TQ Roboter Flexible Base Plate User manual

Product information TQ Roboter Flexible Base Plate

V 2.0 | 03/2023 | ENG Copyright © TQ-Systems GmbH 1/ 2

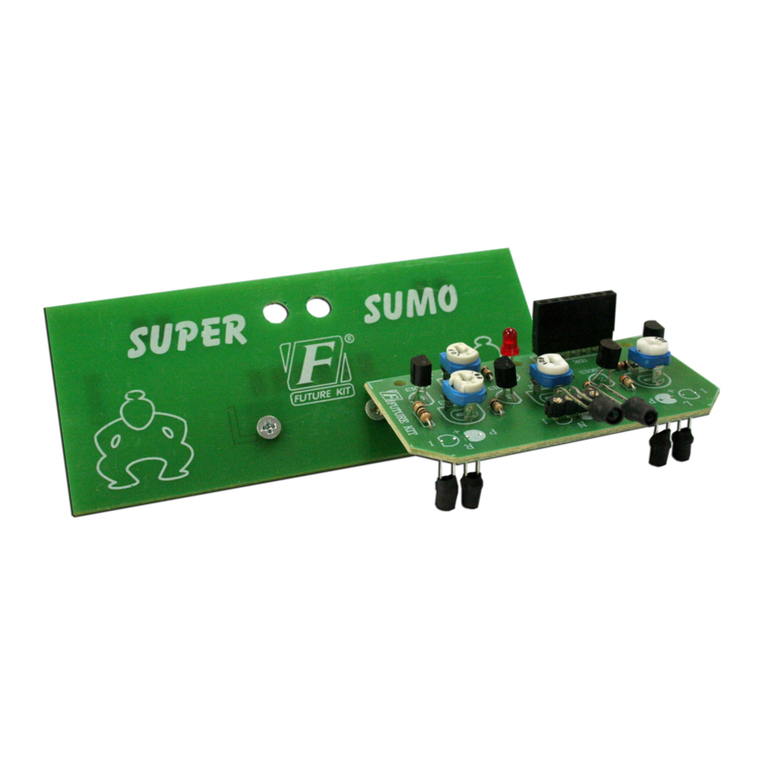

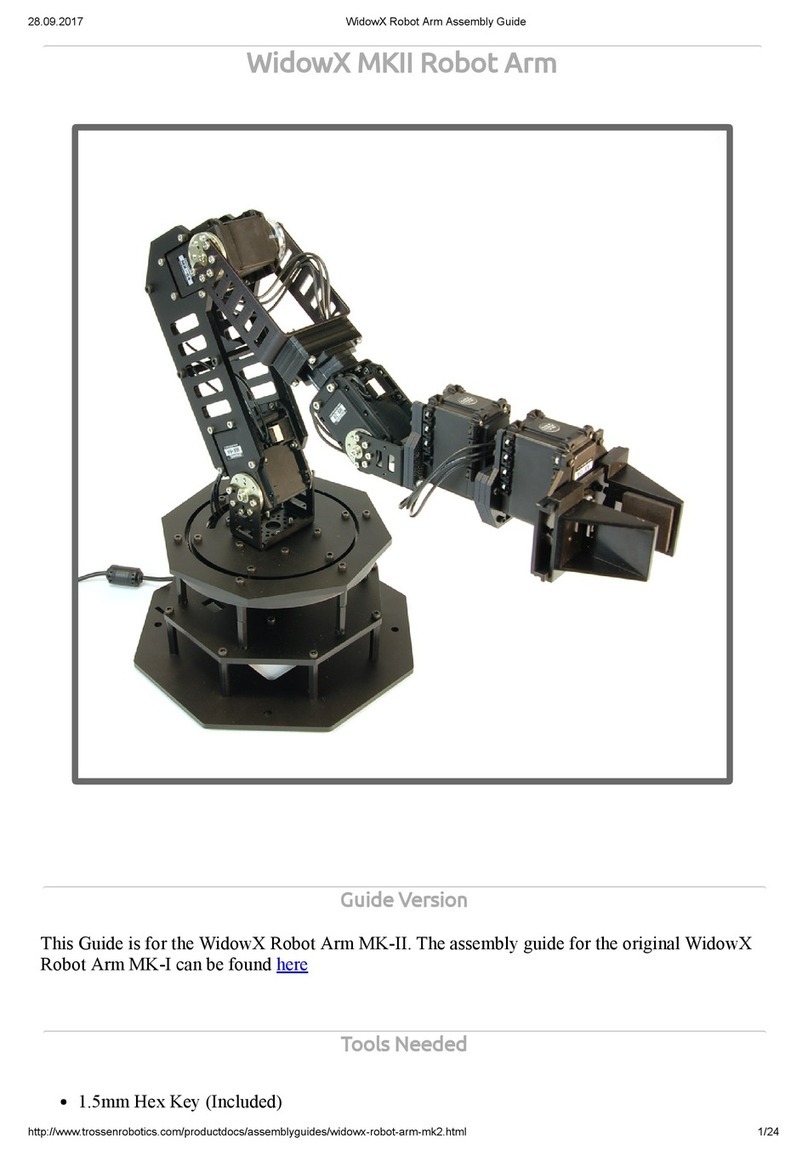

TQ Roboter Flexible Base Plate

TQ robot flexible Base Plate.

