Delta-T Devices DL2e User manual

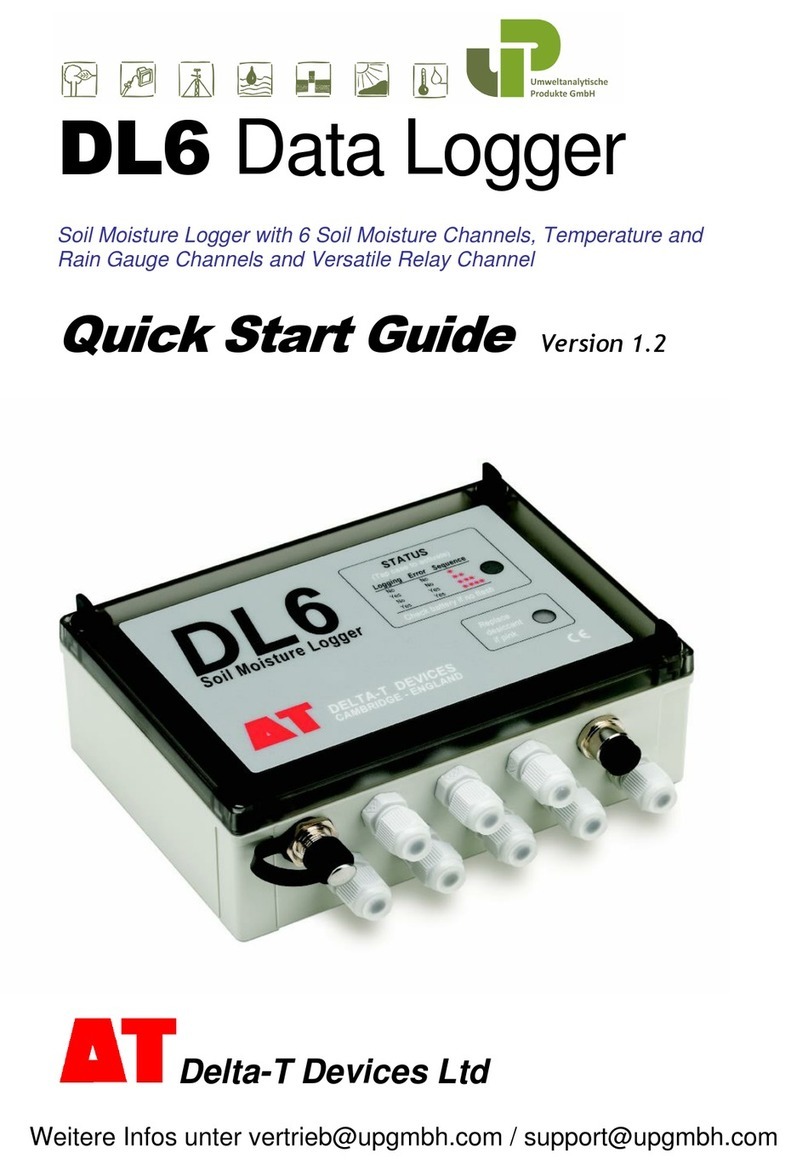

DL2e Data Logger

64 Channel Research-Grade Logger with support for a comprehensive

range of sensors

Quick Start Guide Version 1.1

Delta-T Devices Ltd

Unpacking

Check your contents against your order and any packing lists. You should have:

DL2e fitted with any of the following options:

•input cards LAC1, ACD1, LFW1, DLC1 and/or ACS1

•case height extensions if ordered

Ls2Win PC software on CD and Tutorial Kit

Serial cable type LRS1 for DL2e to PC communication.

Spares and Accessory pack

The following optional accessories are supplied packed separately (if ordered)

Attenuator card type LPR1

Input Protection Card type LPR1V

Rechargeable battery pack type LBK1

Battery charger

Many compatible sensors are available – too many to list here!

Overview

The DL2e can log up to 128,000 readings on up to 64 channels. It has a wide choice of

input cards for recording DC & AC voltage, resistance, counts, frequency and status.

