TQ Environmental GD133 User manual

TQ Environmental Ltd

Filename: 5832T4 Page 1 of 14

GD133 INFRARED

GAS SENSOR

OPERATING MANUAL

©TQ Environmental Ltd 2017

This manual must not be copied or reproduced in part without the express written

permission of TQ Environmental Ltd. All information contained herein is subject to

modification.

TQ Environmental Ltd, Silkwood Court, Wakefield, West Yorkshire, WF5 9TP

44 (0) 1924 271013 FAX 44 (0) 1924 264420

TQ ENVIRONMENTAL LTD BS EN ISO 9001

TQ Environmental Ltd

Filename: 5832T4 Page 2 of 14

CONTENTS:

Page no:

Proprietary 3

Warning, Cautions and Notes 3

Safety Warnings 4

Section 1 Description

1.1 General description 5

1.2 Method of detection 5

1.3 Sensor unit 5

1.4 Performance specifications 8

Section 2 Installation

2.1 Mechanical installation 9

2.2 Electrical installation 10

Section 3 Commissioning and Calibration

3.1 Commissioning 11

3.2 Calibration 11

3.3 Output current fault conditions 12

Section 4 Maintenance

4.1 Routine maintenance 13

4.2 Warranty 13

Section 5 Spares 14

Certification 15

TQ Environmental Ltd

Filename: 5832T4 Page 3 of 14

PROPRIETARY

No part of the hardware or documentation may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language or computer

language, in any form or by any means, without prior written permission of TQ

Environmental LTD

While great efforts have been made to assure the accuracy and clarity of this document,

TQ Environmental LTD assumes no liability resulting from any omissions in this

document, or from misuse of the information obtained herein. The information in this

document has been carefully checked and is believed to be entirely reliable with all of

the necessary information included. TQ Environmental LTD reserves the right to make

changes to any products described herein to improve reliability, function, or design,

and reserves the right to revise this document and make changes from time to time in

content hereof with no obligation to notify any persons of revisions or changes. TQ

Environmental LTD does not assume any liability arising out of the application or any

use of any product or circuit described herein; neither does it convey license under its

patent rights or the rights of others.

WARNINGS, CAUTIONS AND NOTES

Warnings identify an operating or maintenance procedure, practice,

condition, or statement that, if not strictly followed, could result in

death or injury to personnel.

Cautions, which appear elsewhere in this manual, identify an

operating or maintenance procedure, practice, condition, or statement

that if not strictly followed could result in equipment damage or

serious impairment of system operation.

Notes highlight certain operating or maintenance conditions or

statements that are essential but not of known hazardous nature as

indicated by Warnings and Cautions.

Warnings, Cautions and Notes are included throughout this manual,

as required. Additionally, this section contains important Warnings

that may not be contained elsewhere within this instruction manual.

TQ Environmental Ltd

Filename: 5832T4 Page 4 of 14

SAFETY WARNINGS

THE GD133 INFRA RED GAS SENSOR SHOULD ONLY BE OPERATED

IN AN ENVIRONMENT WHICH IS NON-HAZARDOUS. THE GD133 IS

NOT CERTIFIED FOR USE IN ANY HAZARDOUS AREA.

FOR SAFETY REASONS, THE GD133 INFRA-RED GAS SENSOR MUST

BE INSTALLED, OPERATED AND SERVICED BY QUALIFIED

PERSONNEL ONLY. READ AND UNDERSTAND THIS INSTRUCTION

MANUAL COMPLETELY BEFORE OPERATING THE GD133 GAS

SENSOR.

TQ Environmental Ltd

Filename: 5832T4 Page 5 of 14

SECTION 1 - DESCRIPTION

1.1 GENERAL DESCRIPTION

The GD133 Infra-Red Gas Sensor is a highly reliable infra-red (IR) absorption type

sensor designed to give extended service under extreme conditions. The sensor is used

to detect the presence of infra-red active gases, eg carbon dioxide. In a typical

application, the sensor unit is electrically connected to a control system capable of

providing the power, accepting the 4-20mA signal generated and displaying the

concentration of the gas detected by the sensor . The control system may also

incorporate audible and/or visual alarms when the concentration reaches a

predetermined level. TQ control systems which meet these requirements include

models TQ800, TQ8000 and TQ8100.

