TQ Environmental TQ131 User manual

INFRARED

REFRIGERANT GAS

SENSOR

OPERATING

MANUAL

TQ Environmental Limited

Silkwood Court

Wakefield

WF5 9TP

United Kingdom

Tel: +44 (0) 1924 271013

Fax: +44 (0) 1924 264420

Email: sales@tqenv.com

Web: www.tqenv.com

TQ131

Issue:8 March 2020 4951MMA8 Page 2 of 16

CONTENTS Page No

1 Description 5

1.1 General Description 5

1.2 Method of Detection 5

1.3 Sensor Unit Description 5

1.4 Gases Monitored 6

1.5 Models Covered by Manual 6

1.6 Performance Specification 7

2 Installation 8

2.1 Mechanical 8

2.1.1 General 8

2.1.2 Installation Guidelines 9

2.2 Electrical Installation 10

2.2.1 4 – 20 mA Version 10

2.2.2 Alarm Relay Version 10

3 Commissioning & Calibration 11

3.1 Commissioning 11

3.2 Calibration 11

3.3 Output Current Calculation 13

3.3.1 4 – 20 mA Version 13

4 Maintenance 14

4.1 Routine Maintenance 14

4.2 Warranty 14

5 Spares 14

Issue:8 March 2020 4951MMA8 page 3 of 16

PROPRIETARY

No part of the hardware or documentation may be reproduced, transmitted, transcribed, stored in a

retrieval system, or translated into any language or computer language, in any form or by any means,

without prior written permission of TQ Environmental Limited.

While great efforts have been made to assure the accuracy and clarity of this document,

TQ Environmental Limited assumes no liability resulting from any omissions in this document, or from

misuse of the information obtained herein. The information in this document has been carefully

checked and is believed to be entirely reliable with all of the necessary information included.

TQ Environmental Limited reserves the right to make changes to any products described herein to

improve reliability, function, or design, and reserves the right to revise this document and make

changes from time to time in content hereof with no obligation to notify any persons of revisions or

changes.

TQ Environmental Limited does not assume any liability arising out of the application or any use of

any product or circuit described herein; neither does it convey license under its patent rights or the

rights of others.

COPYRIGHT

© TQ Environmental Limited 2000-2015

This manual must not be copied or reproduced in part without the express written

permission of TQ Environmental Limited.

All information contained herein is subject to modification

WARNINGS, CAUTIONS AND NOTES

Warnings identify an operating or maintenance procedure, practice,

condition, or statement that, if not strictly followed, could result in death or injury to

personnel.

Cautions, which appear elsewhere in this manual, identify an operating or

maintenance procedure, practice, condition, or statement that if not strictly followed

could result in equipment damage or serious impairment of system operation.

Notes highlight certain operating or maintenance conditions or statements that are

essential but not of known hazardous nature as indicated by Warnings and Cautions.

Warnings, Cautions and Notes are included throughout this manual, as required.

Additionally, this section contains important Warnings that may not be contained

elsewhere within this instruction manual.

Issue:8 March 2020 4951MMA8 Page 4 of 16

SAFETY WARNINGS

THE GD131 FREON SENSOR MUST ONLY BE USED IN AREAS WHERE

POTENTIALLY FLAMMABLE GASES ARE NOT PRESENT.

FOR SAFETY REASONS, THE GD131 INFRA-RED GAS SENSOR MUST BE

INSTALLED, OPERATED AND SERVICED BY QUALIFIED PERSONNEL ONLY.

.

READ AND UNDERSTAND THIS INSTRUCTION MANUAL COMPLETELY

BEFORE OPERATING THE GD131 GAS SENSOR.

Issue:8 March 2020 4951MMA8 page 5 of 16

SECTION 1 - DESCRIPTION

1.1 GENERAL DESCRIPTION

The GD131 Infra-Red Sensor is a highly reliable infra-red (IR) absorption type sensor

designed to give extended service under extreme conditions. The sensor is used to detect

the presence of Refrigerant gases (R22, R134a, and similar gases). In a typical application,

the sensor unit is electrically connected to a system capable of either providing readouts

indicating the concentration of the gas detected by the sensor or generating alarms from

volt free alarm contacts changing over when a preset concentration of the refrigerant gas is

detected.

The GD131 Sensor is used for diffusion sensing applications. These are applications in

which the sensor continuously monitors that part of the environment with which it is in

contact and the gas diffuses through the sensor’s optical path. This technical manual covers

the use of the GD131 Sensor as a diffusion type sensor. As an alternative the sensor may

be equipped with “flow-through” measurement cell where an external pump is used to

introduce gas from a remote sensing point to the sensor as part of a sampling system.

