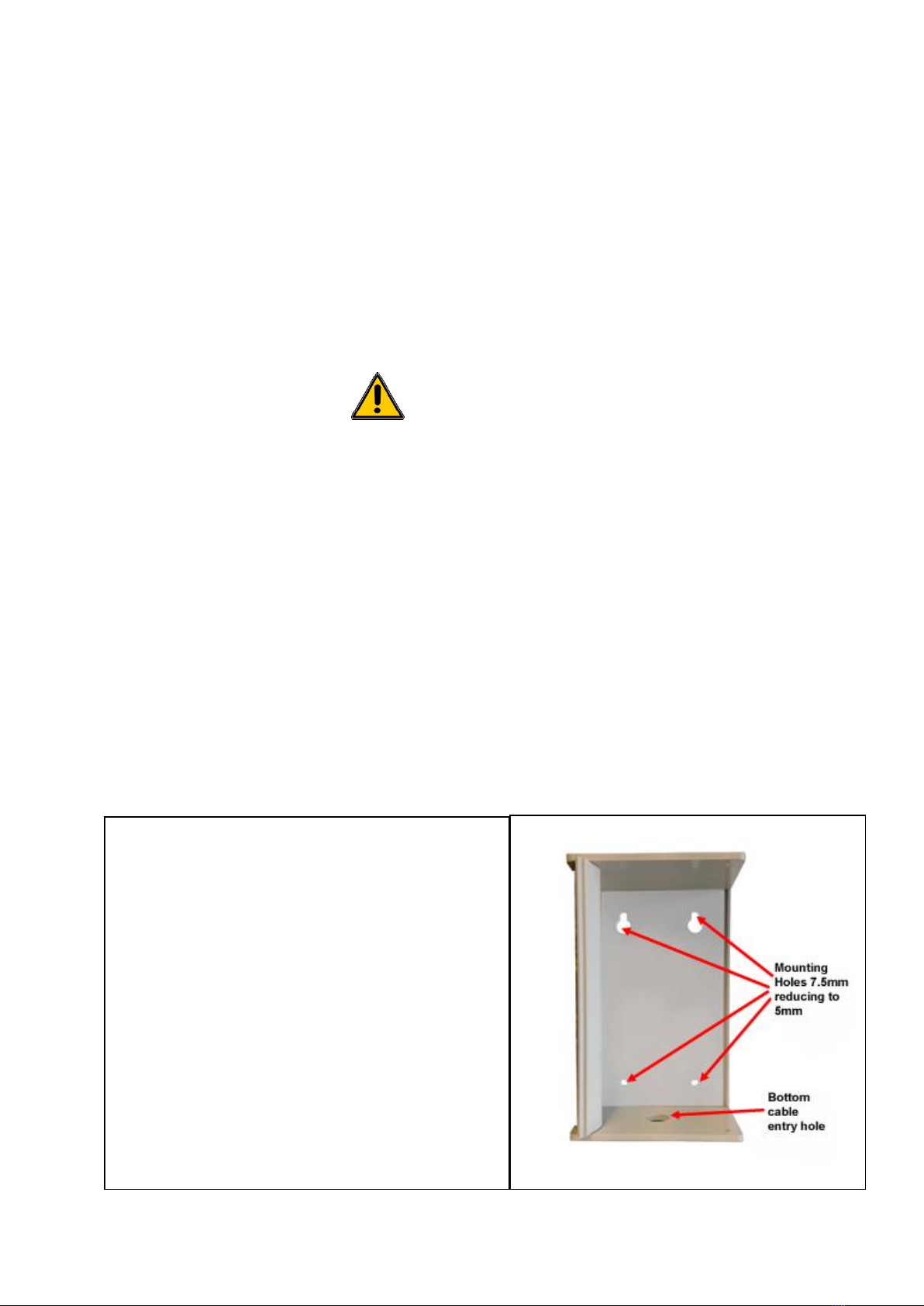

2.1 MECHANICAL INSTALLATION

The enclosure is provided with four 5mm

predrilled holes for mounting on a wall etc. It

is important that screws used for mounting the

enclosure should not be tightened excessively

thus damaging the enclosure.

