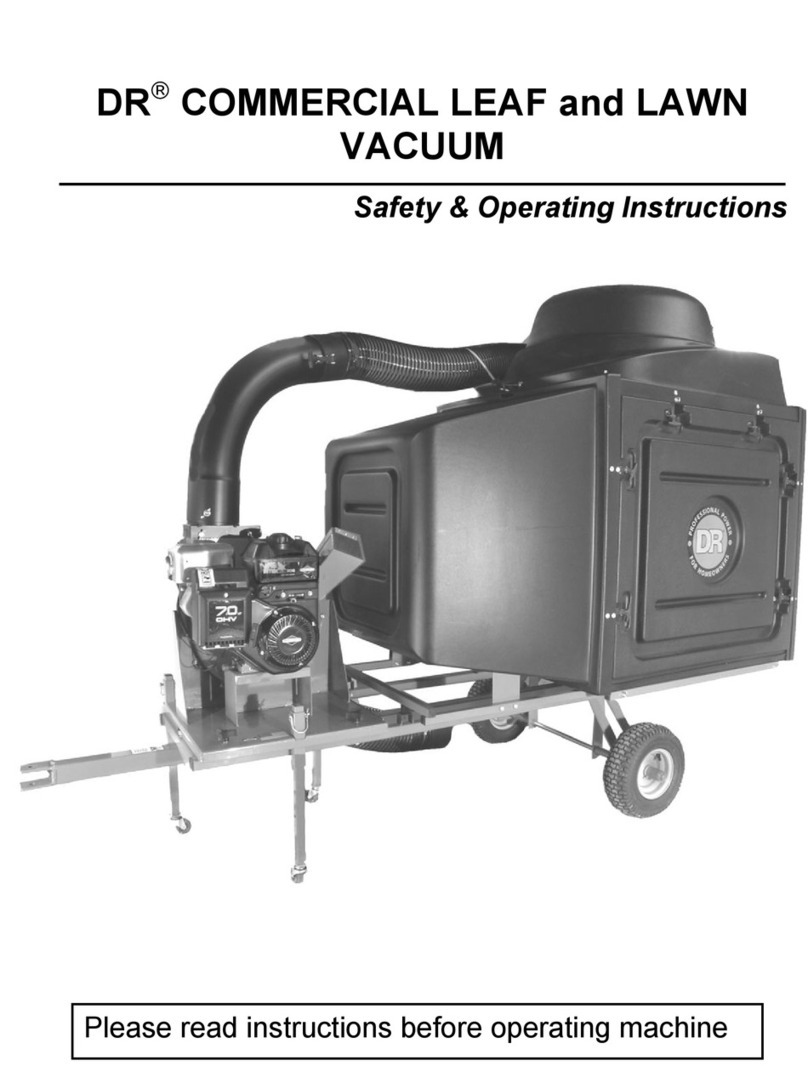

4. Mount air turbine assembly onto frame (1) with four 5/16” x 1 1/4” hexbolts, 5/16”

flatwashers and 5/16” locknuts. Trap the exhaust shield between the engine and the

engine plate as shown. Note: some applications require rotating the engine assembly

90from the standard location to avoid interference between the engine assembly and

the rear of the tractor. If needed, slip the engine plate extension (26) into the end of

engine plate on frame (1) and secure with a minimum of two 5/16” x 3/4” hexbolts

and whizlock nuts. (Note: bolt #3 may be omitted if recoil housing on engine will not

allow it). The exhaust shield is not needed when air turbine assembly mounts 90

with the engine plate extension. Fig. 4-6

5. Attach container holder (20) to frame with two 5/8” x 1” hexbolts and locknuts.

Tighten bolts until ring supports the container (19) in a tilted position. Fig. 7

6. Attach eyebolts (8) to brackets on vertical support by trapping brackets between 5/16”

hexnut and 5/16” whizlock. Rotate eyebolts so that eyelets face from front to back.

Fig. 8

7. The molded top assembly has been partially assembled by the factory. Fit the filter

(16) over the filter support inside the top. Slide intake nozzle (21) through hole in top

from the inside out with the lip inside. Attach the latch (18) to molded top with two

1/4” x 1/2” truss head screws and whizlock nuts. Fig. 9

8. Place container in container ring. Set top assembly down onto container. Align 1/2”

swivel hole in top assembly (hole furthest from top) with top hole in vertical support.

Secure with 1/2” x 2 1/2” hexbolt and 1/2” nylon locknut. Tighten until slight drag

can be felt when pivoting assembly. Fig. 10

9. Pivot top assembly back until the springs (9) can be attached to upper spring retainers

on top support and to the eyebolts on vertical support installed in step 6. Once springs

are attached pull top assembly down onto container and immediately slip 3/8” x

2 1/4” clevis pin through locking hole in top support and secure with 1/8” cotter key.

