TQC Sheen CurveX4 User manual

CurveX4

CX4005, CX4010

IMPORTANT! Before taking

this instrument in use we

this manual carefully.

strongly advise you to read

Operating Instructions (V1.0 0522)

3

|

WARRANTY

Industrial Physics will grant a warranty for a period

of 12 months for CurveX 4 and 12 months for all

related equipment from the date of delivery in

respect of any evidence of faulty workmanship and

materials. Should a delivered consignment prove to

be contrary to contract uponinspection,

the customer shall grant Industrial Physics the

opportunity hereunder of removing the fault, or

else the customer may demand a replacement.

Should the supply or delivery of any improvement

or replacement not prove possible, the customer

may choose between having the purchase price

reduced or in demanding the contract of sale to

be rescinded (conversion). Damage resulting from

natural wear and tear, mechanical or chemical

damage, an act of God or non-compliance with

the operating instructions shall be excluded from

thewarrantyas well as mechanicalinterferenceby

the customer or by third parties with CurveX 4 and

relatedequipmentwithoutIndustrialPhysics’written

permission. No liability will be accepted for defects,

damage or injury caused due to use not carried

out in accordance with the manufacturer’s user

instructions.

Toclaim warranty, the rejected product has to

be sent to Industrial Physics together with the

original invoice, any exchange before the product

has been returned to Industrial Physics is not

possible. Industrial Physics reserve the right to

repair,exchangeorsupplyanequivalentsubstitute.

Industrial Physics is not liable for handling or

transport costs. Warranty on the purchase price is

limited, all liability for consequential damages or

changes in technology is expelled.

This product meets the IEC 61326-1

Electrical equipment for measurement,

control and laboratory use –EMC

requirements.

|

4

INDEX

1

General 5

1.1

Importance of operating manual

1.2

User-responsibility

1.3

Responsibility of personnel

1.4

Dangers

1.5

Designated purpose

1.6

Copyright

1.7

Manufacturer’s/Supplier’s address

2

Safety Instructions 6

2.1

Meaning of Symbols

2.2

Availability of SafetyInformation

2.3

Dangers from Electrical Energy

2.4

Modifications to the Equipment

3

Transport and Storage 7

3.1

Packing

3.2

User: Check on Receipt

3.3

Reporting Transport Damageand

Documentation

3.4

Storage and Protective

Measureswhen not in use

4

Getting Started 8

4.1

Quick start

4.2

Memory - batches

4.3

CurveX 4 tasks

4.4

Downloading Data And Configuring

The CurveX 4

4.5

Logger menu —download all data to PC…

4.6

Logger menu —download express

4.7

Logger menu —RealTime…

4.8

Logger menu —Usersettings…

4.9

Logger menu —Configure & Test…

5

Thermocouple Connectors 12

5.1

Connecting the probes

6

Protection - Using The Insulation Box 14

6.1

Preparing for measurement

6.2

Handling precautions

6.3

Precautions - Batteries in carry-on baggage

(aircraft cabin)

7

Specifications 16

7.1

CurveX 4 package(CX4005)

7.2

CurveX 4 kit (CX4010)

7.3

Accessories

7.4

CurveX4 Logger operation measurement

8

Disclaimer 18

5

|

1

GENERAL

1.1

Importance of operatingmanual

This manual is written in order to become familiar

with all the functions and possible applications of

the instrument. It contains important instructions

about how to use the instrument safely and

economically; according to the purpose designated.

Following these instructions is not only essential to

avoid risks. It also reduces repair costs and down-

time and increases the products reliability and

service-life.

Anyone who works with the instrument shall follow

the instructions in this manual, particularly the

safety related instructions. Additionally local rules

and regulations relating to environmental safety

and accident prevention should be observed. It is

mandatory thatusers have read and understand this

manual prior to first operation of the AutomaticFilm

Applicator Compact.

1.2

User-responsibility

The user should

a)

Only allow persons to work with the instrument

who are familiar with the general instructions on

how to worksafely and topreventaccidents.The

use of the instrument should have been

instructed duly. The safety chapter and the

warnings in this manual should have been read

and understood; acknowledged as evidencedby

their signature.

b)

Regularlycheckthesafety-awarenessof

personnel at work.