Material number: 334600.0101

Follow these instructions for correct and safe

operation.

1. Scope of delivery

1x Base plate

The mounting material is not included in the scope of

delivery.

2. Symbols

General warning sign

Warning: Electricity

General mandatory action sign

Refer to instruction manual / booklet

• Lists

1. Numbering (The consecutive numbering defines

the sequence of the instructions given.)

Reference

3. Intended use

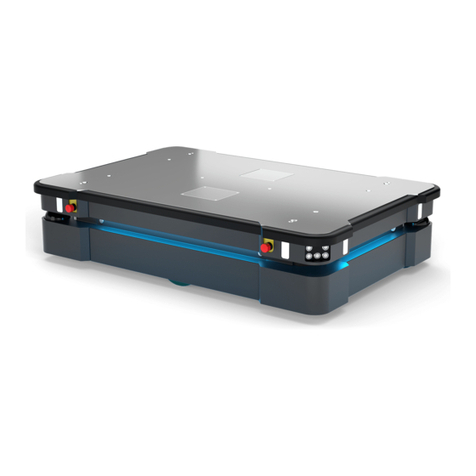

The TQ Flexible baseplate is used for mounting the

Franka Production 3 (Franka Emika GmbH) robot on

different profile systems.

NOTE

The product is used as part of a higher-level

overall system.

Project planning, assembly, and commissioning

exclusively by authorized specialist personnel

with the following knowledge:

• Knowledge of the applicable regulations

on occupational safety and accident

prevention

• Knowledge of applicable EMC regulation.

All applications deviating from the intended use are

regarded as improper use.

These include, for example:

• Do not use outdoors

• Use outside the permissible technical operating

limits

• Do not use in potentially-explosive environments

• Do not ignore safety instructions

• Do not operate a faulty machine

4. Safety Instructions

NOTE

Prior to handling the base plate (assembly, use,

control) , you must have read and understood the

content of this Product information.

• Comply with instructions and notes

NOTE

Assembly and commissioning only by authorized

specialist personnel who have special knowledge

of how to use the product.

5. Assembly

NOTE

Device damage due to incorrect

installation/attachment and unsuitable

environmental conditions.

Prerequisites:

• The profile table on which the base plate for the

Franka Production 3 robot (Franka Emika GmbH)

is mounted must be designed for the load and

anchored to the floor.

• The following maximum forces must be absorbed

by the profile table in static and dynamic mode:

– Vertical force: max. 410 N

– Horizontal force: max. 300 N

– Tilting torque: max. 280 Nm

– Torque around axis 1: max. 90 Nm

• Make sure the mounting surface is level.

• Observe the documentation of the robot Franka

Production 3 (Franka Emika GmbH).

• The robot Franka Production 3 (Franka Emika

GmbH) must not be live during assembly.

NOTE

Do not use any sharp or pointed objects to open

the packaging.

1. Remove packaging

2. Check that the delivery is complete and

undamaged, otherwise contact the manufacturer.

Impressum

NOTE

Tighten the screws with a tightening torque of 23

Nm.