This locking pin will not allow top to rotate all the way around and allow the springs

to come off. Rotate container until container latch (18) lines up with a handle on

container (19) and secure latch by locking it over handle. Note: latch may have to be

adjusted to be tight on handle. Once achieved, tighten bolts in vertical support (7) and

vertical support brace (27). Fig. 11

10. Attach discharge hose (23) to intake nozzle in molded top with 6” band clamp (22)

Note: try to bunch a few ribs of hose up between the band clamp and the molded top

to achieve a more airtight attachment. Once achieved, attach the other end of exhaust

hose to the exhaust on the blower housing with the other 6” band clamp (22)

provided. Fig. 12

11. Attach intake hose (25) to inlet on blower housing with 8” band clamp (24). Fig. 13

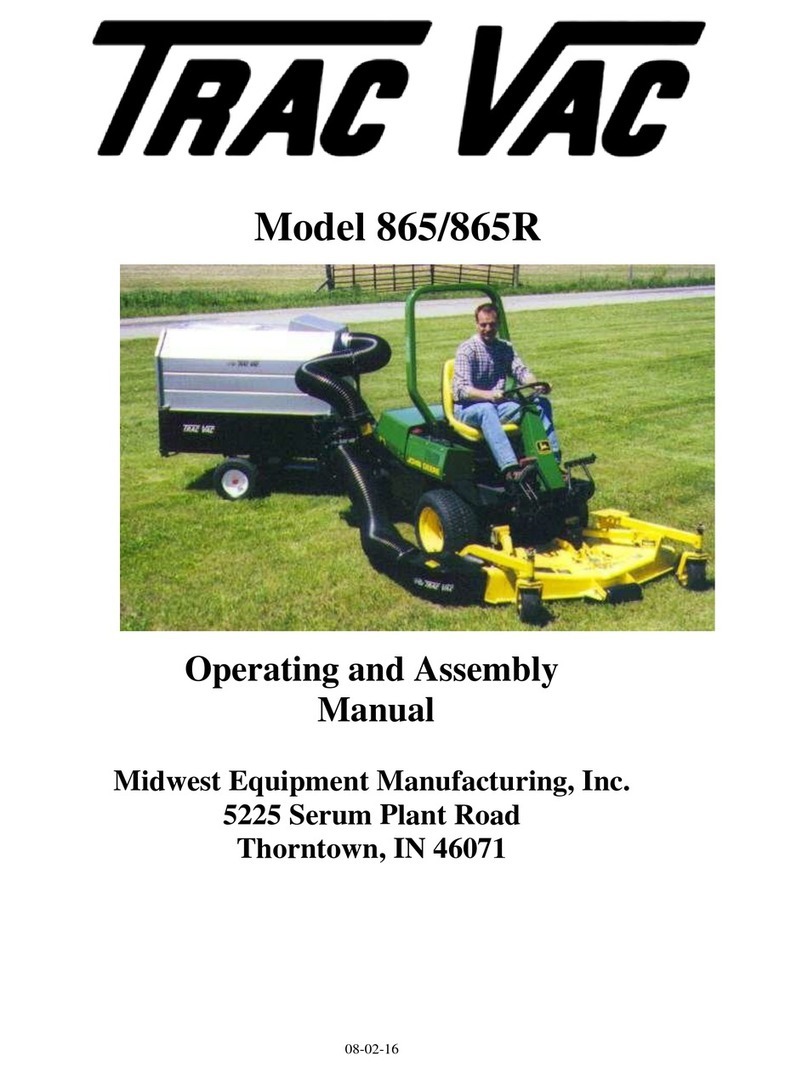

12. Attach chute to mower deck, the chutes are also deck specific so your chute may look

and attach differently than what is pictured. Usually the chutes require mounting an

adapter to the deck to accept the bracket on the chute or for the chute to pin into it.

Most of the time the adapters pick up existing holes on the deck but occasionally they

do not. If they do not, clip or pin the chute into the adapter, hold the chute up to the

deck and adjust to the best fit. Once best fit is achieved, mark and drill holes through

the deck. If 1/4” hardware is to be used drill with 9/32” bit, if 5/16” hardware is to be

used drill with 11/32” bit and if 3/8” hardware is to be used drill with 13/32” drillbit.

After drilled, attach with hardware provided. Fig. 14

13. Cut intake hose to fit and attach free end of intake hose (25) to discharge chute with

8” band clamp (24). Fig. 15

14. Read engine-operating instructions before starting.