1.3

Responsibility ofpersonnel

Before commencing work anyone appointed to

work with the instrument should pay attention to

the general regulations relating to working safety

and accidentprevention.The safetychapterand the

warnings in this manual should have been read and

understood; acknowledged as evidenced by their

signature.

1.4

Dangers

This instrument has been designed and constructed

in accordance with state-of-the-art technology and

the acknowledged safety regulations.

Nevertheless, working with the instrument may

cause danger to the life and health of the operator

or to others, or damageto the instrument or other

property.Thereforetheinstrumentshouldonlybe

used for its designated purpose, and in a perfect

technical condition. Any defect that could have a

negative effect on safety should be repaired and

recorded.

1.5

Designated purpose

The Automatic Film Applicator Compact is

exclusively designed to apply thin films of liquid

or pastes on test specimen. Other applications

constitute improper use.TQC Sheen will not be held

liable for damage resulting from improper use.

Designated purpose also includes properly

observing all instructions in the operation manual,

and adherence to inspection and maintenance

schedules. TQC Sheen is entitled to request these

form when warranty claims are made and during

inspections to ensure safe operation and evaluate

correct usage.

1.6

Copyright

The copyright of this operating manual remains

with TQC Sheen. This operating manual is intended

solelyfortheuserandhispersonnel.Itsinstructions

and guidelines may not be duplicated, circulated

or otherwisepassed on to others, neitherfully, nor

partly. Infringement of these restrictions may lead

to legal action may be taken if this restrictions are

infringed upon.

1.7

Manufacturer’s/Supplier’s address

TQC Sheen

|

Industrial Physics

Molenbaan 19

2908 LL Capelle aan den IJssel

The Netherlands

T +31(0)10 7900 100

|

6

2

SAFETY INSTRUCTIONS

2.1

Meaning of Symbols

The following symbols for dangers are used in this

instruction manual.

Possible immediate

danger to the life or

health ofpersonnel.

If this guideline is notnoted

it can lead to severe danger

to health, up to fatal injury.

A dangeroussituation

could becaused.

Non observance of this

guideline can lead to injury

or to damage to equipment.

Special tips and

particular information.

Guidelines to make optimal

use of the instrument.

2.2

Availability of SafetyInformation

The instruction manual should be kept in proximity

to where the instrument operates and should be

visible and accessible at any time of operation.

In addition to the information contained in the

instruction manual, generaland localregulationsfor

accident prevention and environmental protection

shall be kept available and observed. Always ensure

all guidelines in respect of safety and dangers on the

instrument are in readablecondition.

In case of danger the instrument has to be switched

off by means of the on / off switch at the left back

side of the instrument or by unplugging the mains

power, then the danger should be eliminated.

2.3

Dangers from ElectricalEnergy

•

Work on the electrical supply may only be done

by a qualified electrician.

•

The electrical equipment of theinstrument must

be checked regularly.

Loose connections and cables damaged by heat

must be corrected immediately.

•

Alwaysmake surethe instrument’s power

is turned off while adjusting any electrical

component.

Make sure that no paint or other

liquids are spilled on the electronics

2.4

Modifications to the Equipment

•

Any modifications or additions or alterations to

the instrument may solely be made with

permissionfromthemanufacturerotherwisethe

warranty will be void.

•

Instrumentswhichare notin fault-free condition

must immediately be switched off

•

Only use replacement parts from the original

supplier.Partsusedfromothersourcesaren’t

guaranteed to take the loading and meet the

safety requirements.

7

|

3

TRANSPORT AND STORAGE

3.1

Packing

•

Please take note of pictorial symbols on the

packing.

3.2

User: Check on Receipt

•

Check packing for damage

•

After unpacking check complete supply.

3.3

Reporting Transport Damage and

Documentation

•

Any damage should be documented as accurately

as possible (possibly photographed) and reported

to the relevant insurers or, in the case of sales

“deliveredto customers works”,to thesupplier.

3.4

StorageandProtectiveMeasureswhennot

in use

•

The instrument must be stored in a dry place at a

temperature between 10 -40˚C.

•

If packing is damaged upon receipt immediately

inform the forwarder and make a note on the

packing list and have it signed by the forwarder.

Ideallymake some pictures of the damage as well.