The software is easy to use and supports most sensors. GSM modems and automatic

data collection is possible from remote sites. It is battery powered, weatherproof,

rugged and portable. Weather station packages and evapo-transpiration software are

available.

battery holder

under lid

external power socket

safety earth terminal

sealed RS232 connector

front panel

terminal

compartment

cover

© 2006 Delta-T Devices Ltd v1.1 Page 2

Overview

© 2006 Delta-T Devices Ltd v1.1 Page 3

OFF

1 2

LAC1 input card installed. Set up

for 15 channel, 3-wire/differential

mode, connected to terminal group

1-15 via ribbon cable

Cold boot

Reset

Stop

15-30

channel

slider

External power

connection

Power supply

selection link

RS232

connector

Power supply links for

channel 63 and 64 Ribbon cable

connector blocks

Terminal groups: 46-60 31-45 16-30 1-15

On-board

thermistor

switches

for

channel 1

Digital

Channels

61-62

Warmup or

Relay

channels

63

-

64

Removable screw terminal

block for channels 1-5

Install Ls2Win

What you need:

• A PC running Windows 98, Me, 2000, XP, or a later version

• Microsoft Excel 97 or later for the Excel Dataset Import Wizard

• One free RS232 serial port, or USB-RS232 adapter

• CD ROM drive for software installation

• A minimum of 10MB of available hard disk space

• DL2e to PC RS232 cable (supplied with DL2e).

• Ls2Win software distribution disk (supplied with DL2e)

• Acrobat Reader for reading documentation (free download from www.adobe.com).

To install Ls2Win:

1. Insert the distribution disk into your CD drive.

2. If the Setup program doesn’t start automatically, run Setup.exe on the CD.

Setup installs a program group named Ls2Win on the Programs

menu, including the following:

•Online Documents folder - note the Release Notes and

Hardware Reference

• New DL2 Control Panel, to communicate with your logger

• DL2 Program Editor, to create and view logging programs

• Dataset Viewer, to inspect files containing files of logged data

• Dataset Import Wizard, to import data into Microsoft Excel.

Start New DL2 Control Panel

1. Connect the DL2 to the PC’s serial port using the supplied serial cable. New DL2 Control

Panel

2. Double click on the New DL2 Control Panel icon on your desktop.

3. A DL2 Connections Properties dialog box will open.

Click Help for comprehensive online Help.

Click OK to accept the default settings offered.

Modems: 4800

PC: 9600

4. A Save DL2 Control Panel As dialog appears.

If you have several loggers on modem links, create a

separate control panel for each, with its own phone

number and desktop icon.

5. Click Save to accept the default

MyLogger.dl2 file name.

The control panel now creates a

shortcut to itself on the desktop and

retrieves and displays status information

about the logger.

Logging program status:

Standing By, Armed, Logging or stopped

Refreshes the displayed information

Retrieves the program, not the data

Start logging

DEFAULT

STANDING BY

24 Dec 14:50:77

8.8V. 90%

© 2006 Delta-T Devices Ltd v1.1 Page 4

Tutorial

1) Sensor wiring help

1. Start the DL2e Program

Editor.

2. Select Sensor Library.

3. Scroll down to and click on any

sensor. An Application Notes window

will open with wiring instructions for each

sensor and input card.

4. See if you can find suitable

instructions for the components in the

Tutorial kit.

2) Connect Tutorial Kit sensors

1. Remove the sensor terminal blocks from the side of the logger, and attach the

Tutorial Kit components as shown here, using the screwdriver provided:-

2. Plug the terminal blocks back in to the terminal panel.

OFF

1 2

3. Set the two slider switches UP to the ON position (top right of terminal board) to

connect channel 1 to a thermistor on the terminal board. It can be used as the cold

junction reference for thermocouples.

3) Set up LAC1 Input Card

Open the logger and ensure that:

an LAC1 card is installed with slider switch set to 15-Ch

a ribbon cable connects from the 15 channel terminal on the LAC1 card

to the terminal block for channels 1-15 inside the logger.