The hole positions are shown in Figure 1.

Access to the inside of the enclosure is

gained by removing the 2 screws at the top

and bottom, carefully opening the hinged

front.

Protect the exposed printed circuit board

components during installation.

Figure 1. Inside the Case

TQ Environmental Limited

Issue 6: 01 June 2017

Page 8 of 12 8764UM6

Internal

Control Button

Connection

Function

1

RS485 ground

2 (Note a)

RS485 “A”

3

RS485 “B”

4

Power 0v

5(Note c)

Power +9 to +24 v DC

6

4 –20 mA, +ve

7

4 –20mA, -ve

8(Note b)

Connection for external buzzer (+ve)

9

Connection for external buzzer (-ve)

10 (Note b)

Volt free alarm contact (AL1)

11

Volt free alarm contact (AL1)

12

Volt free alarm contact (AL2)

13

Volt free alarm contact (AL2)

1

2

3

Connections 1 to 3

Figure 2. Electrical Connections

Connections 4 to 13

4

5

6

7

8

9

10

11

12

13

Table 2. Connection & Terminal Functions

TQ Environmental Limited

Issue 6: 01 June 2017

8764UM6 Page 9 of 12

PLEASE NOTE

2 CORE SCREENED CABLE SHOULD BE USED ON ALL

APPLICATIONS

Notes:-

“a”. The option of RS485 output is factory fitted Two core cable with overall

screen should be used for the RS485 connection

“b”. The buzzer and volt free alarm outputs are only available if factory fitted.

The buzzer should be rated according to the power supply used,

e.g. 12 or 24v dc.

“c” If the Unit has a 4-20 output then 24vdc is required

Figure 2 & Table 2 show the electrical connections.

Electrical cable entry to the enclosure should be through the predrilled hole at the

bottom of the enclosure.

The circuit in the PCB supplies a 4-20mA output signal, which is a current source

only. Total circuit load and cable resistance should be less than 600 Ohms for the

4-20mA loop and the unit should be powered from 24v dc for correct operation

After wiring the lid with sensor assembly should be closed and secured by the 2

screws ready for commissioning.

TQ Environmental Limited

Issue 6: 01 June 2017

Page 10 of 12 8764UM6

Figure 2:- Front Panel Functions

Auto-Span Initiated

CO2 Concentration Indicator

Auto-Zero Initiated

Concentration Alarm 1 Status

Concentration Alarm 1 Status

External Control Button

SECTION 3 –OPERATION

3.1 GENERAL

Please refer to Figure 2 for the position of LEDs and button.

The CO2concentration is displayed visually on the “CO2Concentration Indicator”. Lower

CO2concentrations are displayed by the green LEDs at the left of the display (marked “LO”)

and the higheston the red LEDs at the right of the display (marked “HI”. As the concentration

of CO2increases the number of LEDs illuminated will increase from left to right (8 in total).

All 8 LEDs will illuminate when the concentration reaches and exceeds the range of the

GD233.

The red LEDs marked “Concentration Alarm 1” and “Concentration Alarm 2” will

illuminate when the CO2concentration exceeds the set point value. At the same time the

alarm relays (if fitted) will actuate and the associated contacts for buzzer and alarms will

change state. The set points for the alarms and latch facility are factory set only.

TQ Environmental Limited

Issue 6: 01 June 2017

8764UM6 Page 11 of 12

3.2 STARTUP.

Ensure the voltage applied to the PCB is between 12 and 24Vdc.

On application of power, the LEDs associated with the “CO2Concentration Indicator” will

flash in sequence for a few seconds and the sensor will commence its warm up procedure.

This is indicated by the flashing of the green “Auto-Zero initiated” LED.

At the end of the warm up period (5minutes) the 4-20mA output and the “CO2

Concentration Indicator” will be “steady”.

The GD233 CO2Sensor will have been calibrated at the factory and will be ranged in

accordance with the application.

Both the“CO2Concentration Indicator” and 4-20mA output will have been set to this

range (0 - 5000ppm, 0 - 1% or 0 –2% CO2).