•

Store instrument in the original packing ifpossible.

|

8

4

GETTING STARTED WITH THE TQC SHEEN CURVEX 4

The CurveX 4 is an intelligent temperature data

logging system that was specially designed to

control curing processes in the coating industry. This

manual describes how to use the CurveX 4 logger

and how to download the measurements to your

computer with the Ideal Finish Analysis software.

Forthesoftwareinstallationinstructionsseethe

software manual.

4.1

Quick start

The information in the following steps should be

sufficient to allow you to operate the CurveX 4

withoutfurtheruseofthismanual. Formoredetailed

information we refer you to the remainder of the

manual. See Figure1 for more information aboutthe

interface positions.

Step 1

Set the paint type and other parameters of the

CurveX 4 with the Ideal

Finish Analysis software:

•

Start Ideal Finish Analysis on the computer and

connect the logger

•

Choose User settings in the Logger menu and

follow the wizard. See theIdeal Finish Analysis

help for details on theoptions.

•

Disconnect the logger from the computer

Step 2

Connect the thermocouple probes to the input

points at position 7 of the

CurveX 4.

Step 3.

Attach the sensors to the object to be measured.

Step 4.

Press and hold down the Power button (position 1)

for one second to switch on the

CurveX 4.

Step 5.

Start the recording process by pressing the START

button (position 2). The logging, paint and battery

leds (position 4, 5 and 6) will blink once. The logging

LED will blink blue at the specified logging interval.

Step 6

Place the CurveX 4 logger inside the insulation box.

Make sure the insulation

system is set up properly, as specified inthe manual

of the insulation box chosen. The cables are guided

through the cable outlet and the cover is closed

securely, using the gasket to ensure optimal heat

protection.

Step 7

Send the system through the oven and then remove

the instrument from the box as

soon as possible. The paint LED (position 5) blinks

green aftera full cure or red after a partial cure.The

curespecification is setin the software, seethe Ideal

Finish Analysis help for more details (logger menu –

user settings).

Step 8

Stop the recording process by pressing the STOP

button (position 3).

Step 9

Download the results with Ideal Finish Analysis:

•

Choose download all data to PC… in the Logger

menu of Ideal Finish Analysis and follow the

wizard.