© 2006 Delta-T Devices Ltd v1.1 Page 5

4) Select DEFAULT logging program

Check the Program name in the DL2 Control Panel on the Logger page.

If it is a new Logger, skip to (5).

Otherwise ensure that any logged data and programs are saved using the File, Save

As command, then cold boot the logger.

To cold boot the logger

Open the logger case and hold down the COLD BOOT and STOP buttons on the main

circuit board.

If the logger is asleep, also press WAKE on the logger’s keypad.

While the logger is awake, also press and release the RESET button on the main

circuit board.

The message “coldbooting..” appears on the logger’s display, followed by a sequence

of reports as the logger checks RAM chips, installs a DEFAULT logging program and

goes to sleep.

5) Inspect the Sensor Readings

Before logging data, always check the sensors readings are OK.

Check readings via the DL2 keypad and LCD

1. Wait for the logger to sleep.

2. Press WAKE and interrupt the General Status Report by pressing READ almost

immediately.

General Status Report message sequence on keypad after WAKE

© 2006 Delta-T Devices Ltd v1.1 Page 6

3. On “Press any key if required..”, press

READ again to display channel 1 readings. Sensors readings

displayed via the

DL2 keypad

4. Press ▼and ▲to scroll through and

inspect all the programmed channels.

Note: The underline cursor _ indicates

which channel is active.

For further details on keypad operations see

the DL2 Hardware Reference in the

Online Documents Folder.

Check readings via the DL2 Control Panel

© 2006 Delta-T Devices Ltd v1.1 Page 7

Sensors panel showing real-time readings from

the Tutorial Kit using DEFAULT logging

1. Wait until the logger sleeps before

you try to communicate via the PC.

2. Double click on the My Logger

desktop icon to open the DL2

Control Panel.

3. Click Sensors in the DL2 Control

Panel.

4. Enable Read Continuously and

click Select All, and Read Now.

5. Touch the thermocouple tip and

observe channel 6. The sensitivity is

~ 0.04 mV/°C temperature difference

between the thermocouple junction

and the cold junction.

Note: The resistors supplied are ±1%

so readings may differ a little from

the nominal values.

6) Reprogram the

Logger

1. On the Logger panel of the DL2

Control Panel click Retrieve to

upload a copy of the existing

DEFAULT program in the logger.

An Application Notes box also

opens.

2. Examine the ch 1-15 tab. Each

row represents a channel.

3. You have to tell the logger which

input card is connected to each

terminal group.

Select LAC1, 15 channel.

4. Double click on channel 6 to open

the Sensor Type Properties dialog.

5. From the Sensor Type drop

down list on the Input Channels tab,

select Thermocouple: Copper

Constantan (type T).

6. Type in a new label of up to 8

characters e.g. “Temp”.

7. Select channel 1 for the Cold

Junction Channel.

(A cold junction is needed by all

thermocouples. A built-in thermistor

is provided on channel 1).

8. Click OK and inspect channel 6. It is now configured to read type T copper-

constantan thermocouples.

9. We do not need channel 62 configured as a Data Trigger. Select the Ch 61-62 tab.

Highlight Channel 62 and click Delete (on your keyboard).

10. We also do not need channel 64 as a Warm-up channel. Select the Ch 63-64 tab.

Highlight channel 64 and delete this also.

11. Return to the Ch 1-15 tab, highlight channel 6. Note that the Recording Actions

column has changed.

12. Enter a Program Name of up to 8 characters.

13. Select File, Save As and save your new

logging program with a unique File name.

14. Select File, Send to DL2 to display a

choice of DL2 Control Panels.

15. Select the name of your current DL2

Control Panel, e.g. My Logger.

Your chosen Control Panel should then open

and the logging program will be sent to your

logger.

16. Check your new program name appears on the Logger

panel

7) Start Logging

1. Open the DL2 Control Panel by double

clicking on the My Logger icon on your

desktop.