The GD133 Sensor is used for diffusion sensing applications. These are applications

in which the sensor continuously monitors that part of the environment with which it is

in contact and the gas diffuses through the sensor’s optical path. This technical manual

covers the use of the GD133 Sensor as a diffusion type sensor.

1.2 METHOD OF DETECTION.

Detection of infra red active gases is accomplished by measuring the absorption of IR

energy by the gas being monitored. This measurement is made over a fixed distance

within a part of the sensor assembly called the Optical Bench. A miniature filament

lamp mounted, at one end of the optical bench, acts as an IR source. The lamp

illuminates an IR detector at the opposite end of the optical bench. The IR detector is

designed to detect IR energy only at the absorption wavelength. The introduction of an

infra red active gas into the optical path between the IR source and the IR detector

causes the detector output to reduce by an amount that can be calibrated for the gas

present. The filament lamp IR source is switched between two levels at a 1.5-second

rate, and is controlled by a precision circuit which provides high-stability operation and

reduces thermal drift. Through several stages, this signal is amplified to a 4-20mA

signal for local or remote indication.

1.3 SENSOR UNIT DESCRIPTION. Refer to Figure 1.

The fully assembled GD133 Sensor unit has the approximate dimensions of 242mm

(Height) X 106mm (Width) X 92mm (Depth). The main components of the GD133

Sensor unit are:

Junction Box (J-Box) with Amplifier

Sensor Assembly

Guard

TQ Environmental Ltd

Filename: 5832T4 Page 6 of 14

220 APPROX

45

81.3

115

81.3

88 Approx

J-BOX WITH

AMPIFIER

INSIDE

STANDARD CONFIGURATION

SIDEVIEW

PLAN VIEW

M20 THREAD

M25 x 1.5mm

THREAD

WEATHER

PROTECTION

SHIELD

Figure 1 - Configuration

J-Box With Amplifier.

The junction box provides resistance to physical shock and gas-free protection to the

components mounted inside. The J-box contains a gasketed screw-on cover and

provision for a gland at the cable entry point (20mm conduit thread).

The amplifier printed circuit board (PCB) installed inside the J-Box, contains an

amplifier circuit for converting the IR detector’s absorption signals into a 4-20mA

output signal.

Sensor Assembly.

The sensor assembly consists of a Flame Arrestor surrounding an Optical Bench

Assembly. The entire Sensor Assembly is surrounded by a protective stainless steel

Guard. Refer to Figure 2.

TQ Environmental Ltd

Filename: 5832T4 Page 7 of 14

Flame Arrestor.

The Flame Arrestor is made of 316 Sintered Stainless Steel. The stainless steel ensures

high corrosion-resistance. The arrestor has a sheet of filter material fixed around the

outside to stop the entrance of dust, dirt and moisture.

Optical Bench Assembly.

The Optical Bench Assembly is concentrically enclosed within the Flame Arrestor and

the Guard.

Guard.

The stainless steel or resin moulded guard provides physical protection for the Flame

Arrestor and the Optical Bench Assembly. In sensor calibration operations, a

calibration cup can be installed over the Guard to provide for adequate flow of

calibration gas to the sensor.

Figure 2. - Sensor Assembly Location.