9

|

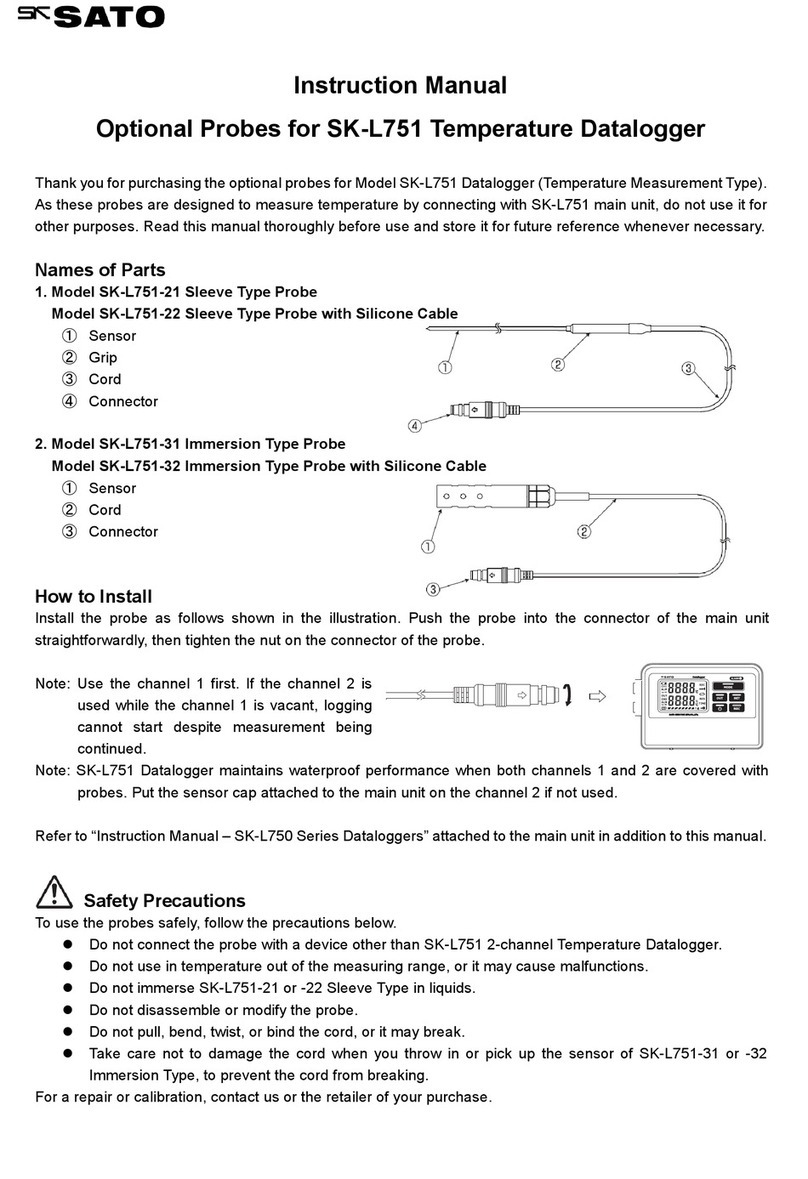

Figure 1

Front View and Top View of CurveX 4

1. POWER button

Press one second to power on

2. START button

Press to start logging

3. STOP button

Press to stop logging

4. Logging LED

Red LED indicates CurveX 4 is logging

5. Paint LED

Red partial cure, Orange active, Green full cure

6. Battery LED

Shows battery status* when powered on:

Red

<25%,

Orange

25% to 75%,

Green

> 75%

7. Thermocouple connectors 1 - 4

Connect up to four probes

8. USB type C port

Connect USB cable to charge and/or download data

*After300 cycles charge from 0 to 100% the battery will retain a capacity of80%. In general such battery

need replacement after approx. 2 years continuoususe.

7

1

4

2

6

5

3

|

10

4.2

Memory - batches

The memory of the CurveX 4 can store a total of

1.000.000readings.Thememoryis dividedinto 20

memory blocks of 50.000 readingseach.

For each new batch, the CurveX 4 will always start

at the beginning of the next memory block, even

if the previous block was only partly used. loggings

that take longer than 50.000 readings are stopped at

reading number 50.000. The maximum number of

batches that can be stored is20.

4.3

CurveX 4 tasks

This table below describes the most frequently

performed tasks:

Task

Action on logger

Ideal Finish

Option

software menu

Power on

Press POWER button

START

logging

Press START button

STOP logging

Press STOP button

Power off

Press POWER button

Download data

Logger

Download all data to PC

Change settings

Logger

user settings

4.4. Downloading Data And Configuring

The CurveX 4

The CurveX 4 is a logger without a display. You will

have to use Ideal Finish Analysis to download data

and change the settings of the logger. The license

key and memory stick with the Ideal Finish Analysis

software are part of the CurveX 4 package. For the

installation of the software you are referred to the

software manual. Toobtain your CurveX 4 license

keyyou are referred totheIdeal FinishAnalysisQuick

Start Manual.

After the installation of the software you can con-

nect the logger to your computer and access the

logger menu where the following options are avail-

able. For information about installing the software

and connecting the logger you are referred to the

software manual.

Step 1. Power on the data logger by pressing the

POWER button (see figure 1, position 1) and

start the Ideal Finish Analysis software.

Step 2. Connect the USB connector to the CurveX 4

(see figure 1, position 8).

Step 3. Connect the other side of the USB cable to

the PC.

Step 4. Choose logger from the menu.

The following options are available:

•

Download all data to PC

•

Download Express

•

Real Time…

•

User settings

•

Configure & test

11

|

4.5

Logger menu —download all data to PC…

Afterselectingthismenuoptionawizardappears

where you can:

•

Set the download folder.

•

Select a template in which the settings of the

oven, the probe layout and the paint type are

defined.

•

Select the batches to bedownloaded.

4.6

Logger menu —download express

Ideal Finish Analysis can speed up the printing of a

report at the click of a single button. Switch

Industrial Physics Ideal Finish Analysis to advanced

mode to enable your line operators to print a report

based ona template for specificprocesses.

4.7

Logger menu —Real Time…

Use this option to view and analyze data the mo-

ment they are measured.

4.8

Logger menu —Usersettings…

use this option to specify the following settings in

Ideal Finish Analysis.

•

Select the logging interval time

•

Specifying the time

-

Check the Synchronize check box. This will set

the data logger time to the PCtime

•

Setup the batch names

-

Double click on the current name to enter a new

batch name

•

Set the paint types in yourlogger

•

Set the cure specifications for the report

•

Configure the properties when logging data in

Real Time.