On the Logger panel click on Start to

display the Start Logging dialog. The

start can be deferred until a set time or

until a logic condition is met on the counter

channels 61 or 62.

2. Click OK to start immediately.

Note: you can click on the Sensors panel and check your sensor readings even when

the logger is logging.

8) Retrieve Logged Datasets

1. Leave your logger logging for a few minutes to create some data

2. On the Dataset panel click Refresh to update the display showing how many

readings are stored.

3. On the Dataset panel click Retrieve to display the

Retrieve Dataset dialog.

4. Click OK to retrieve all the data.

5. A Save As dialog appears. Select a suitable folder

and file name and type.

Note the default binary format is quickest (with .bin

after the filename)

6. Click Save to copy the dataset to your PC

© 2006 Delta-T Devices Ltd v1.1 Page 8

Dataset retrieved from logger to file and displayed as a table

Dataset Import Wizard

Dataset Import Wizard helps you seamlessly import data into MS Excel spreadsheets.

Multiple dataset files may be imported and the data interleaved.

To Install Dataset Import Wizard:

© 2006 Delta-T Devices Ltd v1.1 Page 9

1. Select Start, Programs, Ls2Win,

Install Dataset Import Wizard.

2. If prompted by Excel, select

Enable Macro’s. Note that Excel’s

security settings must allow

macros to run: refer to Excel

Help.

3. Dataset Import Wizard will report

that it has installed successfully,

and will add the Import Dataset(s)

to the File menu.

4. To Start Dataset Import Wizard:

Start Excel, select File, Import

Dataset(s) from the menu, and follow the on-screen instructions.

5. Look for DL2 Dataset Files of type:

*.bin, *.hfd or *.dat

Online Help

Note that LS2Win has a detailed online Help: click Help from any window (or press F1)

for detailed information about operation and functionality.

Select the Document Library folder in the Ls2Win Program group to open a folder of

application notes and technical documentation.

SPECIFICATIONS

LOGGING INTERVAL 1, 5, 10, 30 seconds, 1, 5, 10, 30 minutes, or 1, 2, 4, 12 or 24 hours, programmable for each channel. Readings can also

AND SPEED be reduced to averages, maxima or minima at these intervals. Typically 10 channels per second in total.

INPUT CHANNELS 60 channels maximum, depending on input cards installed, plus 2 resident digital inputs and 2 relay outputs.

Analogue Inputs

STANDARD

ANALOGUE Each LAC1 multiplexer card can select analogue inputs from:

CARD, LAC1 Either: 15 channels of differential voltages and/or 3-wire resistances

Or: 30 channels of single-ended (common ground) voltages and/or 2-wire resistances

Directly measures voltages up to ±2V or resistances <1MΩ. Voltages up to ±50V and currents can be measured using

precision divider or shunt resistors mounted directly on the input screw terminals, or on an LPR1 or LPR1V card.

4-WIRE CARD, LFW1 Each LFW1 card can handle up to 12 bridge, potentiometric, differential voltage or 2- or 4-wire resistance sensors.

4-wire resistance measurements virtually eliminate cable resistance errors. 4-wire Pt100 platinum resistance thermometers,

(e.g. DIN 43760/BS1904 types) are measured over -200 to +850°C. In the -17 to +57°C range of Logger and

Pt100 temperature, resolution of 0.01°C and accuracy of ±0.2°C are obtained.

AC/DC INPUT CARD, Each ACD1 card provides 15 measurement channels which may be individually configured for AC voltage (true rms), DC

voltage

ACD1 (differential), 2- or 3-wire resistance. DC and resistance specifications are the same as for LAC1.