TQ Environmental Ltd

Filename: 5832T4 Page 8 of 14

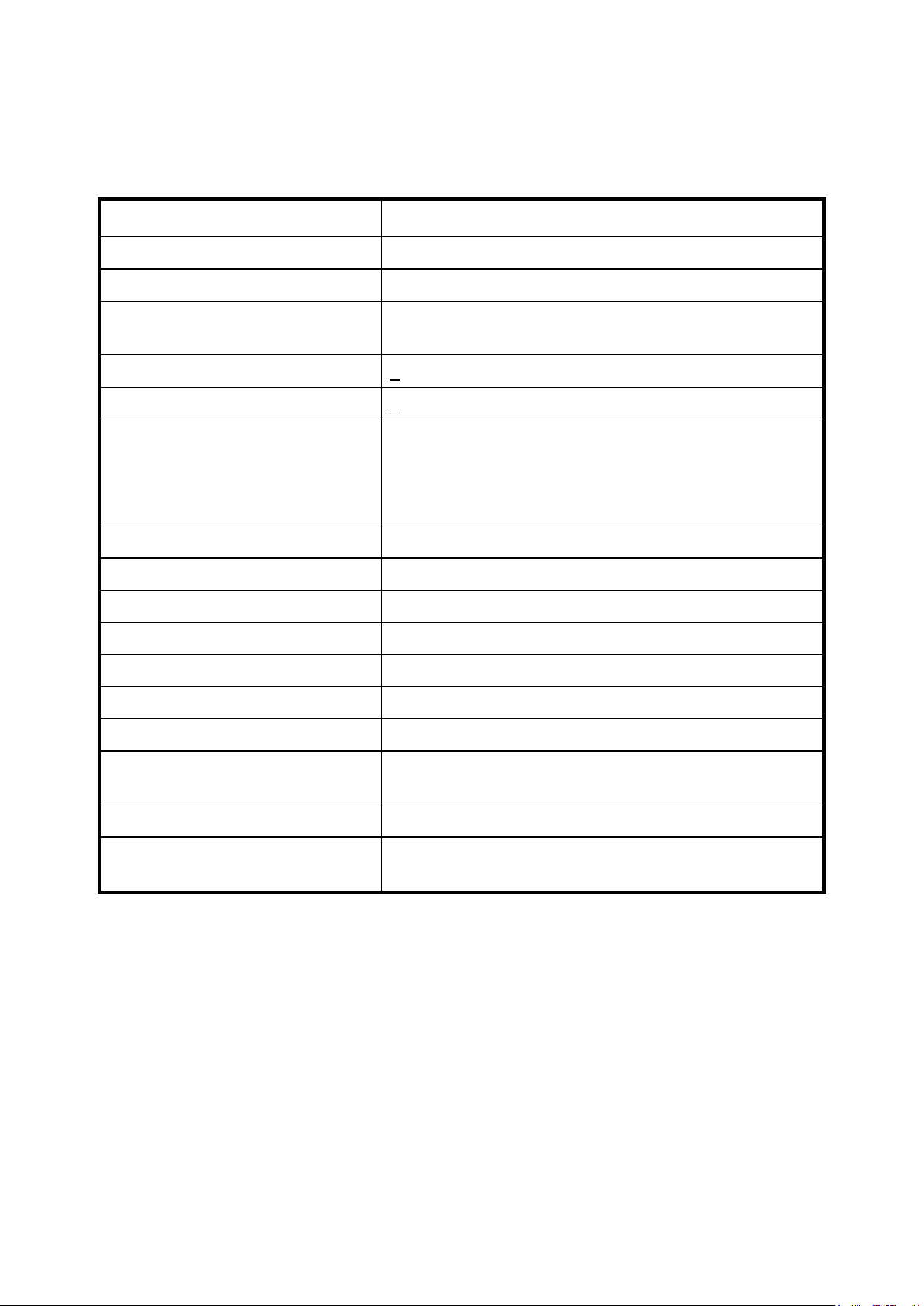

1.4 PERFORMANCE SPECIFICATIONS.

Table 1. GD133 Sensor Performance Specifications.

FACTOR

SPECIFICATION

Detection Method:

IR Absorption

Sampling Method:

Continuous Diffusion

Measuring Range for CO2:

0 –2% volume. (The actual gas and range is displayed

on the label).