-

Enter a description of the object you are

measuring and enter a description of the

location where the measuring takes place.

4.9

Logger menu —Configure & Test…

In order for the data logger to communicate with

a computer, use the USB cable to connect it to an

available port on the computer. once connected,

communication can be tested by taking the follow-

ing steps:

Step 1. Connect the data logger to the computer

using the cable that comes with the logger.

Step 2. Choose Configure & Test…¹ from the logger

menu.

Step 3. The logger starts measuring automatically,

displaying the measurements² in a pop-up

window.

Step 4. Click More to see information about the

connected logger, click OK or Cancel to

close the pop-up window.

¹ If an error message is displayed, switch to another

USB port. Ifall ports display an errormes- sage, make

sure that the rechargeable battery is charged and

the data logger is powered on.

² Measurements will be shown even when no

probes are connected. This is normal behavior and

aretheinternalcold junction temperaturemeasure-

ments.

|

12

5

THE CURVEX 4 THERMOCOUPLE CONNECTORS

The CurveX 4 is equipped with eight thermocouple

(K-type) connectors.The connectors are numbered 1

to 8. See the front of the data logger.

5.1

Connecting the probes

Tomeasure the ambient temperature and the

temperature of a product up to four probes can be

connected to the connectors. The logger

automatically detects the connected probes. To

ensure accurate measurements, useonly the K type

sensors (+: NiCr / -: NiAl). The pins on a

thermocou- ple plug are of different widths and can

only be plugged in one way. See figure2

Common probes as clamp, ring-type, and wire

probes can be used butalso special infrared probes.

Figure 2

Thermocouple K Connector Usage

The position of the sensors on the object can be

stored in Ideal Finish Analysis.The position willthen

also be available in thereports.

Remark:

Make sure that the probe cables are free from

objects and the oven walls, floor, sealing and

burners, etc. to prevent them from snagging, as this

may cause serious damage to the probe and the

instrument. Also check whether the probes have

been placed securely so that they do not fall off

during the process.

Options:

When there is too much cable length you can

connect the extended cable length to the gray loop

on the side of the insulation box next to the grip.

Precautions:

Use heat protective gloves when removing the

sensors. Remove the probes carefully; do not pull

the cables. To prevent tears in the cable s heath

and broken cores, do not wind the probe wires too

tightly.

13

|

The magnet surface probe

This probe can be placed on any ferrous steel object.

The sensor element is located exactly in the middle

of the probe.

•

Take the probe between your thumb and

forefinger at the metal cable support just above

the magnet and place the probe atthe preferred

location on the object.

The clamp surface probe

Use the clamp to place this probe on any object.

The sensor element is located inside the jaw of the

clamp, insulated by a small piece of ceramic.Thereis

some friction on this part in order to align the sensor

element with the surface to ensure good contact.

•

Take the clamp between your thumb and

forefinger. Check which jaw has the sensor

element and place the probe at the preferred

location on the object. The maximum reach of the

clamp is 20mm.

The clamp air probe

This fast-responding probe has its sensorelement

inside the small steel protectivetube.

•

Connect the probe to the object or conveyor belt

in the same way as specified for the clamp surface

probe.

The wire probe

This universal probe can be used for either air or

surface temperature measurements. The measuring

element is an open thermocouple that can be

attached with adhesive tape or by other mechanical

means.

|

14

6

CURVEX 4 PROTECTION - USINGTHE INSULATION BOX

The data loggeritselfmay not exceeda temperature

of 60°C (140°F). Since the logger is used inside

high-temperaturecuringovens,theCurveX4 thermal

barrier system is used to protect it. The CurveX 4

thermal barrier box protects the data logger from

the high outside temperatures.

Either a single bracket or a heat absorber can be

used to increase the heat resistance. The heat

absorber contains material that absorbs the energy

that penetrates the box.

N.B.Priorto runany oventemperaturerecording,it

is very important that both the insulation box and

the heat absorber temperatures are below 20°C

(68°F) before the system is sent through the oven.

Alwaysrefer to the insulation box datasheetfor the

maximum time and temperatureuse.

6.1

Preparing for measurement

Step1. Makesure the box is at room temperature.