VOLTAGE READINGS Full Scale Resolution (12 bits + sign)

4 ranges, user-selected Range 1: ±4mV 1µV

or autoranged: Range 2: ±32mV 8µV

Range 3: ±262mV 64µV

Range 4: ±2.097V 0.5mV

DC Accuracy Logger temperature 15 to 25°C -20 to +60°C

(typical figures Full scale error ±0.07% (0.04%) ±0.2% (0.1%)

in brackets) Long term stability ±0.25% (0.02%) over 1 year

Differential offset ±10µV (3µV) ±0.02% ±12µV ±0.02%

Noise (0.2µV rms)

Input impedance 100MΩapprox.

Common Mode Range ±2V or ±1.05V if “+” input is closer to logger 0V than “-” input

Common Mode Rejection Ratio (140dB), on voltage range 1

AC Accuracy Input level Sinusoidal signals Sinusoidal signals Non-sinusoidal signals

(mV ac rms) 45-60 Hz, -20 to +60°C 65-1000 Hz Crest factor 1.0 to 1.7

0 to 10 Reads zero in this range Reads zero in this range Reads zero in this range

10 to 50 ±3mV maximum additional

50 to 100 ±0.6% reading ±0.25mV ±0.6% reading error ±1.0% reading

g100 to 2000 ±0.6% readin

© 2006 Delta-T Devices Ltd v1.1 Page 10

© 2006 Delta-T Devices Ltd v1.1 Page 11

RESISTANCE READINGS Autoranging 12-bit voltage readings with programmable 2, 20, 200 or 2000µA excitation, giving 1MΩfull scale, or better

than 0.01Ωresolution on lowest range

Accuracy As voltage readings, with additional errors:

Logger temperature 15 to 25°C -20 to +60°C

2µA excitation ±0.3% reading ±0.6% reading (to +50°C)

other excitation currents ±0.05% reading ±0.1% reading

2-wire LAC1, ACD1 ±5Ωtypical ±5Ωtypical

INPUT PROTECTION Analogue inputs withstand ±15V continuously, and much higher voltages in brief pulses (500V 1.2/50µs). For additional

protection, see LPR1V below

ATTENUATOR CARD, For use with Standard Analogue Card LAC1 only. Provides socketed positions for mounting signal conditioning resistors to

LPR1 30 channels. Resistor positions may be left vacant or resistors fitted in shunt or divider configuration, for measuring currents

up to 0.1A or voltages up to ±50V respectively

INPUT PROTECTION Connects transient-absorbing varistors to 30 Standard Analogue Card inputs, or 12 4-wire card inputs, for input protection to

CARD, LPR1V 2kV 1.2/50µs. Also provides socketed resistor positions for signal conditioning, but only when used with LAC1 (as LPR1

above). Can cause significant inaccuracies when measuring resistances >100kΩ

Digital Inputs and Outputs

DIGITAL INPUTS All loggers have 2 resident 16-bit counter channels that continuously monitor logic levels or switch closures, logging digital

status, counts or frequency (up to 100Hz), or for triggering special logging sequences

COUNTER CARD, DLC1 Each DLC1 card provides up to 15 extra 16-bit counter or frequency channels. Maximum frequency: 500Hz for switch closures,

500kHz for 5V logic level signals. Every channel can record up to 65472 counts over the logging interval.

RELAY OUTPUTS 2 SPDT relays for powering up sensors, or for providing alarms or malfunction warnings. 1A, 24V rating.

Other Specifications

PROCESSING The DL2e converts readings into engineering units using look-up tables or a linear conversion y = mx + c. User expandable

OF RAW READINGS sensor library includes Delta-T sensors (pages 15-18), Platinum Resistance Thermometers, Thermistors (Fenwal 2K, 2K252,

10K and 100K types), and Thermocouples (types J, K and T). Cold junction temperature is measured at isothermal terminals.

DISPLAY A 2-line LCD shows instantaneous output from any sensor (in engineering units if appropriate), time, battery and memory

condition, and status messages, without disturbing logging.

MEMORY Highly reliable CMOS RAM, double battery-backed. Expandable from 64k readings (standard) to 128k. Automatic RAM check.