Accuracy:

+ 2% Full Scale (FS) Linearised

Repeatability:

+ 1% FS

Response Time:

1. Raw: <3 seconds to 90% of FS

2. Normal: <20 seconds to 90% of final reading (As

installed using 5% volume CO2test gas)

3. High Gas Levels: <5 seconds to FS Value

Temperature Range:

-20C to +50C

Humidity Range:

0 - 99% Relative Humidity (Non-condensing)

Mean Time Between Failures:

Electronics: 10 Years, IR Source: 7 Years

Warranty:

1 Year

Operating Voltage:

11 - 28Vdc

Operating Current:

135mA at 12 Vdc/75mA at 24 Vdc

Connections:

3 Wire, 4-20mA (Source)

Construction Materials:

Flame Arrestor: 316 Sintered Stainless Steel

Guard: 316 Stainless Steel

Weight:

1.05 kg (including junction box)

Electrical Hazardous Area

Certifications:

None

TQ Environmental Ltd

Filename: 5832T4 Page 9 of 14

SECTION 2 - INSTALLATION

2.1 MECHANICAL INSTALLATION.

2.1.1 GENERAL.

The GD133 Sensor is designed to be installed with the junction box and Flame Arrestor

Assembly with the Guard pointing downward. A typical installation for the GD133

Sensor is shown in Figure 3.

Figure 3. Sensor Unit Installation and Orientation.

2.1.2 INSTALLATION GUIDELINES.

To ensure continued reliable operation of the GD133 Sensor, the following installation

guidelines should be observed:

CAUTION

The calibration of the sensor may be affected by exposure to direct sunlight. If it is

necessary to install the sensor unit in a sunlit area, provide an adequate sunshade for

the sensor unit.

For the monitoring of heavier-than-air gases, mount the sensor unit as close as

practical to the floor or ground. For monitoring of lighter than air gases, install the

sensor unit as high as practical.

The sensor unit should be installed in a location where it is easily accessible for

repairs.

Mount the sensor unit in a position that minimises the risk of mechanical damage.

Prevent water and dust accumulation from affecting operation by mounting the

sensor unit with the guard pointing downward, as shown in Figure 3.

TQ Environmental Ltd

Filename: 5832T4 Page 10 of 14

It is important to ensure the conduit-entry point at the top of the J-Box is watertight.

Use an approved watertight packing gland. Apply commercial-grade pipe thread

sealant, such as Liquid Teflon, to the gland threads and install the appropriate

sealing washers.

When the GD133 is used in conjunction with a calibration cup for checking

operation the junction box must be mounted at least 10mm away from a vertical

surface.

The fixing holes on the junction box accept 5mm diameter bolts.

24VDC

0VDC

4-20mA Sig

Figure 4. Typical Electrical Installation Schematic.

2.2 ELECTRICAL INSTALLATION.

The amplifier circuit in the PCB supplies a 4-20mA output signal, which is a current

source only. An external common ground return must be provided, as shown in Figure

4. Total circuit load and cable resistance should be less than 600 Ohms for the 4-20mA

loop. The +24Vdc and common ground leads must be of sufficiently low resistance to

ensure the correct operating voltage at the PCB (refer to Table 1. for the operating

voltage range).

It is important that screened cable and cable glands are used with the instrument, and

that termination is carried out in the approved manner. The cable screen must NOT be

connected at the detector end, as it is to be connected to ground at the control panel.

See Appendix A for Electrical Connections with Alarm Relay Output.

TQ Environmental Ltd

Filename: 5832T4 Page 11 of 14

After wiring the lid of the junction box shall be screwed back onto the base.

CAUTION:- Ensure that the lid corresponding to its sensor is used when replacing lids

after installation or service.

SECTION 3 - COMMISSIONING & CALIBRATION

3.1 COMMISSIONING.

Prior to connecting power to the GD133 Sensor, the following preliminary checks

should be made.

a. Ensure the Sensor Assembly is screwed tightly into its junction box/enclosure.

b. Check that the Sensor Assembly is correctly wired to its PCB.

