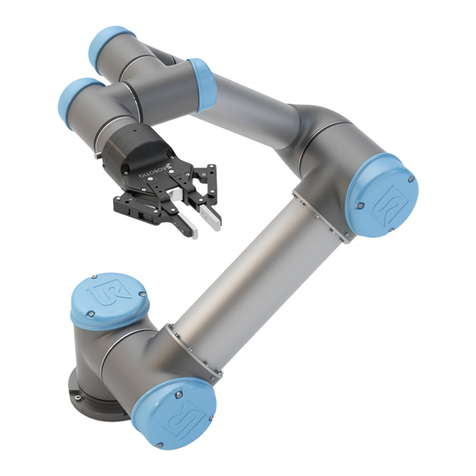

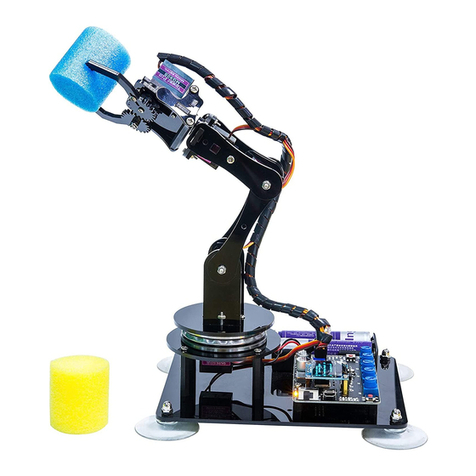

Trossen Robotics WidowX MKII User manual

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 1/24

WidowX MKII Robot Arm

Guide Version

This Guide is for the WidowX Robot Arm MK-II. The assembly guide for the original WidowX

Robot Arm MK-I can be found here

Tools Needed

1.5mm Hex Key (Included)

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 2/24

2mm Hex Key (Included)

2.5mm Hex Key (Included)

Small Flat Head Screw Driver

Parts List

Note: Some of the parts in some assemblies come packaged in separate smaller bags because

they come with a bracket or other various parts. Please review the entire parts list to ensure you

have all necessary components. Some kits will have spare bolts, nuts, or screws included.

2 X 2 X 2 X

1 X 1 X 1 X

1 X 2 X 2 X

2 X 1 X

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 3/24

1 X 1 X 1 X

1 X 1 X 1 X

1 X 1 X 1 X

2 X 2 X 1 X

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 4/24

1 X 1 X 2 X

1 X 1 X 1 X

1 X 1 X 1 X

2 X

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 5/24

10 X 8 X 22 X 10 X

14 X 32 X 8 X

4 X 10 X 16 X 24 X

18 X 40 X 12 X

6 X 1 X 4 X 9 X

8 X 9 X 24 X 8 X

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 6/24

NOTE: The M2 X 4, M2.5 X 4, and M2.5 X 6 listed here are included in the ROBOTIS bracket

and horn packs you have recieved with your arm. Keep that in mind when checking your part

counts.

Assembly Tips

Pre Step: Peel Your Plastic

Some of your plastic pieces will have paper

masking on one or both sides. Peel the masking

paper off before getting started.

There also may be some dust on your parts.

This is from the laser cutting manufacturing

process. It is harmless and can be cleaned up by

wiping with a rag or being washed with water.

ASSEMBLY TIP: Using Turbo Fuse

Your kit comes with Turbo Fuse. The type

provided is non-permanent and plastic safe.

Turbo Fuse is used to keep nuts and bolts in place

on robots since they move and shake around a lot.

To use your Turbo Fuse, squirt a small amount

into a plastic spoon. As you build, before

screwing a bolt into your robot, dip the tip of

each bolt into the Turbo Fuse and brush the

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 7/24

excess off onto the side of the spoon.

Building with Turbo Fuse & Turbo Lock

Horn Installation

Mount one each of the HN05-N102 Servo Horn to the two MX-64 servos using a Hex Socket

Head M3 x 8mm bolt. There is a notch on the spline, indicating the position of the servo. Make

sure this is facing up (centered position) and that the single dot on the horn is aligned with the

notch, as shown. NOTE: there is a plastic washer that you will place between the horn and the

servo.

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 8/24

Mount one each of the Servo Horn to MX-28 servos using the included bolt. There is a notch on

the spline, indicating the position of the servo. Make sure this is facing up (centered position) and

that the single dot on the horn is aligned with the notch, as shown. NOTE: there is a plastic washer

that you will place between the horn and the servo.

Mount the HN07-I101 Idler Bearing on the back of one of the MX-28 Servos and the HN05-I101

Idler Bearing on both of your MX-64 Servos. Pay attention to the idler stack, and make sure you

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 9/24

assemble it as shown.

ID The Servos Before Assembly

You will need to ID your servos before building.

If you have not done so yet, go to the DynaManager Guide and ID your servos.