DATA FORMAT ASCII, easily loaded into many spreadsheets and other packages, e.g. Excel, Lotus 1-2-3. Transmitted readings are date/time

stamped, and labelled in engineering units with errors flagged. Data files created by the LS2e software are comma separated.

INTERFACE RS-232 serial, up to 9600 baud. Up to 10000 readings transferred per minute without disturbing logging.

POWER 6 internal AA alkaline cells typically provide power for 500k readings, or 24 hours’ operation using the keypad/LCD or RS-232

interface, or 12 months’ quiescent operation. An external 7-15V DC supply can be used, with the alkaline batteries providing

a back-up. The internal lithium cell will retain data for 2 months in the event of a power supply failure.

ENVIRONMENTAL Operating temperature: -20 to +60°C. IP65 weatherproof main case with desiccant and humidity indicator.

EMC CONFORMITY Tested to comply with EN 50081-1 and EN-50082-1 (1992) harmonised emissions and immunity standards

SIZE/WEIGHT 280 x 220 x 140mm / 2.7kg.

Product Care and Maintenance

To keep the logger functioning properly:

• Keep the batteries and desiccant fresh.

• Avoid use beyond -20ºC to +60ºC.

• Avoid storage beyond -30ºC to + 60ºC.

• Don’t leave the logger in direct strong sunlight.

Replacing batteries

When replacing batteries:

Use alkaline cells only. Other less expensive types of primary battery are not

suitable. They can leak corrosive chemicals and cause permanent damage.

Insert the batteries the right way round, as indicated on the battery holder.

Always replace a complete set of batteries. Don’t mix batteries that have been

discharged by different amounts.

You can change batteries without stopping logging, but you must ensure that you can

complete the procedure while the logger is asleep, between LOGs. If the logger’s

power supply is interrupted during a LOG, it may be unable to resume logging.

If you need to change the batteries and continue to log data at frequent intervals,

provide an external power supply while changing the batteries.

Storage

If the logger is put away for storage for a long period of time, remove the main battery

and the lithium cell and keep the logger in a dry place within -30ºC to +60ºC.

When the logger is again required for use, replace the batteries and cold boot.

Regenerating desiccant

Place the bags in an oven at 110-120°C for 7 hours (approx.) to regenerate expired

desiccant. Exceeding this temperature may cause the glue sealing some types of

desiccant package to melt. When the water has been driven off, remove the capsules

or bags and seal them in a plastic bag to cool down, until they are ready for use.

Legal Notices

This product uses software code. It should not be used in safety-critical applications or where

consequential loss may occur. It is the responsibility of the user to ensure appropriate

safeguards are in place for regularly monitoring and checking the equipment.

In no event shall Delta-T’s liability exceed the selling price of the product. Delta-T is not liable for

indirect, incidental or consequential damages in connection with the use of equipment, including

but not limited to: data loss, vegetation loss, loss of energy or water, cost of substitute equipment

or services, property damage, or personal injury that results from installer’s negligence. The

customer agrees to the limitations and exclusions of liability by purchase or use of this product.

The DL2 product is CE compliant, conforming to EN61326 (1997). This device complies with part

15 of the FCC rules. Operation is subject to the following conditions: (1) this device may not

cause harmful interference, (2) this device must accept any interference received, including

interference that may cause undesirable operation. Please ensure you read Product Usage.pdf

in the Document Library folder.

Delta-T Devices Ltd

128 Low Road, Burwell

Cambridge CB5 0EJ

UK

Tel: +44 1638 742922

Fax: +44 1638 743155

email: [email protected]

web: www.delta-t.co.uk

Table of contents

Other Delta-T Devices Data Logger manuals

Popular Data Logger manuals by other brands

pico Technology

pico Technology USB DrDAQ user guide

ICP DAS USA

ICP DAS USA CL-201-WF user manual

Crane Electronics

Crane Electronics TorqueStar Plus Operator's manual

Rotronic

Rotronic RMS-LOG-915 Short instruction manual

Sorel

Sorel Data logger Installation and operating instructions

Sutron

Sutron 9210 Series manual