CAUTION

TO AVOID DAMAGE TO THE EQUIPMENT, ENSURE THE VOLTAGE

APPLIED TO THE PCB DOES NOT EXCEED 30 VOLTS.

c. Ensure the voltage applied to the PCB is between 12 and 28Vdc.

d. Inspect the unit for signs of damage or corrosion to the sensor assembly or its

junction box/enclosure.

After power has been applied, let the sensor unit function for 60 minutes prior to further

monitoring.

Please note that the current output from the GD133 will be 0.5mA for approximately

45 seconds after power has been applied.

3.2 CALIBRATION.

The GD133 is calibrated before it leaves the factory. The 4-20mA output will equate to

the gas and range requested by the Customer when the order is placed. The gas

monitored by the instrument and the range of the instrument are displayed on the label

on the enclosure cover.

It is likely that the GD133 Sensor will remain stable at its initial calibration settings for

long periods (typically 3 years) and on-site calibration is NOT required. Please refer to

4.1 (Routine Maintenance) for details of how to check the output from the sensor.

TQ Environmental Ltd

Filename: 5832T4 Page 12 of 14

3.3 OUTPUT CURRENT FAULT CONDITIONS.

The GD133 provides differing current output levels between 0mA and 4mA to

indicate various sensor fault conditions.

Indicated Current

Output

Description

0.5mA

Warm up after application of power to the unit until the

GD133 has completed its self-testing.

0.5mA

The optical bench (sensor head) output is too high.

1.0mA

The optical bench (sensor head) output is to low.

2.0mA

General optical bench fault or failure.

NOTE:

In the event of more than one fault occurring, the output currents for the

respective faults will be added together.

TQ Environmental Ltd

Filename: 5832T4 Page 13 of 14

SECTION 4 - MAINTENANCE

4.1 ROUTINE MAINTENANCE.

The design of the sensor unit is such that no calibration should be necessary for

extended periods of up to 3 years. However, it is recommended that a system calibration

check is performed more frequently at 3 to 6 monthly intervals depending on the

application and local ambient conditions. In this case, any small adjustment of the

output can be corrected on the control system receiving the signal from the GD133.

Please refer to the documentation associated with the control system for details on how

to carry out any adjustment which is necessary. TQ control systems which allow

adjustment of the incoming signal include models TQ800, TQ8000 and TQ8100.

The sensor unit may require corrective maintenance if any of the following occur:

Output current is at a maximum level, even if no infra red active gas is present.

Sensor response time is slower than noted in Table 1.

In each case refer the unit to TQ Environmental LTD for service.

CAUTION

THE OPTICAL BENCH AND THE SENSOR AMPLIFIER CIRCUITS ARE

MATCHED TO EACH OTHER AT THE FACTORY AND EITHER ONE

SHOULD NOT BE REPLACED AS A SINGLE UNIT. FOR THIS REASON

REPLACEMENT OF THE OPTICAL BENCH OR MAIN BOARD SHOULD

NOT BE ATTEMPTED IN THE FIELD. REFER THE UNIT TO TQ

ENVIRONMENTAL LTD FOR SERVICE.

If the unit ever becomes defective such that it is necessary to refer the unit to a service

facility, an exchange unit can be provided while the defective unit is being serviced at

the facility. Contact the local TQ representative or contact TQ directly. See the front

cover of this manual for details on how to contact TQ.

Please note there are no User Serviceable parts on the GD133.

4.2 WARRANTY

When the GD133 Infra-Red Gas Sensor is operated in accordance with conditions

described in this Manual the Standard Warranty is One Year from the date of purchase

of the instrument from of TQ Environmental LTD

TQ Environmental Ltd

Filename: 5832T4 Page 14 of 14

Table of contents

Other TQ Environmental Accessories manuals

Popular Accessories manuals by other brands

Axis

Axis 260A12 Installation and operating manual

Vertiv

Vertiv SmartRow DCR Installer/user guide

netvox

netvox Contact Sensor Series user manual

Jaypro Sports

Jaypro Sports RDC SERIES Assembly & instruction manual

Tecfluid

Tecfluid FLOMID Series instruction manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS HT640B71 Installation and operating manual