Step 2. Place the CurveX 4 data logger, with the

probes already connected, insidethe box.

Step 3. lead the probe cables over the gasket and

edge of the box at the cable outlet point.

Step 4. Start the logger.

Step 5. Mount the cover on the box and make sure

the stainless steel edge slides a few

millimeters over the box on all sides. Also

check whether the cutout of the cable

outlet of the cover is facing the same cutout

in the box and whether the probe cables are

positioned properly.

Step 6. Tighten the cover with the four latches and

check again whether the box is properly

closed on all sides.

The system is now ready to be sent through the

oven. Use the grip to hang the box, if necessary.

The isolation box has a ferrous steel plate on top,

which can be used for mounting the magnetic

probes while transporting theset.

15

|

6.2

Handling precautions

Since the heating process inside the box is not

stopped instantly after the box has left the oven, we

strongly advise you to take the following

precautions:

•

Always wear heat protective gloves when

handling the box and the probes after a run

becausethe box will be hot after a measurement.

•

Open the box as soon as possible after the test in

the oven.

•

Takethelogger and bracket / heat absorber out of

the box so that they can cooldown.

Note

•

The heat absorber needs quite a long time to cool

down once it gets hot.

•

When storing the box, do not lock the cover

with the latches.This will extend the life span

and preserve the elasticity of the rubber

gasket!

6.3

Precautions - Batteries in carry-on baggage

(aircraft cabin)

The battery employed in our CurveX 4 is a standard

set of 2 AA batteries. The batteries employed in the

CurveX 4 may fall under restrictions in airline carry

on policies. Commonly dry batteries like the AA,

AAA,C and D batteries will not be subject to these

restrictions.

Basedon USDoT regulations(49CFR, Sec.175.10),

the CurveX 4 battery satisfies all demands, most

notably:

-

The battery is a drybattery

-

Thebatteryisratedbelow100Watt-hoursper

battery

-

The battery is protected from damage and short

circuit

Based on the known airline regulations the batteries

might need to be removed from the instrument

during transport. Allowing the logger to be caried in

carry-on and check-in luggage, the batteries might

be only carry-on.

|

16

operating temperature: 0 °C to 60°C

7

SPECIFICATIONS CURVEX4

CurveX 4 logger

Measuring range

-100°C to 1200°C

Operational temperature:

0°C to 60°C

Accuracy

±1 °C / 1.8 °F

Channels

8

Sample interval time

1 s to 60 min

Memory

20 batches with 50.000 readings

Display

Three multi-colour LED’s

Interface

USB -c

housing material

Anodised Aluminium / Plastic

Dimensions (D x W x h)

110 x 85 x 35 mm

Power supply

2 AA batteries (standard or rechargeable)

Battery life time*

35h with rechargeable batteries, 60 with alkaline batteries

Weight

205 g / 7.2 oz. (Excluding batteries)

Industrial Physics Ideal Finish Analysis software

Supported operating Systems

Windows vista,Windows 7 andWindows8 /8.1,Windows10

Platform

32 b or 64 b

Memory

32 MB

required hard Disk space

128 MB

* After300 cycles charge from 0 to 100% the battery will retain a capacity of 80%.

Ingeneral such battery need replacement after approx. 2 years continuous use.

7.1

CurveX 4 package(CX4005)

The CurveX 4 comes with the following items:

•

CX4005 CurveX 4 Oven Logger

-

Ideal FinishAnalysis Software

-

Rechargeable AA batteries

-

Factory calibrated, calibration

certificate included(CL0018)

-

USB-C Cable (GL0400)

-

PlasticCarrying Case (CX3059)

7.2

CurveX 4 kit(CX4010)

•

CX4005 CurveX 4Logger

-

Ideal Finish software

-

USB-C Cable (GL0400)

-

Insulation box 300°C (CX2005)

-

Energy Absorber (CX2011)

-

Silicone Seal (CX2071)

-

Probe Identification Set(CX2100)

-

Plastic Carrying Case (CX3060)

-

Factory calibrated, calibration

certificate (CL0018)

7.3

Accessories

•

CX2005 CurveX insulation box

(H=140 mm, T=300 °C / 572 °F)

•

CX3050 InsulationBoxLogger Bracket

•

CX2011

CurveX heat-absorber

•

CX2100 CurveX Basic probe identification kit

(1-6)