The 4-20mA is linear over the range of the instrument.

The zero point (0ppm CO2) will have been established in the factory using nitrogen or CO2

free air. In its intended application the GD233 CO2Sensor may have its zero point set

using air thus eliminating any offset due to the natural presence of CO2in the atmosphere.

Please refer to Auto-Zero Initiation below.

3.3 OPERATION.

3.3.1 Internal & External Control Buttons

These buttons may be used to initiate Auto-Zero, Auto-Span and cancel any latched

concentration alarms. The “Internal Control Button” (see Figure 2 for location) will

perform all the above functions. However, the “External Control Button” will only allow

any concentration alarms to be reset unless fully activated at the factory.

The functions of the Control Buttons are activated as follows:-

Press the appropriate control button. This will colour sequence the “CO2Concentration

Indicator”. The “CO2Concentration Indicator” will continue to sequence its colours

whilst the button remains pressed. Releasing the button when the appropriate sets of

coloured LEDs are illuminated will initiate the appropriate action.

The sequence of colours on the display is as follows:-

All LEDs on the “CO2Concentration Indicator” illuminated.

The GD233 CO2Sensor will return to normal operation, no action will have been initiated.

All 4 RED LEDs illuminated. This will cancel all latched concentration alarms.

NB, the alarms will immediately be reactivated if the CO2concentration is above its alarm

set point after cancellation.

TQ Environmental Limited

Issue 6: 01 June 2017

Page 12 of 12 8764UM6

All 3 GREEN LEDs illuminated. This will start the Auto Zero procedure. The green LED

marked “Z” will illuminate during this automatic procedure.

This will not operate if the “External Control Button” is pressed.

All 3 YELLOW LEDs illuminated. This will start the Auto Span –this procedure must only

be carried out by trained personnel.

This will not operate if the “External Control Button” is pressed.

3.3.2 Auto-Zero

This function will set the output to 0ppm CO2(0% CO2), 4.0 mA based upon the

concentration of CO2inside the enclosure. If a true zero-point at 0ppm CO2is required

instead of the CO2concentration inside the enclosure then nitrogen gas should be used to

fill the enclosure.

SECTION 4 - MAINTENANCE

4.1 ROUTINE MAINTENANCE.

The design of the sensor unit is such that no adjustment or calibration should be necessary

for extended periods of 2 years or longer. However, it is recommended that a system

function check is performed more frequently at 3 to 6 monthly intervals depending on the

application and local ambient conditions.

The sensor unit may require corrective maintenance if the output current is at a maximum

level, even if no combustible gas is present. Refer the unit to TQ Environmental PLC for

service.

If the unit ever becomes defective then it is necessary to refer the unit to a local TQ

representative or contact TQ directly. See the front cover of this manual for details on how

to contact TQ.

Please note there are no User Serviceable parts on the GD233 CO2Sensor.

4.2 WARRANTY

When the GD233 CO2Sensor is operated in accordance with conditions described in this

Manual the Standard Warranty is 12 months from the date of purchase of the instrument

from of TQ Environmental plc

SECTION 5 - SPARES

There are no spare parts associated with the GD233 CO2Sensor

TQ Environmental Limited, Silkwood Court, Wakefield, West Yorkshire, WF5 9TP. United Kingdom

Tel: +44 (0) 1924 271013 Email: [email protected]

Fax: +44 (0) 1924 264420 Web: www.tqenv.com

Table of contents

Other TQ Environmental Accessories manuals

Popular Accessories manuals by other brands

OLEI

OLEI LR-1BS3 user manual

Brüel & Kjaer Vibro

Brüel & Kjaer Vibro ds822 Series instructions

Asus

Asus ZenPower PD 10000 manual

ORION TELESCOPES & BINOCULARS

ORION TELESCOPES & BINOCULARS 8743 manual

ekwb

ekwb EK-FB KIT GA-X99 INSTALLATION AND MOUNTING MANUAL

Dini Argeo

Dini Argeo LTP Installation and operating instructions