1.2 METHOD OF DETECTION.

Detection of refrigerant gases is accomplished by measuring the absorption of IR energy

by the gas being monitored. This measurement is made over a fixed distance within a part

of the sensor assembly called the Optical Bench. A high intensity IR emitting lamp is

mounted, at one end of the optical bench. The lamp illuminates an IR detector at the

opposite end of the optical bench. The IR detector is designed to detect IR energy only

within a specific wavelength range at which adsorption of energy by the refrigerant gases

occurs. The introduction of the refrigerant gas into the optical path between the IR source

and the IR detector causes the detector output to reduce by an amount proportional the

refrigerant gas present. The IR source is switched between two levels at a 1.5-second rate,

and is controlled by a precision circuit which provides high-stability operation and reduces

thermal drift. Through several stages, this signal is amplified to a 4-20mA signal for remote

indication or to generate the concentration alarm.

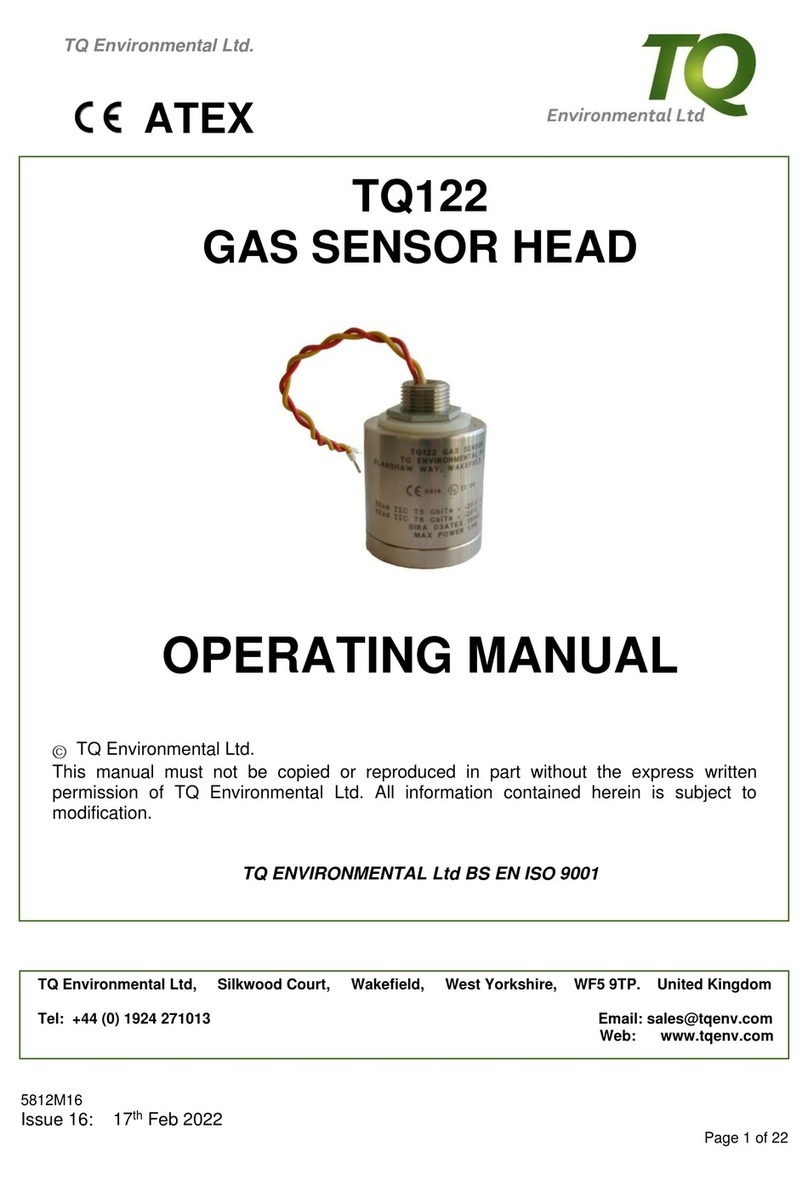

1.3 SENSOR UNIT DESCRIPTION.

The fully assembled GD131 Sensor unit has the approximate, overall dimensions of

285mm (Height) X 154mm (Width) X 80mm (Depth). The main components of the GD131

Sensor unit are:

Junction Box (J-Box) with Amplifier

Optical Bench Assembly

Guard

Filter

Table of contents

Other TQ Environmental Accessories manuals