•

GL0400 USB-C Cable

17

|

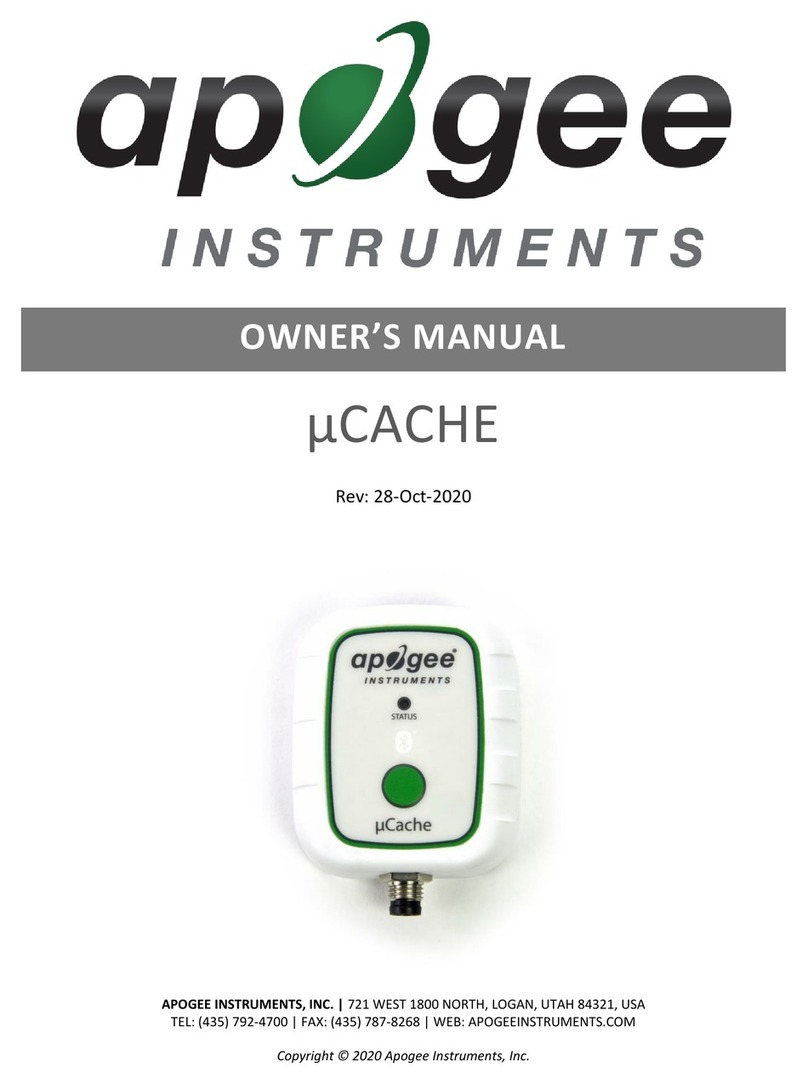

7.4

CurveX4 Logger operationmeasurement

ºC

+8

+6

+4

+2

0

-2

-4

-6

-8

-200ºC 1200ºC

The above-stated graphic depicts the total

maximum difference between loggers in the total

population of the loggers. This graphic is thus an

absolute worst-case scenario.

The green zone shows the worst-case performance

at standard environmental conditions.

The orange part is its full-designed temperature

use. Meaning the maximum deviation between

2 loggers measuring -200°C at an operational

temperatureof 65°C is7°C.Thedailyperformance

of the loggers will be significantly better than the

above stated.

-10 - | +65ºC

25 ±5ºC

-10 - | +65ºC

|

18

6 DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product

for any purpose other than that specifically recommended in this manual without first obtaining written

confirmation from us as tothe suitability of the product for the intended purpose does so at his own risk.

Whilst we endeavor to ensure that all advice we give about the product (whether in this manual or other-

wise) is correct we have no control over either the quality or condition of the product or themany factors

affecting the use and application of the product. Therefore, unless we specifically agree in writing to do

so, we do not accept any liability whatsoever or howsoever arising for the performance of the product

or for any loss or damage (other than death or personal injury resulting from our negligence) arising out

of the use of the product. The information contained in this manual is liable to modification from time to

time in the light of experience and our policy of continuous product development.

19

|

This manual suits for next models

2

Table of contents