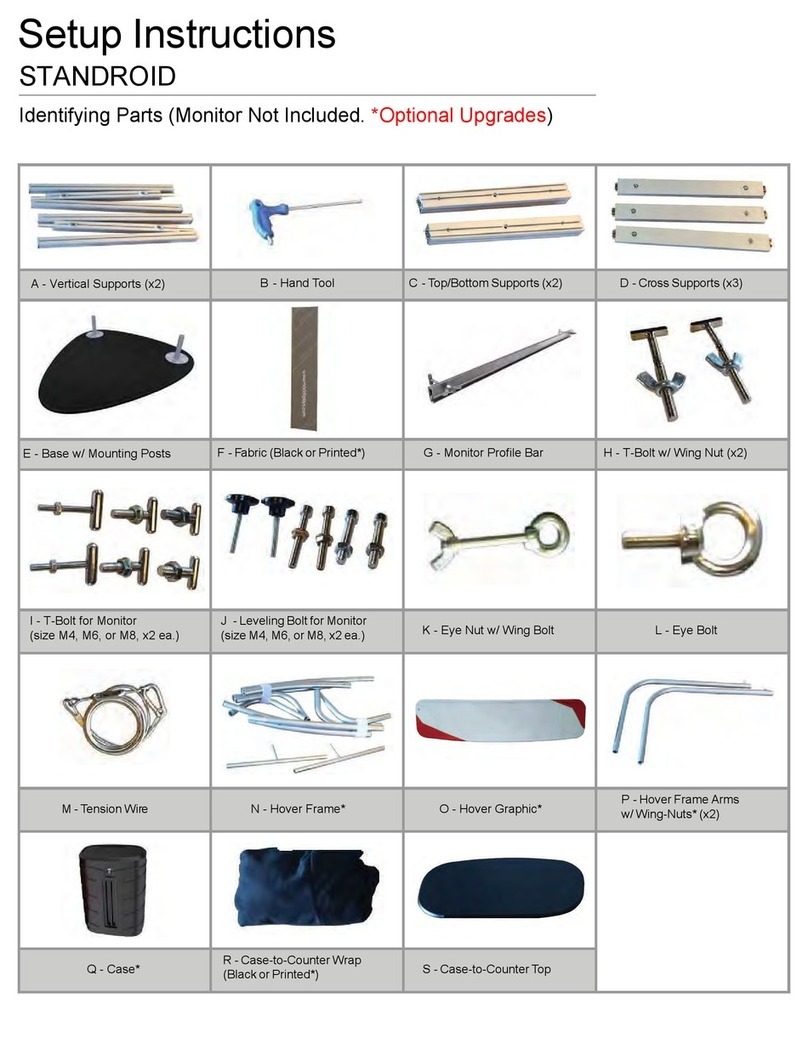

Mounting base plate on the profile table

Required tool:

• Allen key M8

Required mounting material:

• 4x Cylinder Screw with hexagon socket DIN 912

A2 M8x25 strength class 8.8

• 4x Washer DIN 125 A2 for M8

Possible grids for mounting:

20 mm & 40 mm

25 mm & 50 mm

30 mm & 60 mm

45 mm

Product information TQ Roboter Flexible Base Plate

2/ 2 Copyright © TQ-Systems GmbH 03/2023 | V 2.0 | ENG

3. Determine grid for attachment.

4. Fasten the base plate to the profile table with the

4 cylinder-screws and the associated washers.

NOTE

Only use high-performance sliding blocks with the

M8 thread from the profile manufacturer.

⇒Installation of base plate completed

Mounting robot Franka Production 3 (Franka Emika

GmbH) on base plate

Required tool:

• Allen key M8

Required mounting material:

• 4x Cylinder Screw with hexagon socket DIN 912

A2 M8x25 strength class 8.8

• 4x Washer DIN 125 A2 for M8

Possible mounting positions:

Position 1

Position 2

5. Determine mounting position.

6. Fasten the robot to the base plate with the 4

cylinder-screws and the associated washers.

⇒Assembly of the robot on the base plate

is complete

6. Control and Maintenance

NOTE

In case of damage or wear, the entire product

must be replaced.

The following checks are required to ensure trouble-free

and permanent function:

• Clean only with a dry, lint-free cloth

• Secure fastening of all components

• Retighten all connections after 100 hours of

operation with the specified tightening torque.

7. Disposal

Dispose of the disassembled components, packaging,

operating materials, etc. in accordance with the

applicable provisions and, to the extent possible, recycle

them.

• Dispose of cardboard packaging material as

waste paper in the local waste disposal system.

• Dispose of plastic films and packaging in

accordance with the national laws and

regulations.

• Collect all materials used for the base plate

operation as per the manufacturer’s product

information and separate, dispose of, or recycle

accordingly.

Dispose of all waste properly and in accordance

with the

– Emissions Control Act,

– Waste Disposal Act,

– and the Water Resources Act.

Supplementary, higher-level, company-internal,

or regional provisions may apply.

8. Warranty

If the above Conditions for the intended use are not met

or if the safety instructions are not followed or if any

maintenance work is not carried out as required, this

leads to an exclusion of liability and the loss of the

warranty.

Parameter

Value

Material

3.3535 (EN AW-5754) H26 (AlMg3)

Mounting position

horizontally on profile system

Environmental

temperature

-10 °C - +80 °C

Air humidity

20 bis 85% rel.

Dimensions

335 x 120 x 20 mm

Weight

3.475 g

Imprint:

TQ-Systems GmbH | TQ-Robotics

Gut Delling

Mühlstraße 2

82229 Seefeld

Germany

P. +49 (0) 8153 9308-0

F. +49 (0) 8153 4223

www.tq-group.com

E-Mail: info@tq-group.com

District court Munich, HRB 105018

© V 2.0 | 03/2023 | ENG

Document: PI_334600.0101

Copyright note

(according to DIN ISO 16016:2007-12):

The dissemination and reproduction of this document as

well as the exploitation and communication of its content

is not permitted, unless explicitly authorised.

Infringements shall result in an obligation to provide

compensation for damages. All rights are reserved in the

event of a patent being granted or a utility model or

design being registered.

This manual suits for next models

1