You will need to ID each one of your servos with the appropriate ID shown below, and set their

Baud rate to 1mbps from the default of 57600. Information on how to do this can be found in our

Arbotix Documentation section of learn.trossenrobotics.com.

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 11/24

Pre Step: Sand your Gripper Rails

AX Parallel Gripper: Fine Tuning

For proper functionality of your gripper, please pay attention to this guide. The gripper rails are

designed tightly, and you may cause irreversible damage to your gripper if you do not sand it in

advance.

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 12/24

Build the Base

Mount Standoffs to the bottom side of the Middle

Base.

8 x 8 x

Mount Standoffs for the ArbotiX Board to the

bottom side of the Middle Base.

4 x 4 x

Mount Standoff Sets to the top side of the Middle

Base.

6 x 6 x

24 x 6 x

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 13/24

Mount the MX-28T Actuator with ID #1 to the top

side of the Middle Base.

*Insert nuts first in their respective positions for

mounting.

8 x 8 x

Mount the ArbotiX Board to the standoffs on the

bottom side of the Middle Base.

*Note the ArbotiX orientation when mounting.

Ensure Barrel Jack is facing towards the rear of the

base.

4 x

Connect a 200mm cable from the left side of ID #1

to the ArbotiX Board, through the cut out on the

Middle Base.

1 x

(Bottom View of cable connection to the ArbotiX

Board)

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 14/24

Mount the Bottom Base to the standoffs on the

bottom side of the Middle Base.

8 x

Apply the Rubber Feet to the bottom side of the

Bottom Base.

8 x

Pay close attention to the orientation of the plates. Misaligning the plates can cause your arm to

be at the wrong angle when centered.

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 15/24

Mount the Bottom and Top Spacer Plates to the

horn of ID #1.

8 x

Mount the Pan Plate to the inside ring of the

Bearing.

*Note the Pan Plate orientation when mounting.

6 x 6 x

Mount the FR05-H101 Hinge Frame to the top side

of the Pan Plate. Mounting holes on the frame are

tapped and do not require nuts.

4 x

Mount the Bearing Assembly to the Top Spacer

Plate.

Nuts will position into hex-shaped holes in the

Bottom Spacer.

*Note the Bearing Assembly orientation when

mounting.

6 x 6 x

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 16/24

Mount the Pan Cover to the outer ring of the

Bearing and into the standoff assemblies from the

Middle Base.

*Note the Pan Cover orientation when mounting.

6 x

Build the Arm

Mount the MX-64T Actuator ID #2 to the Hinge

Frame.

*Note the ID #2 orientation when mounting.

*Use the M2.5x4mm Bolts from the HN05-N102

and HN05-I101 packages.

10 x

Run the cable from the back side of ID #2 to the

right side of ID #1 through the cut out in the Pan

Plate.

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 17/24

1 x

Insert the M2.5 nuts in the appropriate sockets and

mount the two Shoulder Plates to the Shoulder

Servo ID #2 & Elbow Servo ID #3 as shown.

Repeat for other side.

16x 16 x

Combine the 15mm M-F & 20mm FF Standoffs.

Attach between shoulder plates as shown. Bolt them

in on each side.

6x 3 x

3 x

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 18/24

Picture shown for reference (ignore forearm section

for now). Run a 200mm cable from the Shoulder

servo to the Elbow servo.

1x

Next we will build the forearm portion of the arm.

Stack Forearm Spacers 3, 4, 5 (2x), as shown and

bolt together with the FR07-S101K Frame.

4 x 4 x

Stack Forearm Spacers 1 (2x), 2, 3, as shown and

bolt together to the X-Long Bracket & forearm

assembly from previous step.

4 x 4 x

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 19/24

=

Attach the X-Long Bracket & Forearm assembly to

Elbow Servo ID #3 as shown. You will use the 2x

clear spacers included with the bracket assembly.

*Note the ID #3 orientation when mounting. The

servo should be centered and the forearm should be

mounted at 90 degrees from the shoulder.

10 x

Connect a cable to the bottom side of ID #3.

*Note the ID #3 orientation when mounting. The

servo should be centered and the forearm should be

mounted at 90 degrees from the shoulder.

1x

28.09.2017 WidowX Robot Arm Assembly Guide

http://www.trossenrobotics.com/productdocs/assemblyguides/widowx-robot-arm-mk2.html 20/24

Seat 4x M2.5 nuts in the bottom sockets of the ID #

4 servo and attach it to the FR07-S101K Frame as

shown.

4 x

4 x

Connect the cable coming from Servo ID # 3 to

Servo ID #4. Picture shown for reference, arrows

reference bolts in prior step.

Build the Wrist

Mount the Bottom Reverse Bracket to FR07-H101

Hinge Frame.

2 x 2 x

Table of contents

Other Trossen Robotics Robotics manuals